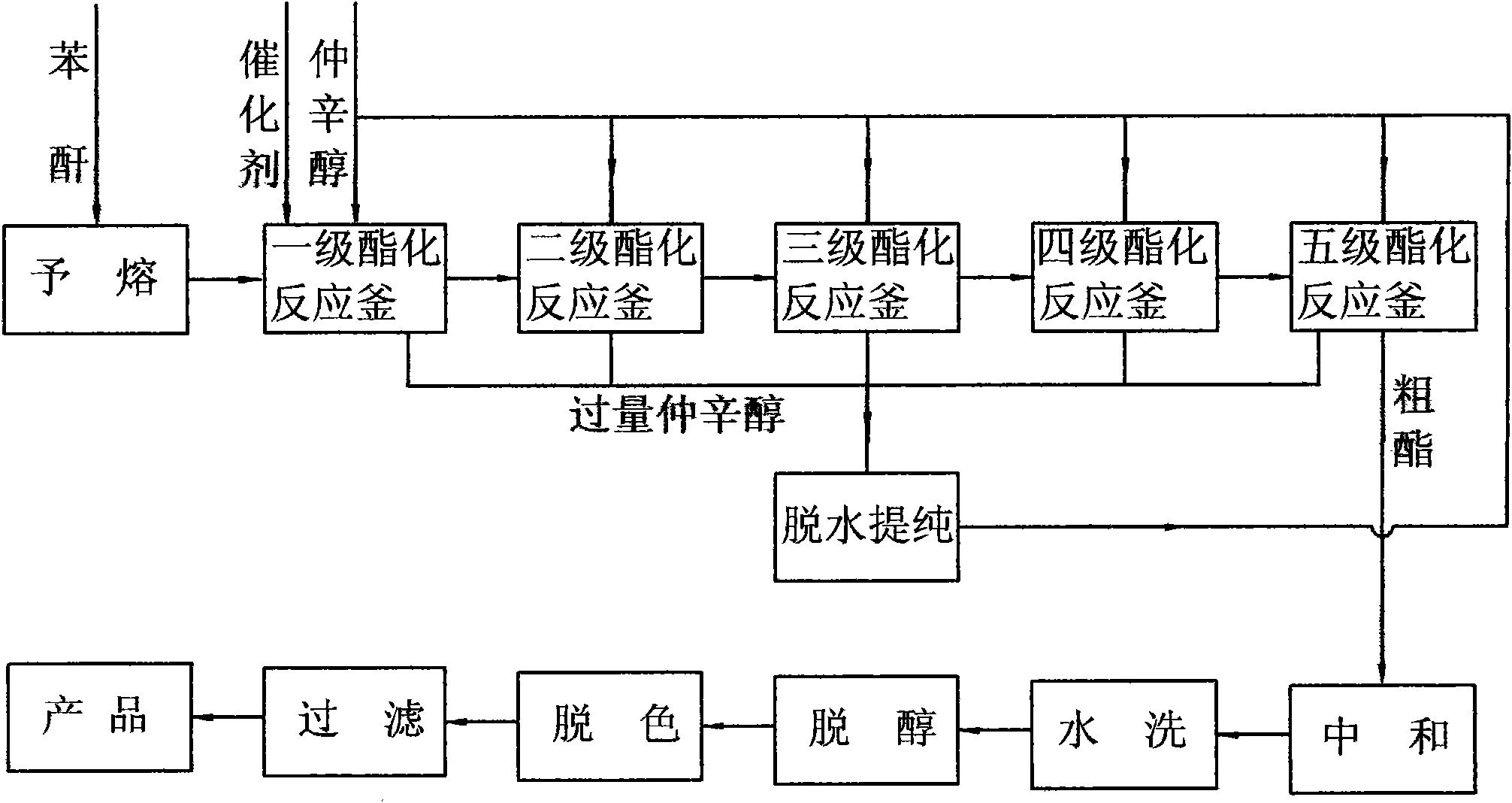

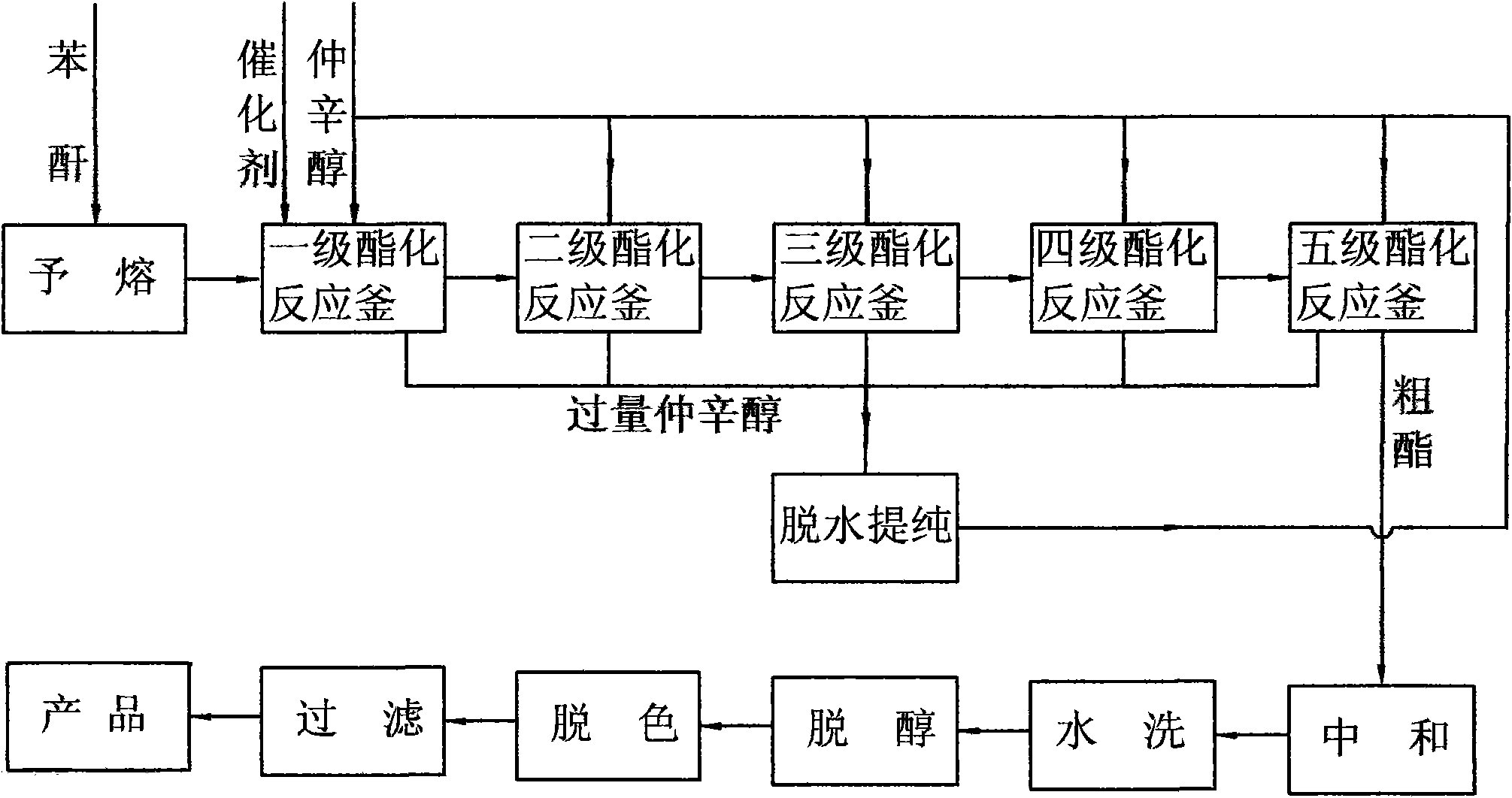

Continuous esterification production method of di-sec-octyl phthalate

A technology of di-sec-octyl phthalate and a production method, applied in the field of esterification synthesis, can solve the problems of intermittent esterification energy consumption, high material consumption, inability to realize large-scale production, restricting the output of DCP, etc., so as to reduce dust pollution , The quality of the product is stable and uniform, and the effect of improving the utilization rate and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put the raw material phthalic anhydride and secondary octanol (99.5wt% secondary octanol content, 0.2wt% octanol, 0.3wt% impurity) into the primary esterification reaction kettle in a molar ratio of 1:2.5 after pre-melting, and add phthalic anhydride at the same time With a titanate catalyst with a total amount of 2wt‰ of 2-octanol, the temperature of the primary esterification reaction kettle starts to rise when the feed amount of the primary esterification reaction kettle reaches 30% of the volume of the esterification reaction kettle, and the primary esterification reaction is carried out. The temperature is 200°C, and after the esterification reaction is completed, the material overflows from the side wall of the first-stage esterification reactor and enters the second-stage esterification reactor, and the fifth-stage esterification reaction is carried out in sequence. The temperature of the second-stage esterification reaction is 204°C , The temperature of the third...

Embodiment 2

[0027] Add raw material phthalic anhydride and secondary octanol (99.5wt% secondary octanol content, 0.2wt% octanol, 0.3wt% impurity) in a molar ratio of 1:2.6 into the primary esterification reactor after pre-melting, and add phthalic anhydride at the same time With a titanate catalyst with a total amount of 4‰ of 2-octanol, the temperature of the primary esterification reactor starts to rise when the feed amount of the primary esterification reactor reaches 30% of the volume of the esterification reactor, and the primary esterification reaction is carried out. The primary esterification reaction The temperature is 202°C, and after the esterification reaction is completed, the material overflows from the side wall of the first-stage esterification reactor and enters the second-stage esterification reactor, and the fifth-stage esterification reaction is carried out in sequence, and the temperature of the second-stage esterification reaction is 206°C , The tertiary esterificatio...

Embodiment 3

[0029] Add raw material phthalic anhydride and secondary octanol (99.5wt% secondary octanol content, 0.2wt% octanol, 0.3wt% impurity) in a molar ratio of 1:2.7 into the primary esterification reactor after pre-melting, and add phthalic anhydride at the same time With a titanate catalyst with a total amount of 2wt‰ of 2-octanol, the temperature of the primary esterification reaction kettle starts to rise when the feed amount of the primary esterification reaction kettle reaches 30% of the volume of the esterification reaction kettle, and the primary esterification reaction is carried out. The temperature is 203°C, and after the esterification reaction is completed, the material overflows from the side wall of the first-stage esterification reactor and enters the second-stage esterification reactor, and the fifth-stage esterification reaction is carried out in sequence, and the temperature of the second-stage esterification reaction is 207°C , The tertiary esterification reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com