Rotor spinning machine full automatic joint control method and device thereof

A technology of rotor spinning machine and control device, applied in spinning machine, comprehensive factory control, comprehensive factory control and other directions, can solve the problems of over-reliance on communication control, low control accuracy, complex overall system structure, etc. System maintainability and convenience of system upgrade, simplifying the control system structure, overcoming the effect of low control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

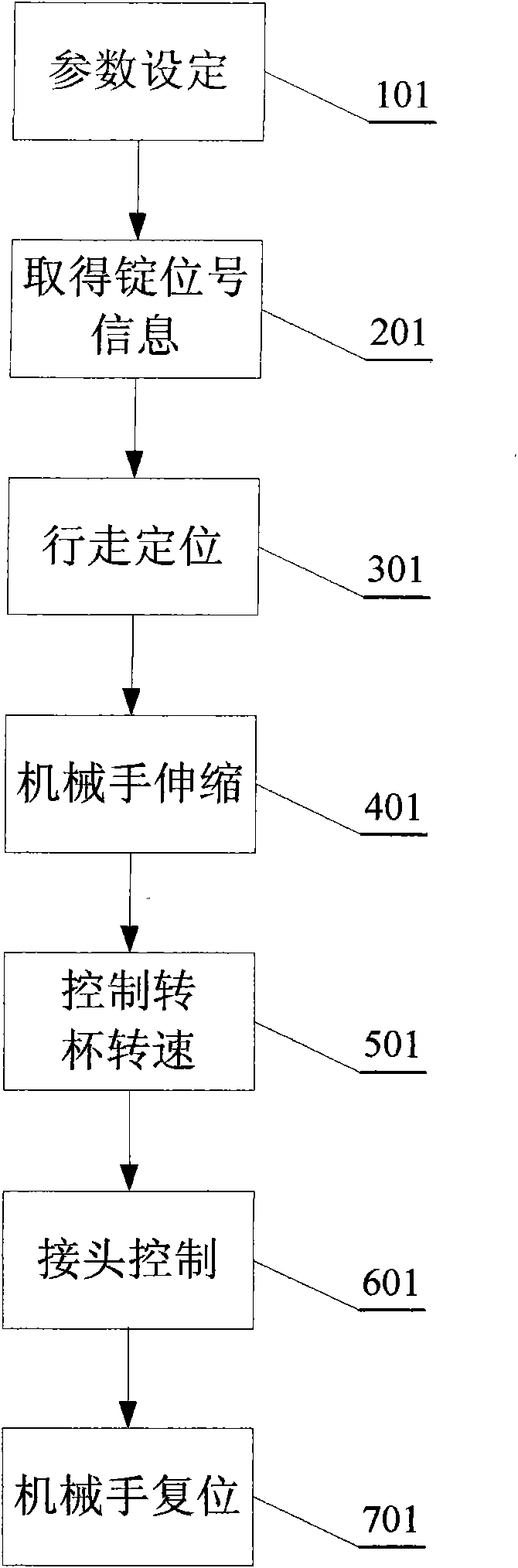

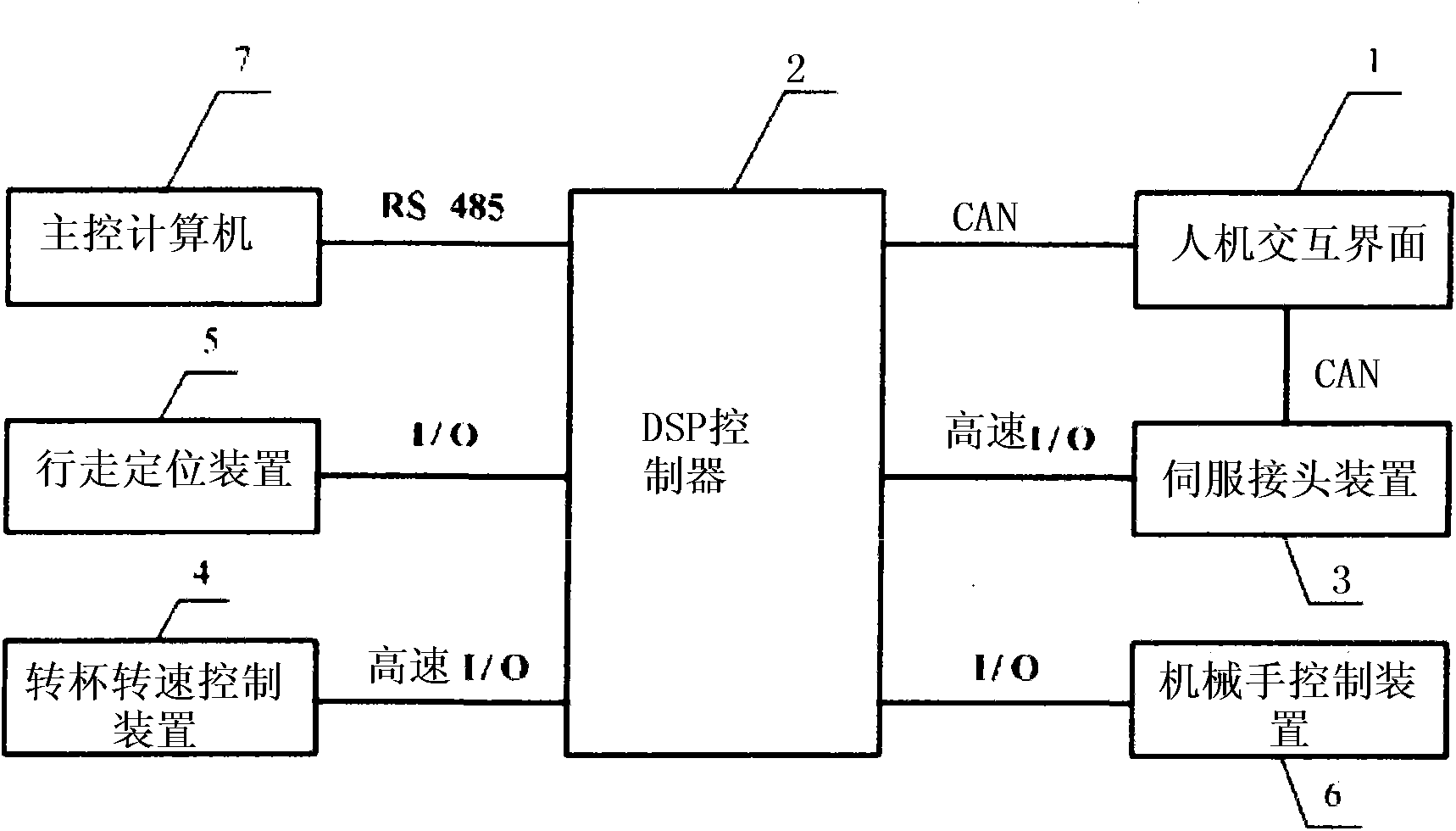

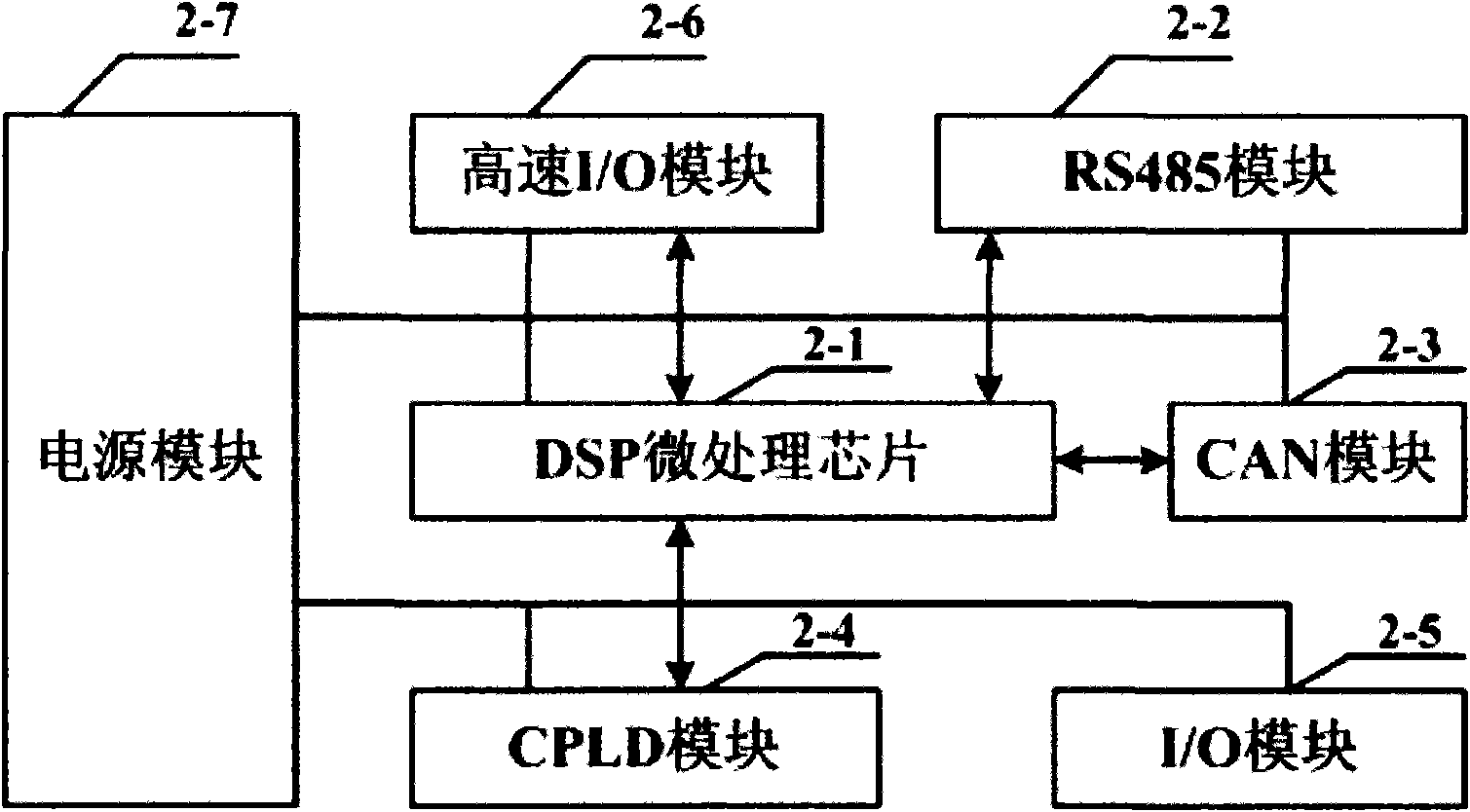

[0057] figure 1 It is a flowchart of the control method of the present invention. In step 101, set process parameters on the man-machine interface, and then transmit them to the DSP controller and the servo joint device respectively through the CAN communication module or the CAN bus module, so as to realize process parameter setting and storage.

[0058] In step 201, the DSP controller is connected with the main control computer through the RS485 communication module or the RS485 interface module, and sends a request to the main control computer to obtain the information of the spinning splicing spindle number, and the main control computer sends the joint The spinning position number information is sent to the DSP controller, so that the DSP controller can obtain the required piecing spinning position number information. Among them, the spindle position number information is mainly composed of information such as the positioning of the spinning spindle number, the splicing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com