Sulfuric acid-copper sulfate-copper scrap corrosion test device for austenitic stainless steel

A technique for corrosion testing of austenitic stainless steel, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as inability to continue, uneven heating, water and power failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

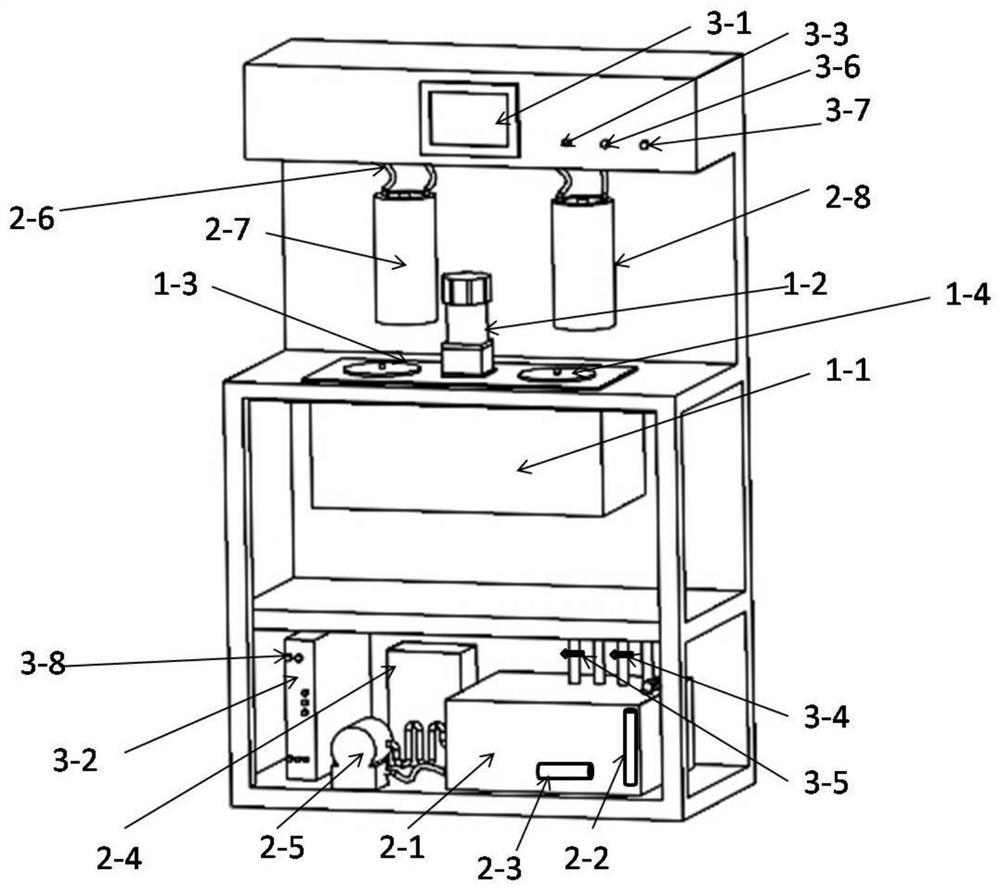

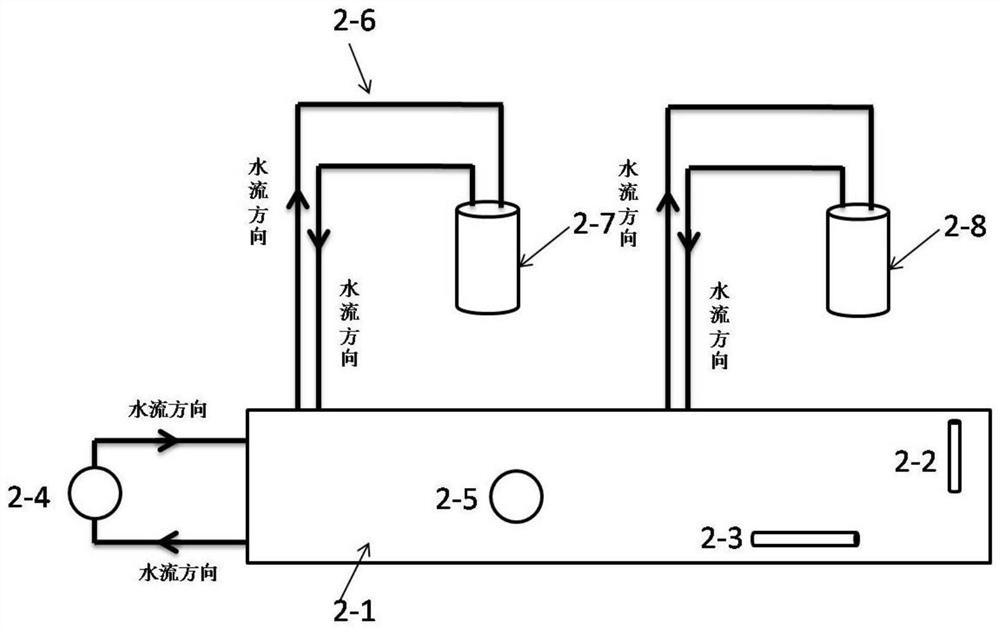

[0024] This embodiment proposes an austenitic stainless steel sulfuric acid-copper sulfate-copper chip corrosion test device, the overall structure is as follows figure 1 As shown, including heating system, circulating cooling system and control system.

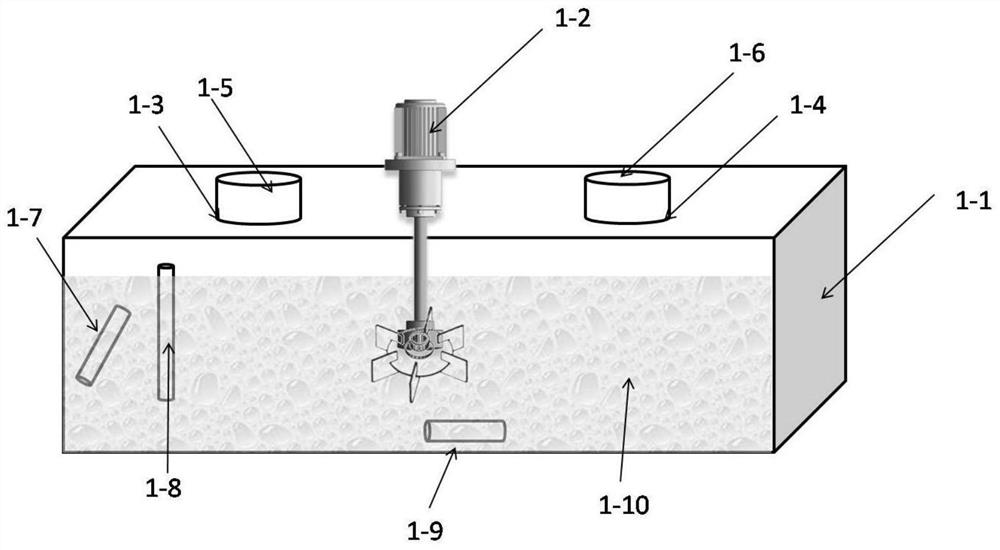

[0025] The heating system is heated by an oil bath, and the actual solution reaction temperature is measured by a high-precision AA grade Pt100 sensor. like figure 2 As shown, the heating system includes an oil bath 1-1, a stirrer 1-2, a first station tank 1-3, a second station tank 1-4, a first reaction vessel 1-5, a second reaction vessel 1- 6. Heating rods 1-7, oil bath liquid level sensors 1-8, oil bath temperature sensors 1-9 and heating medium 1-10. Wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com