Automatic mold oil spraying system for mold frame

A release oil and oil supply system technology, which is applied in the field of building material processing, can solve the problem of quality impact in the pouring, release, peeling and steaming of aerated concrete blocks, different atomization effects of release oil, and spraying Inconsistent thickness and other problems, to ensure the uniformity of spraying, reduce the difference in spraying distance, and achieve the effect of uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

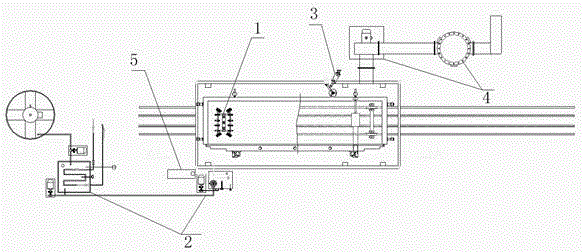

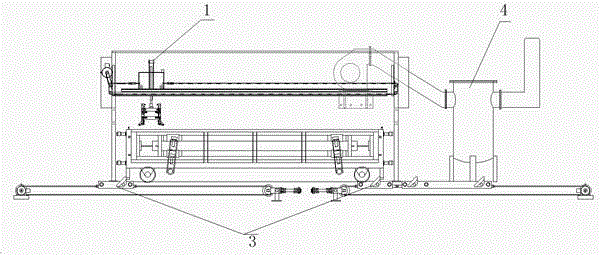

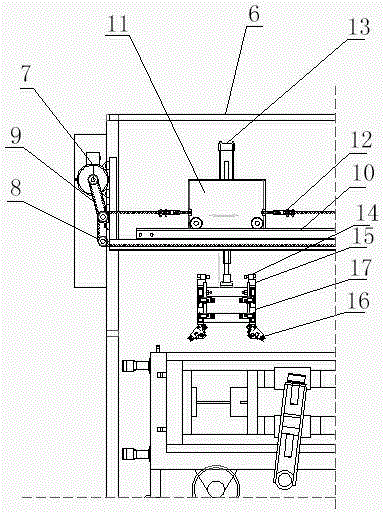

[0033] Below in conjunction with preferred embodiments, the mold frame release oil spraying system proposed according to the present invention, its specific implementation, structure, features and methods are described in detail below.

[0034] Such as Figure 1-3 As shown, the mold frame release oil spraying system of the present invention includes an oil injection system 1, an oil supply system 2, a mold frame positioning system 3, an exhaust purification system 4 and an electric control system 5, wherein: the oil injection system 1 is constructed by The traveling mechanism and the spraying mechanism on the main frame 6 of the fuel injection system are composed; the traveling mechanism includes a horizontal movement drive motor 7, a synchronous wheel 8 connected with the drive motor 7, a synchronous belt 9, a track 10 and a horizontal movement trolley 11, and the horizontal movement The trolley 11 is connected to the timing belt 9 through a timing belt connector 12; the spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com