Technology for recovering and processing organic exhaust gas by activated carbon adsorption and N2 desorption

A technology of activated carbon adsorption and activated carbon adsorption tank, which is applied in the field of activated carbon adsorption, N2 desorption, recovery and treatment of organic waste gas, can solve the problems of increased control difficulty, complex process and high energy consumption, and achieves reduction of production costs, simplification of processes, and overcoming energy consumption. high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

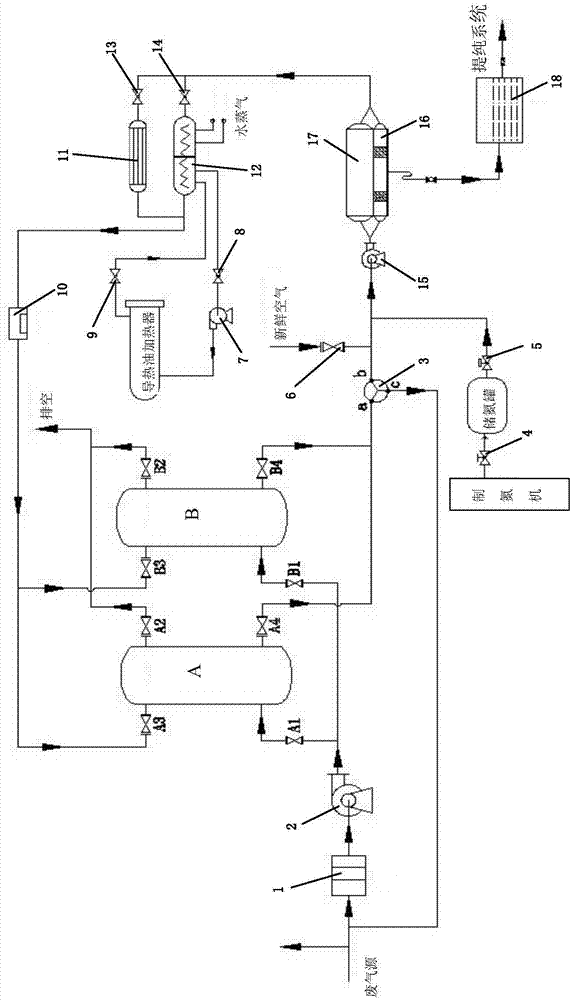

[0046] key reference figure 1 , the process steps are as follows:

[0047] 1. The organic waste gas enters the surface cooling filter 1 through the main fan 2 for pretreatment, and the pretreated organic waste gas is sent to the first activated carbon adsorption tank A for adsorption, and the first valve A2 is opened to pass the purified gas through Discharge from the air outlet; the second activated carbon adsorption tank B is in the desorption regeneration stage or standby stage at this time, ensuring that the purification system can continue to operate without affecting the normal production of the workshop;

[0048] 2. When the first activated carbon adsorption tank A reaches the breakthrough point after adsorption for a period of time, close the first valves A1 and A2, open the second valves B1 and B2, so that the second activated carbon adsorption tank B enters the adsorption system, and the first activated carbon adsorption tank A enters the desorption system.

[0049...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com