Control system with auxiliary pushing fixed type garbage compression equipment

A control system and garbage compression technology, which is applied in the direction of garbage transmission, garbage collection, comprehensive factory control, etc., can solve the problems of low automation level, large manpower, complex manual control of sub-systems, etc., and achieve the effect of improving work efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

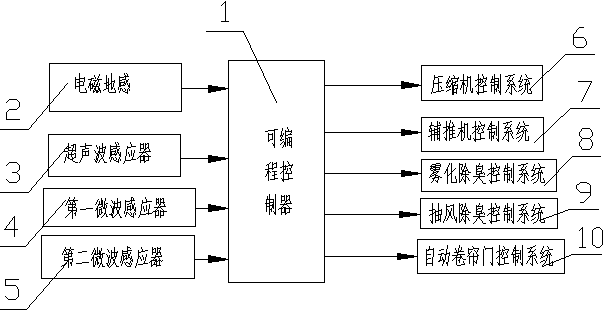

[0011] Such as figure 1 Shown, the present invention comprises programmable controller 1, and the input end of programmable controller 1 is connected with the electromagnetic inductor 2 that is installed in the front of the automatic rolling door door of unloading room, the ultrasonic sensor 3 that is installed in the unloading room, The first microwave inductor 4 installed in the compressor and the second microwave inductor 5 installed in the auxiliary booster.

[0012] The output end of the programmable controller 1 is connected with a compressor control system 6 , an auxiliary thruster control system 7 , an atomization deodorization control system 8 , a draft deodorization control system 9 and an automatic rolling door control system 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com