New technique for extracting D-glucosamine hydrochloride

A glucosamine hydrochloride, a new process technology, applied in the direction of amino sugar, sugar derivatives, sugar derivatives, etc., can solve the problems of unstable product quality, power consumption, color deepening of semi-finished products, etc., to reduce the amount of side reactions generated , Improve the product yield, the effect of pure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

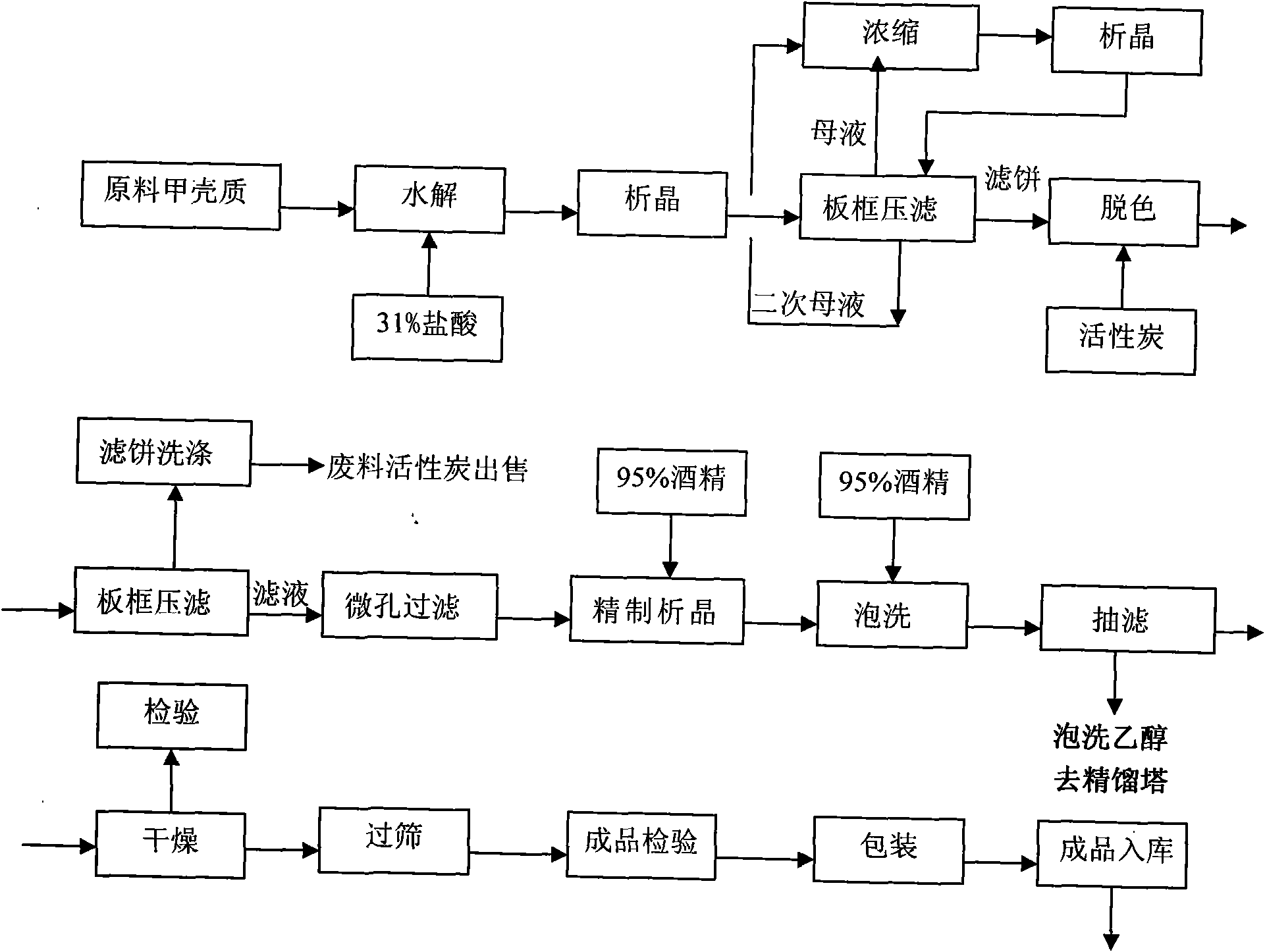

Image

Examples

Embodiment Construction

[0024] A new process for extracting D-glucosamine hydrochloride, comprising the steps of:

[0025] (1) Hydrolysis

[0026] Vacuum pump the measured 31-36% hydrochloric acid to the hydrolysis kettle, start stirring, raise the temperature to 25-55°C, put the prepared chitin into the kettle one after another, and open the vacuum valve at the same time, the weight ratio of chitin to hydrochloric acid The ratio is 1:2~6. After the feeding is completed, the hydrolysis kettle is closed and N 2 Protection, heat up to 55-65°C for 1-1.5 hours, continue to heat up to 65-85°C for 1-1.5 hours, continue to heat up to 85-95°C for 2 hours, turn off the N 2 Valve; the feed liquid is vacuum pumped through the filter tank to the crystallization tank for crystallization. After crystallization for 2 to 4 hours, 0.2 to 0.35 MPa compressed air is introduced to press the feed to the underflow plate and frame filter press for pressure filtration to obtain glucosamine Hydrochloride semi-finished prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com