Automatic argon blowing method and system of steel ladles

A ladle and automatic technology, applied in the field of steelmaking, to reduce labor intensity, save temperature measurement materials, and improve the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

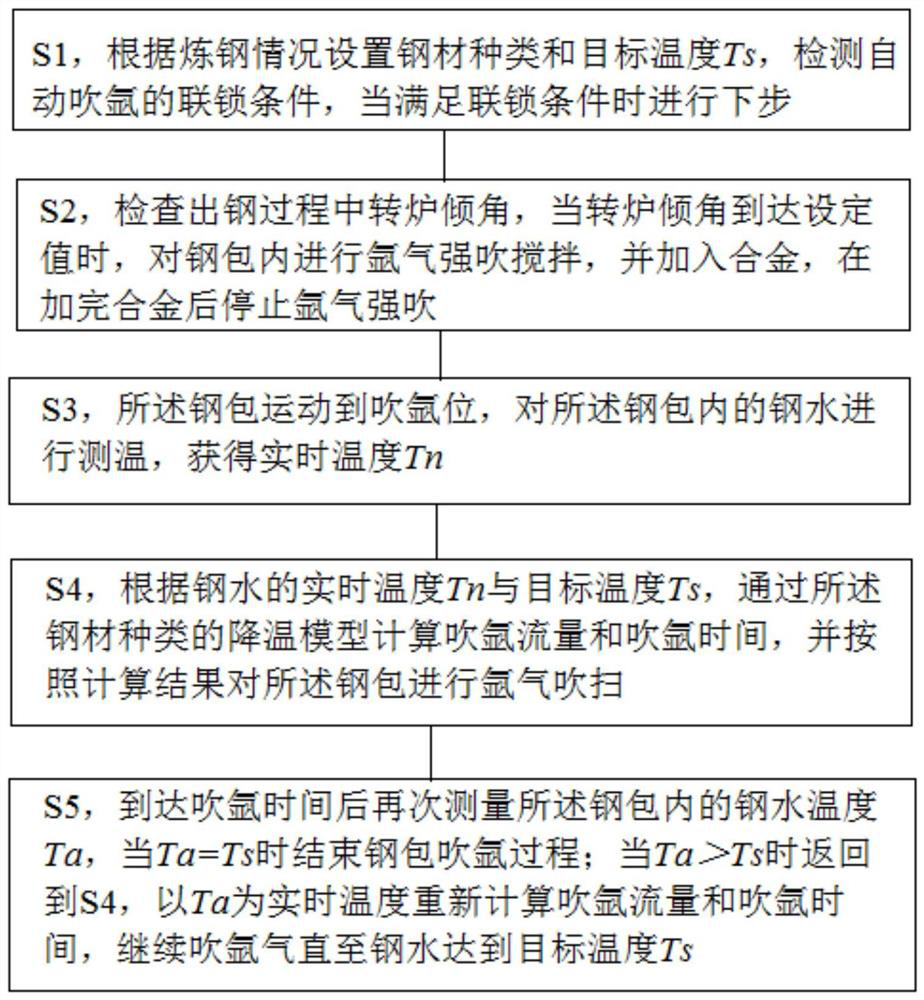

[0039] A method for automatically blowing argon in a ladle, refer to figure 1 , including the following steps:

[0040] S1, set the steel type and target temperature Ts according to the steelmaking situation, detect the interlocking conditions of automatic argon blowing, and tap the steel when the interlocking conditions are met;

[0041] S2, check the inclination angle of the converter during the tapping process, when the inclination angle of the converter reaches the set value, carry out strong argon blowing and stirring on the ladle, and add the alloy, and stop the strong argon blowing after adding the alloy;

[0042] S3, the ladle is moved to the argon blowing position, and the temperature of the molten steel in the ladle is measured to obtain the real-time temperature Tn;

[0043] S4, according to the real-time temperature Tn and the target temperature Ts of molten steel, calculate the argon blowing flow rate and argon blowing time through the cooling model of the steel ...

Embodiment 2

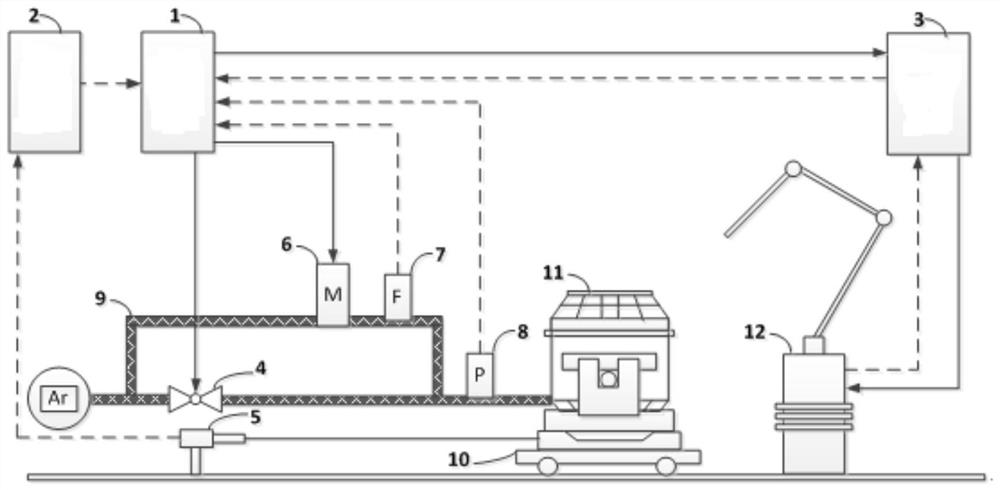

[0056] A system for automatically blowing argon in a ladle, refer to figure 2 , including argon blowing control module 1, blowing control module 2, robot control module 3, temperature measurement and sampling robot 12, valve 4, distance measurement module 5, digital flow valve 6, flow meter 7, pressure gauge 8, argon pipeline 9 , Ladle moving module 10, steel ladle 11.

[0057] Specifically, the argon blowing control module 1 is used to receive the tapping signal, the numerical value of the inclination angle of the converter and the angle of the alloy adding chute in the tapping stage, and when the inclination angle of the converter reaches a set angle, start the The argon pipeline blows and stirs the ladle strongly; when the angle of the alloy adding chute is 0 and the alloy addition is completed, the argon blowing control module closes the argon pipeline. Further, the argon blowing control module 1 is used to receive the molten steel temperature data sent by the robot cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com