Nodular cast ball and manufacturing method thereof

A production method and technology of casting balls are applied in the field of wear-resistant casting balls to achieve the effects of low production cost and avoiding oil quenching pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Smelting: single smelting in intermediate frequency electric furnace, pig iron, scrap steel and recarburizer are used as raw materials for batching according to the proportion of special balls produced for mines, and scrap steel with the following chemical composition is selected for scrap steel: C0.3~1.0% , Si ≤ 0.4%, Mn ≤ 0.3%, Cr ≤ 0.3%, and the balance is iron; the pig iron has the following chemical compositions: C ≥ 4.0%, Si ≤ 2.0%, S ≤ 0.1%, P ≤ 0.1 %, the balance is iron; after starting the electric furnace, first add scrap steel and recarburizer into the electric furnace, then add pig iron, the melting temperature is 1530 ° C, so that the percentage content of the chemical components of molten iron meets: C3.8% ~ 4.0% , Si0.9%~1.1%, Mn0.5%~0.8%, Mo0.1%~0.2%, Cu0.1%~0.2%, S≤0.05%, P≤0.05%, Cr≤0.3%;

[0027] (2) Spheroidizing treatment: Place the spheroidizing agent on the bottom of the ladle by using the flushing method. The spheroidizing agent is 75 barium ...

Embodiment 2

[0033] (1) Smelting: single smelting in intermediate frequency electric furnace, pig iron, scrap steel and recarburizer are used as raw materials for batching according to the proportion of special balls produced for mines, and scrap steel with the following chemical composition is selected for scrap steel: C0.3~1.0% , Si ≤ 0.4%, Mn ≤ 0.3%, Cr ≤ 0.3%, and the balance is iron; the pig iron has the following chemical compositions: C ≥ 4.0%, Si ≤ 2.0%, S ≤ 0.1%, P ≤ 0.1 %, the balance is iron; after starting the electric furnace, first add scrap steel and recarburizer into the electric furnace, then add pig iron, the melting temperature is 1550°C, so that the chemical composition percentage of molten iron meets: C3.8% ~ 4.0% , Si0.9%~1.1%, Mn0.5%~0.8%, Mo0.1%~0.2%, Cu0.1%~0.2%, S≤0.05%, P≤0.05%, Cr≤0.3%;

[0034] (2) Spheroidizing treatment: Place the spheroidizing agent on the bottom of the ladle by using the flushing method. The spheroidizing agent is 75 barium ferrosilicon wit...

Embodiment 3

[0040] (1) Smelting: single smelting in intermediate frequency electric furnace, pig iron, scrap steel and recarburizer are used as raw materials for batching according to the proportion of special balls produced for mines, and scrap steel with the following chemical composition is selected for scrap steel: C0.3~1.0% , Si ≤ 0.4%, Mn ≤ 0.3%, Cr ≤ 0.3%, and the balance is iron; the pig iron is selected from pig iron with the following chemical compositions: C ≥ 4.0%, Si ≤ 2.0%, S ≤ 0.1%, P ≤ 0.1 %, the balance is iron; after starting the electric furnace, first add scrap steel and recarburizer into the electric furnace, and then add pig iron. The melting temperature is 1580°C, so that the chemical composition percentage of molten iron satisfies: C3.8%~4.0% , Si0.9%~1.1%, Mn0.5%~0.8%, Mo0.1%~0.2%, Cu0.1%~0.2%, S≤0.05%, P≤0.05%, Cr≤0.3%;

[0041] (2) Spheroidizing treatment: Put the spheroidizing agent on the bottom of the ladle by using the flushing method. The spheroidizing agen...

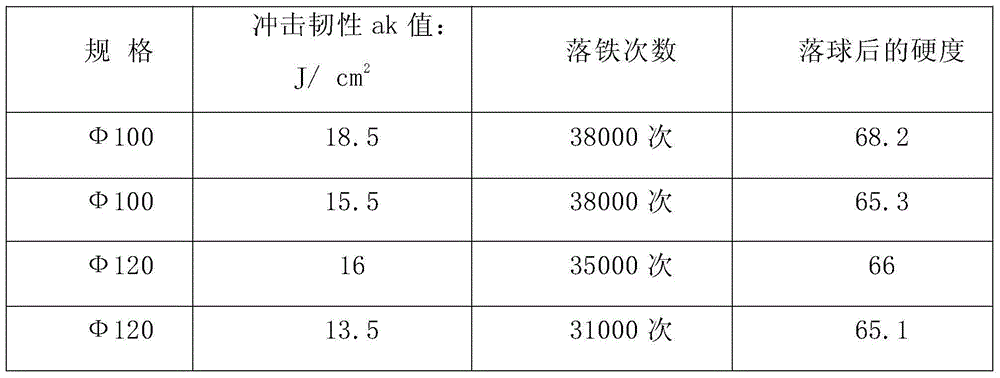

PUM

| Property | Measurement | Unit |

|---|---|---|

| tenacity | aaaaa | aaaaa |

| tenacity | aaaaa | aaaaa |

| tenacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com