Measurement system, method and device of scattered materials and material piling and taking control system

A measurement system and material technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems that affect the efficiency of coal yard operations and the bucket wheel machine cannot be measured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

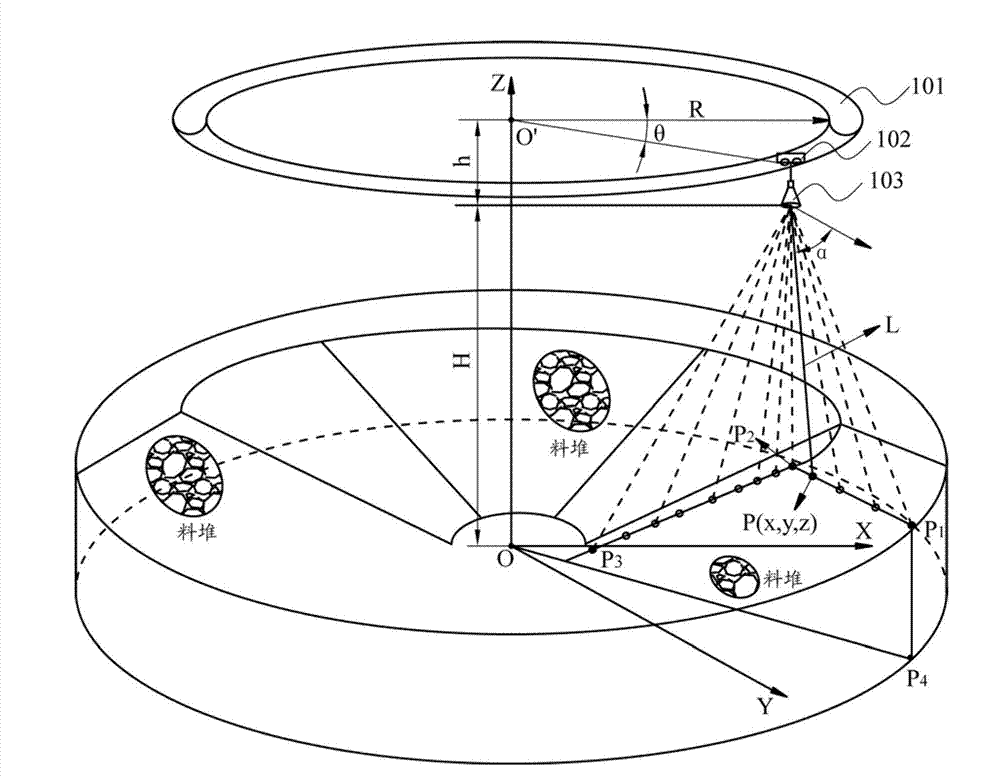

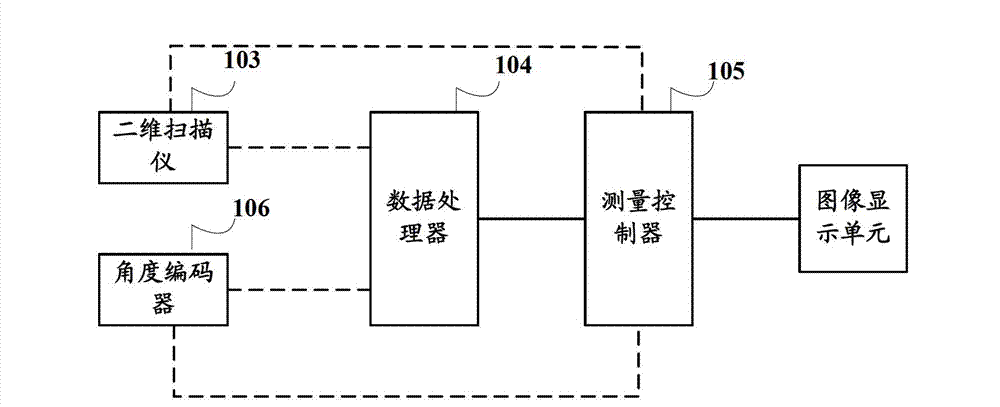

[0075] The invention provides a bulk material measurement technology and a stacking and retrieving control technology for bulk materials in a circular stockyard, which can build a three-dimensional model of bulk materials according to needs, and measure the volume, area, and size of large irregular bulk materials. And determine the boundary position, based on the information to automatically inventory the physical quantity of the stockyard, and further realize the stacking and reclaiming control of the stockyard, it can be widely used in large-scale mine stockyards, port terminals, iron and steel enterprises, thermal power generation enterprises and other raw material stockyards .

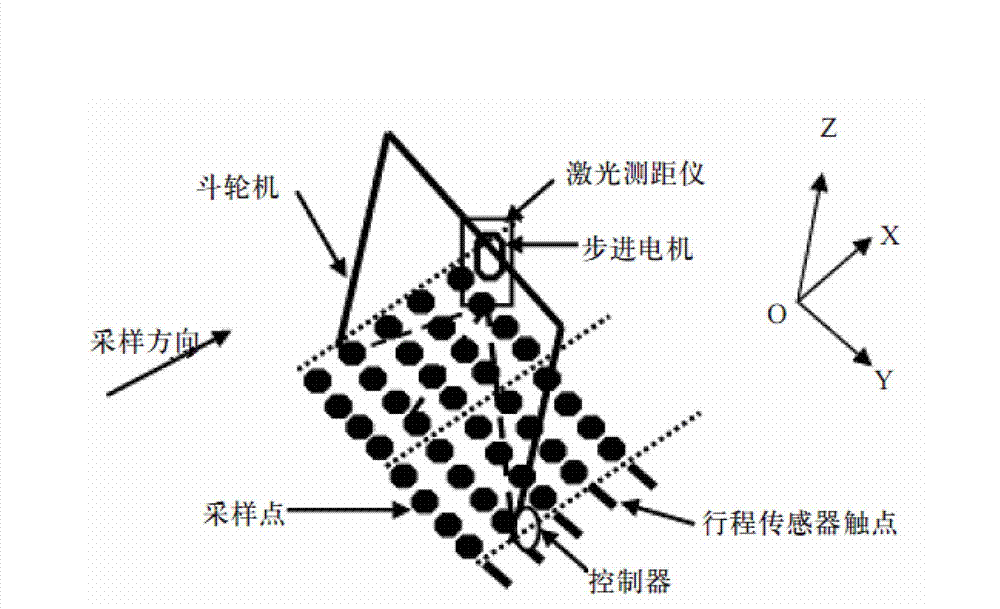

[0076] The present invention can adopt Delaunay triangulation algorithm to realize above-mentioned object for circular stockyard, and circular stockyard is cylindrical dome structure, in order to obtain the surface scanning point data of stockpile required by Delaunay triangulation algorithm, can ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com