Extraction composition and application thereof

A composition and extraction technology, applied in the chemical industry, can solve the problems of low selectivity and low extraction efficiency of lithium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

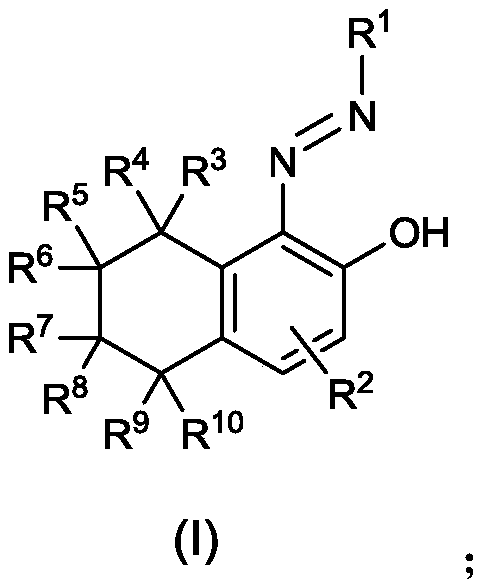

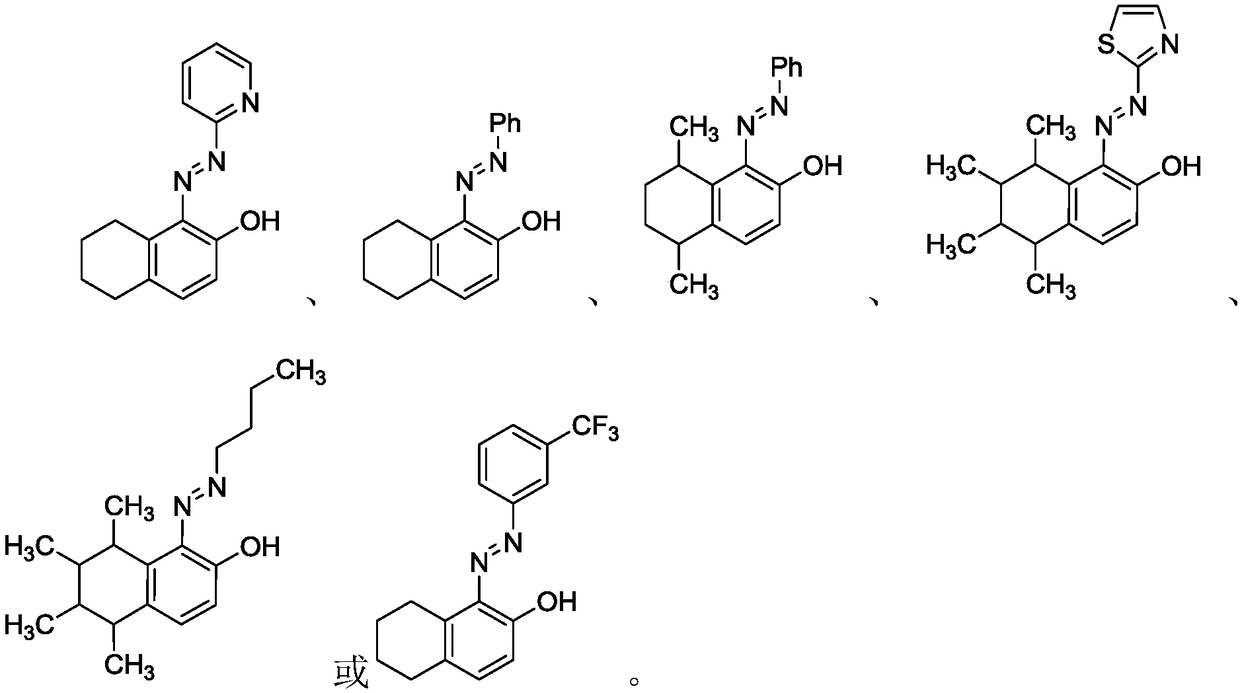

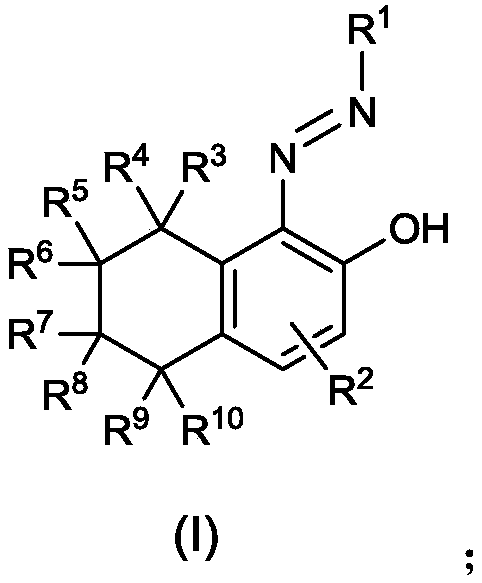

Image

Examples

Embodiment 1

[0068] Prepare the extraction organic phase system, extractant: 0.60mol / L Modifier: 0.60mol / L dioctylmethylsulfonium chloride; diluent: sulfonated kerosene. In the lithium-containing aqueous phase, the concentration of lithium ions is 0.05mol / L.

[0069] Extraction method: Add a certain amount of NaOH to the lithium-containing aqueous phase to adjust the pH value to 13-14. The organic phase system is compared with the aqueous phase at a ratio of 1:1, and fully exposed to single-stage extraction. After phase separation, 2mol / L hydrochloric acid was used as the stripping liquid, and the organic phase system was recovered and recycled after stripping to obtain the stripped lithium product, and the single-stage extraction rate of lithium was 88%.

Embodiment 2

[0071] Prepare the extraction organic phase system, extractant: 0.80mol / L Modifier: 0.60mol / L trioctylmethylammonium chloride; diluent: xylene. The lithium-containing aqueous phase is lithium hydroxide aqueous solution, and the concentration of lithium ions is 0.20 mol / L.

[0072] Extraction method: Extract the organic phase system and the water phase according to the ratio of 1:1, fully contact with single-stage extraction, and stand to separate the phases. The obtained organic phase uses 2mol / L sulfuric acid as the stripping solution, and the organic phase system is recycled after stripping to obtain the stripped lithium product, and the single-stage extraction rate of lithium is 75%.

Embodiment 3

[0074] Prepare the extraction organic phase system, extractant: 0.80mol / L Modifier: 0.80mol / L trioctyl ammonium methylsulfate; diluent: 2-octanone. The lithium ion concentration in the lithium-containing aqueous phase is 0.15mol / L, the sodium ion concentration is 0.25mol / L, and the potassium ion concentration is 0.32mol / L. The lithium-containing aqueous phase in this example is a simulated aqueous phase prepared according to the composition of industrial wastewater.

[0075] Extraction method: add a certain amount of ammonia water to the lithium-containing aqueous phase, adjust the pH value to 12-13, extract the organic phase system and the aqueous phase according to the ratio of 1:1, fully contact with single-stage extraction, and stand still for phase separation. For the obtained organic phase, 2mol / L hydrochloric acid was used as the back-extraction solution. After the back-extraction, the organic phase system was recovered and recycled, and the back-extracted lithium pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com