Walking type air floatation mixer

A walking type, mixer technology, applied in mixer, dissolving, neutralizing water/sewage treatment and other directions, can solve the problems of increasing labor intensity of workers, lack of safety and reliability, lack of anti-settling and other problems, achieving simple structure and mixing reaction. Fast, prevent the effect of acidification tank precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

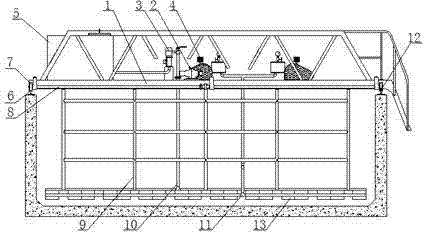

[0010] refer to figure 1 , walking type air flotation mixer, comprising a walking platform 1, the upper surface of the walking platform 1 is equipped with a motor 2, a dosing pump 3, a blower fan 4 and a dosing box 5 connected with the dosing pump 3, the walking platform 1 Both ends of the platform are provided with walking rollers 7 moving in the guide rail 6, the motor 2 is connected with the walking rollers 7 through a transmission shaft 8, and the bottom of the walking platform 1 is also provided with a support frame 9, on which A liquid distribution pipe 10 connected to the dosing box 5 and an aeration pipe 11 connected to the fan 4 are respectively fixed, and the outlet end of the liquid distribution pipe 10 is higher than the outlet end of the aeration pipe 11 .

[0011] The end of the guide rail 6 is provided with a touch switch 12 for controlling the forward and reverse rotation of the motor 2 . The motor 2 can be controlled by the touch switch 12 to drive the walkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com