Generatively produced turbine blade and device and method for producing same

a turbine blade and generative production technology, which is applied in the direction of blade accessories, machines/engines, waterborne vessels, etc., can solve the problems of unfavorable property profile that is unacceptable for the intended use, unfavorable use in aircraft turbine construction, etc., and achieves low impurity content, different alloy compositions, and low oxygen content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Further advantages, characteristics and features of the present invention will become clear in the description of an exemplary embodiment detailed hereinbelow.

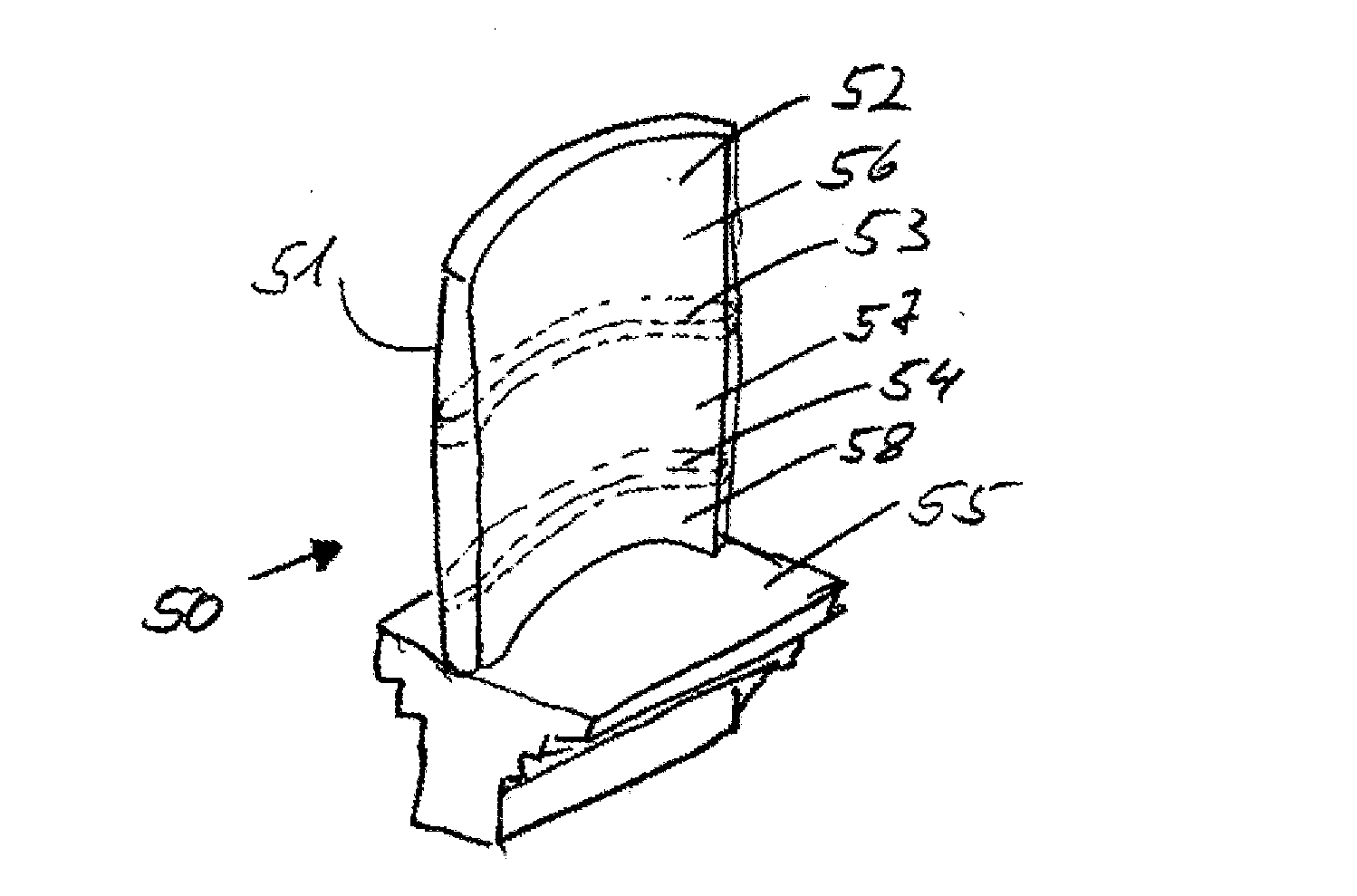

[0025]FIG. 1 shows a purely schematic illustration of an apparatus 1 which can be used for producing turbine blades by the method according to the invention. The apparatus 1 has a housing 2, which surrounds two spaces or chambers 3 and 4 that are partitioned off by a partition wall (not shown in more detail) having a through-opening 15 in the housing 2. The powder production is effected in one space 4, while the component 27 is sintered in the other space 3.

[0026]The spaces 3 and 4 each have a vacuum pump 5 and 6, such that the spaces 3 and 4 can be pumped out separately from one another. Alternatively, however, provision can be made to provide merely a single pump for pumping out the entire interior of the housing 2.

[0027]In addition, provision is made of a plurality of gas feeds 7, 8, 9, which in turn make it possible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com