Patents

Literature

62results about How to "Realize full automatic control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

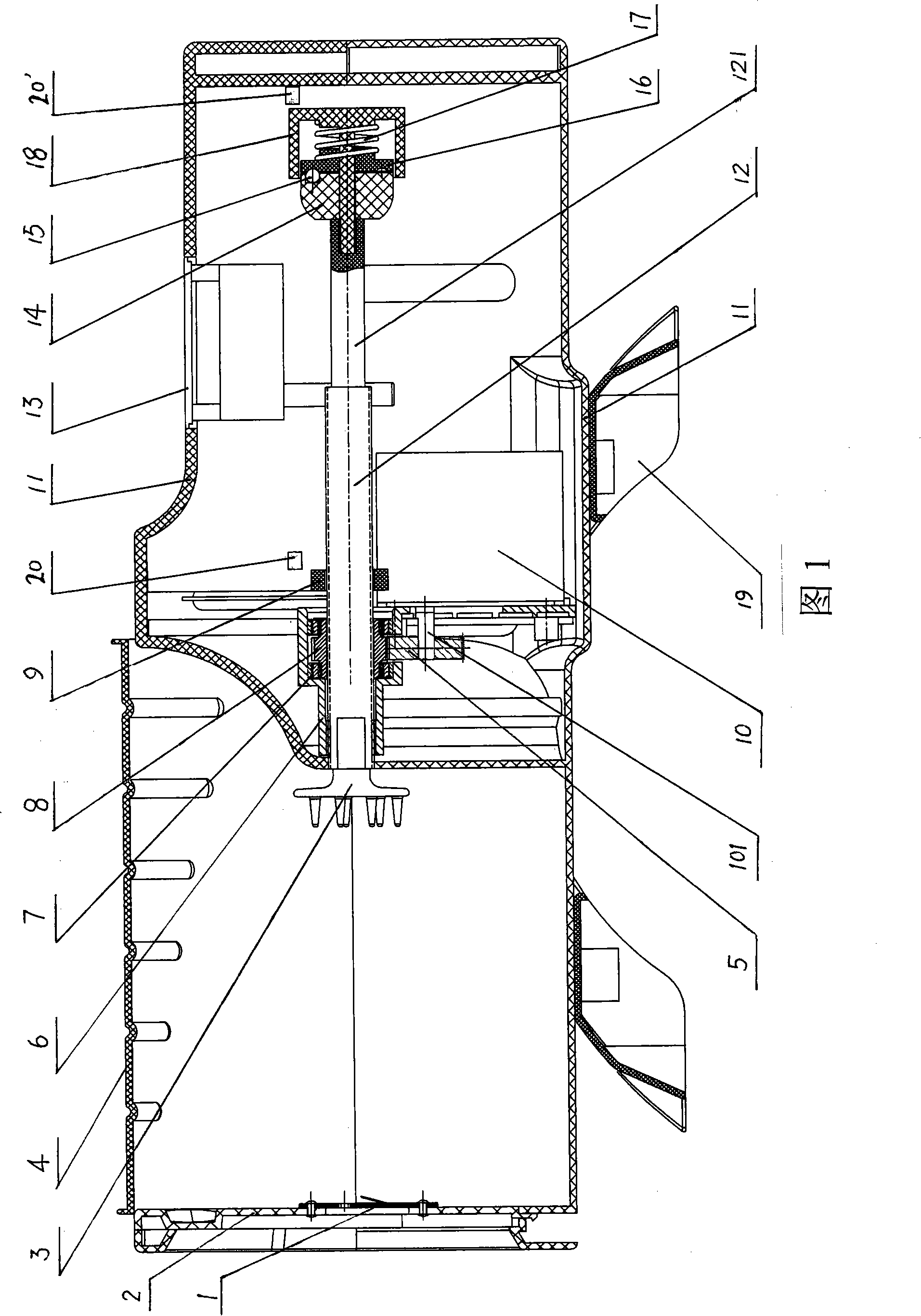

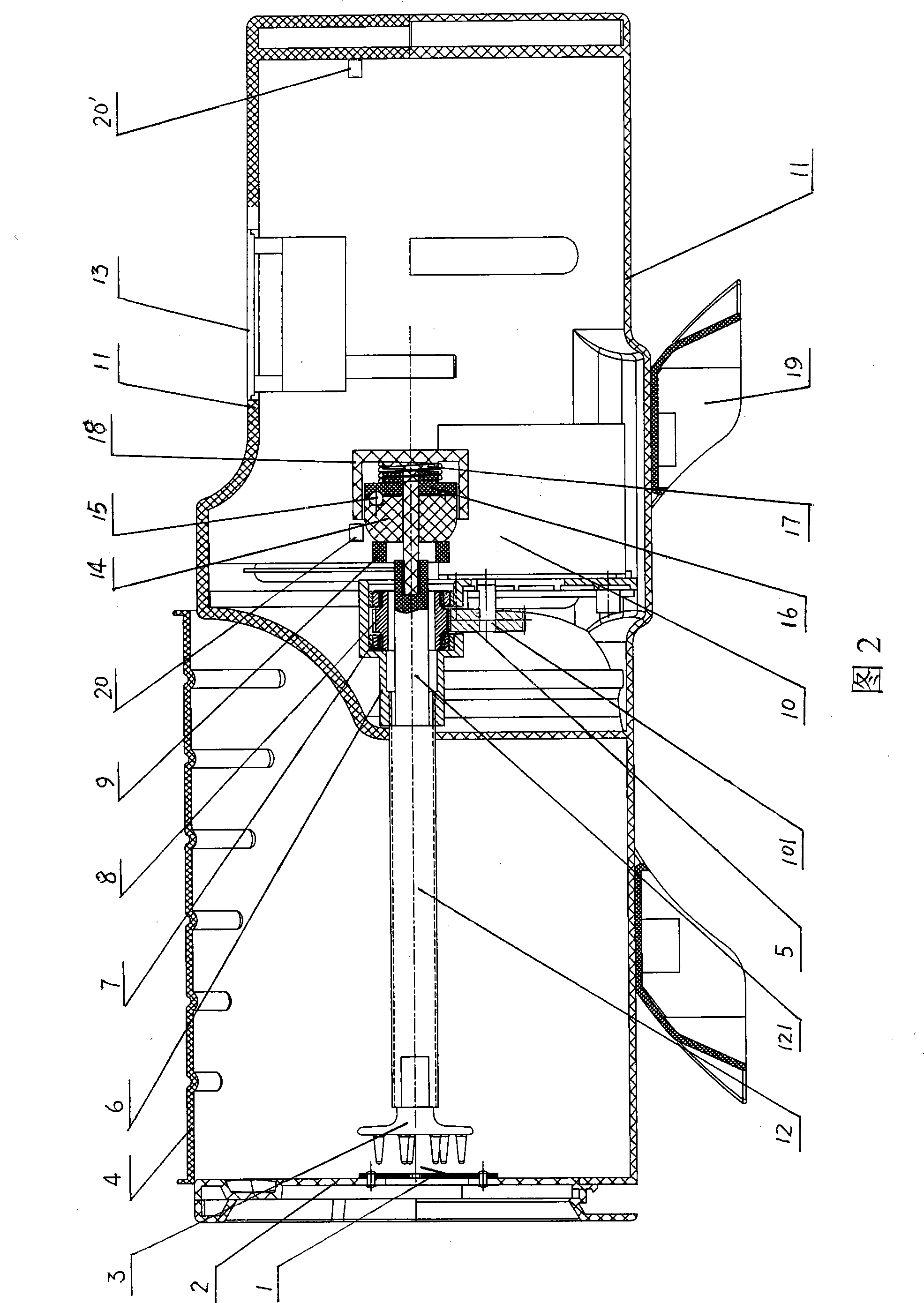

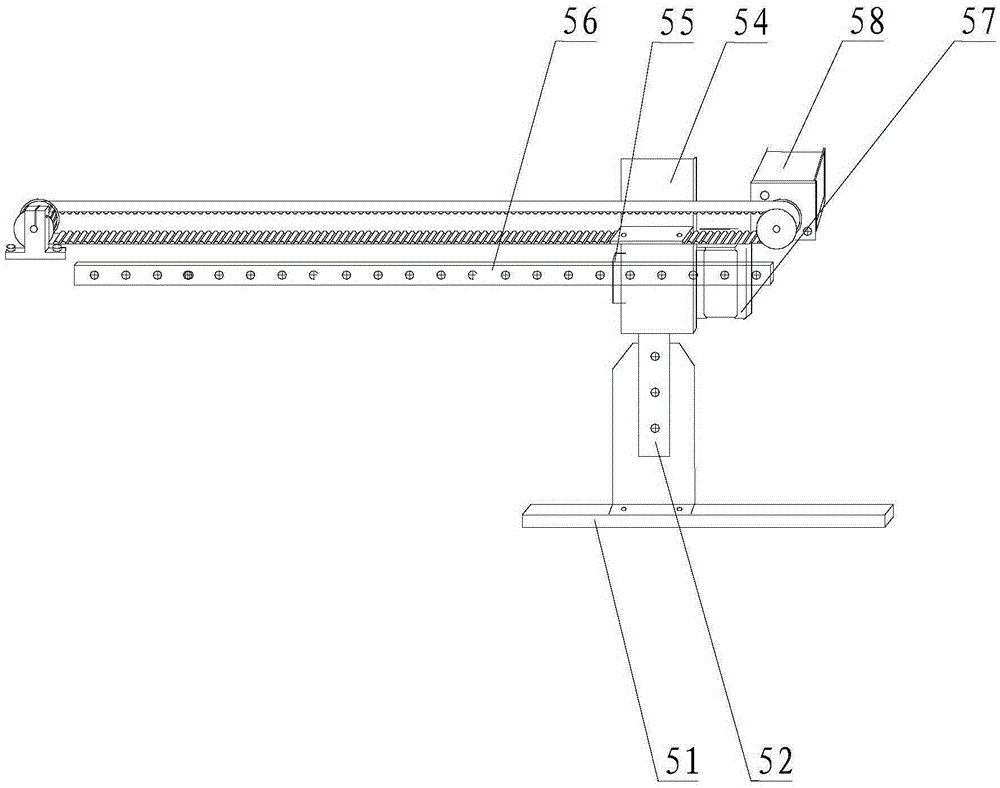

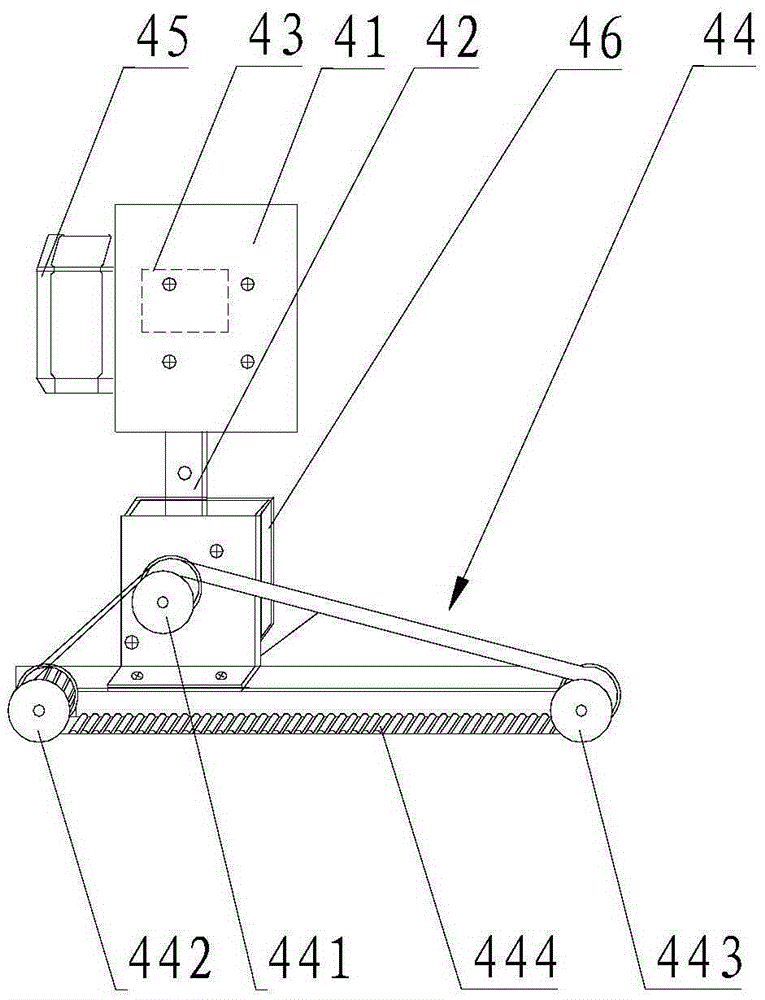

Measurement system, method and device of scattered materials and material piling and taking control system

ActiveCN103090791ARealize full automatic controlImprove measurement efficiencyUsing optical meansStopped workMeasurement device

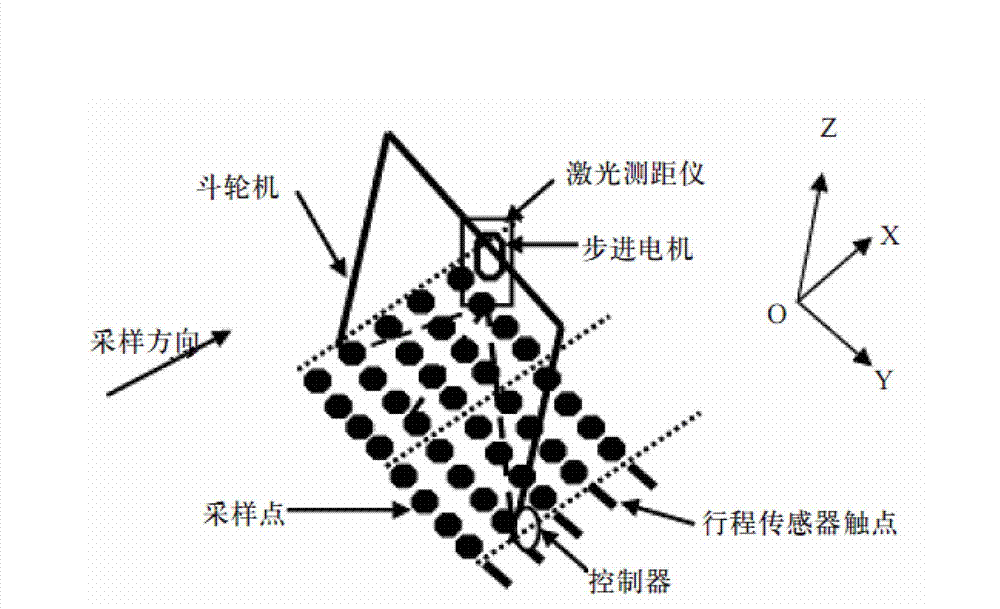

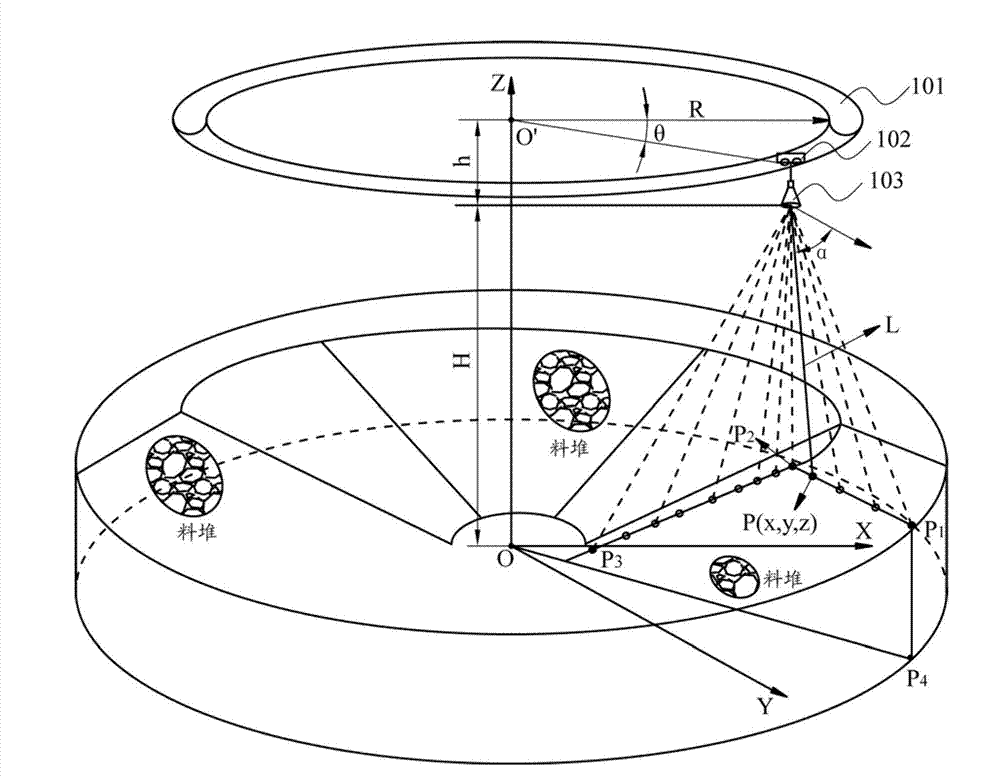

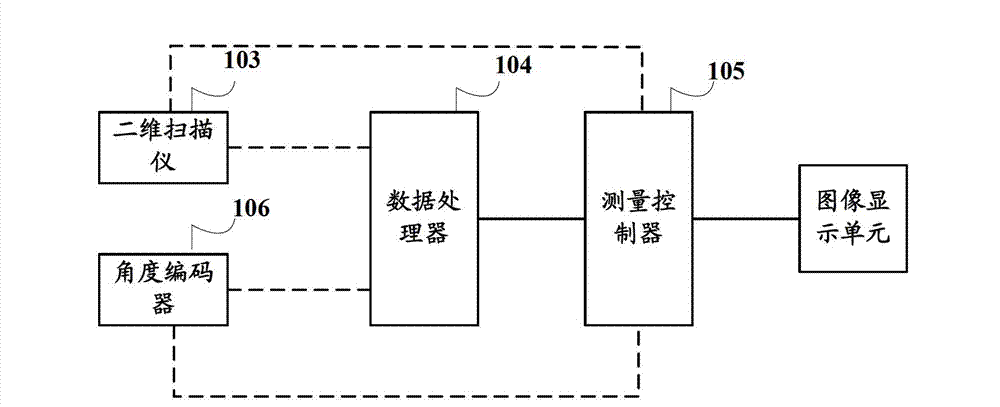

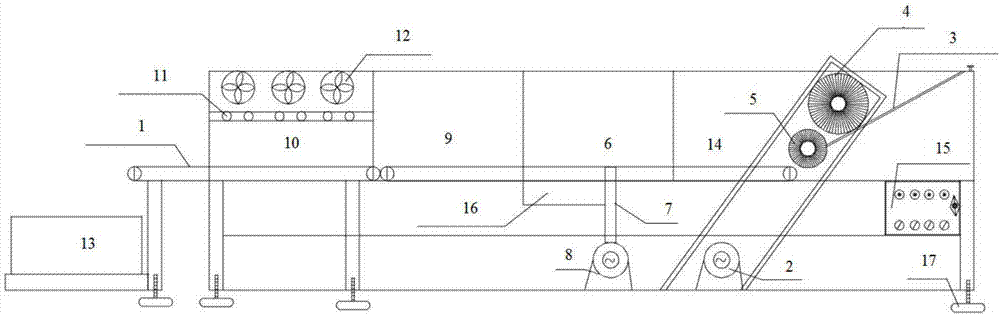

The invention relates to automatic control technologies and particularly relates to a scattered material measurement technology and a material piling and taking control technology in a circular material field to improve measurement efficiency of the scattered materials and furthermore realize material piling and taking control according to measurement results. A scattered material measurement system in the circular material field comprises a drive device, a two-dimension scanner, a data processor and a measurement controller, wherein the drive device operates along a circular track built in the upper portion space of the circular material field, and the two-dimension scanner is arranged below the drive device in a lifting mode. Material piling and taking control further comprises a central control room server and the like. The scattered material measurement technology and the material piling and taking control technology in the circular material field can realize whole-course automatic control, scan the circular material field by utilizing a two-dimension laser scanner which is loaded by a circular dome track trolley, and conducts gang control with a material piling and taking machine, and therefore avoids the defects that when the measurement device is arranged on the material piling and taking machine, measurement can be conducted only after the material piling and taking machine stops working, and measure efficiency is improved.

Owner:ZOOMLION HEAVY IND CO LTD

Technology for recovering and processing organic exhaust gas by activated carbon adsorption and N2 desorption

ActiveCN103585854AOvercome the limitations of large investmentPure qualityDispersed particle filtrationActivated carbonOrganic solvent

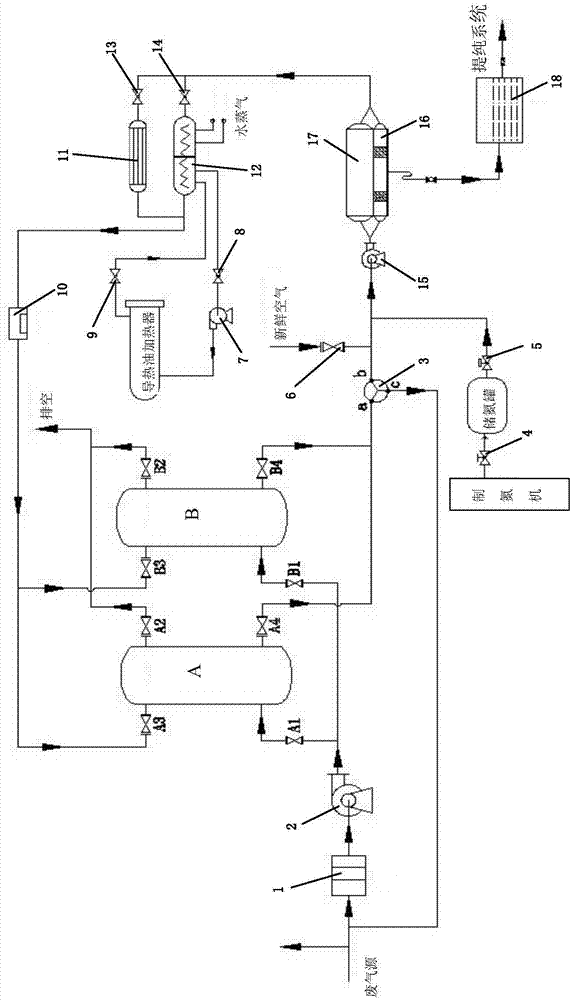

The invention provides a technology for recovering and processing organic exhaust gas by activated carbon adsorption and N2 desorption. The technology comprises the following steps: organic exhaust gas is pretreated by a coil-cooling filter; the organic exhaust gas which has been pretreated is then sent into a first activated carbon adsorption tank for adsorption; after adsorption of the first activated carbon adsorption tank, the system enters a desorption stage, and a second activated carbon adsorption tank enters an adsorption stage; the desorbed organic exhaust gas is condensed and then recovered, and after desorption of the system, the first activated carbon adsorption tank is cooled to a certain temperature, and back-purging is conducted on the first activated carbon adsorption tank, and the temperature drops to normal temperature after back-purging so as to use the exhaust gas in the next circulation; and the first activated carbon adsorption tank and the second activated carbon adsorption tank recycle and alternate the above steps. By the adoption of the technology, secondary pollution will not be caused; energy consumption is low; and the quality of recovered organic solvents is pure.

Owner:GARDEN ENVIRONMENTAL PROTECTION

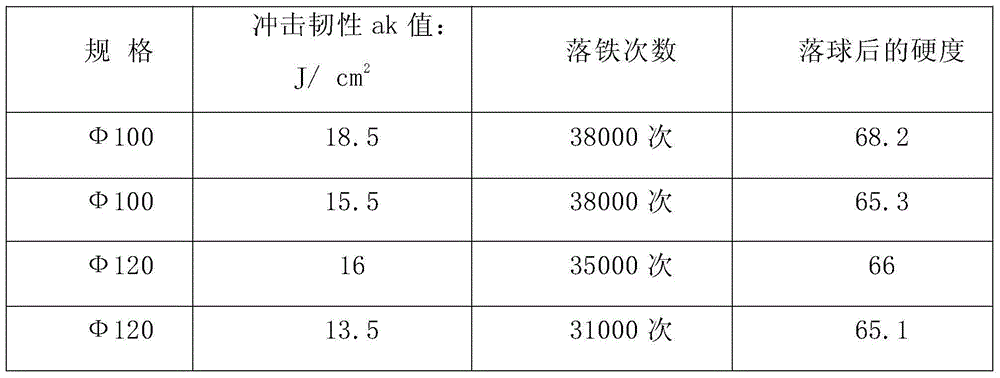

Nodular cast ball and manufacturing method thereof

ActiveCN104152787AAvoid oil quench contaminationRealize full automatic controlChemical compositionWear resistant

The invention relates to the technical field of wear-resistant cast balls, and discloses a nodular cast ball and a manufacturing method thereof. The nodular cast ball comprises the following chemical components in percentage by weight: 3.6-3.9% of C, 2.4-4.0% of Si, 0.5-0.8% of Mn, 0.1-0.2% of Mo, 0.1-0.2% of Cu, at most 0.05% of S, at most 0.05% of P, at most 0.3% of Cr and the balance of iron. The heat treatment quenching medium adopts a high-polymer quenching liquid, thereby avoiding oil quenching pollution and implementing energy saving and environment protection. The inoculation is completed by three times, so that the nodulizing effect reaches Grade 2-3, the product HRC reaches 60 above, the hardness impact toughness of the high-chromium ball reaches 12 J / cm<2> above, the number of times of falling after tempering reaches more than 30000, and the hardness of the ball after long-time impact and collision reaches 65 above; and the production cost is lower.

Owner:安徽省宁国诚信耐磨材料有限公司

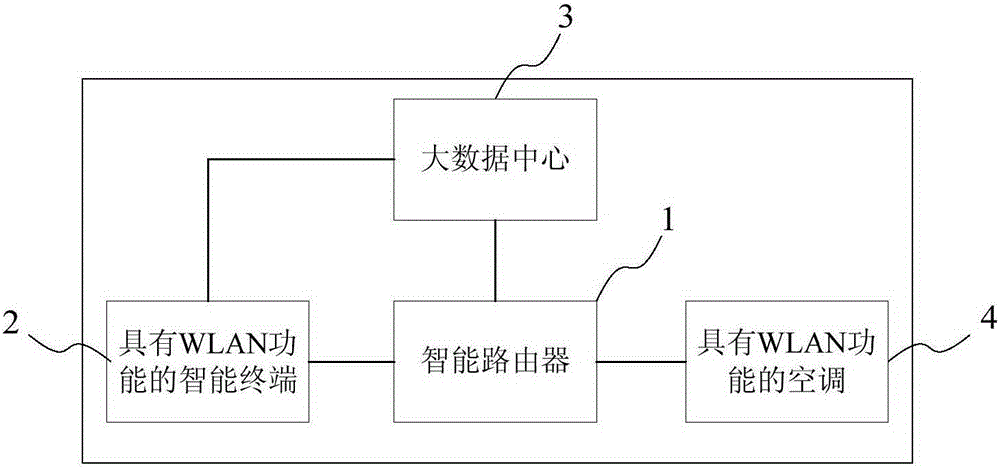

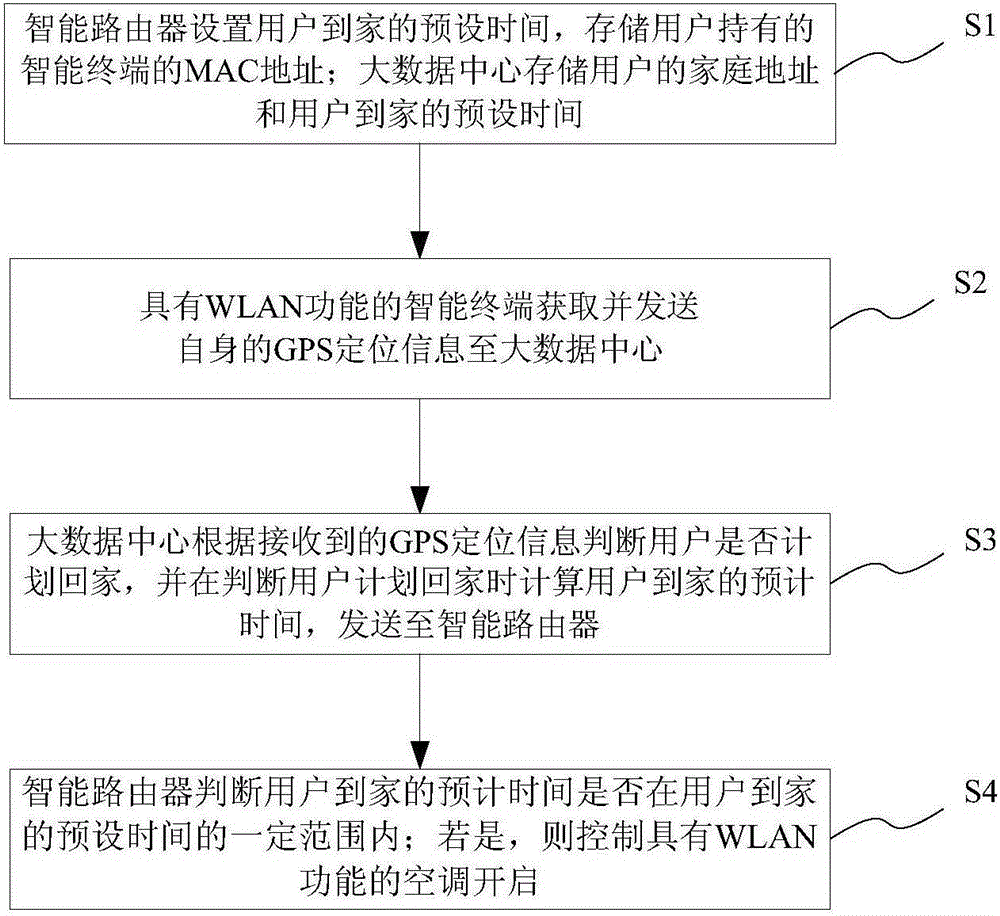

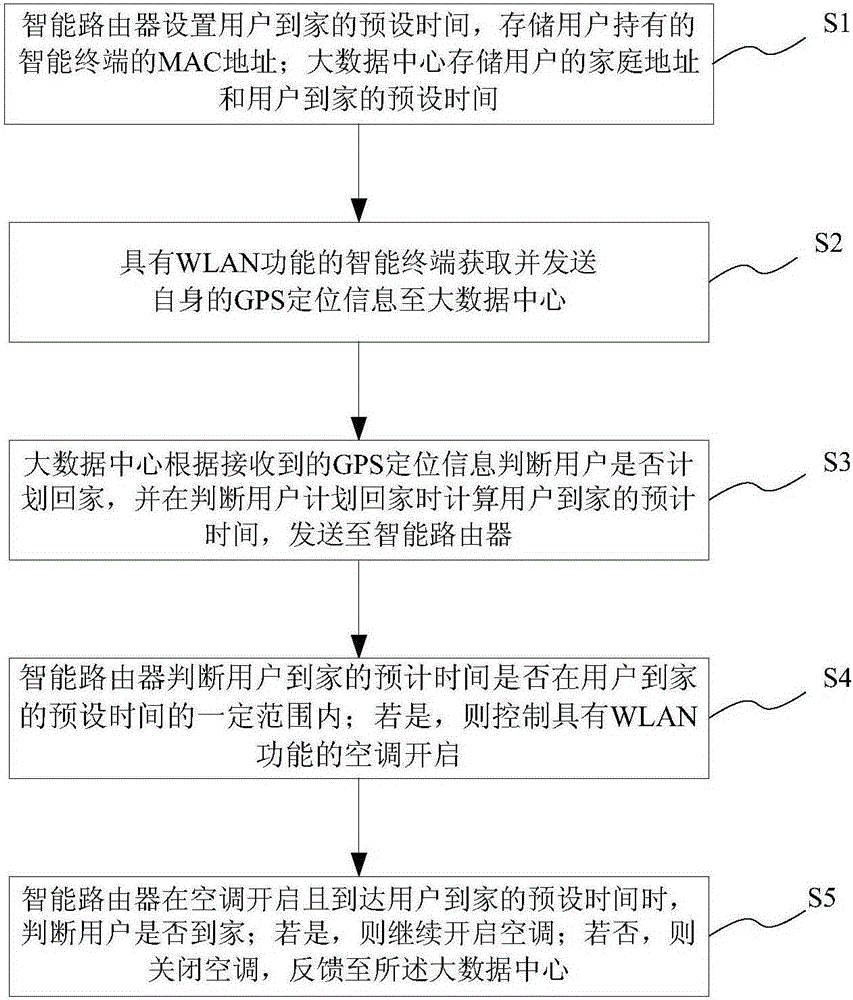

Air-conditioner long-distance automatic control system and method based on GPS

InactiveCN105180346ARealize full automatic controlPrecise and effective controlSpace heating and ventilation safety systemsLighting and heating apparatusAutomatic controlControl system

The invention provides an air-conditioner long-distance automatic control system and method based on a GPS. The air-conditioner long-distance automatic control system comprises an intelligent router, an intelligent terminal with a WLAN function, a big data center and an air conditioner with a WLAN function; the intelligent terminal is used for obtaining and sending self GPS positioning information to the big data center; the big data center is used for storing house addresses of users and home arrival time of the users, calculating home arrival preset time of the users when it is judged that the users plan to go home, and sending the home arrival preset time to the intelligent router; the intelligent router is used for judging whether the home arrival preset time of the users is within a certain scope of the user home arrival preset time; the air conditioner is controlled to be started if the home arrival preset time is within the certain scope of the user home arrival preset time; and the air-conditioner is automatically started or stopped under control of the intelligent router. By means of the air-conditioner long-distance automatic control system and method based on the GPS, manual operation is not needed, air-conditioner control can be carried out in advance, and it is guaranteed that a preset indoor temperature can be obtained when the users arrive at a room.

Owner:PHICOMM (SHANGHAI) CO LTD

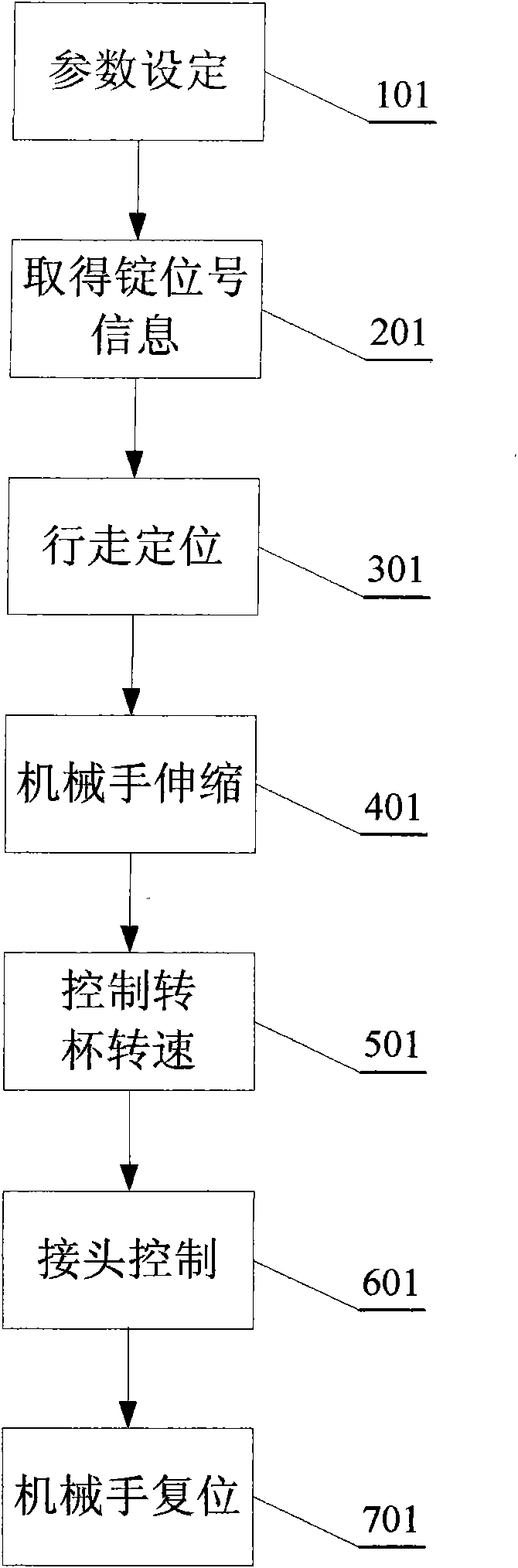

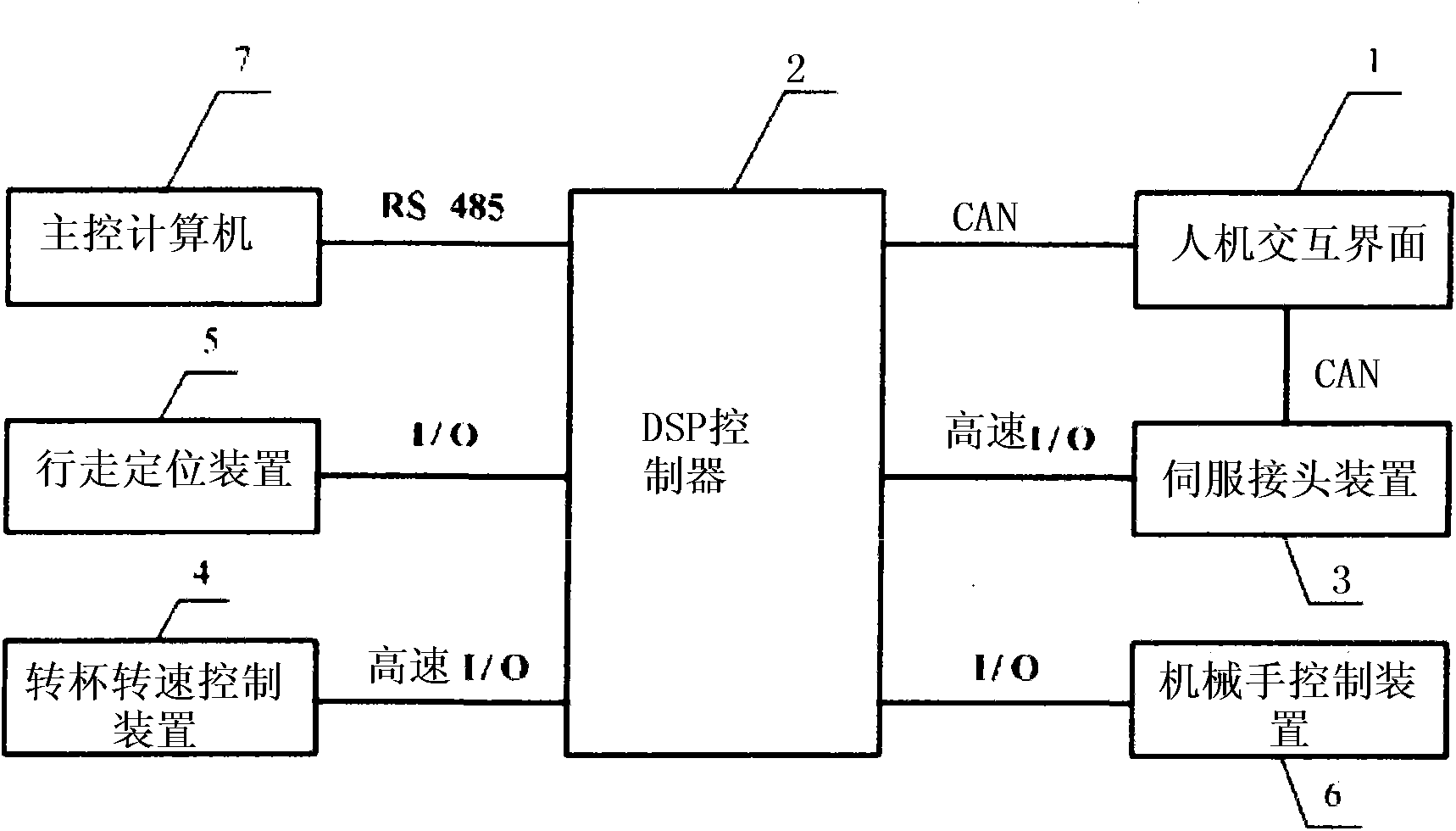

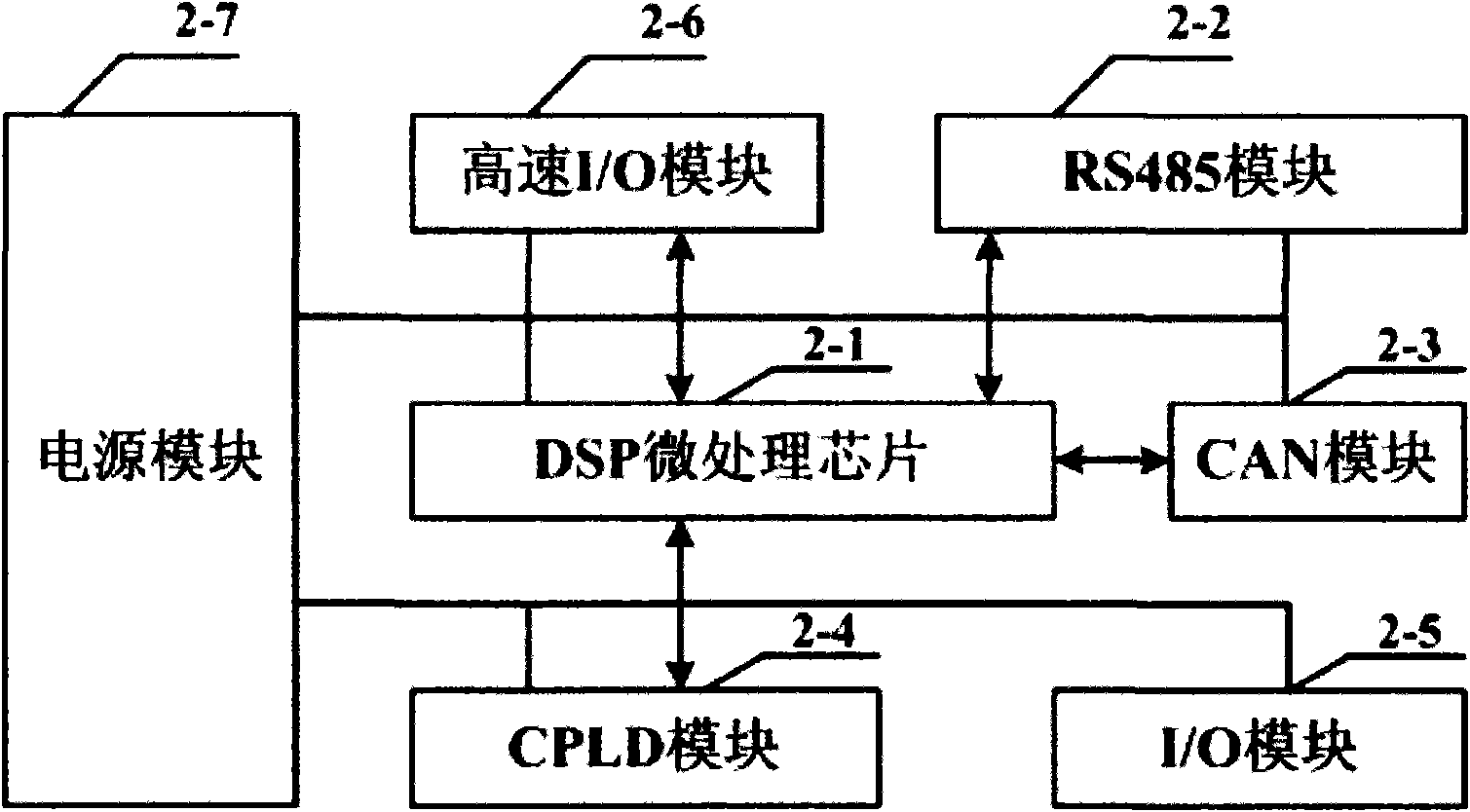

Rotor spinning machine full automatic joint control method and device thereof

InactiveCN101565866ASimple control methodOvercoming low control precisionContinuous wound-up machinesOpen-end spinning machinesAutomatic controlRobotic control

The invention relates to a rotor spinning machine full automatic joint control method comprising seven steps: setting parameters, obtaining spindle number information, positioning walking, extending and retracting a manipulator, controlling the rotor speed, controlling the joint and resetting the manipulator in turn. The device realizing the control comprises a human-computer interface, a servo joint device, a rotor speed control device, a walking-positioning device and a manipulator control device which are respectively connected with a DSP controller by the transmission medium. The human-computer interface device is also connected with the servo joint device. The transmission medium comprises an RS485 module, a CAN module, an IO-signal and a high-speed I / O signal. The control method of the invention is simple; can realize the full automatic control of yarn joint operation, and overcome the deficiencies of low control precision, poor quality of joints and low efficiency of the existing semi-automatic joint spinning machine; and compensates shortcomings of larger power consumption, and low anti-interference and stability of the existing full automatic joint control system.

Owner:BEIJING JINGWEI TEXTILE MACHINERY NEW TECH

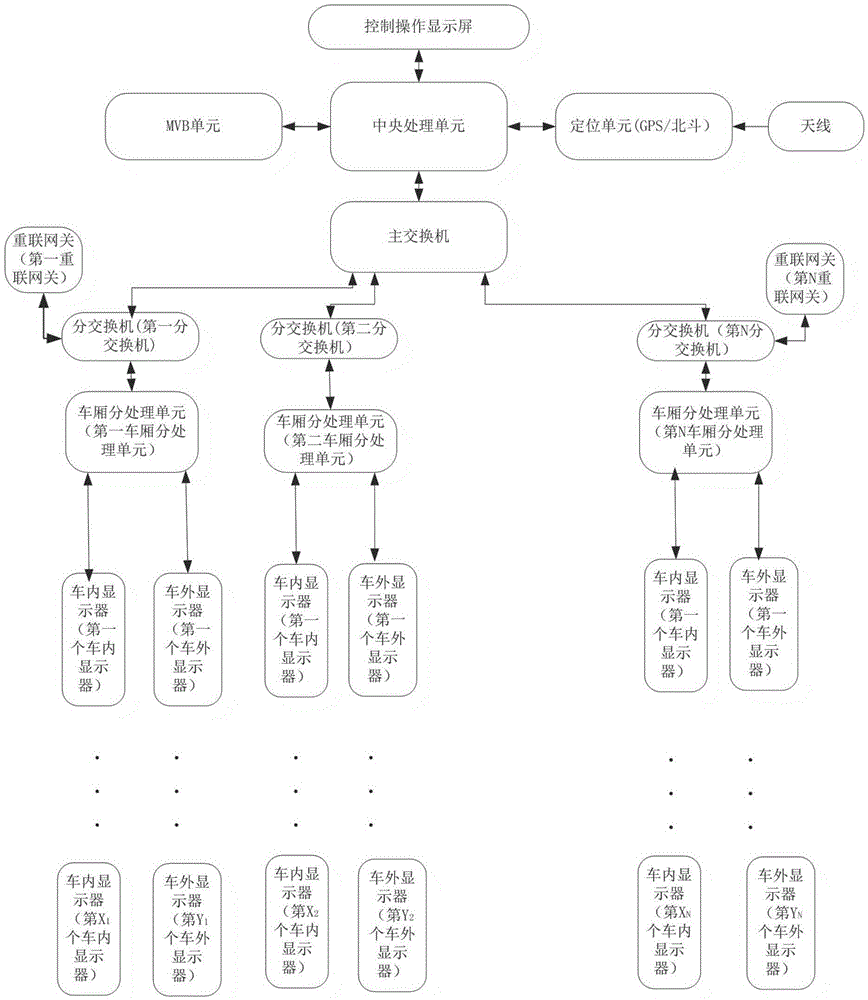

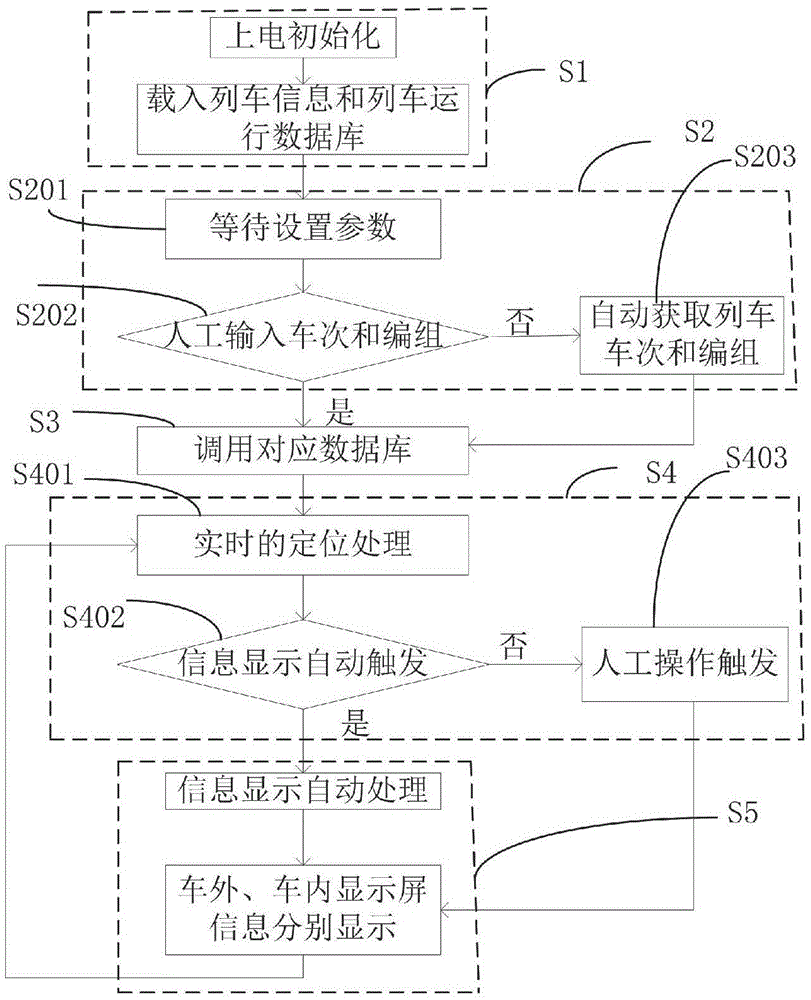

Train information displaying system and method

ActiveCN105589672AReliable data transmissionSimple networkingStatic indicating devicesLocomotivesDisplay deviceVehicle bus

The invention provides a train information displaying system and method. The train information displaying system comprises a central processing unit, a control operation display screen, a positioning unit, an antenna, an MVB (Multifunction Vehicle Bus) unit, a main switch, a branch switch, a carriage branch processing unit, a train internal displayer and a train external displayer, wherein the positioning unit, the MVB unit, the control operation display screen and the main switch are respectively connected with the central processing unit; the branch switch is connected with the main switch through Ethernet; the train internal displayer and the train external displayer are respectively connected with the branch switch through the carriage branch processing unit; and the antenna is connected with the positioning unit. When data of the positioning unit are lost, a mileage redundancy positioning algorithm is started through the central processing unit, train operating data are provided through the MVB unit and a train operation route database is combined so as to work out real-time mileage information and realize the positioning. The system provided by the invention has the advantages that trains can be accurately positioned; the data are transmitted at a high speed; and the information is intelligently displayed.

Owner:SHENZHEN HANGSHENG ELECTRONICS

Nodular cast iron and method for manufacturing hammer and liner plate through nodular cast iron

InactiveCN105838977AGuaranteed hardnessImprove toughnessProcess efficiency improvementQuenching agentsProduction lineAutomatic control

The invention discloses nodular cast iron and a method for manufacturing a hammer and a liner plate through the nodular cast iron. The nodular cast iron includes, by weight percentage, 3.6%-3.9% of C, 2.4%-2.9% of Si, 2%-3% of Mn, 0.1%-0.3% of Mo, 0.1%-0.3% of Cu, smaller than or equal to 0.05% of S, smaller than or equal to 0.05% of P, smaller than or equal to 0.3% of Cr and the balance Fe. The hammer used for mine breaking and the inner liner plate of a grinding machine are made of nodular cast iron materials so as to have the beneficial effects that the toughness is good and not prone to break, in addition, very high work hardening performance is achieved, and the longer the hammer and the inner liner plate are used, the harder the hammer and the inner liner plate become, and high-manganese steel materials and high-chromium cast materials can be completely replaced. By means of the nodular cast iron and the method for manufacturing the hammer and the liner plate through the nodular cast iron, macromolecule quenching liquid is adopted for a heat treatment quenching medium, oil quenching pollution is avoided, and energy conservation and environment friendliness are achieved; a quenching-tempering production line is adopted for quenching equipment, and automatic control in the whole process is achieved; inoculation is completed by three times, and it is ensured that the nodulizing effect reaches the second level to the third level; and the microelements of Mo and Cu are added, the hardenability is improved, and the core hardness is ensured. The HRC of the products reaches 58 or higher and reaches the hardness of high alloy materials, and the impact toughness ak value reaches 18 J / cm<2> or higher.

Owner:安徽省宁国诚信耐磨材料有限公司

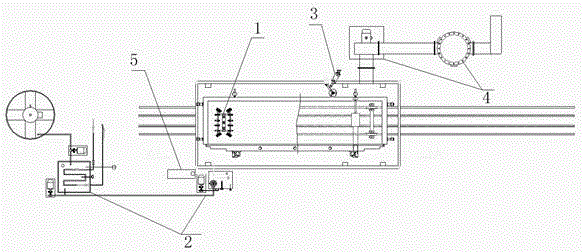

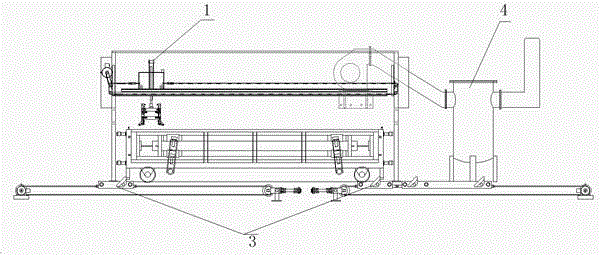

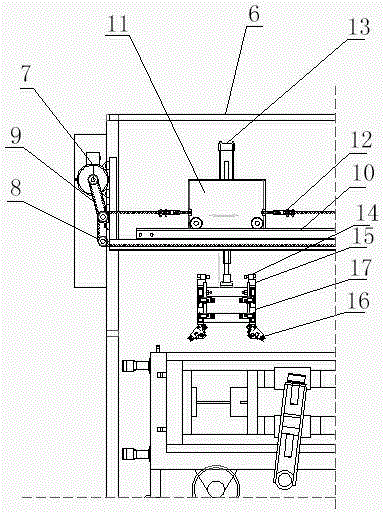

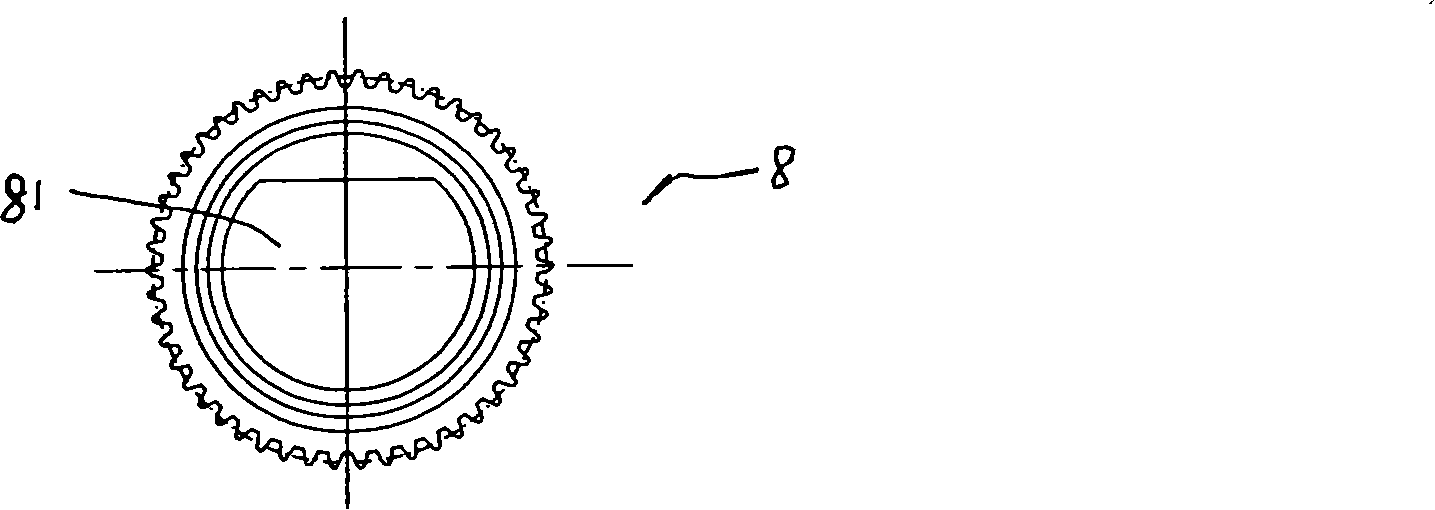

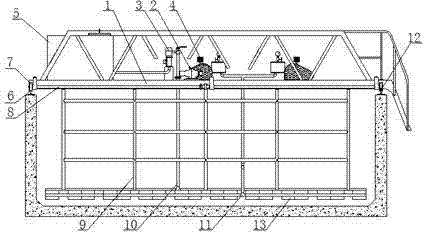

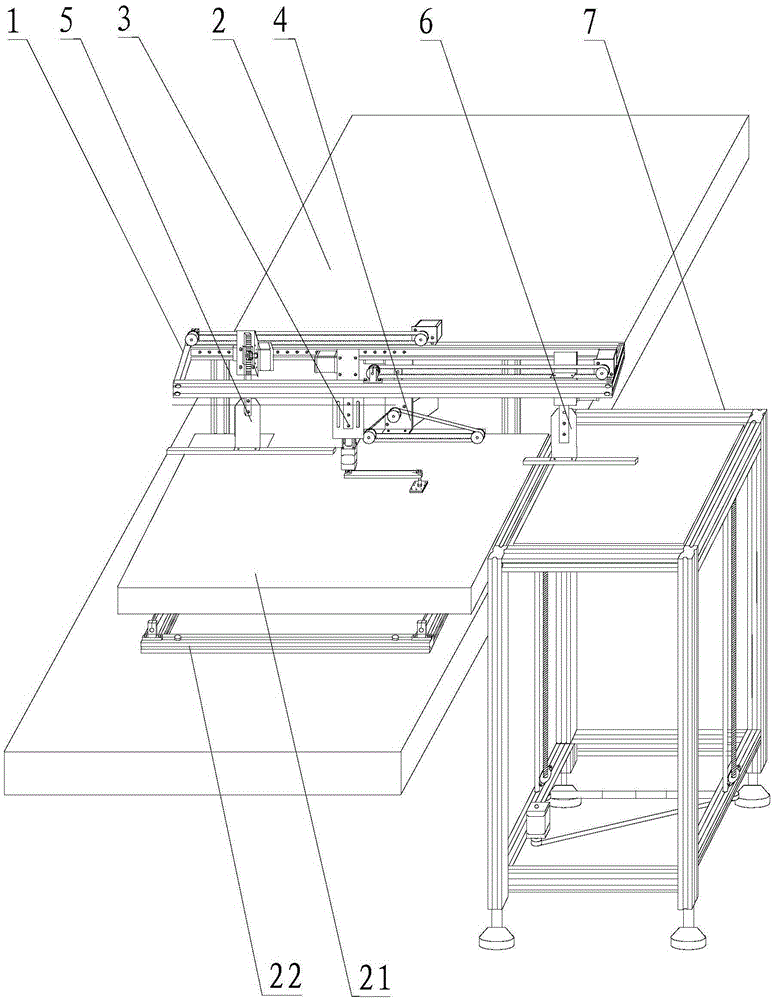

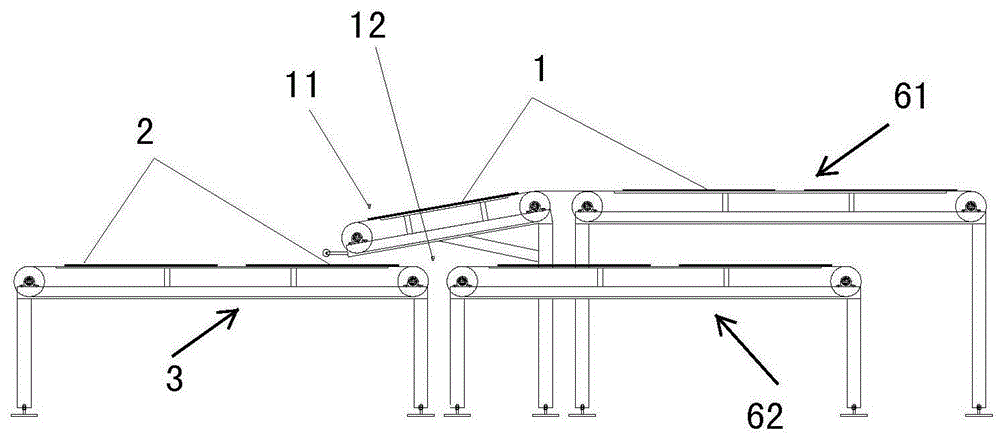

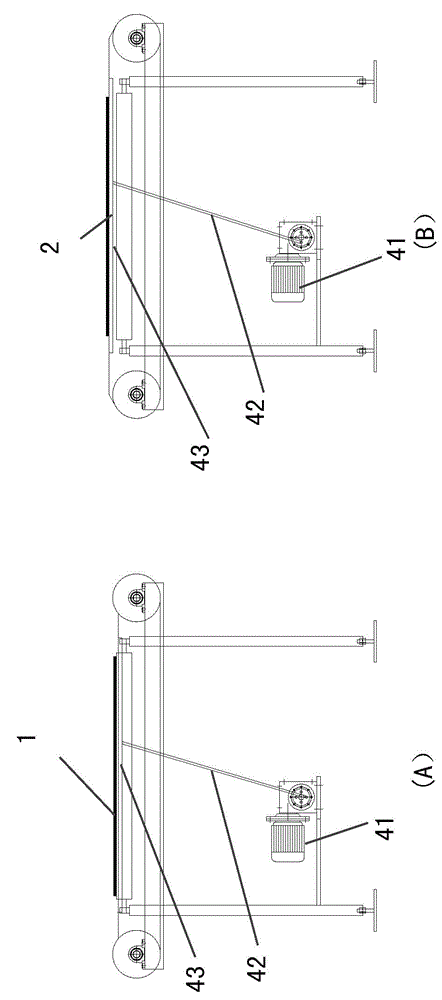

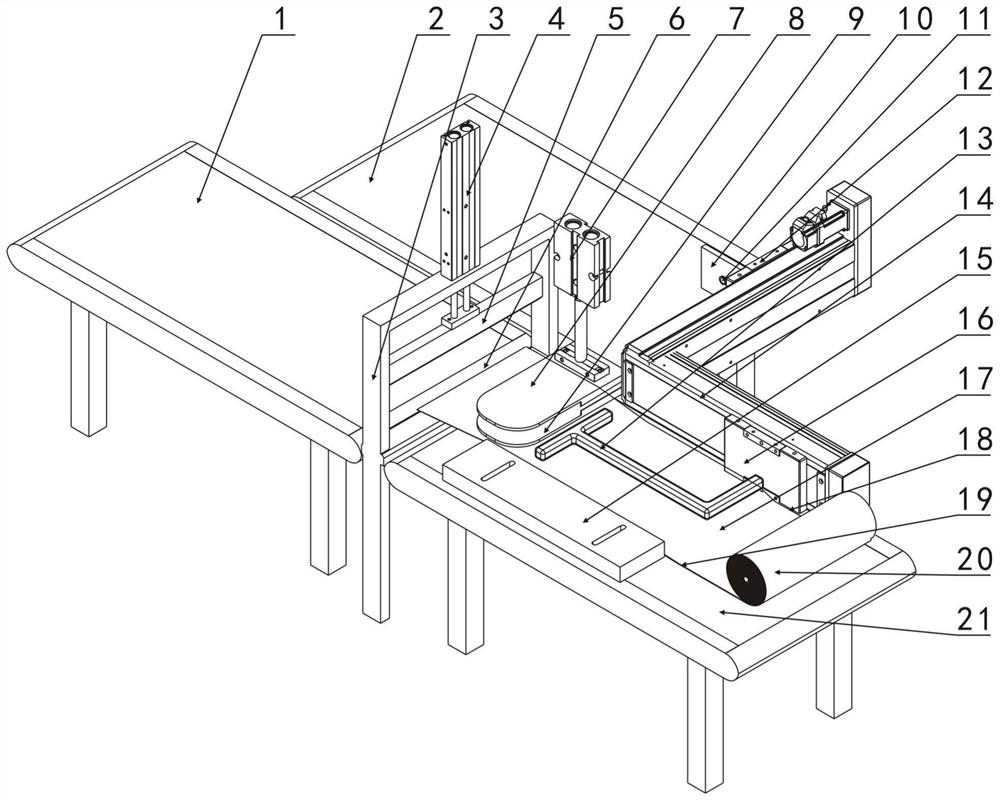

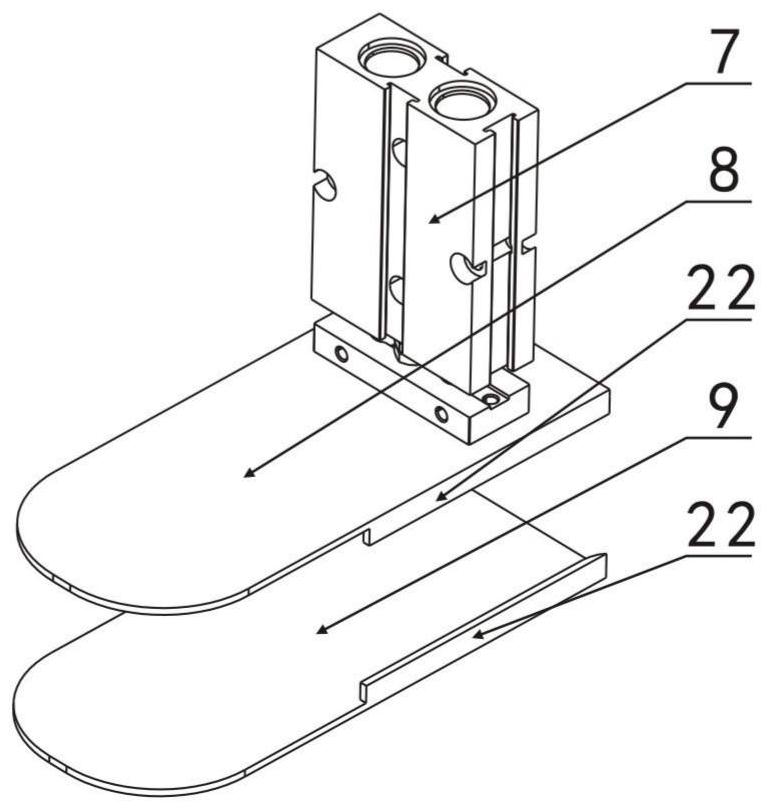

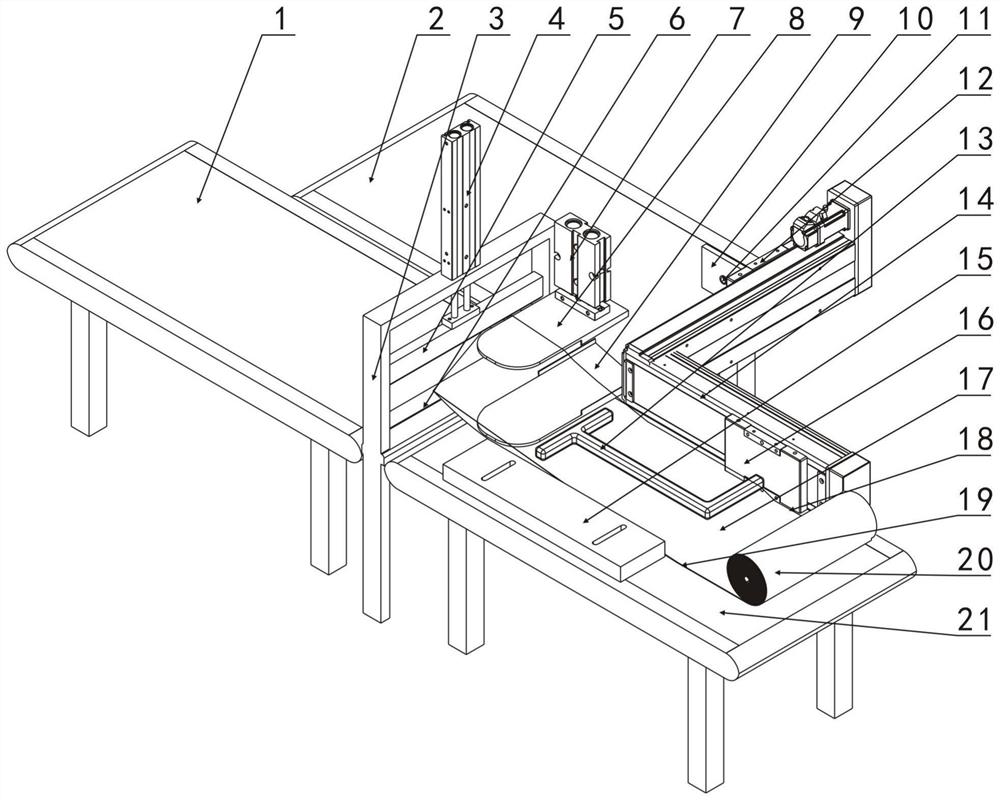

Automatic mold oil spraying system for mold frame

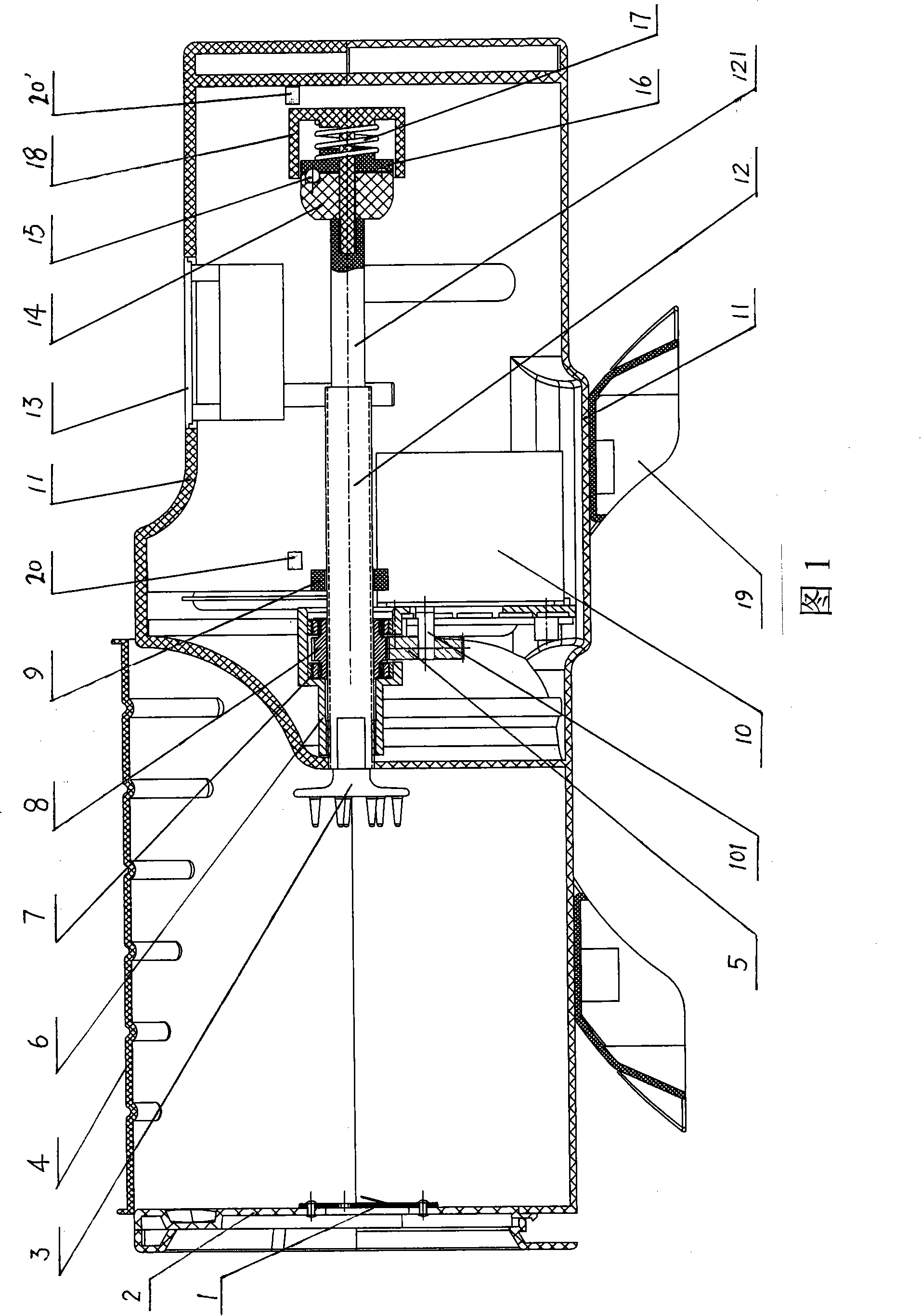

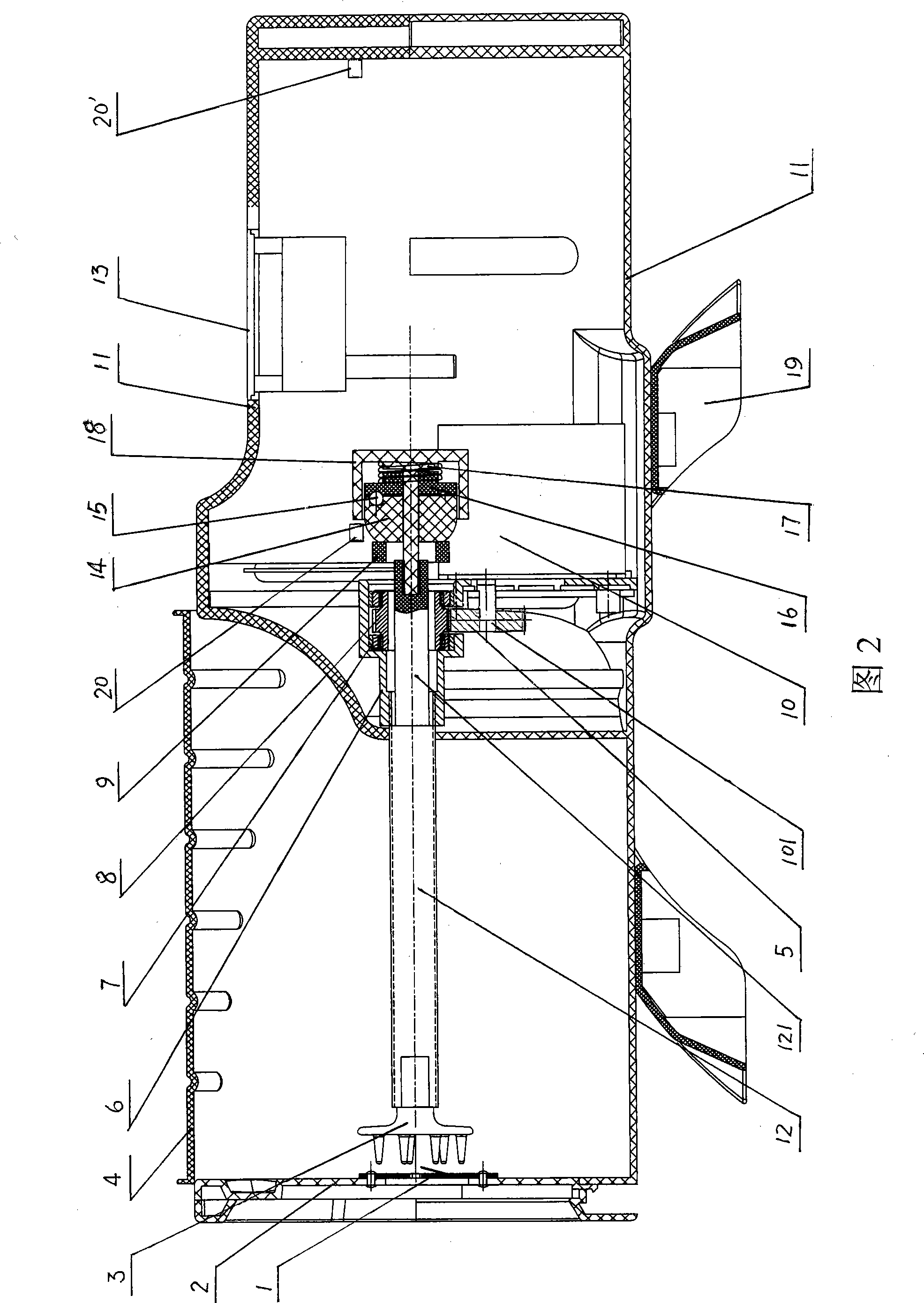

InactiveCN104802292AReduce wasteIncrease the number ofCeramic shaping apparatusSprayerElectric machine

The invention discloses an automatic mold oil spraying system for a mold frame. The system comprises an oil spraying system (1), an oil supply system (2), a mold frame positioning system (3), an exhaust purification system (4) and an electric control system (5), wherein the oil spraying system (1) consists of a traveling mechanism erected on a main oil spraying system architecture (6) and a spraying mechanism; the traveling mechanism comprises a horizontal moving driving motor (7), a synchronizing wheel (8) connected with the driving motor (7), a synchronous belt (9), a rail (10) and a horizontal moving trolley (11); the horizontal moving trolley (11) is connected with the synchronous belt (9) through synchronous belt connectors (12); the spraying mechanism comprises a cylinder (13) and a sprayer connected onto the cylinder (13); the sprayer comprises CYL motion control electromagnetic valves (14) fixedly arranged on a bracket (17), valve terminals (15) and front, rear, left and right rows of spraying guns (16). The system has the characteristics of uniform spraying, high controllability, high efficiency and easiness in popularization.

Owner:GUIZHOU CHANGTAIYUAN ENERGY SAVING BUILDING MATERIALS CO LTD

Foodstuff chip cutter

InactiveCN101249656ARealize full automatic controlSimple mechanical structureMetal working apparatusAutomatic controlElectric machinery

The invention relates to a food slicing machine comprising a frame and a fixed claw for fixing food. The fixed claw is driven by a rotating and marching mechanism to go forward and backward. A cutting tool is arranged on the marching direction of the rotating and marching mechanism, and the rotating and marching mechanism is fixed on the frame, and driven by a motor, and comprises a screw and a screw rotating and marching mechanism. The fixed claw is fixed at the front end of the screw, and an idling mechanism is arranged at the rear of the screw, wherein, the screw rotating and marching mechanism drives a gear group by the motor, and the gear group drives the screw to rotate. The screw is arranged in the casing with a cavity, and at least one part of the inner wall in the cavity is provided with internal thread, which is meshed with the thread of the screw. The machine has the advantages of use of motor for driving, automatic control for the whole process, realization of three steps of positive rotating and forward going, halt idling after go forward to the position, and inverse rotating and backward going, only use of one motor, synchronous completion of rotating and marching actions, and simple and compact structure. The idling mechanism is cooperated with the circuit control to achieve the automatic resetting of the mechanism. Therefore, the machine can be operated for a long time, and has a long service life.

Owner:顾江永

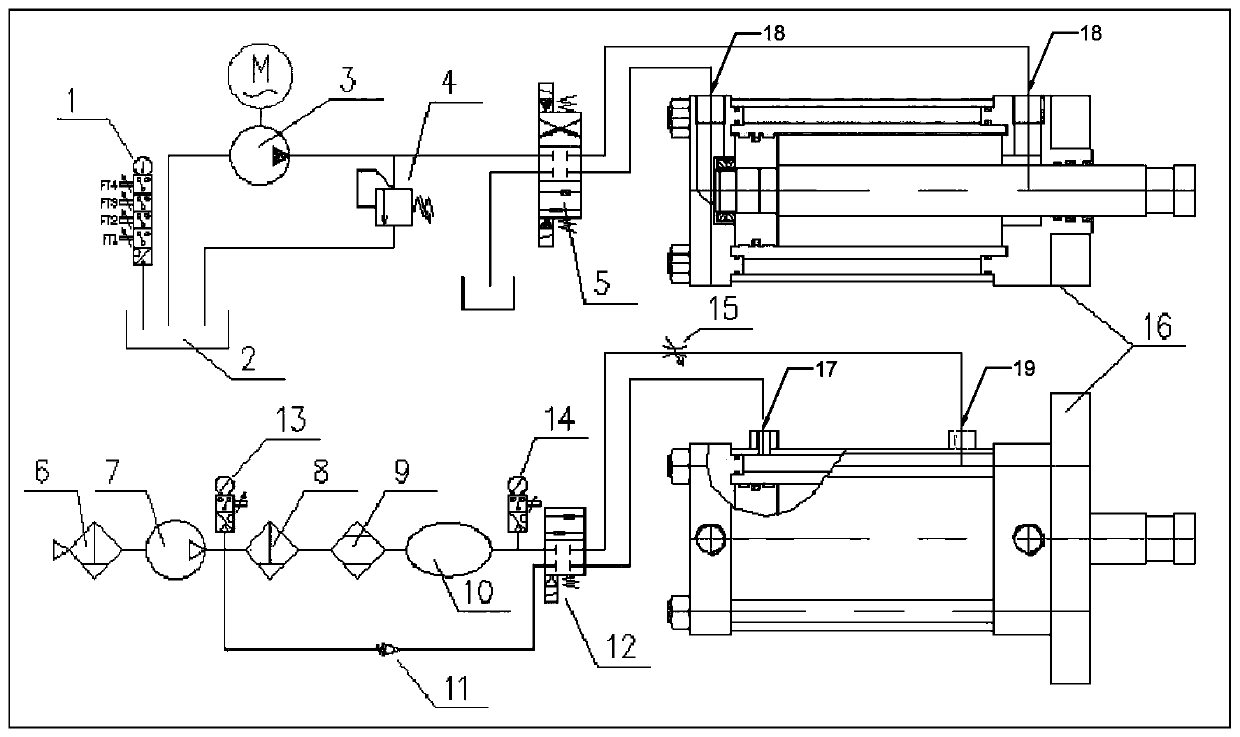

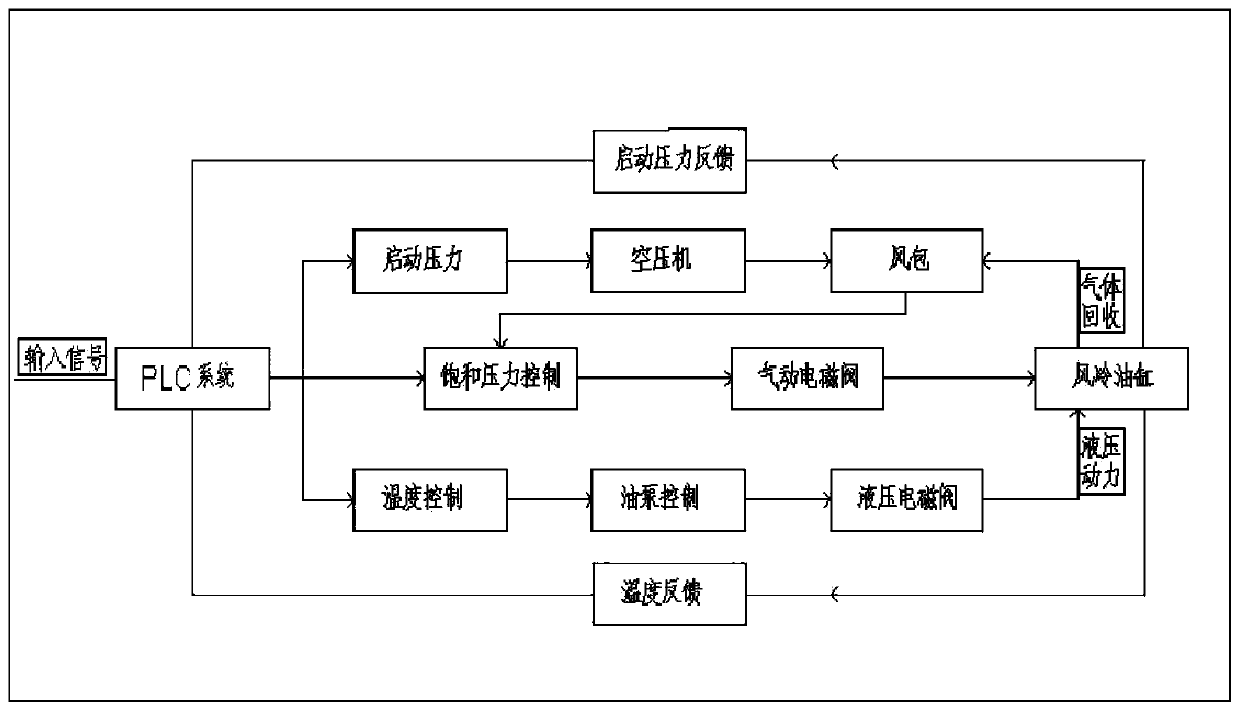

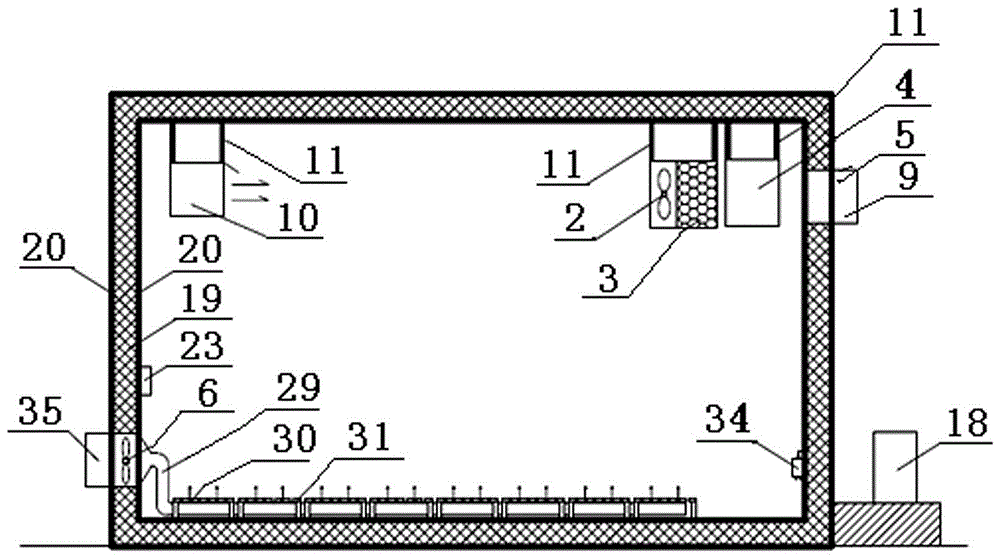

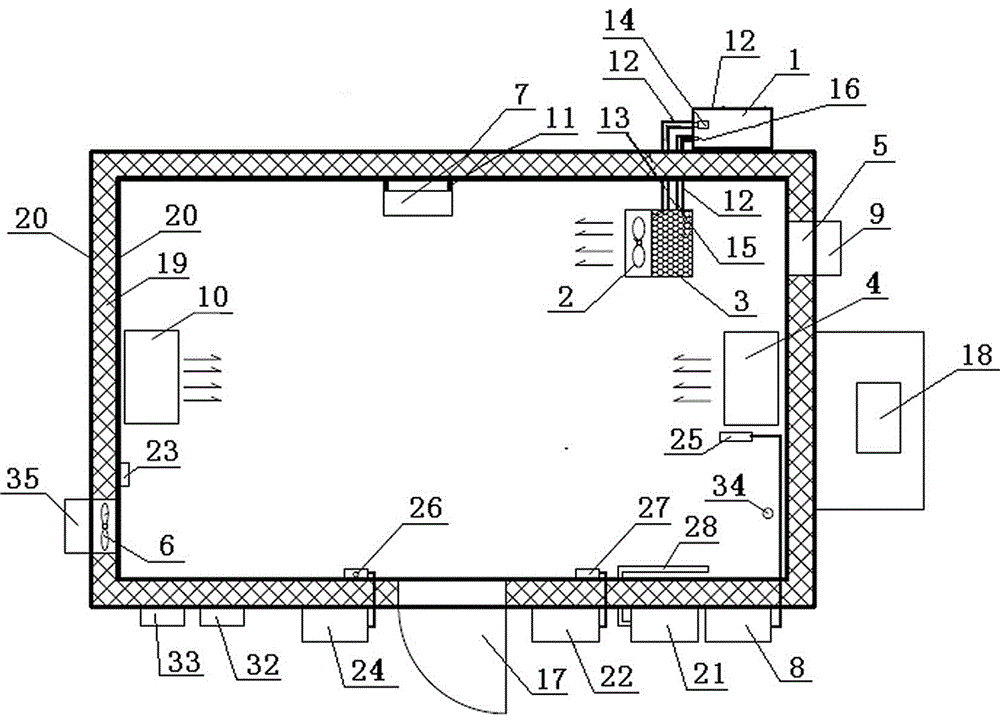

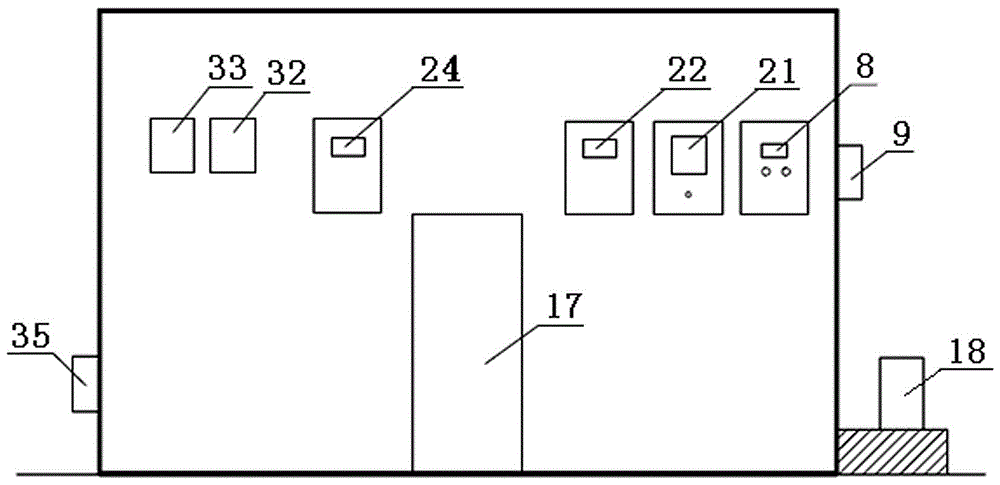

Intelligent temperature control system for hydraulic oil temperature of coke oven vehicle

InactiveCN109780006AExtended service lifeRealize full automatic controlFluid-pressure actuator componentsTemperature controlAutomatic control

The invention provides an intelligent temperature control system for the hydraulic oil temperature of a coke oven vehicle. The intelligent temperature control system comprises a PLC control system, ahydraulic system and a pipeline. The hydraulic system comprises a temperature sensor (1). The intelligent temperature control system further comprises a pneumatic valve (12), an air compressor (7), afreezing type air drying device (9), an air pocket (10) and an air return pipeline. The temperature sensor (1) is arranged on an oil tank of the hydraulic system. The temperature sensor (1) sends a detected temperature signal to the PLC control system. The PLC control system sends the signal to control the cooling air electromagnetic valve (12) of an oil cylinder to be opened. Air enters the air pocket (10) through the air compressor (7) and the pipeline. According to the intelligent temperature control system, whole-course automatic control is achieved during operation of coke oven vehicles such as a coal loading vehicle, a coke pushing vehicle and a coke guide vehicle, the service life of hydraulic oil and the oil cylinder is prolonged, and residual air can be recycled.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

Tuber storage method

ActiveCN105993417ATemperature controlReduce humidityAgriculture tools and machinesHarvested fruit hanging devicesPlant TubersBiology

The invention provides a tuber storage method. The method includes the following steps that firstly, raw materials are harvested, wherein tubers which are not damaged are harvested and selected; secondly, pre-storage is conducted, wherein ventilation, airing and preprocessing are conducted; thirdly, tubers are selected, wherein the damaged tubers and the rotted tubers are removed; fourthly, the tubers are packaged and stacked, wherein the tubers are packaged with mesh bags or plastic boxes and placed on stacking piles; fifthly, the tubers are put in storage, wherein the tubers are stored in a ventilating heat-preserving storehouse or a multifunctional storage fresh-keeping storehouse; sixthly, the tubers are moved out of the storehouse. The storage period is long, storage is not influenced by seasons, freshness and flavor are kept, and quality is good.

Owner:INST OF AGRO PROD PROCESSING SCI & TECH SICHUAN ACAD OF AGRI SCI

Walking type air floatation mixer

InactiveCN103896386ASimple structureReduce energy consumptionTransportation and packagingMixersAutomatic controlAgricultural engineering

The invention discloses a walking type air floatation mixer which comprises a walking platform; the upper surface of the walking platform is provided with a motor, a dosing pump, a fan and a dosing tank connected with the dosing pump; a walking roller wheel capable of moving in a guide rail is arranged at each of the two ends of the walking platform; the motor is connected with the walking roller wheels by transmission shafts; the bottom of the walking platform is provided with a support frame; a liquid distribution pipe connected with the dosing box and an aerator pipe connected with the fan are respectively fixed on the support frame; and an outlet end of the liquid distribution pipe is higher than that of the aerator pipe. The walking type air floatation mixer is simple in structure, low in energy consumption, even in dosing and rapid in mixed reaction; the walking type air floatation mixer gives priority to air agitation and is supplemented by mechanical agitation, and the solution in a tank can be completely mixed, so that the power is saved, and precipitate is prevented in an acidification pool; and the walking type air floatation mixer is simple to operate and can be automatically controlled in the whole process.

Owner:卓建立

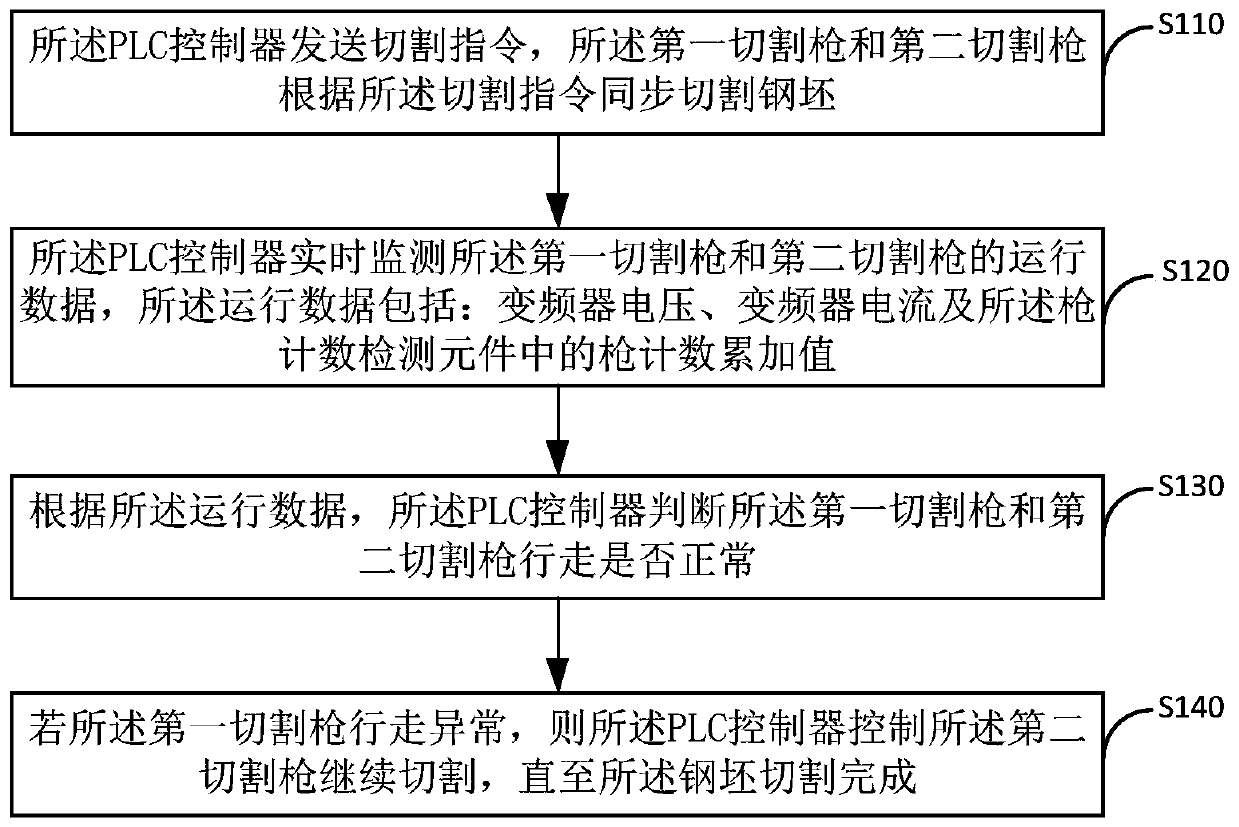

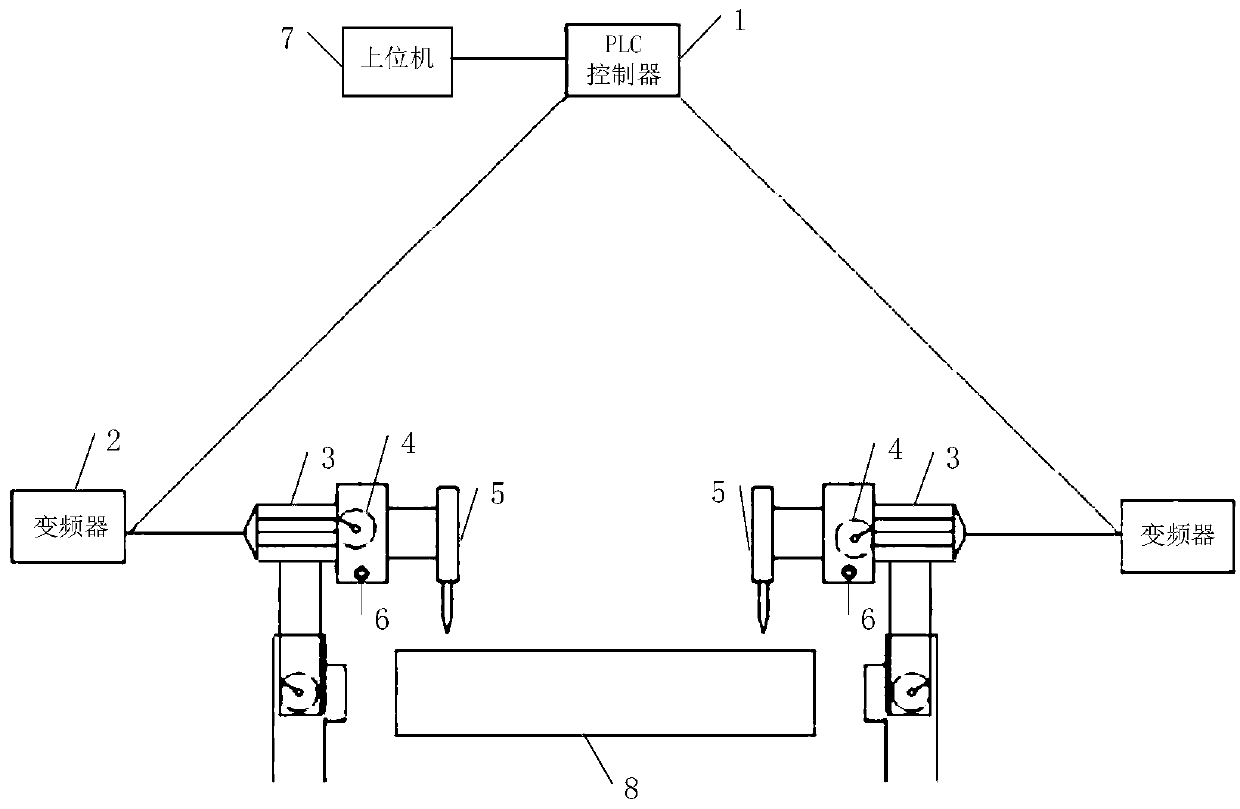

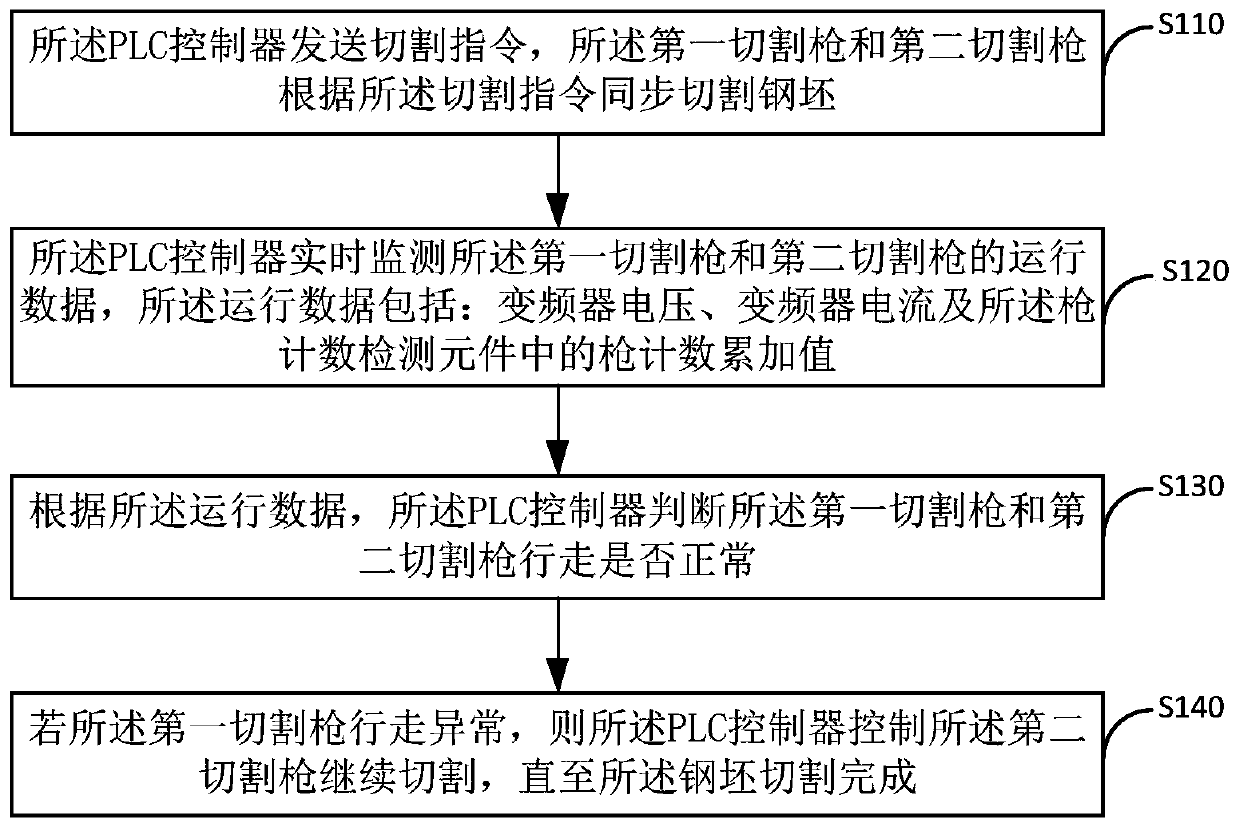

Controlling method and device for cutting performed by flame cutting machine of continuous casting machine

The invention discloses a controlling method and device for cutting performed by a flame cutting machine of a continuous casting machine. The device is characterized in that two driving motors are correspondingly controlled by a PLC through two frequency converters, first and second cutting guns in the flame cutting machine are correspondingly controlled by the two driving motors, and gun countingdetecting members are arranged on the first and second cutting guns. The method comprises the steps that a cutting instruction is sent by the PLC, and a steel blank is synchronously cut by the firstand second cutting guns according to the cutting instruction; operation data of the first and second cutting guns is monitored in real time by the PLC; whether or not the moving of the first and second cutting guns is normal is judged by the PLC according to the operation data; if the moving of the first cutting gun is abnormal, the second cutting gun is controlled to cut continuously until the cutting of the steel blank is completed. According to the method and the device, cutting can be conducted by the other cutting gun after any of the cutting gun is damaged, an operator does not need to hold the cutting gun to cut the blank, the labor intensity of the operator is reduced, the safety performance is improved, and fully automatic controlling of the flame cutting machine is achieved.

Owner:SHANDONG IRON & STEEL CO LTD

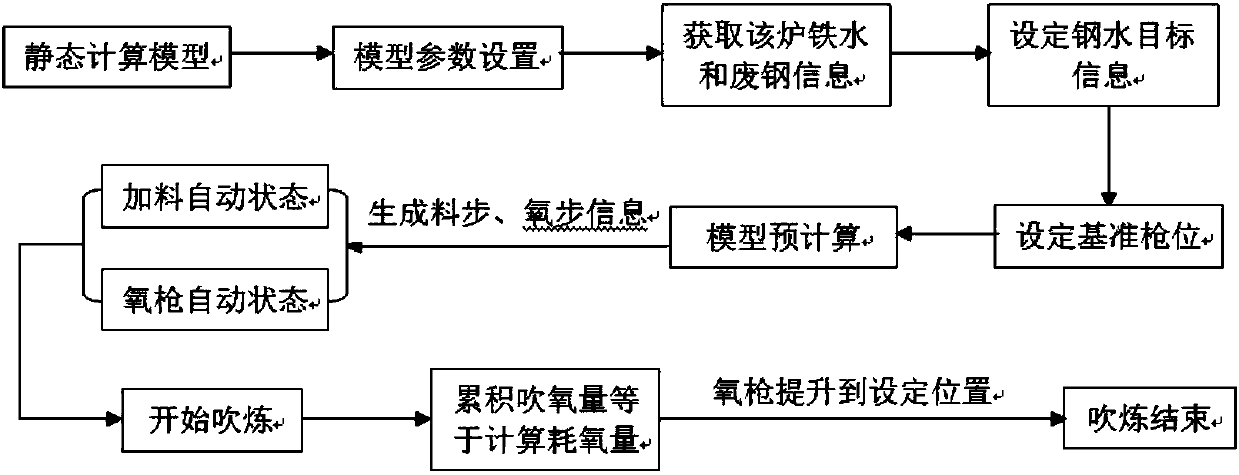

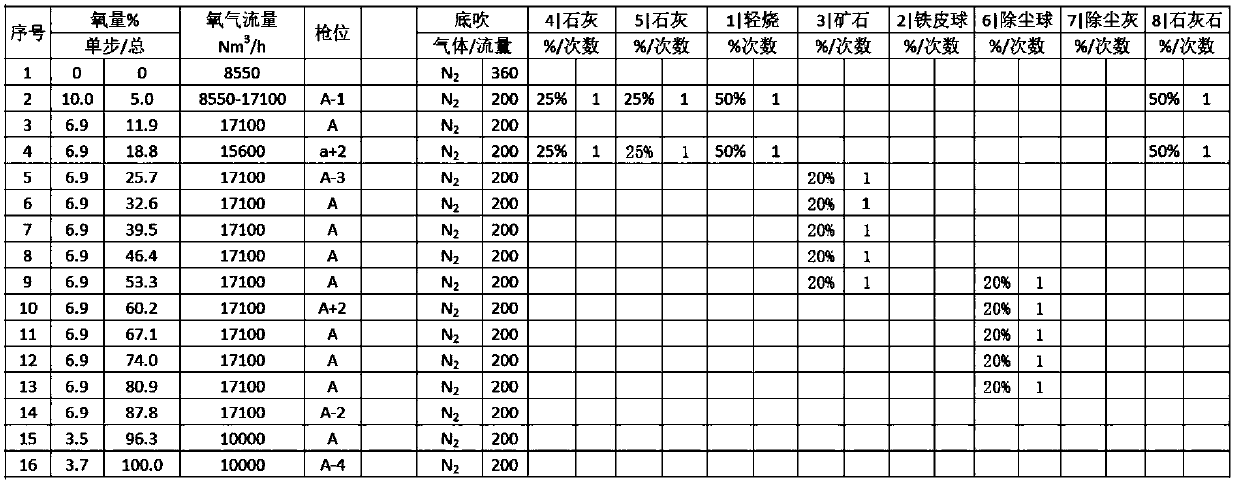

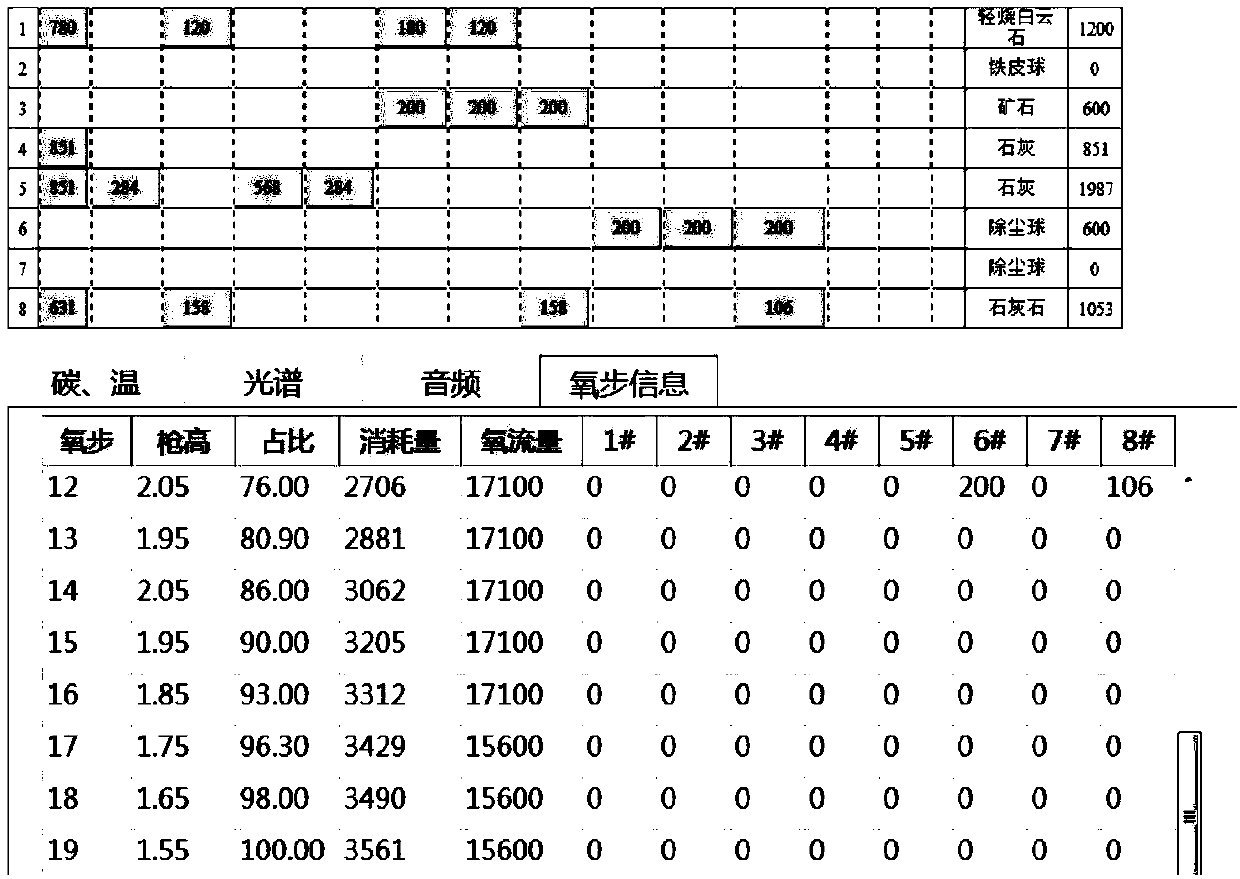

Automatic control method for feeding, oxygen lance position and oxygen flow in converter steelmaking process

InactiveCN107557520AIntegrity guaranteedRealize full automatic controlManufacturing convertersSteelmakingAutomatic control

The invention relates to an automatic control method for feeding, the oxygen lance position and the oxygen flow in the converter steelmaking process and belongs to the technical field of converter steelmaking processes. According to the technical scheme of the automatic control method, three parts of a static calculation model, a feeding control module and an oxygen lance control module are included; the feeding control module transmits a material step information instruction in the smelting process to a PLC of a feeding system, and automatic control over feeding operation in the smelting process is achieved through a basic automation system of the feeding system; and the oxygen lance control module transmits an oxygen step information instruction in the smelting process to a PLC of an oxygen lance system, and automatic control over the oxygen lance position and the oxygen flow in the smelting process is achieved through execution of a basic automation system of the oxygen lance system. The automatic control method has the beneficial effects that full-process automatic control over feeding, the oxygen lance position and the oxygen flow in the converter steelmaking process is achieved, the standard operation level of smelting and the quality stability of molten steel are advantageously improved, the production efficiency of a converter is improved, consumption of raw materials and auxiliary materials of the converter is reduced, and the steelmaking cost of the converter is reduced.

Owner:TANGSHAN IRON & STEEL GROUP +1

Automatic overlocking device

ActiveCN105332167AImprove accuracyImprove work efficiencyWork-collecting devicesAutomatic controlControl system

The invention relates to an automatic overlocking device. The device comprises a machine frame, a workbench, a cloth feeding mechanism, a cloth pushing mechanism, a first cloth pulling mechanism, a second cloth pulling mechanism, a feeding lifting mechanism and a control system, wherein the machine frame is arranged on the workbench and located above the workbench, the cloth feeding mechanism, the cloth pushing mechanism, the first cloth pulling mechanism and the second cloth pulling mechanism are arranged on the machine frame and can move towards the workbench, the first cloth pulling mechanism, the cloth feeding mechanism, the cloth pushing mechanism and the second cloth pulling mechanism are arranged in the length direction of the machine frame in sequence, the first cloth pulling mechanism and the second cloth pulling mechanism are movably arranged in the length direction of the machine frame, and the control system controls the cloth feeding mechanism, the cloth pushing mechanism, the first cloth pulling mechanism, the second cloth pulling mechanism and the feeding lifting mechanism to work. The device has the advantages that overlocking accuracy is improved effectively, overlocking efficiency is improved remarkably, and automatic control is achieved in the whole process.

Owner:陈 文荣

Foodstuff chip cutter

InactiveCN101249656BRealize full automatic controlSimple mechanical structureMetal working apparatusAutomatic controlElectric machinery

A food slicing device is disclosed for slicing potatoes, apples, cucumbers and the like. The device comprise holding means for holding the food to be sliced and conveyance means for conveying the food to be sliced in a conveyance direction along the device and for simultaneously rotating the means for holding the food substantially about an axis comprising the conveyance direction. The device further comprises a cutter positioned substantially within the conveyance direction and is arranged to cut the food at one side of the axis of rotation as the food is conveyed along the conveyance direction and rotates about an axis comprising the conveyance direction, to produce a substantially helical food shape.

Owner:顾江永

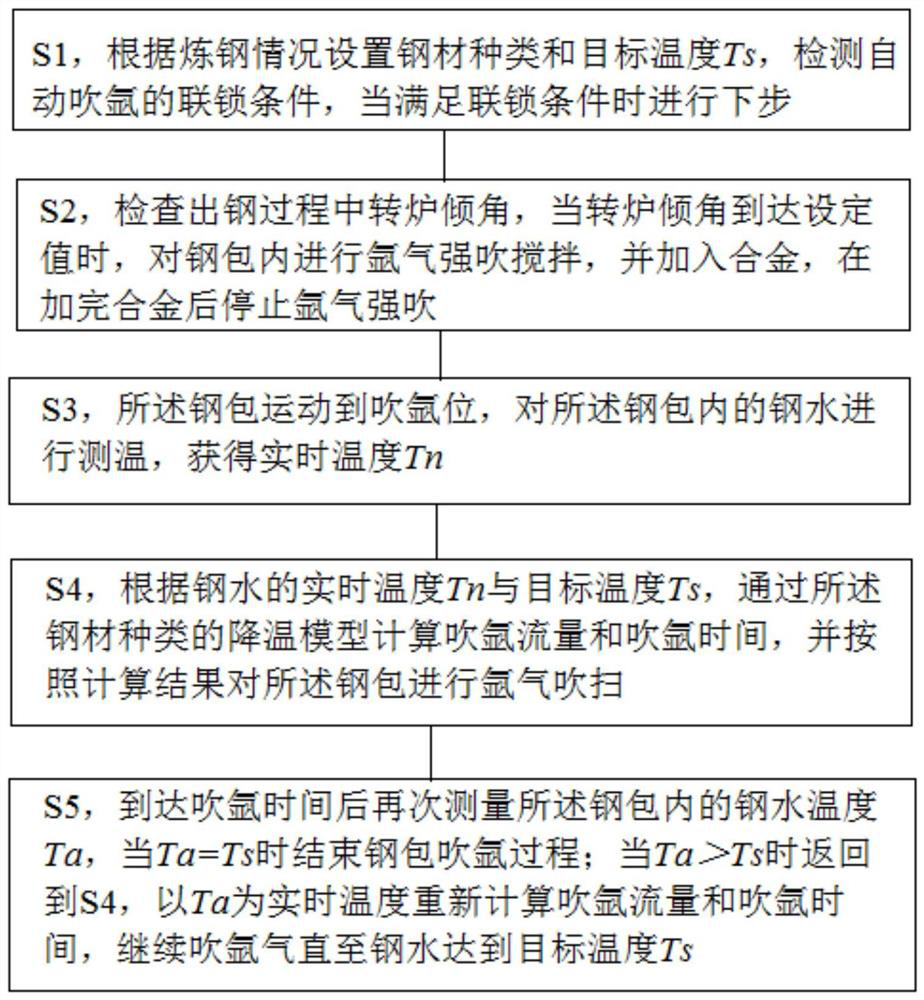

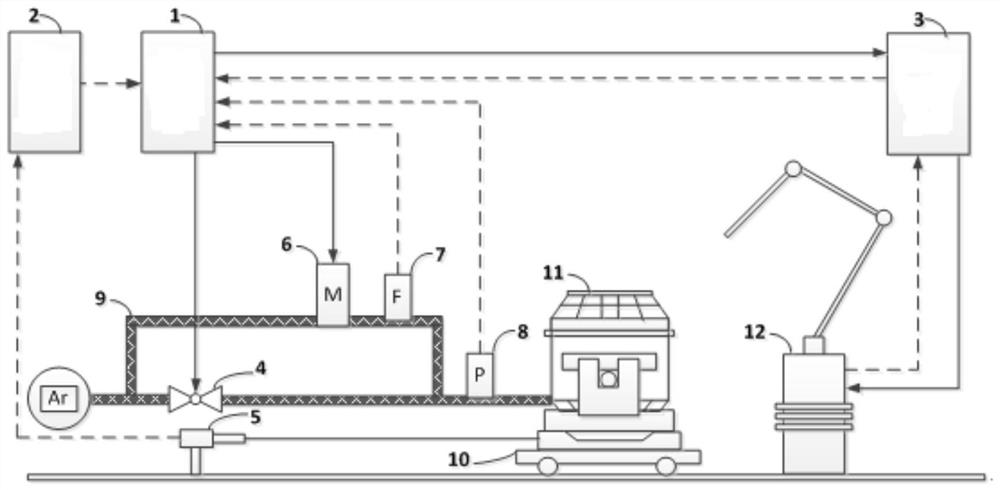

Automatic argon blowing method and system of steel ladles

ActiveCN112410510AReduce labor intensityQuality improvementIncreasing energy efficiencyAlloyMolten steel

The invention relates to an automatic argon blowing method and system of steel ladles. The method comprises the following steps: S1, setting the types and target temperature Ts of steel, and detectingan automatic argon blowing interlocking condition; and S2, performing argon strong-blowing and stirring of the steel ladles when a converter inclination angle reaches a setting value in a steel discharging process, and stopping strong-blowing of the argon after alloys are processed completely; S3, detecting the temperature of molten steel in the steel ladles to obtain real-time temperature Tn; S4, calculating the argon blowing flow and the argon blowing time through a cooling model according to Tn and Ts, and performing argon blowing; and S5, measuring the temperature Ta of the molten steel in the steel ladles again, ending the argon blowing process of the steel ladles when Ta is equal to Ts, and returning to the step S4 when Ta is more than Ts. According to the automatic argon blowing method of the steel ladles provided by the invention, whole-process automatic argon blowing before feeding of the steel ladles onto a continuous casting machine at the beginning of steel output is realized, so that the labor intensity of working personnel is reduced, and the automatic argon blowing operation safety is improved.

Owner:WISDRI ENG & RES INC LTD

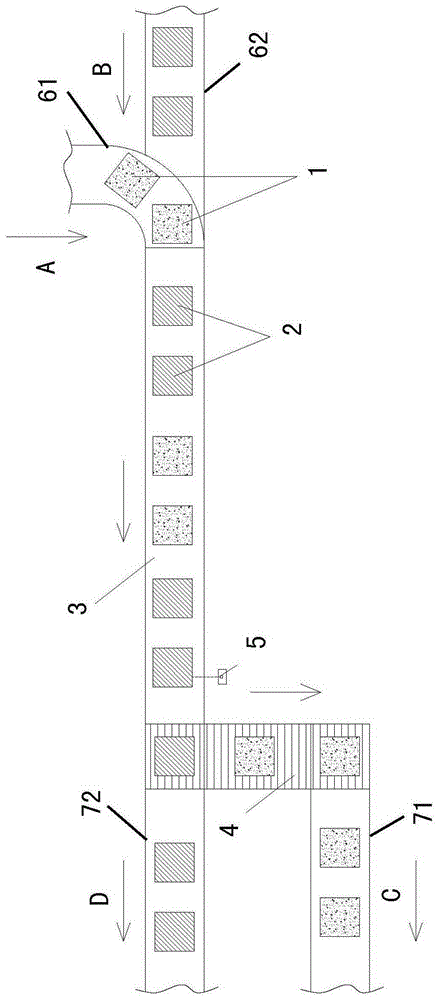

Ceramic tile conveying device

The invention provides a ceramic tile conveying device. The ceramic tile conveying device comprises a plurality of dispersed conveying lines used for conveying ceramic tiles discharged from a plurality of kilns respectively, marking units used for marking the side faces of the ceramic tiles from the different kilns respectively, an integral conveying line used for integrally conveying the ceramic tiles after converging the ceramic tiles on the multiple dispersed conveying lines, a recognition unit used for recognizing the ceramic tiles conveyed on the integral conveying line to distinguish the ceramic tiles from the different kilns, and a control unit used for conveying the ceramic tiles which are recognized through the recognition unit and come from the different kilns onto different polishing lines. By the adoption of the ceramic tile conveying device, equipment can be simplified, space is saved, and energy saving is achieved.

Owner:广东清远蒙娜丽莎建陶有限公司

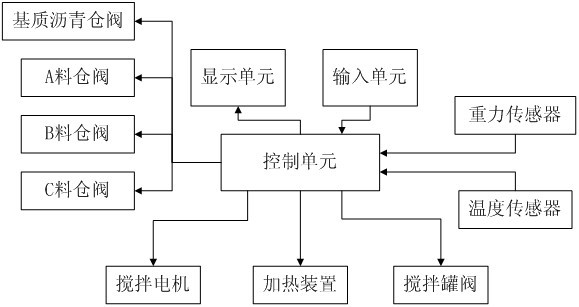

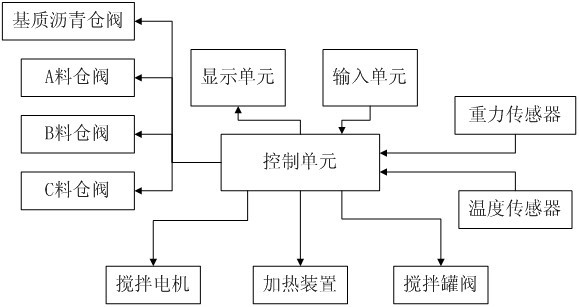

Automatic asphalt batching system for waterproof roll production line

InactiveCN102319544ARealize full automatic controlAdjust the Asphalt RecipeRotary stirring mixersMixer accessoriesAutomatic controlAsphalt

The invention discloses an automatic asphalt batching system for a waterproof roll production line. The automatic asphalt batching system comprises an agitation tank, a raw material storage bin, a control unit, and an input unit, a gravity sensor, a temperature sensor, a stirring motor, a heating device, a raw material bin valve and an agitation tank valve which are electrically connected with the control unit. The automatic asphalt batching system for the waterproof roll production line realizes automatic control in a whole process, and is safe, reliable, flexible and applicable to waterproof roll production lines of various modified asphalts; and an asphalt formula can be adjusted according to requirements.

Owner:CHANGSHU JINGHAI MACHINERY MFG

Full-automatic welding machine for dual-rotation-disc motor rotors

PendingCN111168185AAvoid affecting performanceAvoid overall overheatingWelding/soldering/cutting articlesMetal working apparatusAutomatic controlElectric machinery

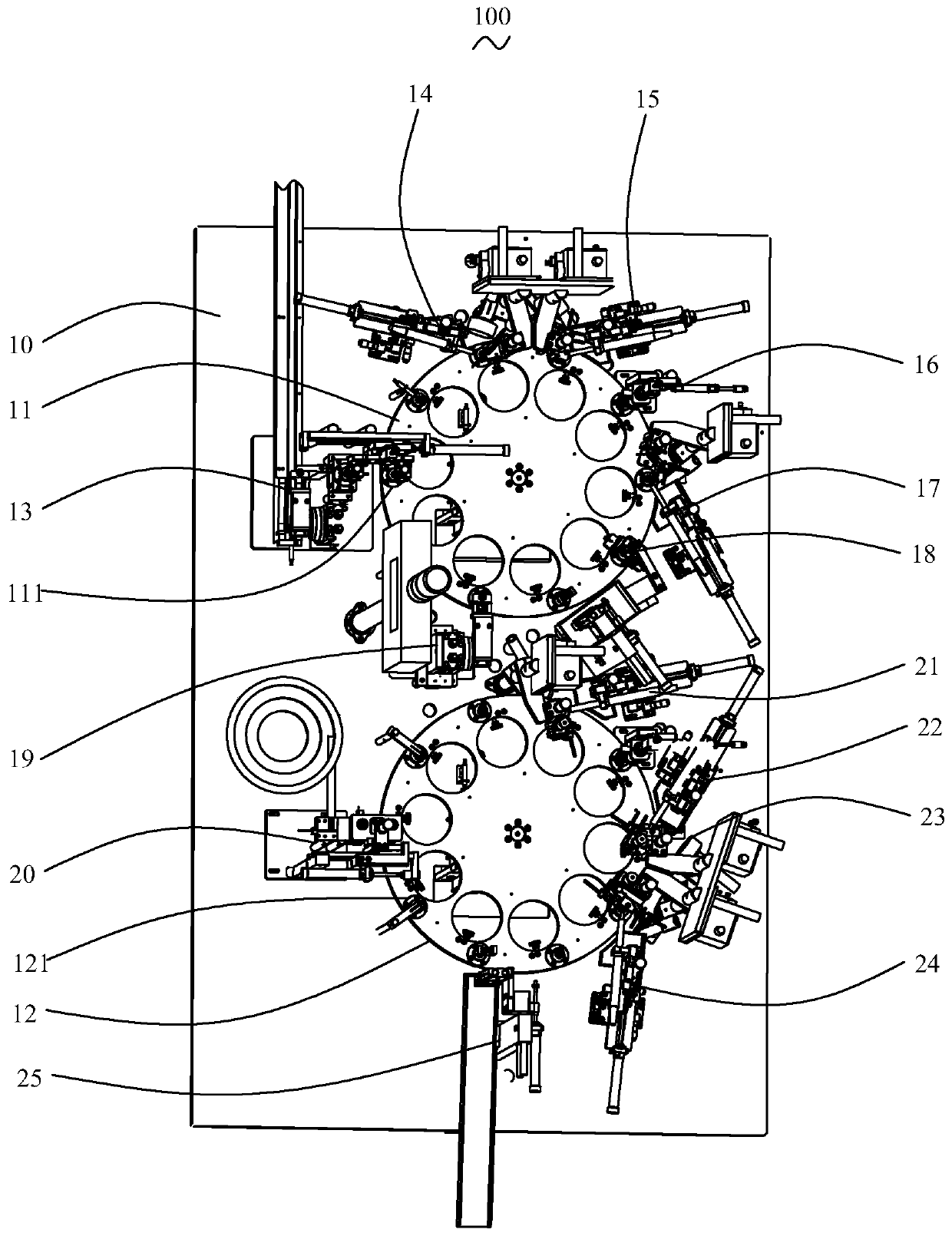

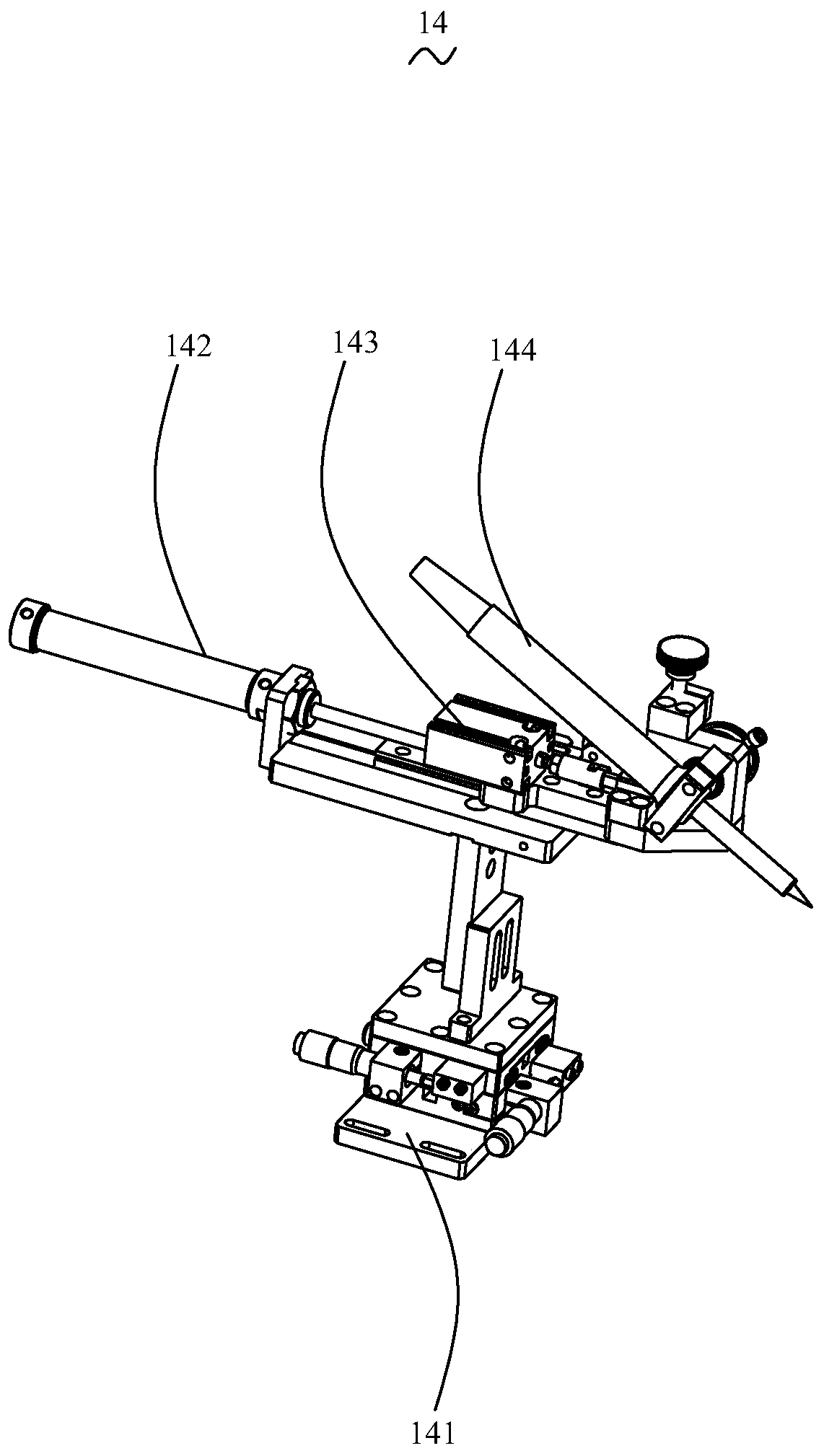

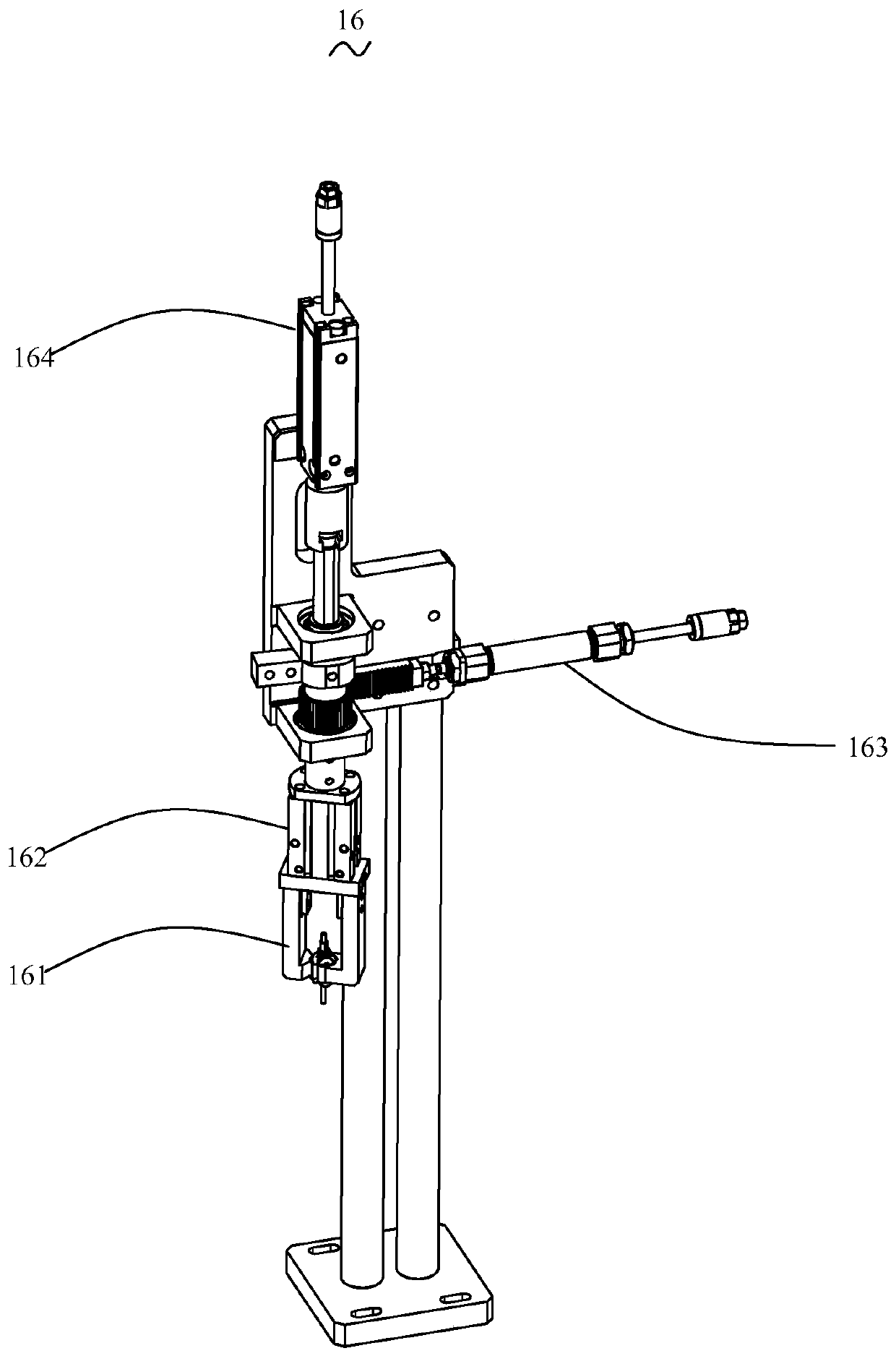

The invention relates to a full-automatic welding machine for dual-rotation-disc motor rotors. The machine comprises a workbench, a first rotation disc, a second rotation disc, a clamp rotor mechanism, a first welding mechanism, a second welding mechanism, a first positioning mechanism, a third welding mechanism, a resistance value testing mechanism, an overturning mechanism, a pressure sensor taking mechanism, a fourth welding mechanism, a fifth welding mechanism, a second positioning mechanism, a six welding mechanism and a finished product discharging mechanism. The first rotation disc andthe second rotation disc are arranged on the workbench. The clamp rotor mechanism, the first welding mechanism, the second welding mechanism, the first positioning mechanism, the third welding mechanism and the resistance value testing mechanism are arranged round the first rotation disc in sequence. The overturning mechanism is arranged between the first rotation disc and the second rotation disc. The pressure sensor taking mechanism, the fourth welding mechanism, the fifth welding mechanism, the second positioning mechanism, the six welding mechanism and the finished product discharging mechanism are arranged around the second rotation disc in sequence. Compared with the prior art, the full-automatic welding machine for the dual-rotation-disc motor rotor has the advantages that a dual-rotation-disc structure is adopted for driving the motor rotors to move, the motor rotors are tested and welded step by step in sequence, overheating can be avoided, the performance of the motor rotorsis prevented from being influenced, full-process automatic control is achieved, the efficiency and rate of finished products are improved, and the labor cost is reduced.

Owner:深圳市鑫科德自动化有限公司

Automatic steaming disk cleaning technology with high efficiency

InactiveCN107457237AEasy to cleanImprove cleaning efficiencyHollow article cleaningDrying gas arrangementsWater savingDisinfectant

The invention relates to an automatic steaming disk cleaning technology with high efficiency. The cleaning technology comprises the steps that a steaming disk to be cleaned is put into a steaming disk sliding chute, then enters a steaming disk channel between two brushes through the face of the sliding chute, and the steaming disk enters a conveyor belt after being cleaned rotationally up and down by the brushes; the steaming disk is conveyed through the conveyor belt to enter a high pressure rinsing tank for washing with high pressure water; the washed steaming disk enters a disinfection tank for cleaning with disinfectant fluid; the disinfected steaming disk enters a high temperature drying tank for drying at high temperature; the steaming disk dried at high temperature is continuously conveyed to a disk collection mechanism for storage; in the above process, an electric control box is used for controlling the on-off and operating parameters of an adjustable speed motor, a high pressure water pipe, a disinfectant fluid pipe, an automatic heating pipe and a high speed fan. According to the automatic steaming disk cleaning technology, the steaming disk can be cleaned thoroughly and efficiently, and blind corners are cleaned; the cleaning efficiency can be improved obviously, and water consumption and labor cost are saved; and the degree of automation is high.

Owner:无锡汇盈食品有限公司

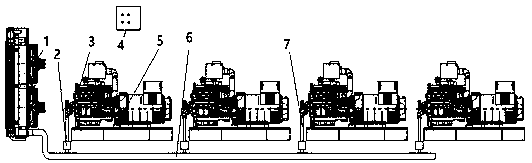

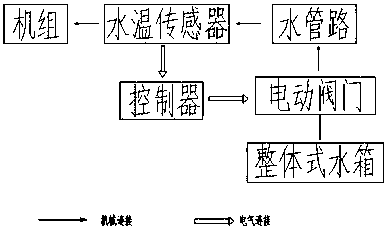

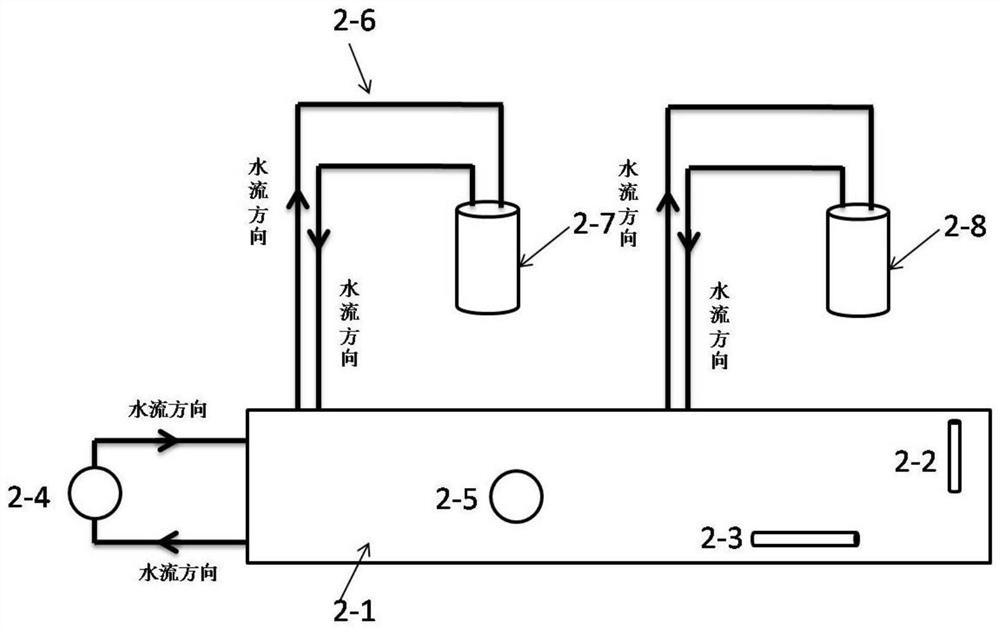

Multi-machine integral type coolant pipeline automatic regulation system

PendingCN108562096ASave human effortRealize full automatic controlLighting and heating apparatusCooling fluid circulationMulti machineEngineering

The invention discloses a multi-machine integral type coolant pipeline automatic regulation system which comprises units, an integral type water tank, water temperature sensors, electric valves, a controller and a water pipeline; a water inlet of a cooling water pipe of each unit is provided with the corresponding water temperature sensor; each water temperature sensor is electrically connected with the controller; the integral type water tank is connected with the cooling water pipe of each unit through the water pipeline; the water pipeline comprises a main water pipe and branch water pipes;the water inlet end of the main water pipe is connected with a water outlet of the integral type water tank; water outlets with a same amount as the units are distributed on the main water pipe and are connected with the cooling water pipes of the units through the branch water pipes; each branch water pipe is provided with the electric valve; each electric valve is electrically connected with the controller; and a display module is also connected to a signal output end of the controller. The multi-machine integral type coolant pipeline automatic regulation system provided by the invention ishigh in intelligent degree, saves manpower and prolongs service life of each unit.

Owner:山东速力动力科技有限公司

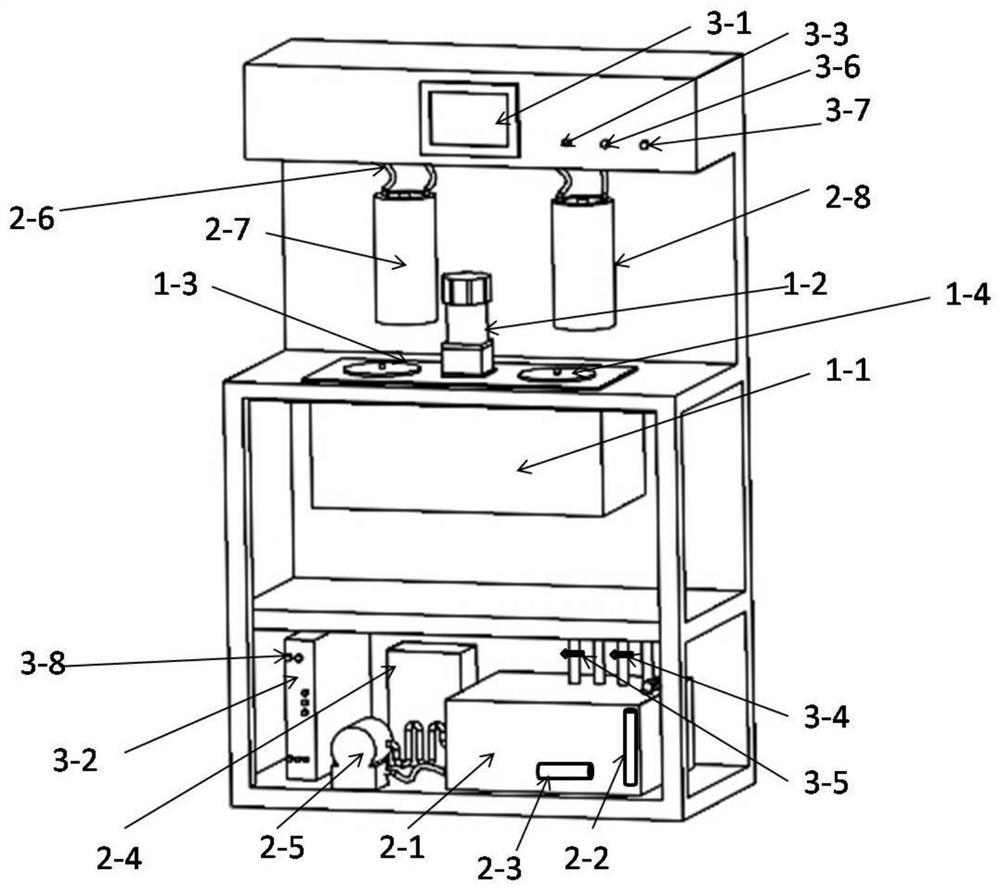

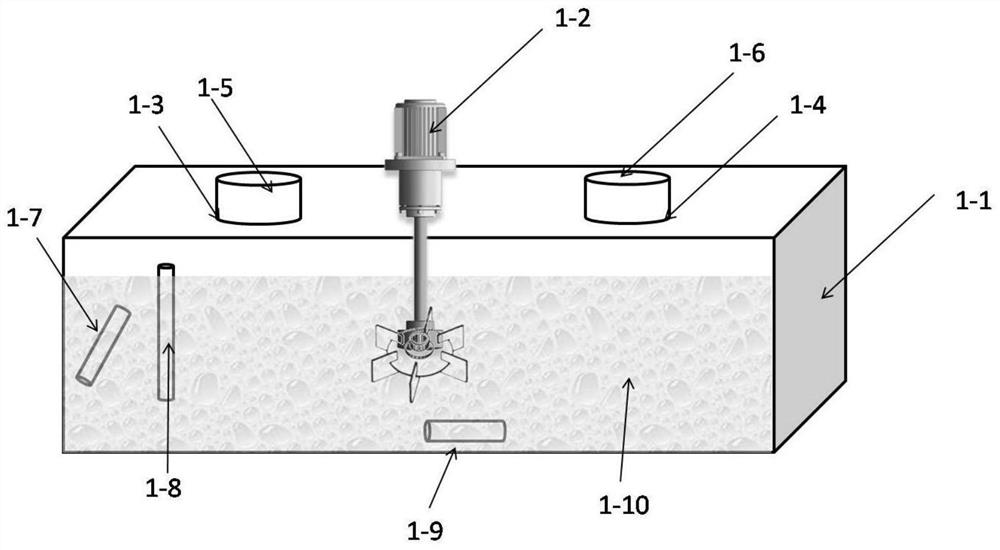

Sulfuric acid-copper sulfate-copper scrap corrosion test device for austenitic stainless steel

PendingCN111766195ARealize full automatic controlGuaranteed accuracyWeather/light/corrosion resistanceAutomatic controlHeater Rod

The invention provides a sulfuric acid-copper sulfate-copper scrap corrosion test device for austenitic stainless steel. A heating system comprises an oil bath cylinder, a stirrer, a station groove, areaction container, a heating rod, an oil bath cylinder liquid level sensor, an oil bath cylinder temperature sensor and a heating medium, a circulating cooling system comprises a water tank, a watertank liquid level sensor, a water tank temperature sensor, a refrigerating unit, a circulating pump, a water pipe and a condenser, and a control system comprises a touch screen, a controller, a switch, a cooling medium release valve, a current sensor, a voltage sensor and an oil and water shortage power failure alarm. Whole-process automatic control of an intergranular corrosion test can be realized, and an oil bath heating mode is adopted, so that heating is uniform; an internal circulation mode is adopted for cooling, and the refrigerating unit is added for refrigerating, so the refrigerating effect can be improved, and water resources are saved; and the control system can ensure rapid temperature rise and accurate temperature control of a reaction solution, has a water-break, power-break and oil-break alarm function, and can effectively ensure the accuracy of intergranular corrosion test.

Owner:BEIJING NORTH VEHICLE GROUP CORP +1

Full-automatic bagging system for packaging box bagging

PendingCN113716109AImplement automatic detectionImprove intelligencePackaging automatic controlAutomatic controlProximity sensor

The invention discloses a full-automatic bagging system for packaging box bagging. The full-automatic bagging system comprises a machine frame, a conveying belt, a proximity sensor, a first automatic mechanical arm, a push plate, a bag opening mechanism, a second automatic mechanical arm, a push rod, a flexible outer packaging bag, an outer packaging bag roll, a first workbench, a second workbench, a cutter air cylinder, a heat-sealing cutter and a controller, wherein the conveying belt, the proximity sensor, the first automatic mechanical arm, the push plate, the bag opening mechanism, the second automatic mechanical arm, the push rod, the flexible outer packaging bag, the outer packaging bag roll, the first workbench, the second workbench, the cutter air cylinder, the heat-sealing cutter and the controller are installed on the machine frame. According to the full-automatic bagging system, by arranging the proximity sensor, the first automatic mechanical arm, the bag opening mechanism, the second automatic mechanical arm, the flexible outer packaging bag, the cutter air cylinder and the heat-sealing cutter which are matched with one another, the functions of automatic detection, pushing, bagging and heat sealing of packaging boxes are achieved, the whole bagging process is mechanically controlled, and the automation degree is remarkably improved; and according to the full-automatic bagging system for packaging box bagging, full-process automatic control can be achieved, the full-automatic bagging system can be matched with a whole production line to form an automatic system, and intelligent, automatic and large-scale production of the packaging boxes is facilitated.

Owner:THE WING FAT PRINTING SICHUAN

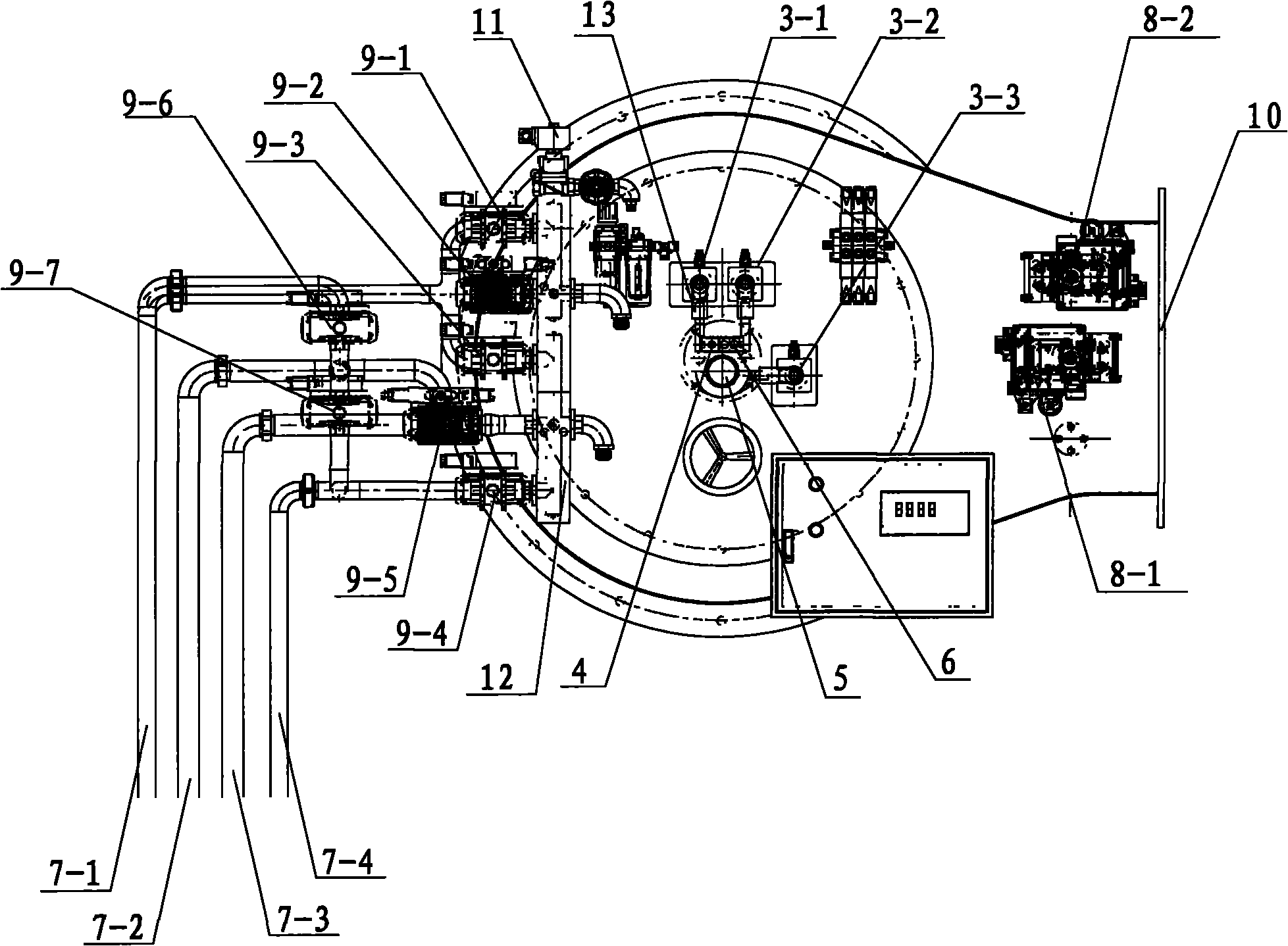

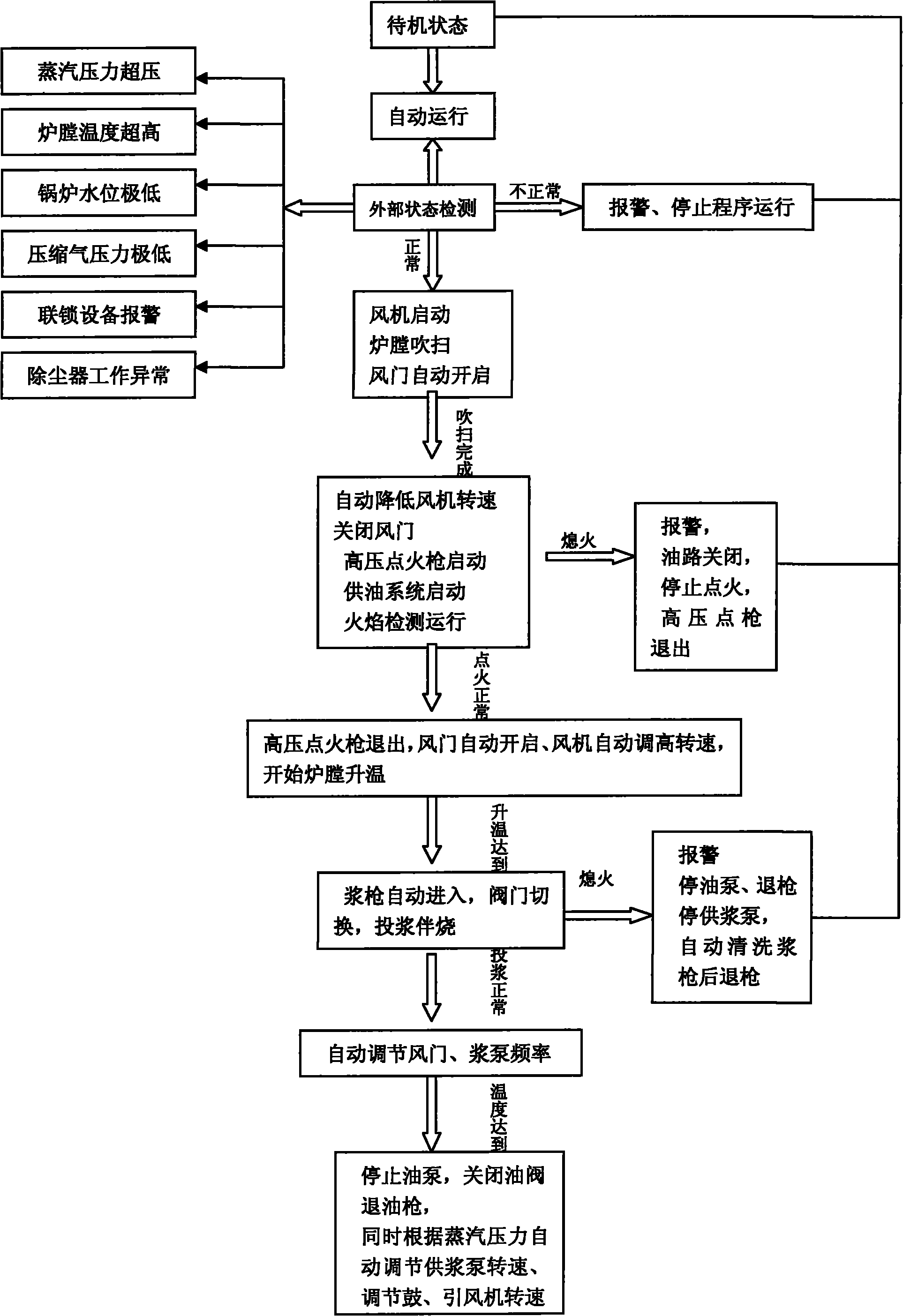

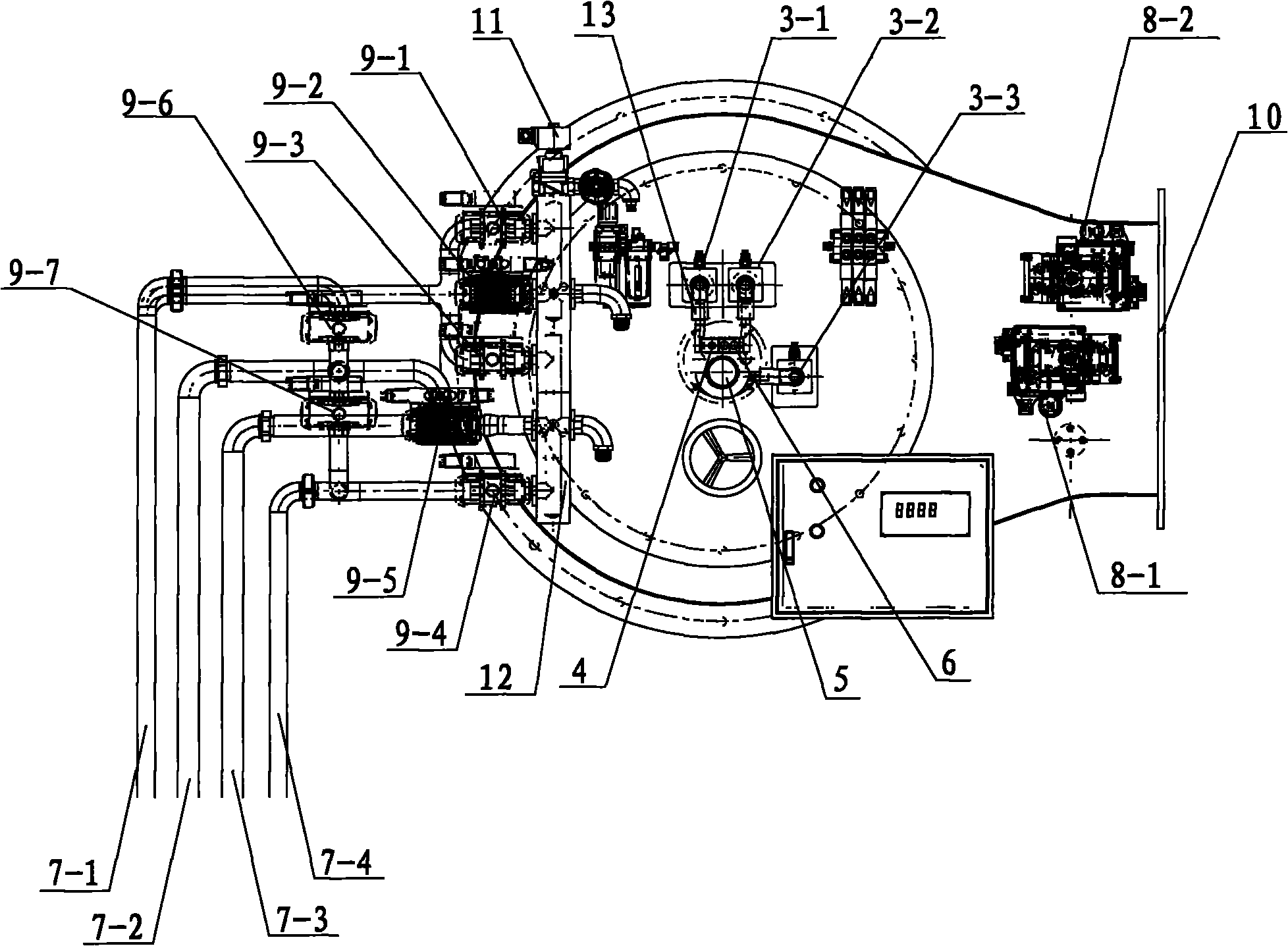

Full automatic water coal slurry burner and control method by adopting same

InactiveCN101936526ARealize automatic controlCompact and reasonable structureBurnersCombustion regulationCombustorAutomatic control

The invention relates to an automatic control device and an automatic control method for a water coal slurry burner. The full automatic water coal slurry burner comprises a shell; the shell is hollow to form an inner chamber of the shell; a spray gun executing component is arranged in the inner chamber of the shell; an outer panel of the shell is provided with an air cylinder which is rigidly connected with the spray gun executing component through a claw; the shell is provided with a fixing module of which one end is connected with a pneumatic ball valve and the other end is connected with the spray gun executing component through a stainless steel flexible hose; the other end of the pneumatic ball valve is connected with a feed line component; an end face of an air inlet of the shell is provided with a positioner which is connected with a shaft of a wind deflector at the air inlet; and the fixing module is fixedly provided with a solenoid valve which is electronically connected with the air cylinder and controls the action of the air cylinder. The full automatic water coal slurry burner has the advantages of high degree of automation, great improvement of working efficiency, reduction of cost and reduction of labor intensity.

Owner:青岛威特水煤浆技术开发有限公司

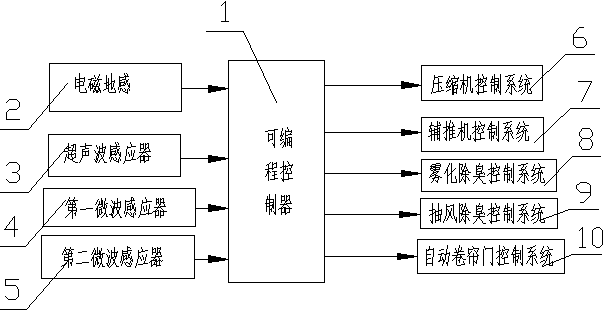

Control system with auxiliary pushing fixed type garbage compression equipment

InactiveCN104340571ARealize full automatic controlImprove work efficiencyRefuse transferringTotal factory controlUltrasonic sensorAutomatic control

A control system with auxiliary pushing fixed type garbage compression equipment belongs to the field of electrical control and comprises a programmable logic controller, wherein the input end of the programmable logic controller is connected with an electromagnetic sensor installed in front of an automatic rolling door in a discharge room, an ultrasonic sensor installed in the discharge room, a first microwave sensor installed in a compressor and a second microwave sensor installed in an auxiliary pushing machine, and the output end of the programmable logic controller is connected with a compressor control system, an auxiliary pushing machine control system, an atomization deodorization control system, a ventilation deodorization control system and an automatic rolling door control system. The control system with the auxiliary pushing fixed type garbage compression equipment achieves whole-process automatic control through the programmable logic controller without manual control, thereby improving operation efficiency and lowering cost.

Owner:扬州市金威机械有限公司

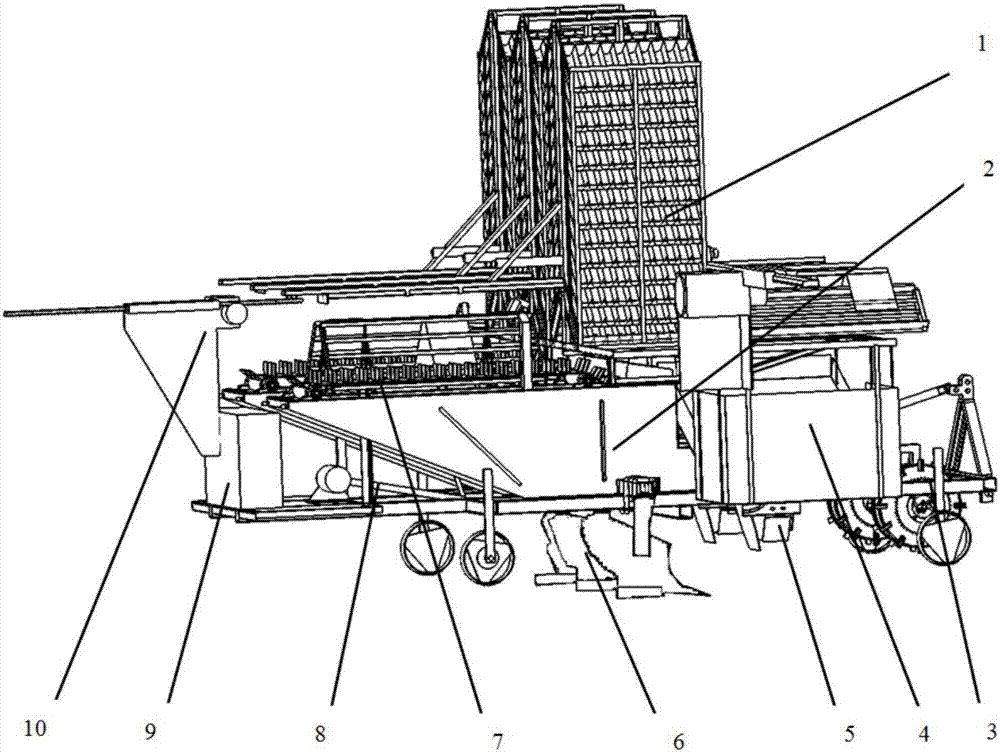

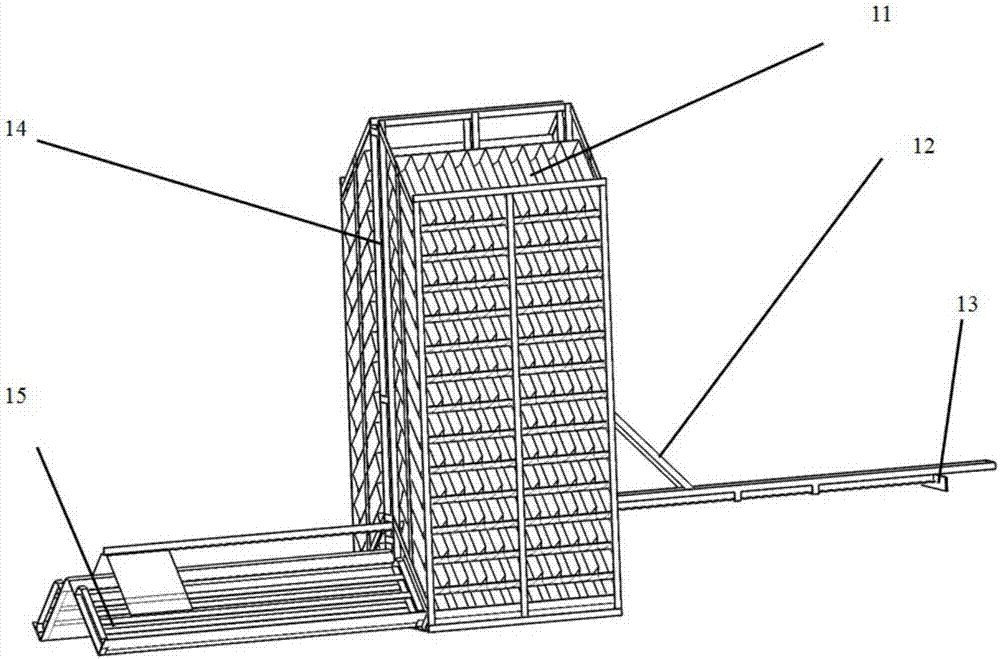

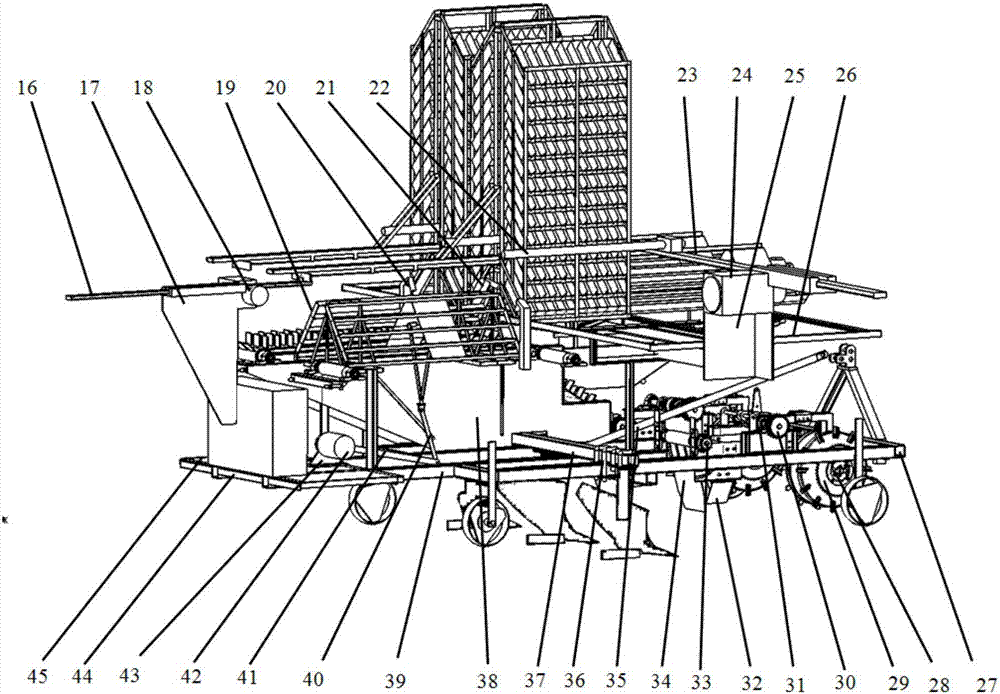

Fully-automatic transplanting machine

The invention relates to a fully-automatic transplanting machine. The fully-automatic transplanting machine is composed of an independent rice-seedling tray frame, a frame, a transmission system, a storage device, a seedling uprighting plate, a ridging mechanism, a conveyor belt, an overturning mechanism, a power and control system and a sensor and execution mechanism. According to the invention, a motor is adopted to control the overturning form of a rice-seedling tray, and two rows of rice seedlings are automatically transplanted at the same time; a plurality of rice-seedling trays are placed in the independent rice-seedling tray frame and can be independently replaced; the transmission belt transmits the rice seedlings to a seedling uprighting mechanism, and the rice-seedling trays exit and enter a storage box at the same time; a tractor is utilized to pull and input powder, and the functions of seedling planting and ridging are obtained at the same time, so automatic control in the whole process is realized; the uniformity of seedling planting distances is guaranteed when the speed of pulling changes; and the fully-automatic transplanting machine provided by the invention has the advantages of unique structure, simple constitution, convenient production, assembly and maintenance, light weight, reliable work, convenient operation, large seedling loading capacity and high efficiency, can be used for transplanting of a plurality of crops, can correspondingly adjust a size according to different row distances, can meet popularization and application of an industrialized carrier-free seedling-raising technology, and promotes intensive and large-scale production.

Owner:HUBEI UNIV OF TECH

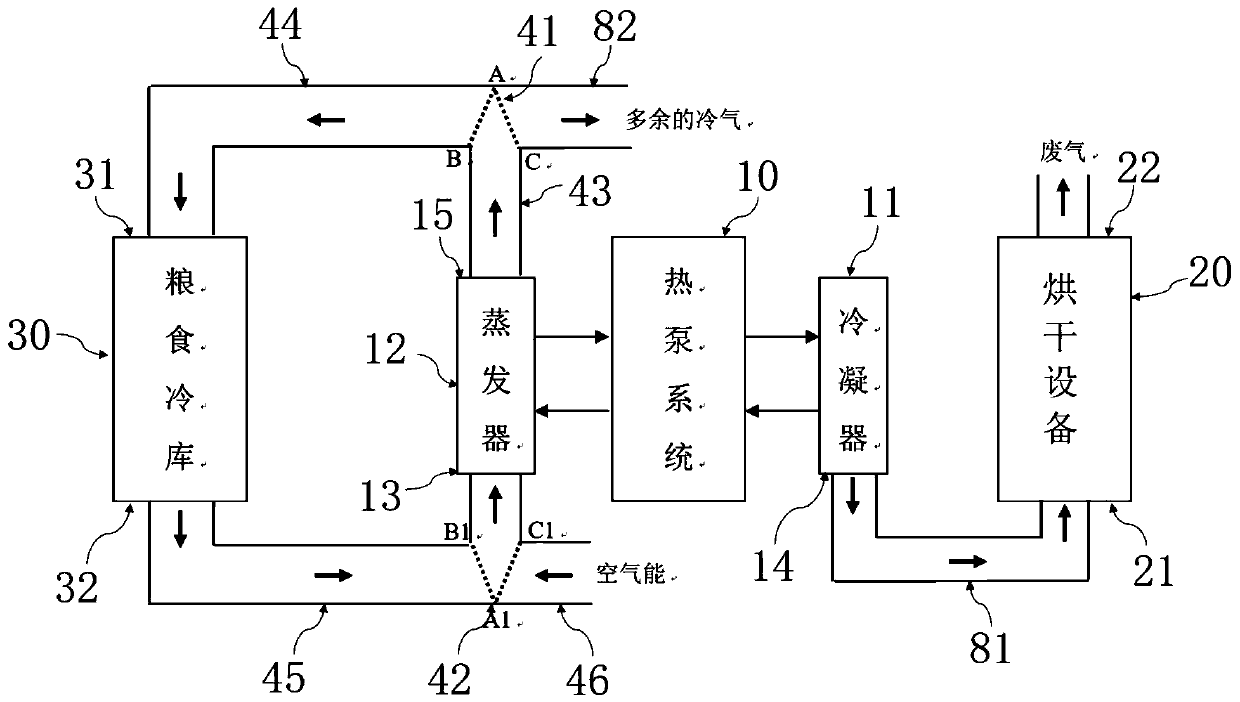

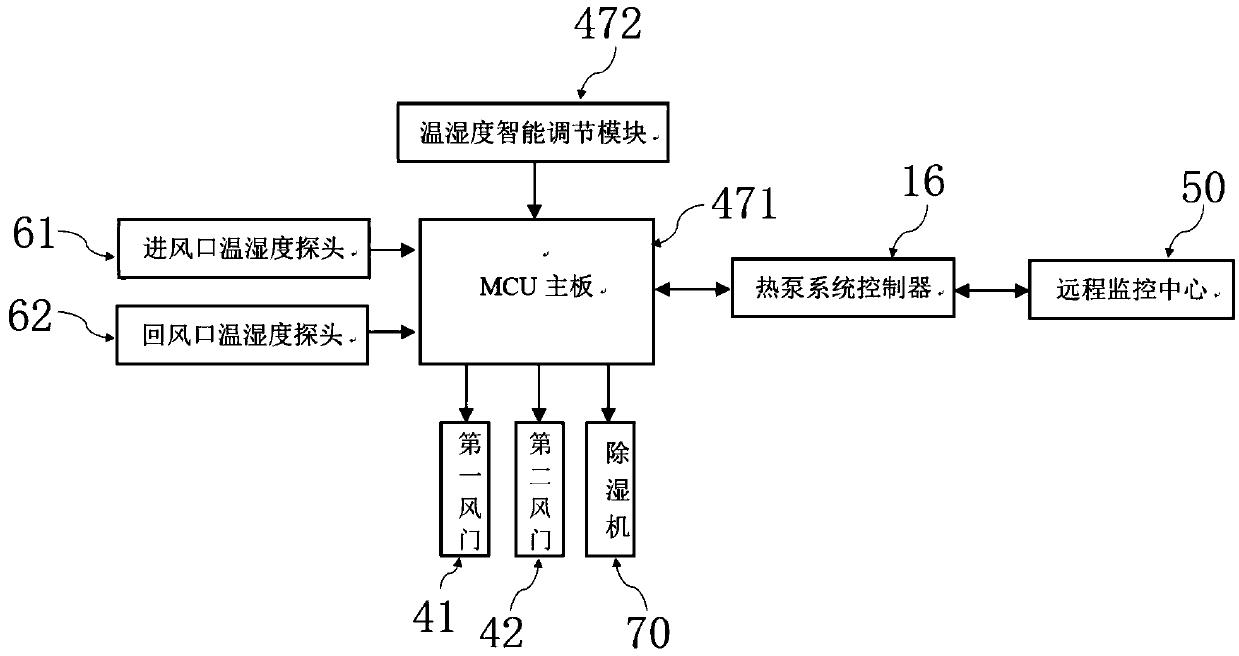

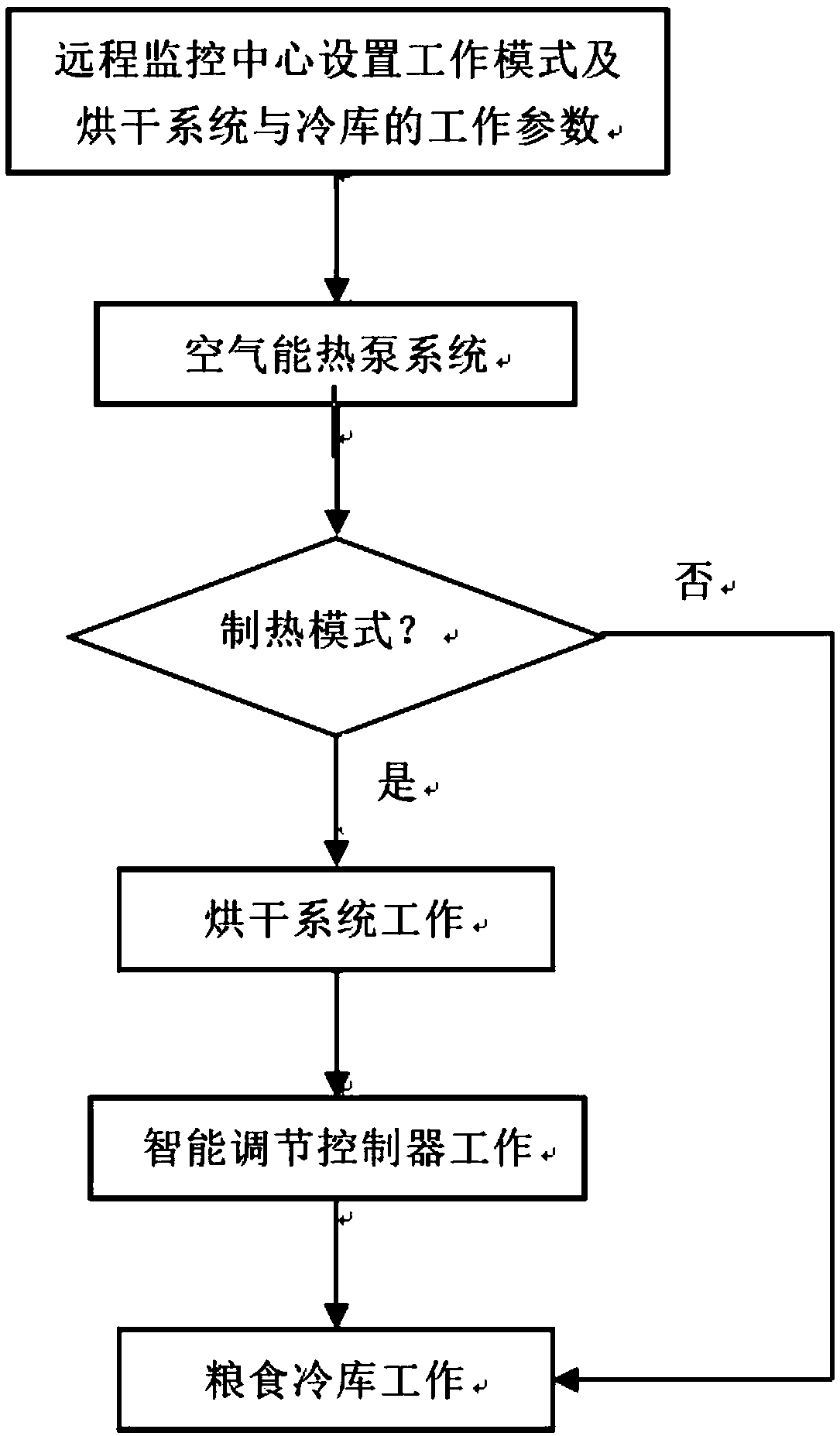

Air energy grain drying and refrigeration energy-saving integrated device and intelligent controlling method thereof

PendingCN109682201ATo achieve the effect of one machine with multiple functionsRealize full automatic controlHeat pumpsHeat recovery systemsCold airEngineering

The invention discloses an air energy grain drying and refrigeration energy-saving integrated device. The air energy grain drying and refrigeration energy-saving integrated device comprises a remote monitoring center, a heat pump system, drying equipment, a cold storage and cold air recycling equipment, wherein the cold air recycling equipment comprises a first air door, a second air door, a coldair output pipe, a cold storage air feeding pipe, a cold storage air returning pipe and an air input pipe; a cold air output hole of the heat pump system is separately connected with the cold storageair feeding pipe and cold air output pipe through the first air door; the cold storage air feeding pipe is connected between the first air door and a cold storage air inlet; the first air door has a first communication state and a second communication state; an air inlet of the heat pump system is separately connected with the air input pipe and the cold storage air returning pipe through the second air door; the cold storage air returning pipe is connected between the second air door and the cold storage air returning hole; and the second air door has a third communication state and a fourthcommunication state. The air energy grain drying and refrigeration energy-saving integrated device disclosed by the invention has the advantages that through additional arrangement of the cold air recycling equipment, recycling of cold air can be realized, design of the grain drying and refrigeration integrated device is realized, so that the effect of one machine with multiple purposes can be achieved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

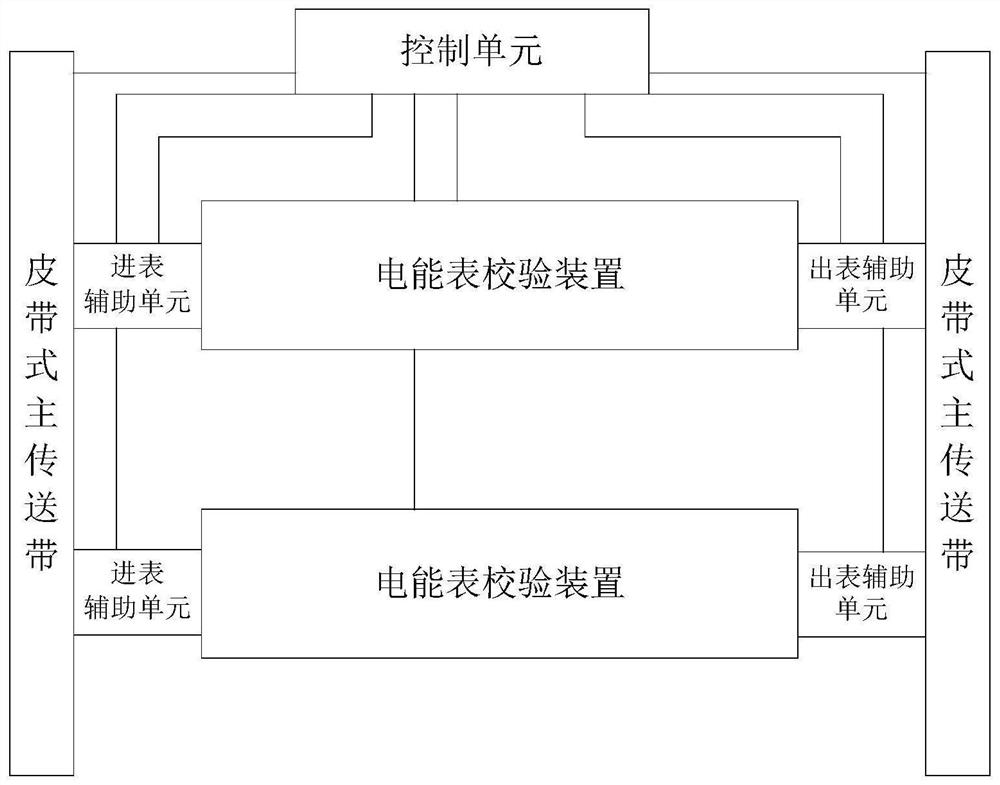

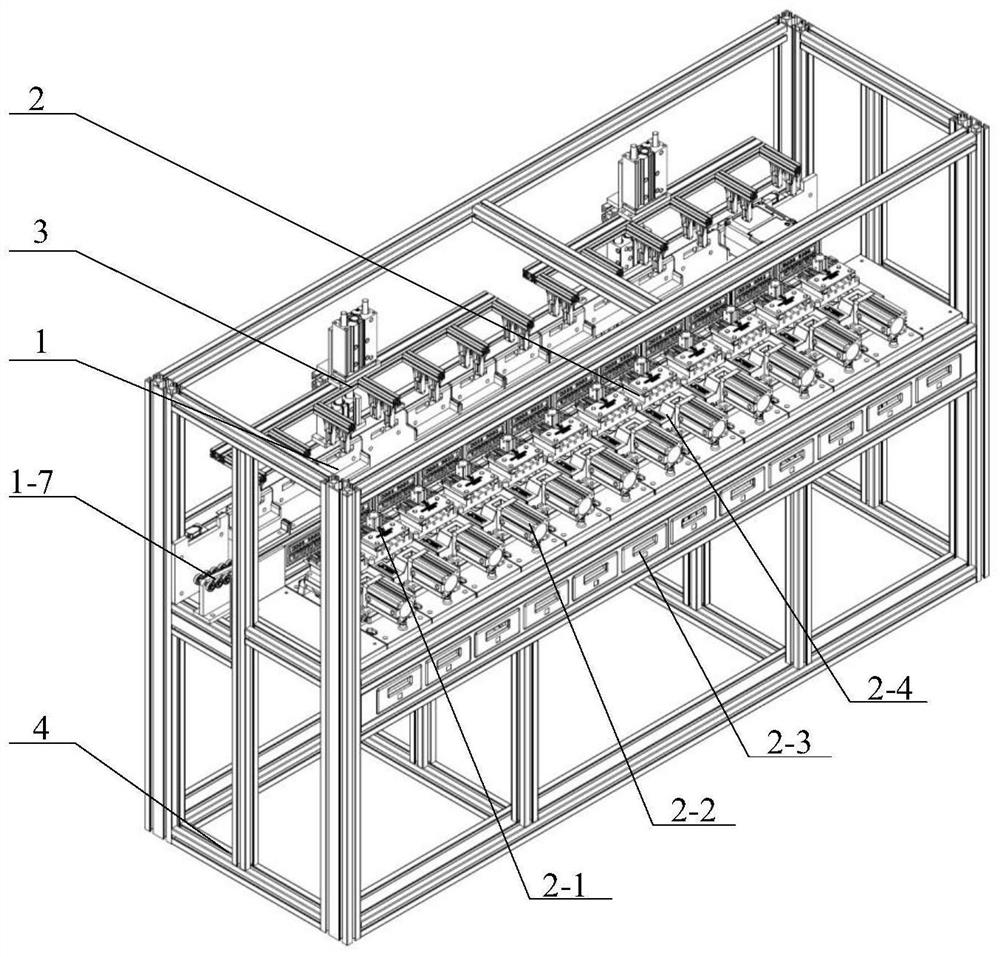

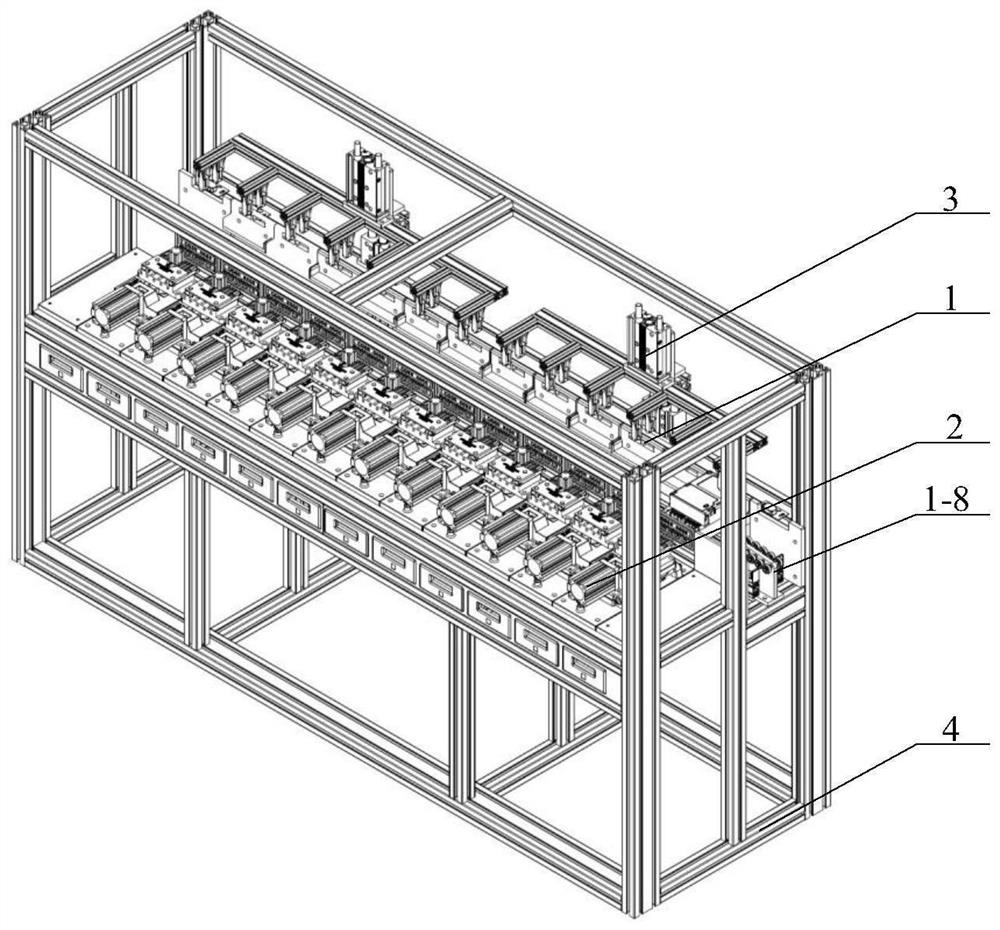

Electric energy meter verification system and method

PendingCN113495246AImprove verification efficiencyReduce error rateElectrical measurementsAutomatic controlElectric energy

The invention discloses an electric energy meter verification system, and belongs to the field of electric power metering device verification. The electric energy meter verification system comprises an electric energy meter transmission mechanism, at least one set of electric energy meter verification devices and a control unit, the electric energy meter transmission mechanism comprises a plurality of belt type main conveyor belts and auxiliary units, and the main conveyor belts are arranged at the two sides of the inlets and the outlets of the electric energy meter verification devices respectively; the auxiliary units are arranged between the main conveyor belts and the electric energy meter verification devices, and are used for sending the electric energy meters into and out of the electric energy meter verification devices; and the electric energy meter transmission mechanism and the electric energy meter verification devices are connected with the control unit. The invention further discloses a verification method adopting the electric energy meter verification system. According to the present invention, the whole-process automatic control of the electric energy meter is achieved, the manual assistance is not needed, and the verification efficiency of the electric energy meter is greatly improved.

Owner:南京电力自动化设备三厂有限公司

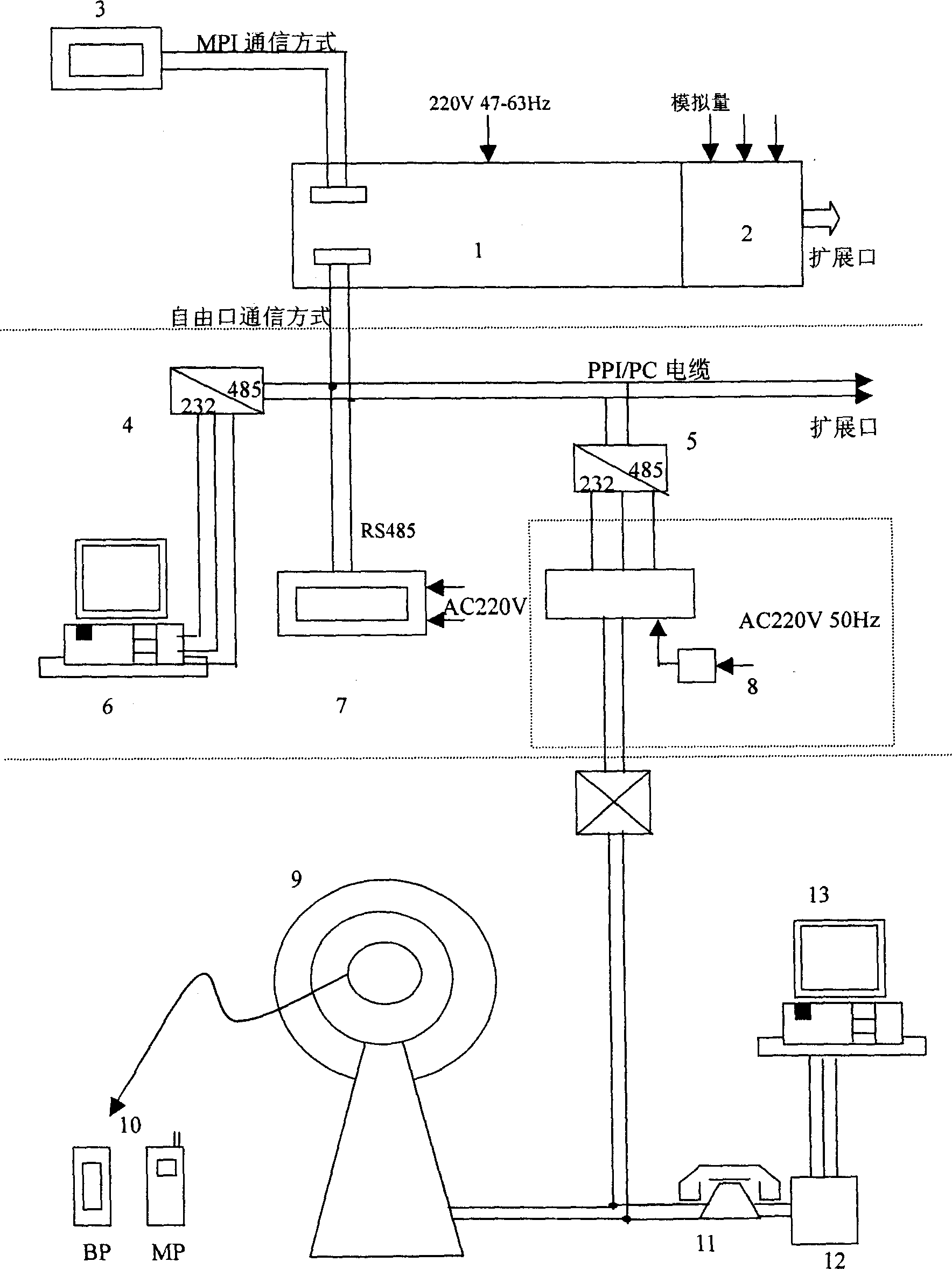

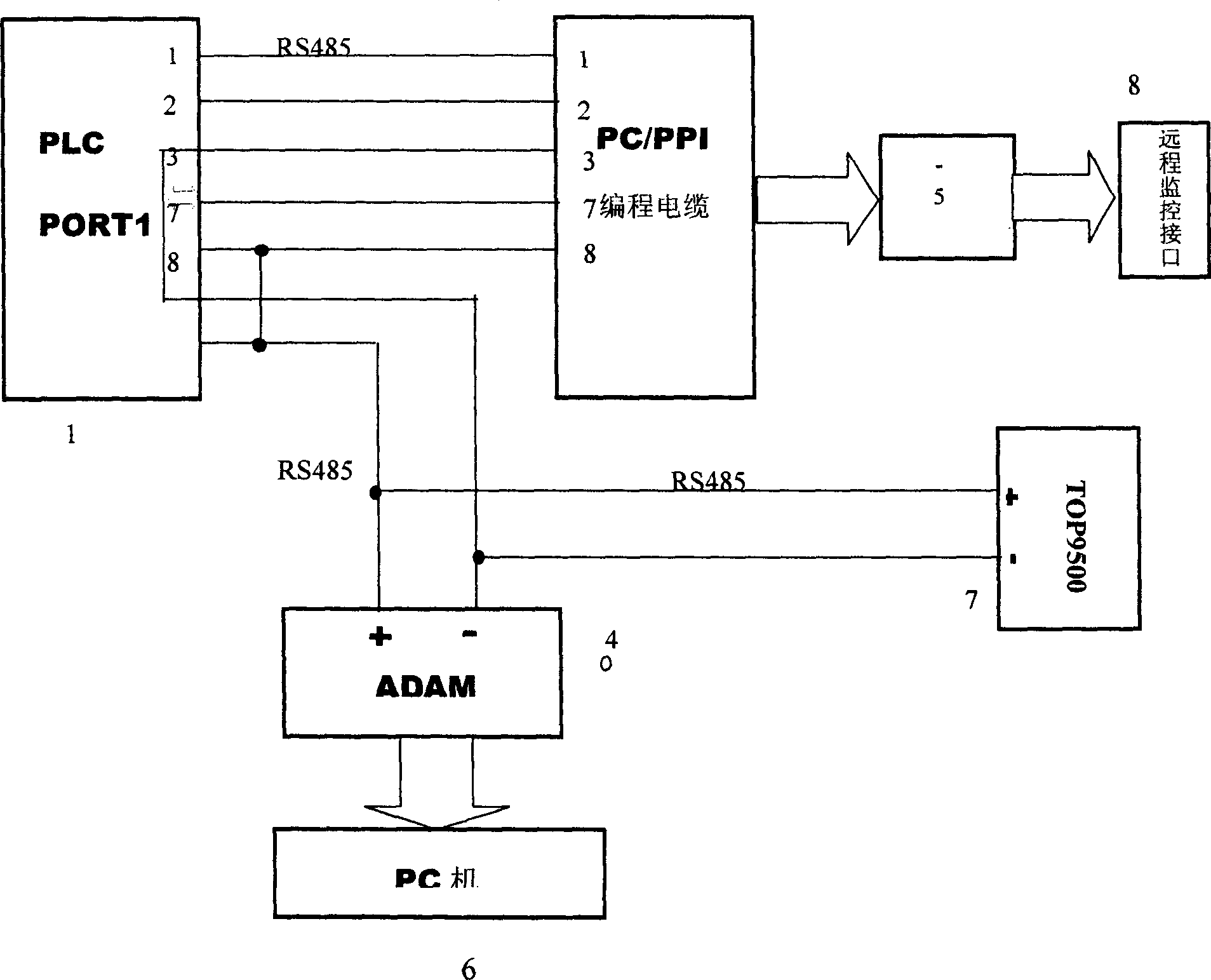

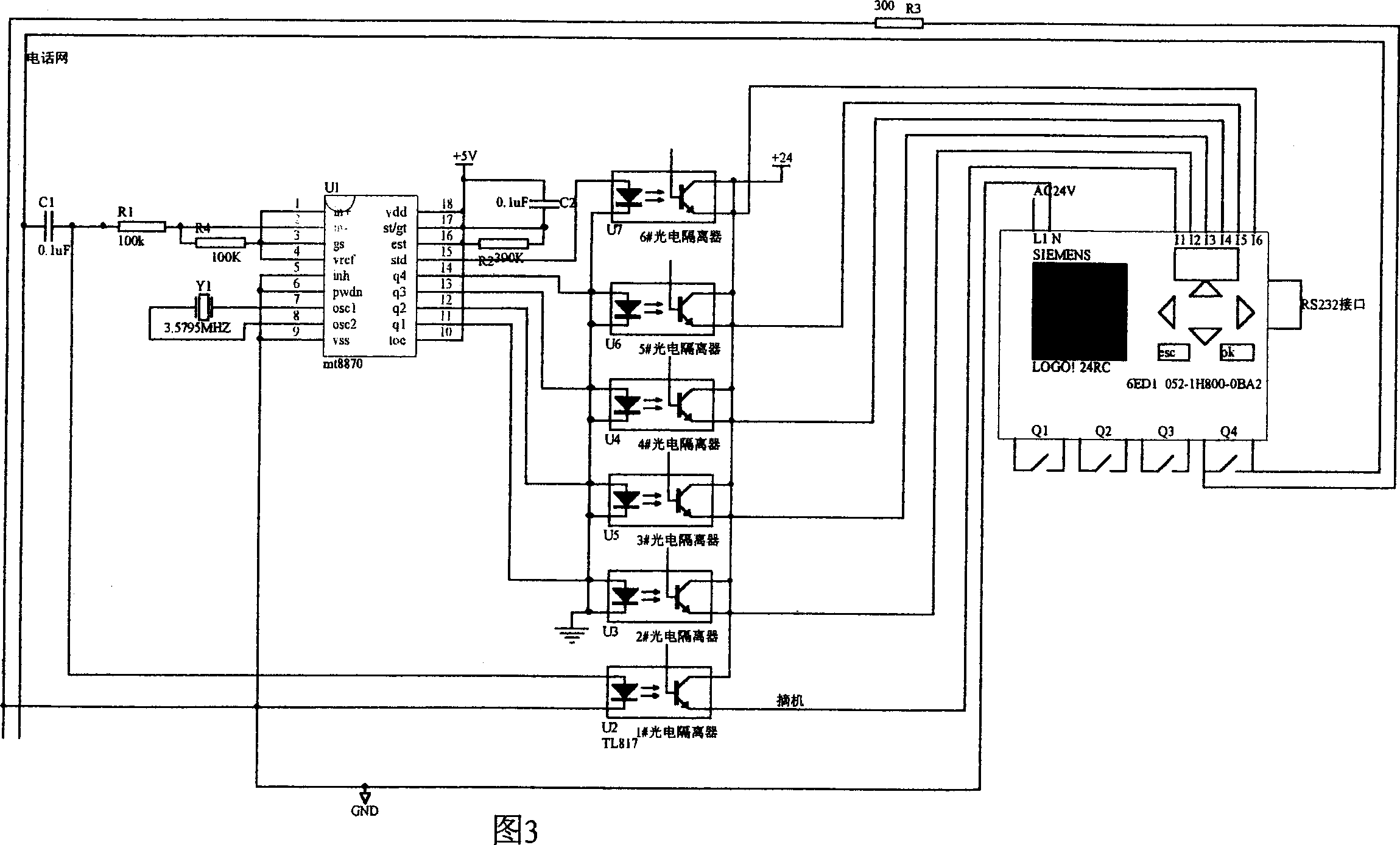

Low-cost unattended automatizing system

InactiveCN1146762CReliable and affordableReliable control functionProgramme controlComputer controlHuman–machine interfaceDistributed structure

An unattended automatic system is composed of centrol control module (CPU S7226), electric sampling module (TOP 9500), man-machine interface module (TP 170A and / or PC), and remote monitor interface, all of which are connected via RS 485 bus. Its advantages include distributed structure, high P / C ratio and high reliability.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com