Electric automobile wheel type driving control system based on hierarchical control and control method thereof

An electric vehicle, layered control technology, applied in electric vehicles, control drive, electric vehicle charging technology, etc., can solve the problem of single control strategy, no consideration of wheel speed synchronization, etc., to achieve reasonable location layout, easy maintenance, and control methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

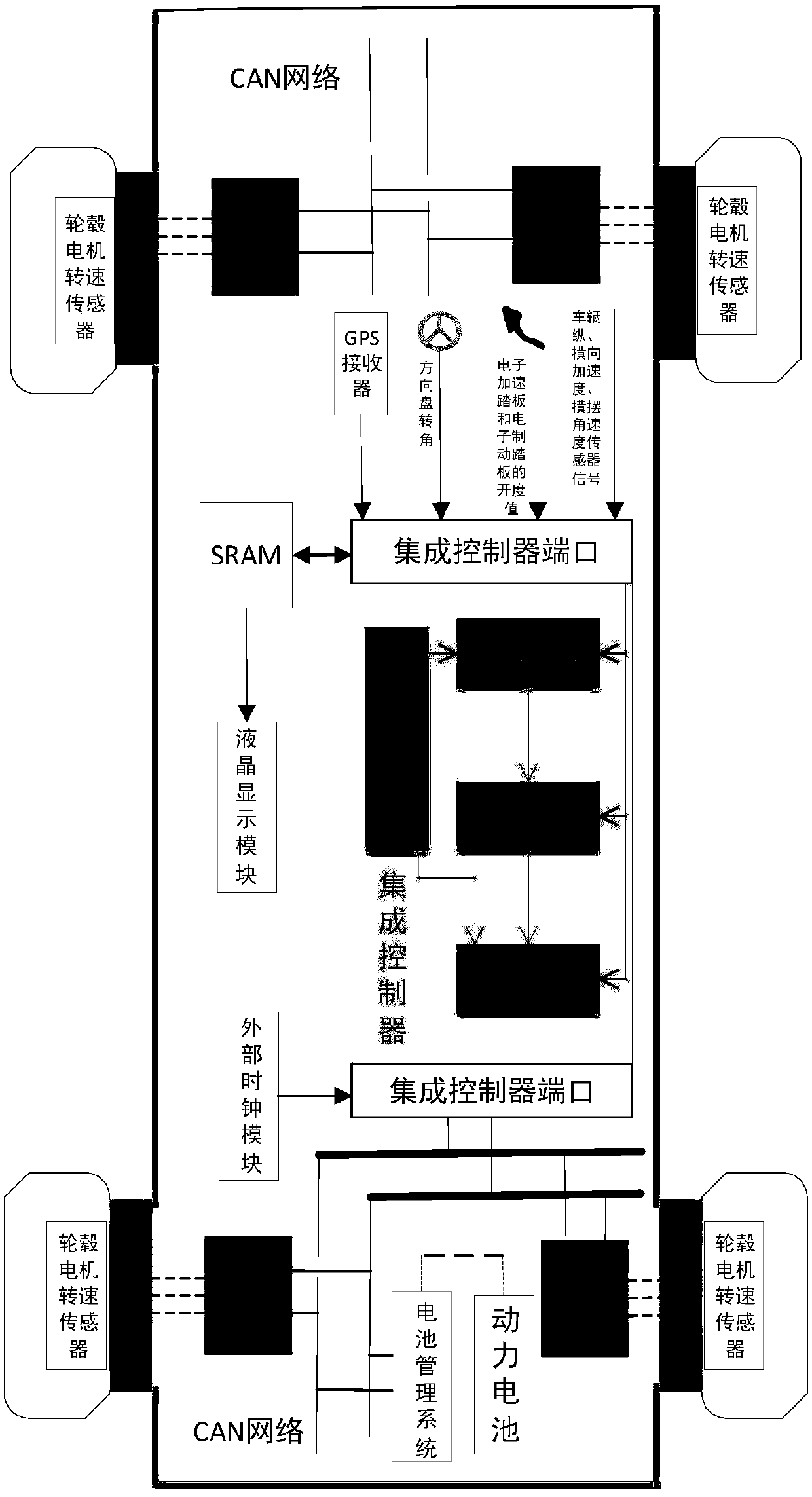

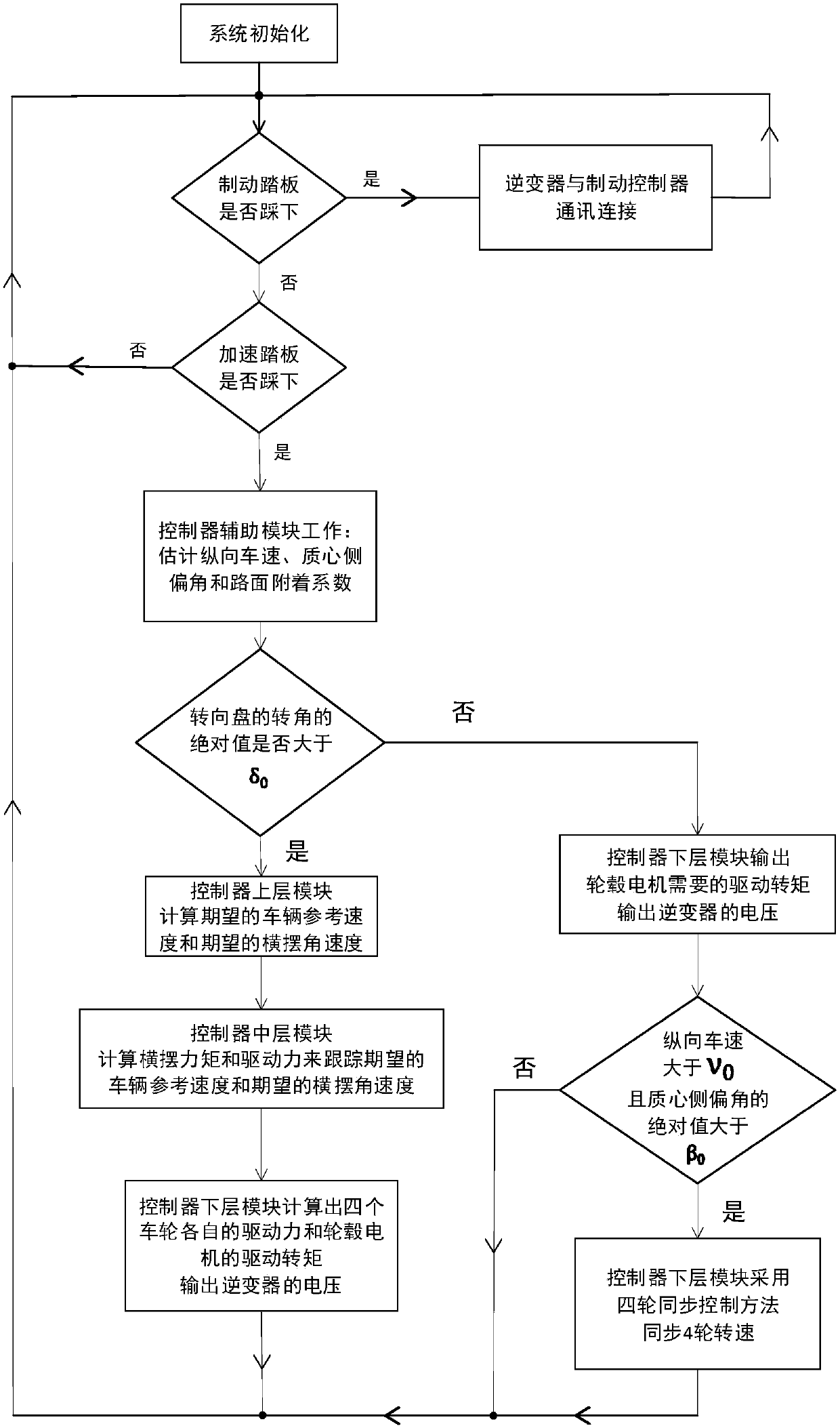

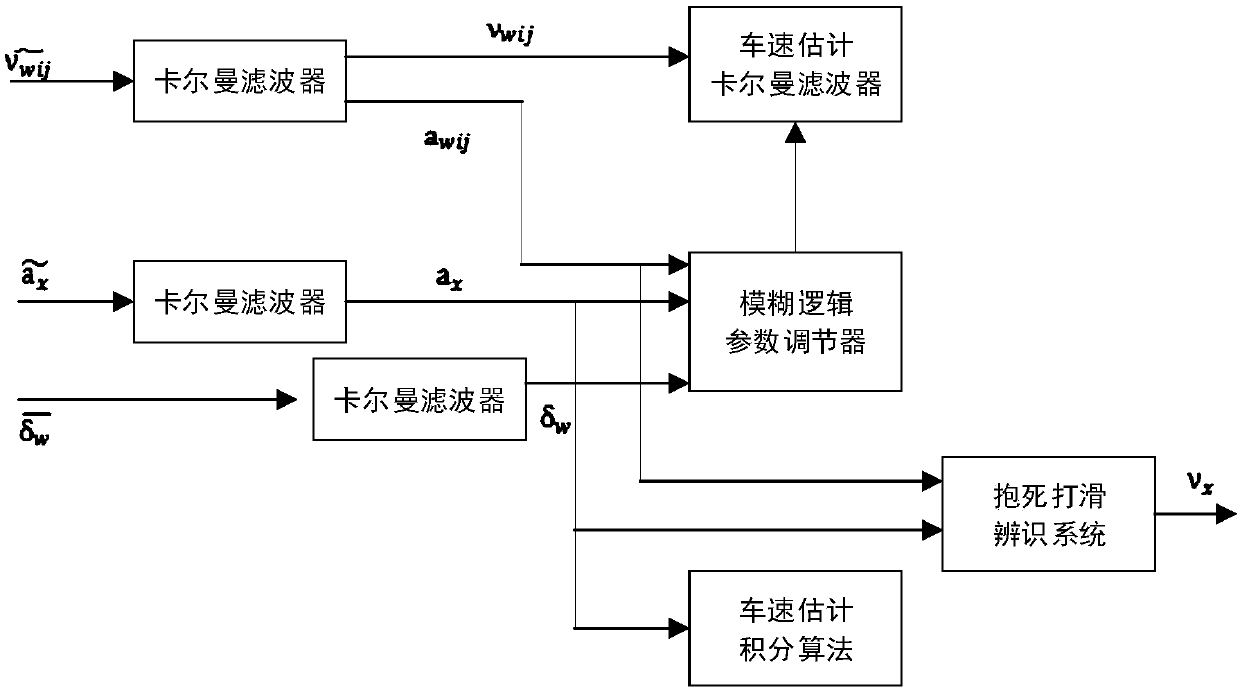

[0033] Such as figure 1It is a schematic diagram of the structure of the electric vehicle wheel drive control system based on layered control, including an integrated controller, an inverter and an in-wheel motor. The integrated controller includes an auxiliary module, an upper module, a middle module and a lower module. The auxiliary module is used to judge the vehicle The state of motion (whether the car is braking, driving, or turning), the output terminals of the auxiliary module are respectively connected to the input terminals of the integrated controller, the upper module, and the lower module, and the output terminal of the upper module is connected to the input terminal of the middle module. The output terminal of the middle module is connected with the input terminal of the lower module, and the integrated controller port is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com