Automatic control method for feeding, oxygen lance position and oxygen flow in converter steelmaking process

An oxygen flow, converter steelmaking technology, applied in the direction of manufacturing converters, etc., to improve the stability of molten steel quality, reduce the consumption of raw and auxiliary materials, and reduce the cost of converter steelmaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

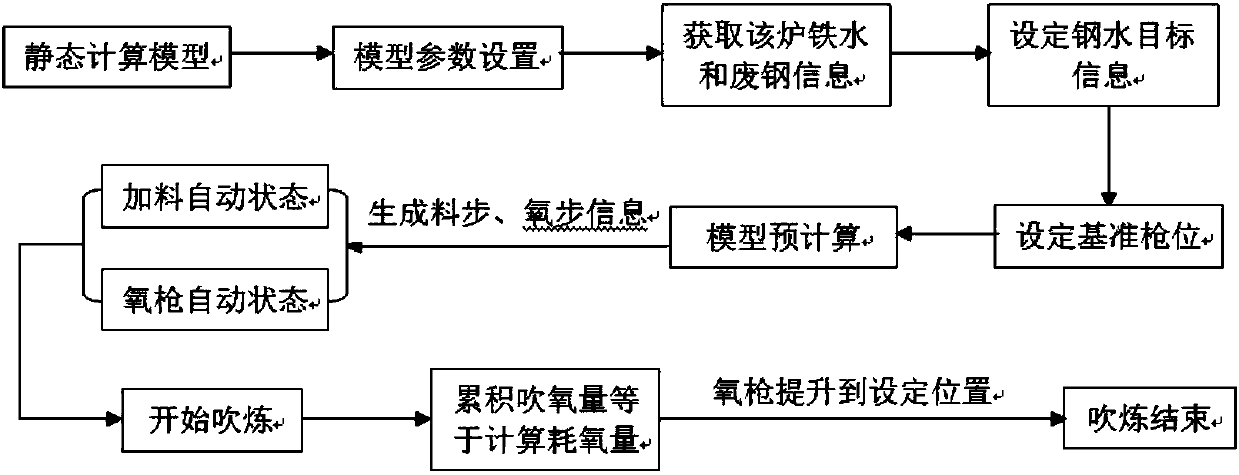

[0042] Embodiment one of the present invention, referring to the attached image 3 :

[0043] 1) Start the static calculation model and set various material parameters in the static model;

[0044] 2) The static calculation model automatically obtains the information of molten iron and steel scrap for smelting furnaces, the amount of molten iron charged is 72.4t, the temperature of molten iron is 1320°C, and the amount of scrap steel added is 6.23t;

[0045] 3) Set the target value of the molten steel in the smelting furnace in the static calculation model, the target temperature of the molten steel is 1665°C, and the target carbon content is 0.06%;

[0046] 4) In the static calculation model, set the reference lance position of the oxygen lance according to the charging amount of the smelting furnace, and the reference lance position is 1.85m;

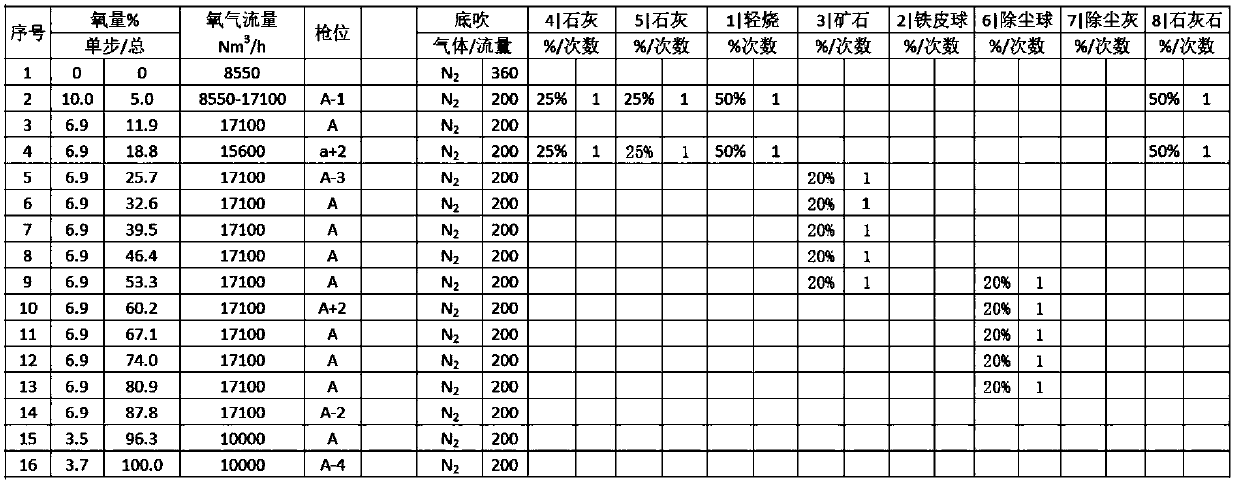

[0047] 5) Use the pre-calculation function in the static model to generate the material step information and oxygen step informati...

Embodiment 2

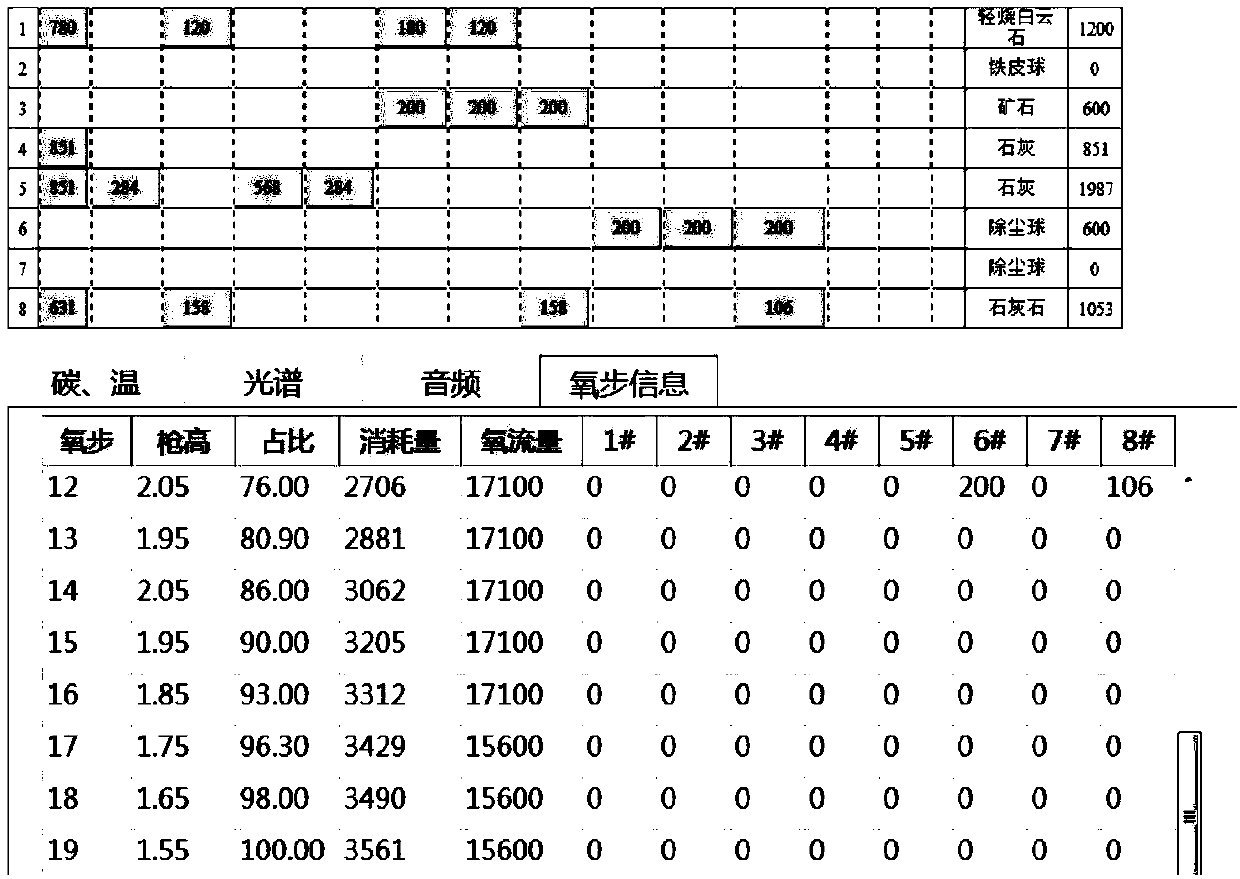

[0052] Embodiment two of the present invention, referring to the attached Figure 4 :

[0053] 1) Start the static calculation model and set various material parameters in the static model;

[0054] 2) The static calculation model automatically obtains the molten iron and steel scrap information of smelting furnaces. The molten iron loading is 72.1t, the molten iron temperature is 1336°C, and the scrap steel loading is 5.1t;

[0055] 3) Set the target value of the molten steel in the smelting furnace in the static calculation model, the target temperature of the molten steel is 1665°C, and the target carbon content is 0.06%;

[0056]4) In the static calculation model, set the reference lance position of the oxygen lance according to the charging amount of the smelting furnace, and the reference lance position is 1.85m;

[0057] 5) Use the pre-calculation function in the static model to generate the material step information and oxygen step information of the smelting furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com