Automatic overlocking device

A technology of hemming and driving parts, which is applied in the field of automatic hemming devices, can solve the problems of reducing the working efficiency of hemming, and achieve the effects of easy control, improving work efficiency and shortening operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

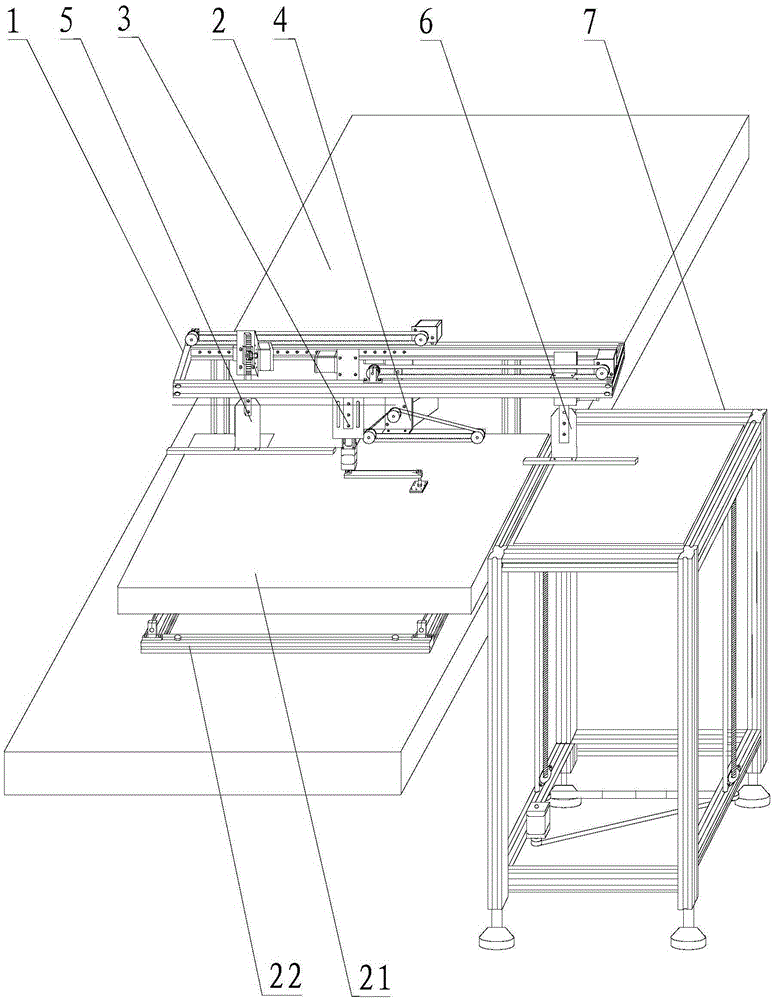

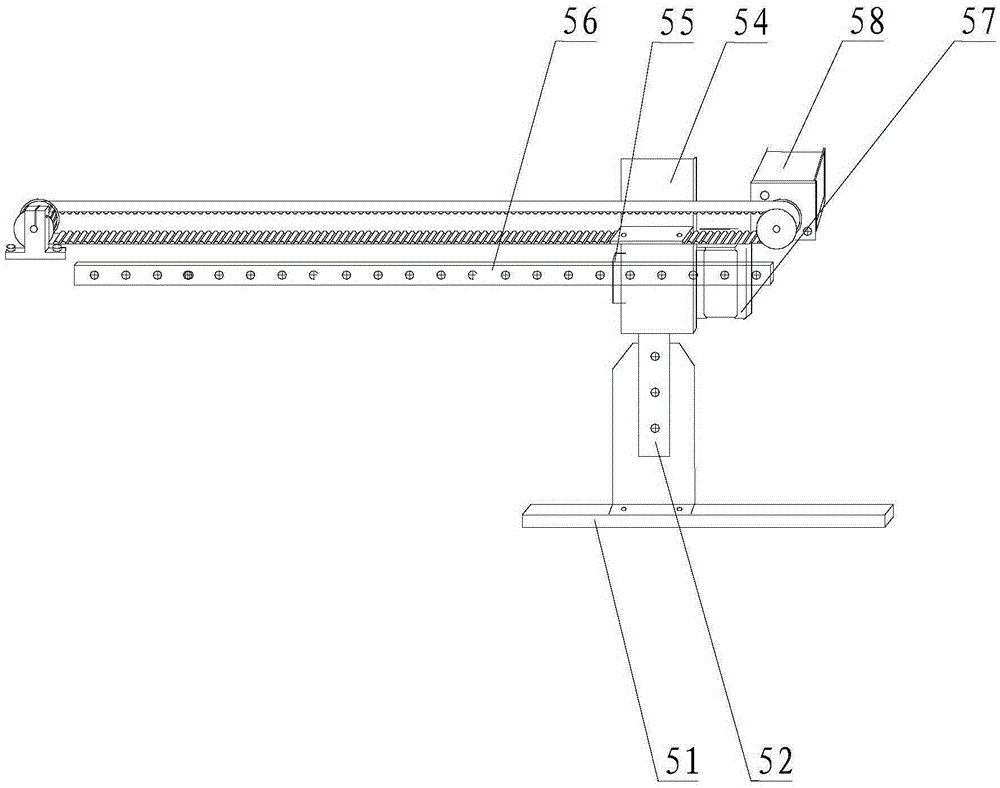

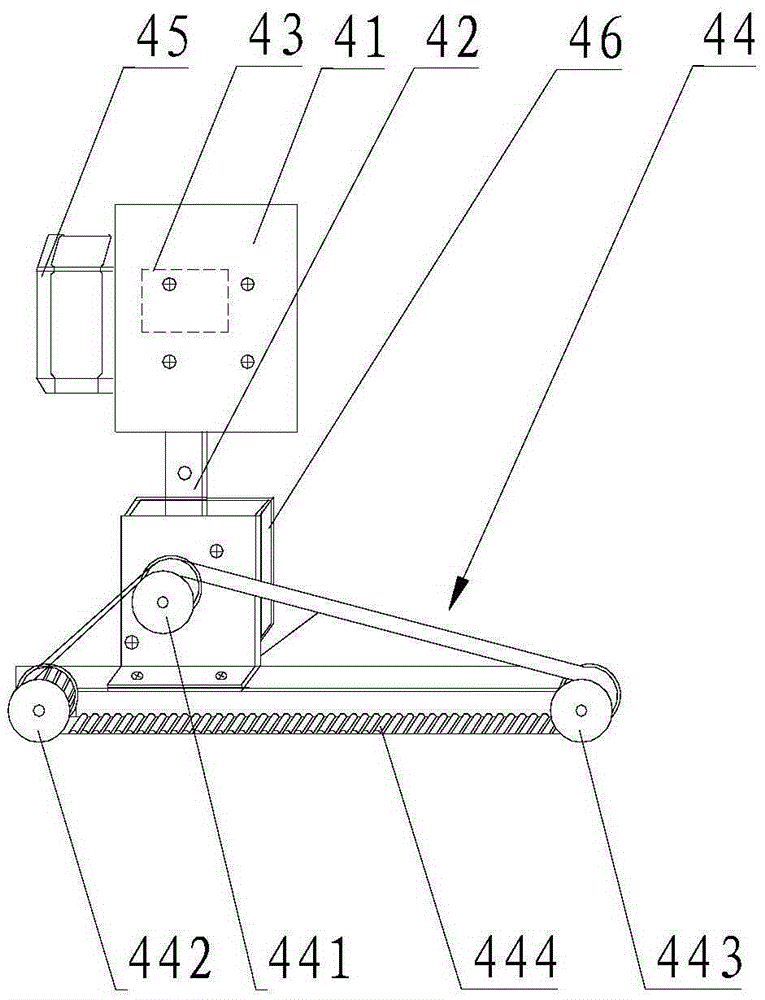

[0043] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 as well as Image 6 , Embodiment 1 of the present invention is:

[0044] The automatic edge locking device of this embodiment includes a frame 1, a workbench 2, a cloth feeding mechanism 3, a cloth pushing mechanism 4, a first mopping mechanism 5, a second mopping mechanism 6, a feeding lifting mechanism 7 and a control system. The frame 1 is arranged on the workbench 2 and is positioned above the workbench 2. The cloth feeding mechanism 3, the cloth pushing mechanism 4, the first mopping mechanism 5 and the second mopping mechanism 6 are respectively arranged on the frame 1 and facing the workbench. 2 directions can be moved, the first mopping mechanism 5, the cloth feeding mechanism 3, the cloth pushing mechanism 4 and the second mopping mechanism 6 are respectively arranged along the length direction of the frame 1 in sequence, and the first mopping mechanism 5 and the second mopping mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com