Patents

Literature

40results about How to "Typical style" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flower fruit/vegetable honey wine and preparation method thereof

InactiveCN101649276AEnhance and exert medicinal valueHigh nutritional valueMicroorganism based processesAlcoholic beverage preparationFruit wineYeast

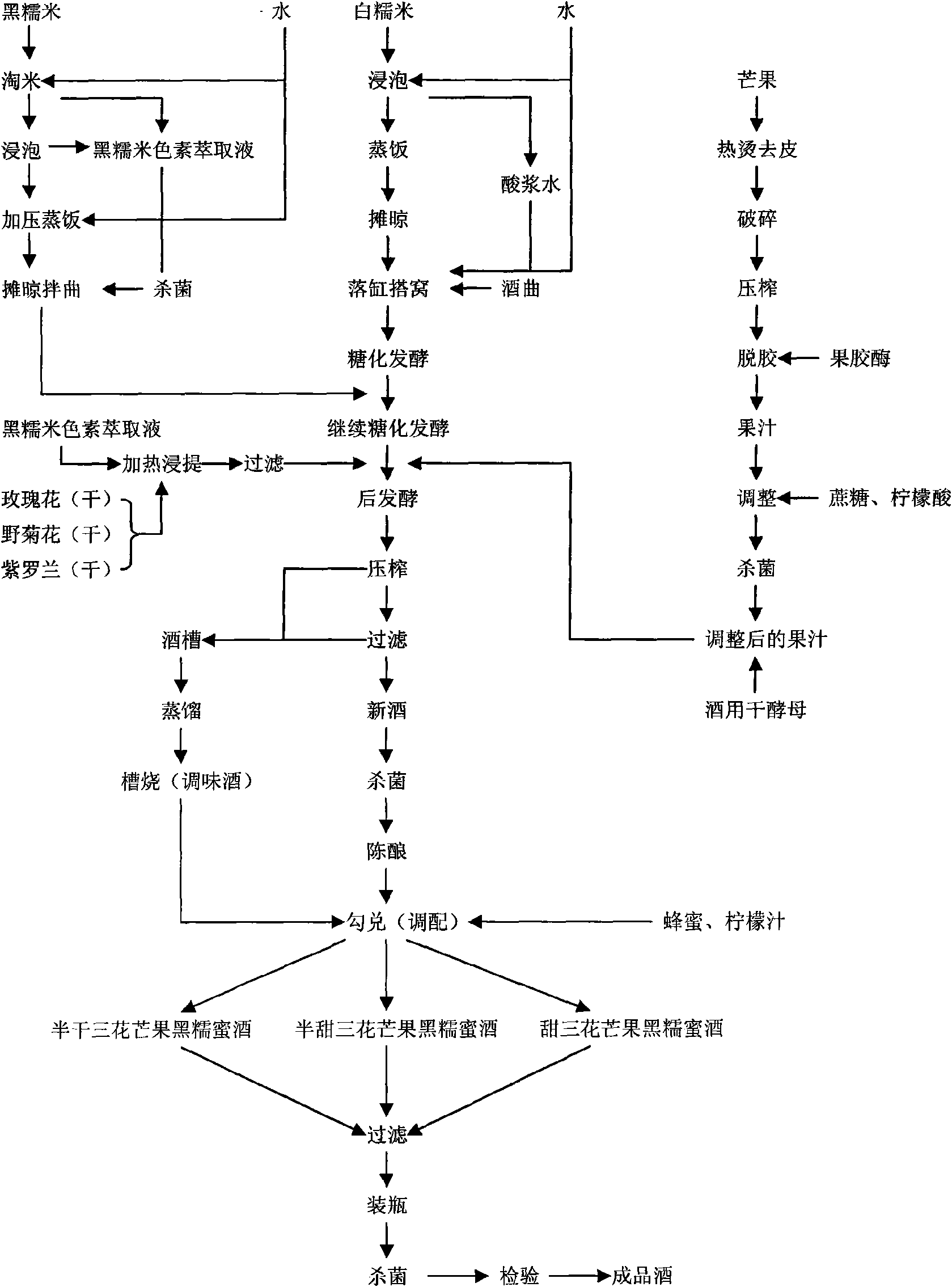

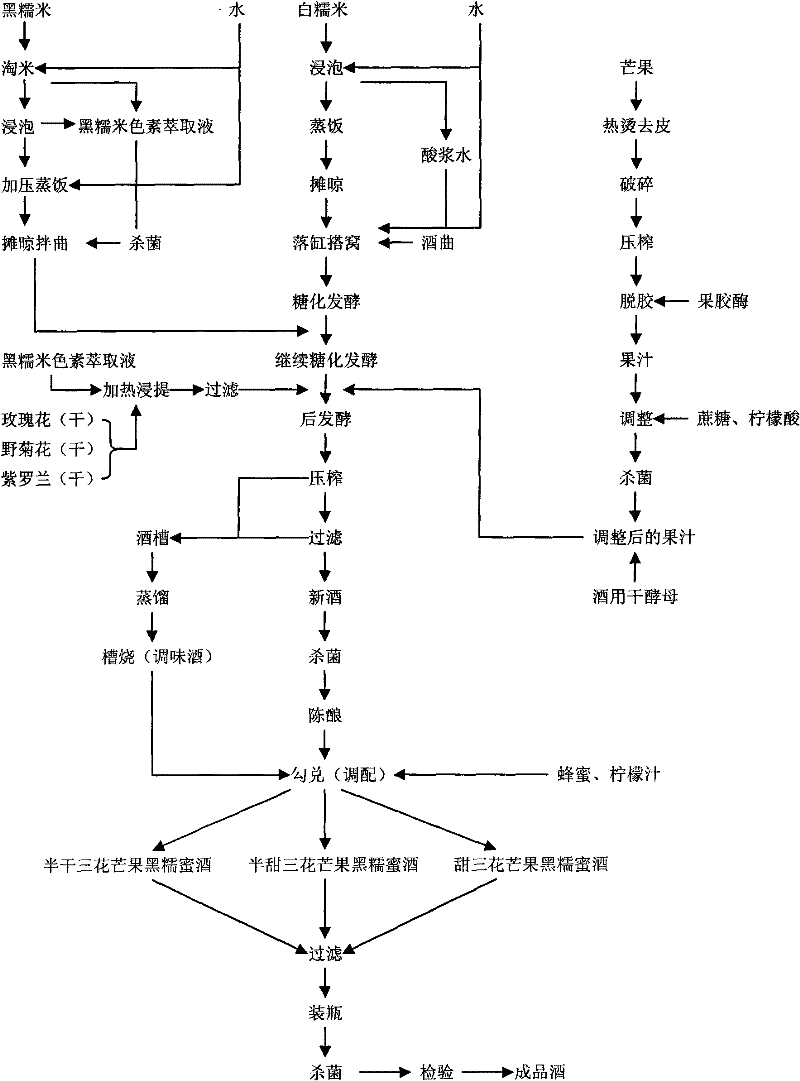

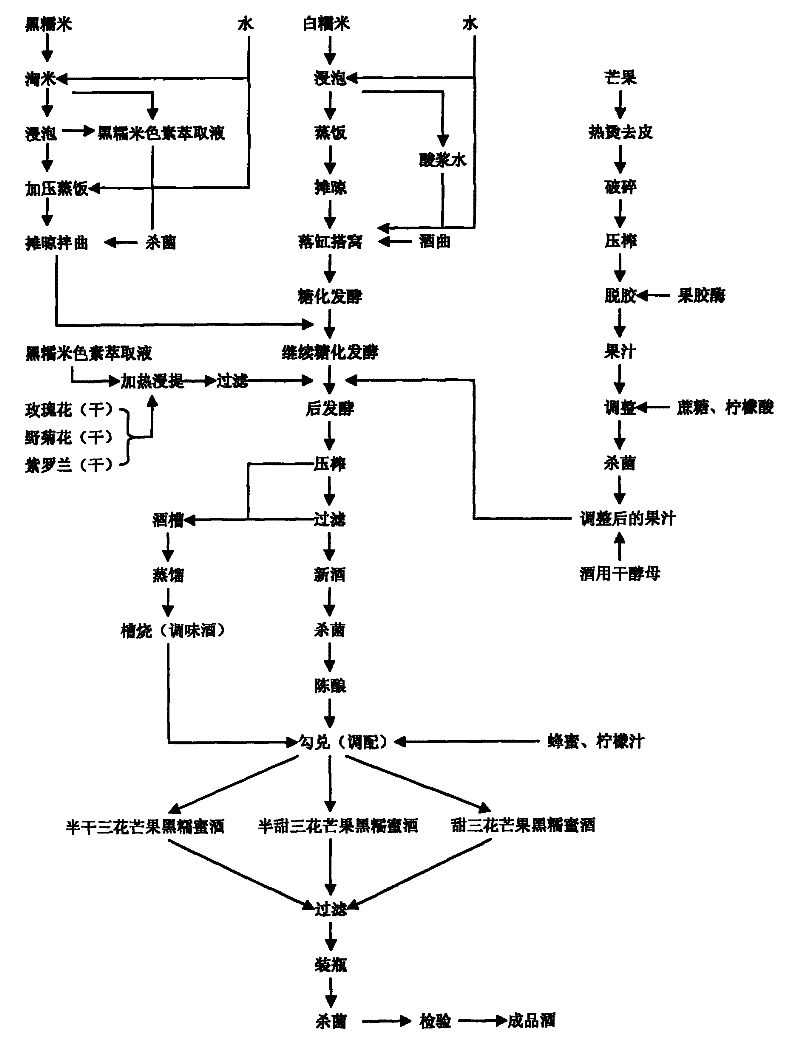

The invention discloses a flower fruit / vegetable honey wine and a preparation method thereof. The preparation method has the technique scheme that: taking advantages of nutritive characteristics and the like of a plurality of raw materials and auxiliary materials such as edible flowers, fruits (vegetables), black glutinous rice white glutinous rice and the like; using a pure saccharifying fermenting agent and an active dry yeast to carry out the compound fermentation with a plurality of raw materials and auxiliary materials; and using edible flower leaching liquor and cool fruit (vegetable) juice instead of brewing water so as to reduce the alcoholic strength of the yellow wine, increase the content of the dry extractive, increase the nutrients and the content of the yellow wine, enhance the health-care functions for beautifying and maintaining the face and improve the mouth feel. The honey wine tastes elegant, pure, sweet and thick, has peculiar flavor and has the characteristics of both yellow wines and fruit wines. The honey wine is a clear yellow wine having the advantages of elegant taste and health care, is suitable to drink in all seasons, and is especially suitable for women to drink.

Owner:刘名汉

Method for producing acerbity-removing persimmon wine

ActiveCN101215498AReduce astringencyTypical styleAlcoholic beverage preparationMicroorganism based processesYeastAlcohol

The invention discloses a production method for persimmon wine to remove acerbity, which comprises the following procedures: (1) selecting fruits, cleaning and beating; (2) protecting the color; (3) enzymolysising; (4) removing acerbity and clarifying; (5) adjusting ingredient; (6) fermenting; (7) ageing; (8) filtering, filling in bottles and sterilizing; (9) stocking, wherein removing acerbity and clarifying is completed via charging 0.3-0.6g gelatin into one kilogram persimmon juice, standing for 30-40 minutes, clarifying and filtering. The invention protects the color of persimmon juice and reduces oxidation by adding ascorbic acid and citrate, applies gelatin to remove acerbity and clarify, which can effectively remove acerbity and suspended granules in persimmon juice and enable persimmon wine without acerbity and to be easily clarified,) and employs brewing dry yeast to ferment at higher temperature, which has short ferment period. The persimmon wine is clear, transparent, lucidus and free of sediment, which has typical style, good taste, pure flavour, coordinated alcohol and acerbity, full wine body, tasty, good aftertaste, no objectionable odour, fresh persimmon flavour and wine flavour.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Herb-tea fruit/vegetable yellow wine and preparation method thereof

InactiveCN101649275AHigh nutritional valueEnhance heat-clearing and heat-relieving health functionAlcoholic beverage preparationMicroorganism based processesBiotechnologyMedicinal herbs

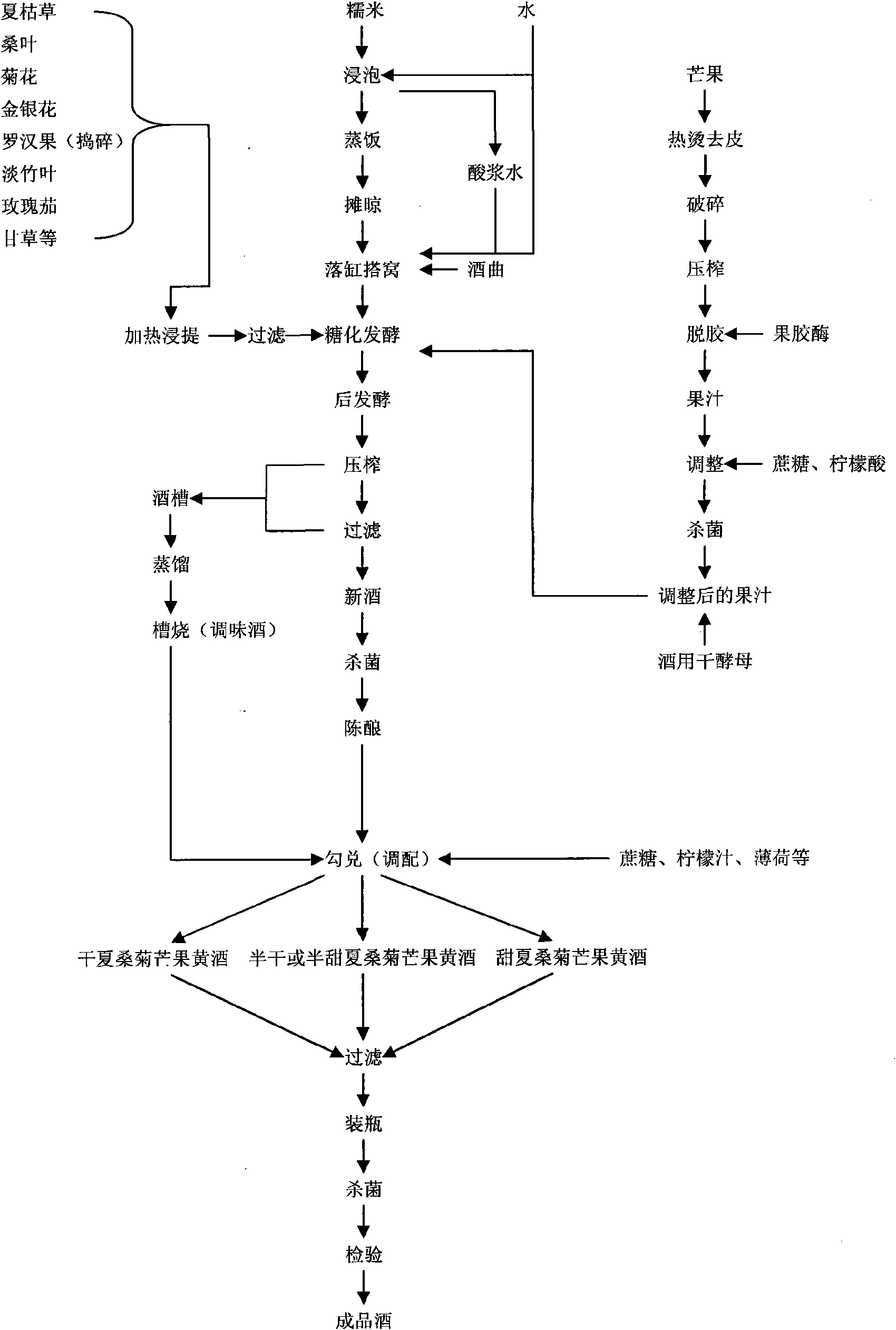

The invention discloses a herb-tea fruit / vegetable yellow wine and a preparation method thereof. Aiming at the problems of high alcoholic strength, strong flavor, high heat productivity, inadaptability to summer drink and the like of the common yellow wine, the method employs the technical proposal that: utilizing a plurality of raw and auxiliary materials having the advantages of nutritive characteristics and the like, such as Chinese medicinal herbs for herb tea, cool fruits (vegetables), glutinous rice and the like; using a pure saccharifying fermenting agent and an active dry yeast to carry out the compound fermentation with a plurality of raw and auxiliary materials; and using Chinese medicinal herb leaching liquor for herb tea and cool fruit (vegetable) juice instead of brewing waterso as to reduce the alcoholic strength and the heat value of the yellow wine, increase the content of the dry extractive, increase the nutrients and the content of the yellow wine, enhance the health-care functions for clearing away the heat and relieving the summer heat and improve the mouth feel. The yellow wine tastes, elegant, pure, sweet and thick, has peculiar flavor and has the characteristics of both yellow wines and fruit wines.

Owner:刘名汉

Method for storing Luzhou-flavor liquor

ActiveCN102181357ARich varietyImprove the quality of the wineAlcoholic beverage preparationFlavorBoiling point

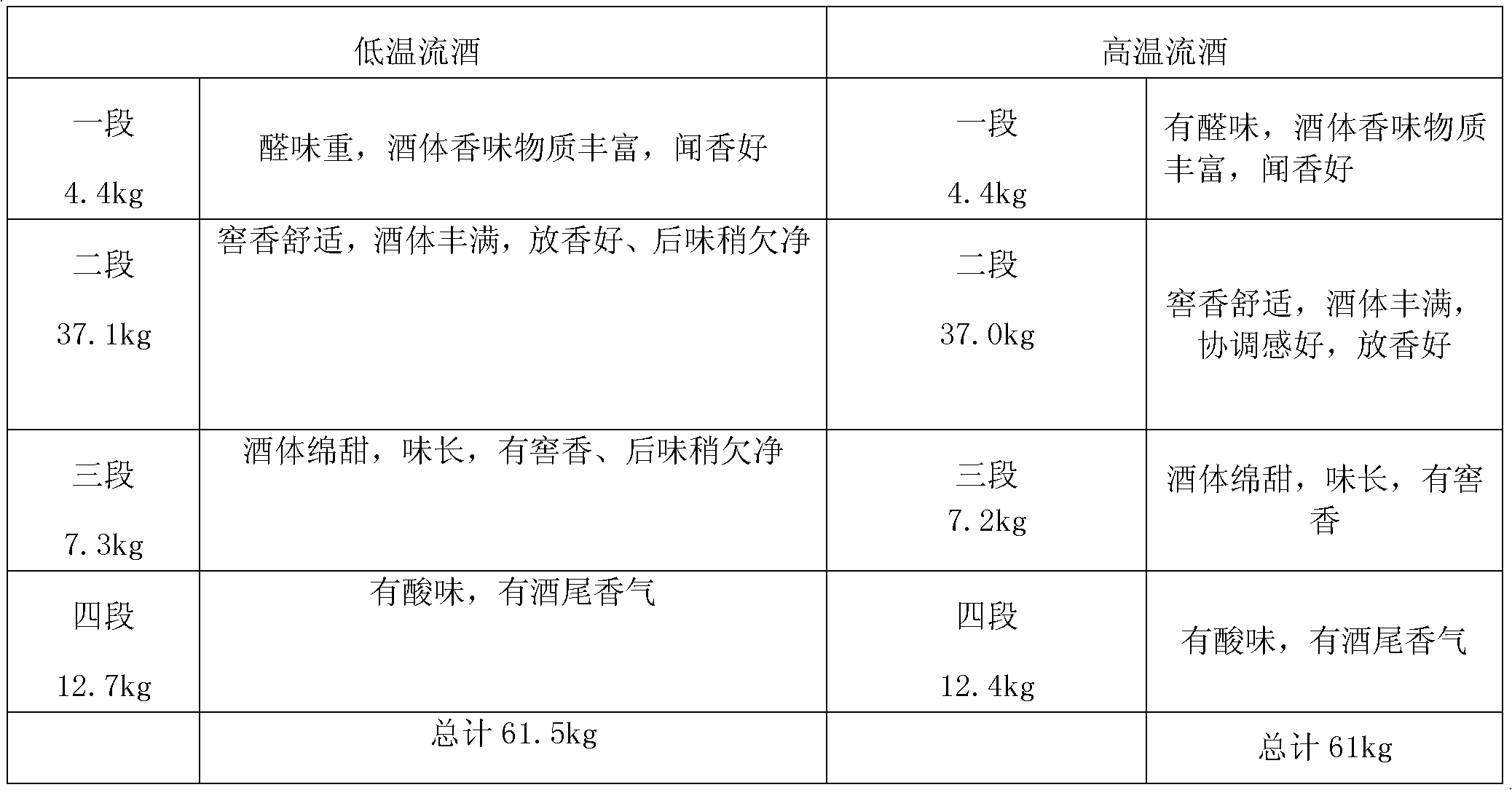

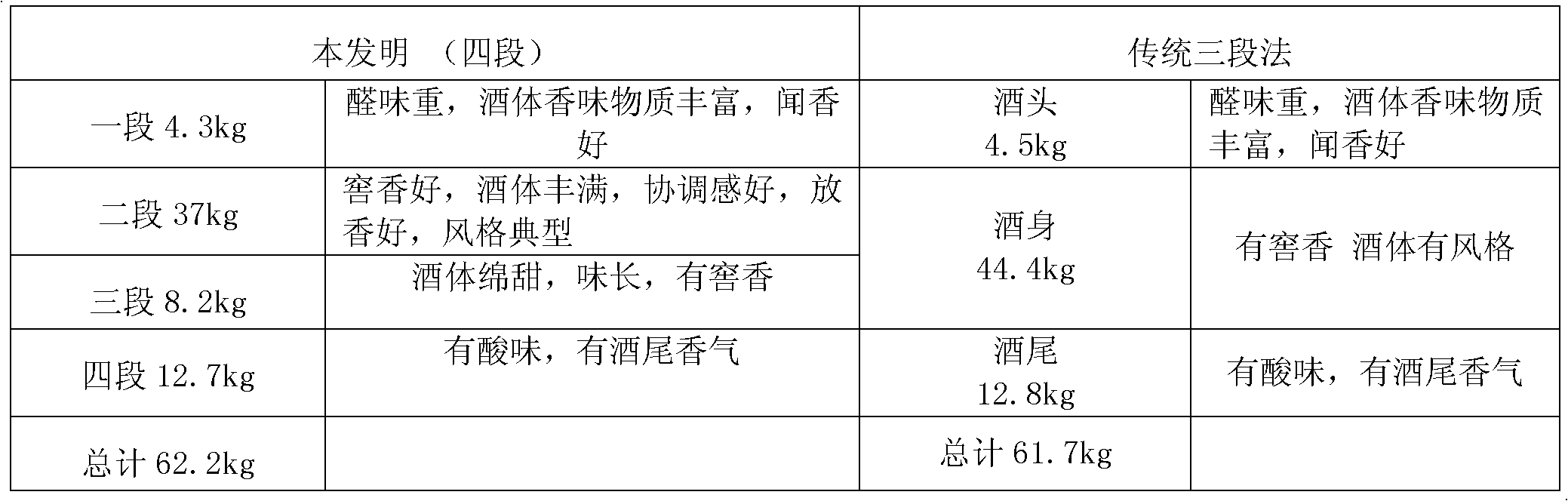

The invention relates to a method for storing Luzhou-flavor liquor, and belongs to the technical field of liquor brewing. The invention provides the method to solve the problems that the variety of basic liquor sources is few, the flavor type is not fine, and the design selection of liquor bodies at a later stage is not adequate after liquor storage in the prior art. The method comprises the following steps of: a, controlling the water content, the pressure and the temperature; b, removing aldehyde taste; c, flowing liquor until hops are converted from small hops to second-stage liquor; d, flowing until the hops disappear and are converted into third-stage liquor; and e, performing liquor storage until the alcoholic strength is less than 0 percent vol to obtain fourth-stage liquor. In the method, the stage-by-stage liquor storage is performed according to different boiling points of aromatic substances, so that the quality of liquor bodies is improved, the foreign flavor is removed, and the liquor bodies are more harmonious and the style is more typical. The characteristics of the liquor bodies at various stages are also maintained; and the variety of the basic liquor sources is more and the design selection of the liquor bodies at the later stage is enriched after liquor storage.

Owner:LUZHOU PINCHUANG TECH CO LTD

Sweet kiwi fruit wine and brewing method thereof

ActiveCN103589575ATypical styleLow priceAlcoholic beverage preparationACTINIDIA POLYGAMA FRUITHealth food

The invention discloses a sweet kiwi fruit wine and a brewing method thereof, and belongs to the field of healthcare foods. The brewing method comprises the following steps: adopting a high fructose syrup to adjust the sugar degree of a fruit pulp; carrying out primary fermentation in a batch sugar addition and batch yeast addition manner twice; adding SO2 to inhibit the fermentation after ending the two-time primary fermentation, and adding deodorized edible alcohol to stop the fermentation; and controlling the ageing temperature after the complete ending of the fermentation in a range of 14-16DEG C for 8-10 months. The brewing method has the advantages of reduction of the production cost, increase of the alcohol degree of the fruit wine, increase of the fragrance generated during the fermentation of the yeast, and acceleration of the esterification reaction of the fruit wine in the ageing process; and the sweet kiwi fruit wine obtained in the invention has the advantages of moderate alcohol degree, protruding fragrance, sour, sweet and tasty taste, pure and sweet mouthfeel, and reduction of the bitter aftertaste, can satisfy demands of different consumer groups, and has a very strong market competitiveness.

Owner:神农架绿源天然食品有限责任公司

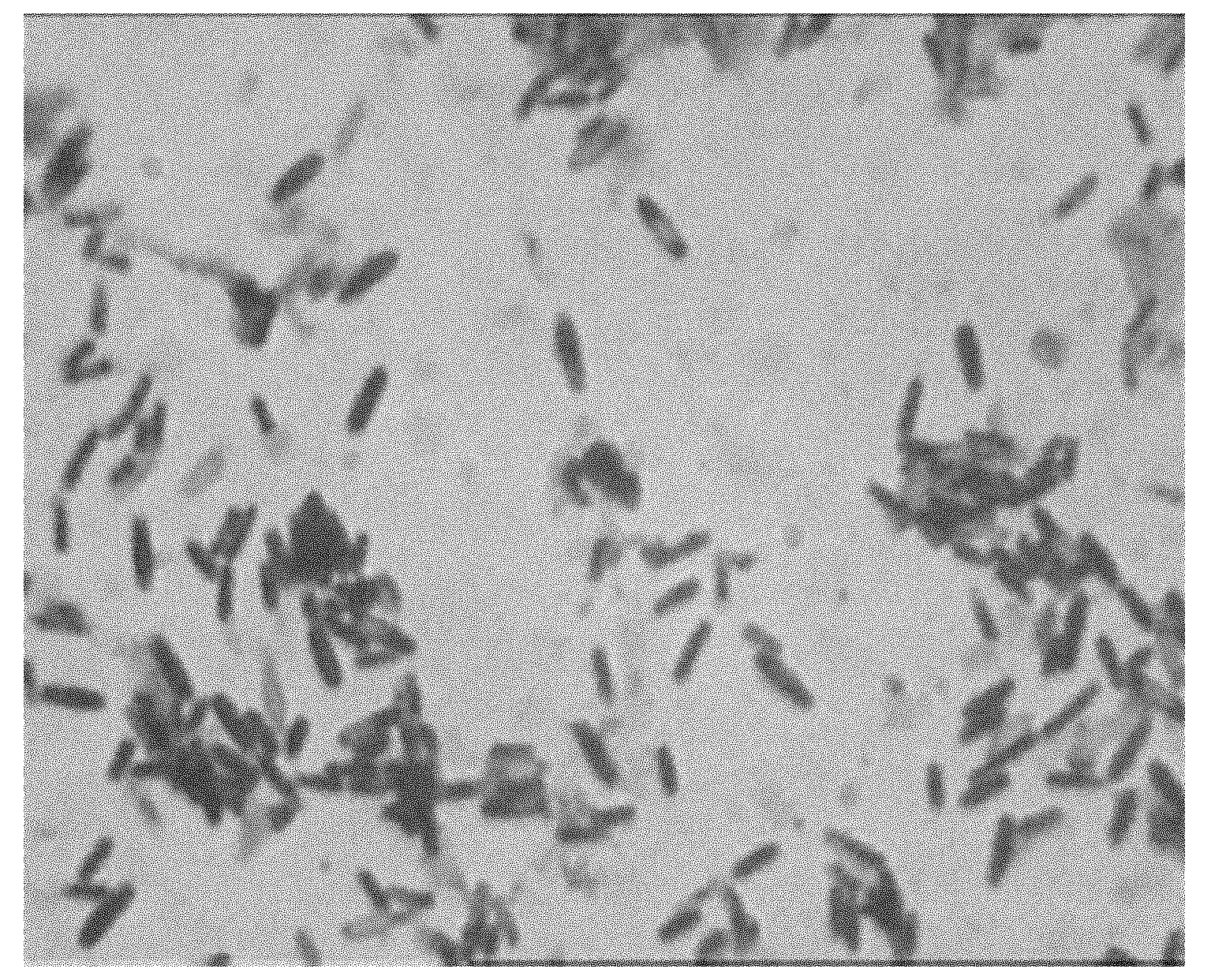

Method for producing white spirit

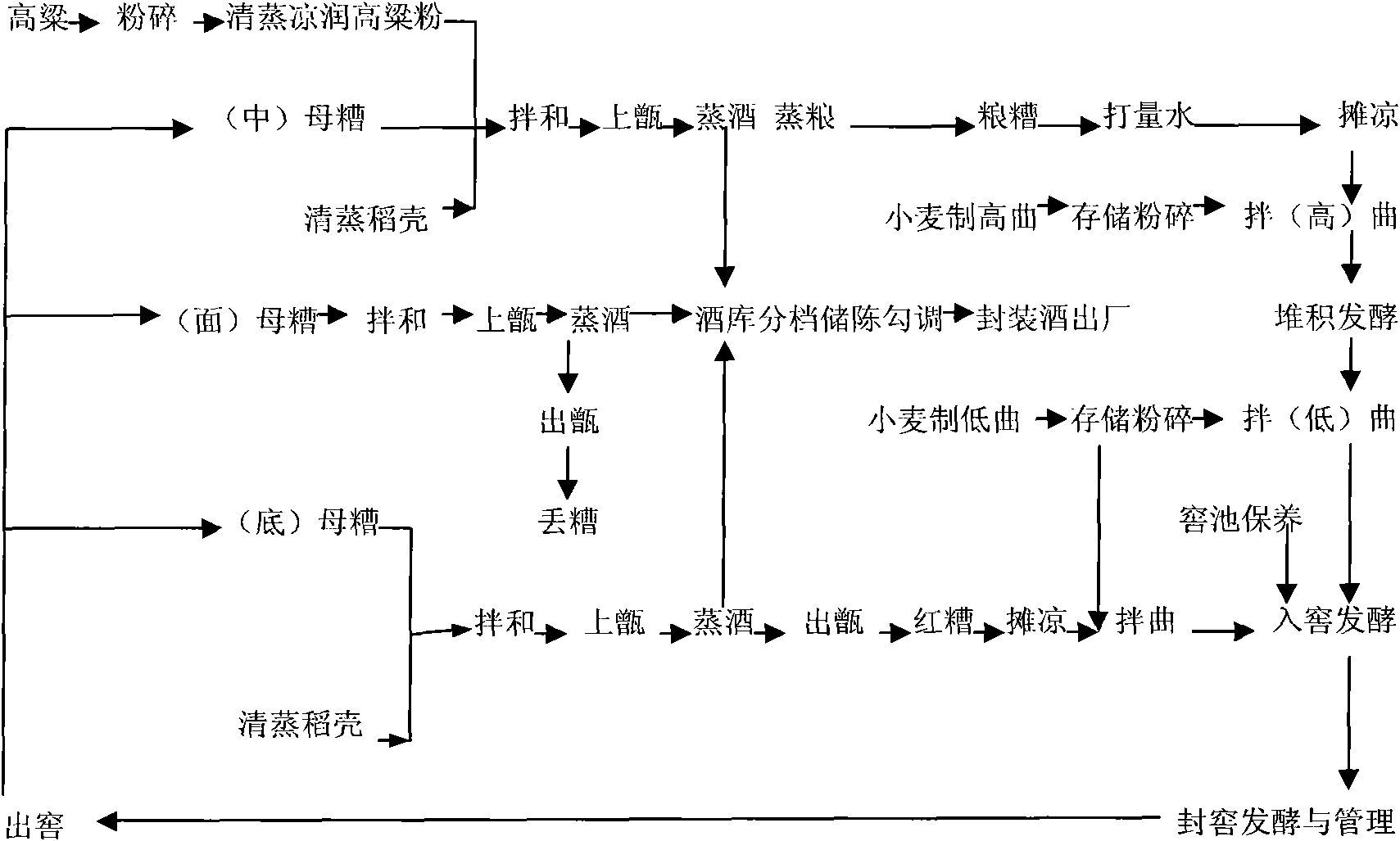

ActiveCN101792706AAuxiliary and personalityIncrease refreshing sweetnessAlcoholic beverage preparationDistillationVinasse

The invention discloses a method for producing white spirit. By adopting the method, the white spirit which is characterized by clearness and transparentness, full-bodied cellar vinasse, soft, sweet and mellow taste, harmonious flavors, and safety and health by green raw materials selection, steaming and impurity removal, mixed steaming and reaction in an aged pit mud, double aspergillus driving,high and low combination, high-temperature accumulation, polyxenie coexistence, same tank and different vinasse, thermophilic fermentation, laminated distillation, liquor storage according to quality, long air storage and aborative blending. The method has the advantages of simplicity and easily controlled condition and the produced white spirit is characterized by clearness and transparentness, full-bodied cellar aroma, secluded soya sauce, comfortable aroma, soft, sweet and full-bodied taste, harmonious favors, thick wine body, unique style and typical character.

Owner:安徽省金裕皖酒业有限公司

Method for preparing intensified daqu applied to nongjiang-flavor Chinese spirits

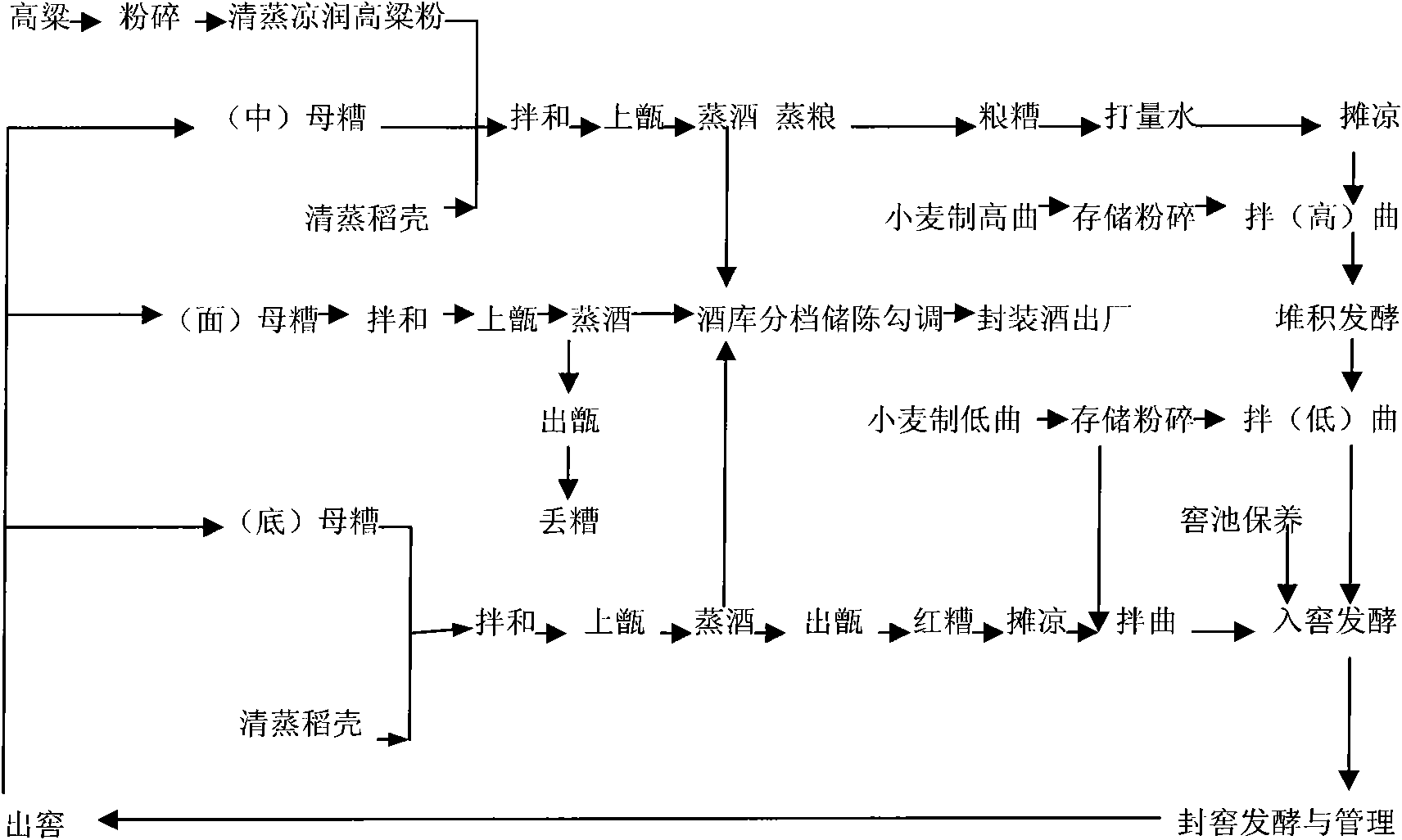

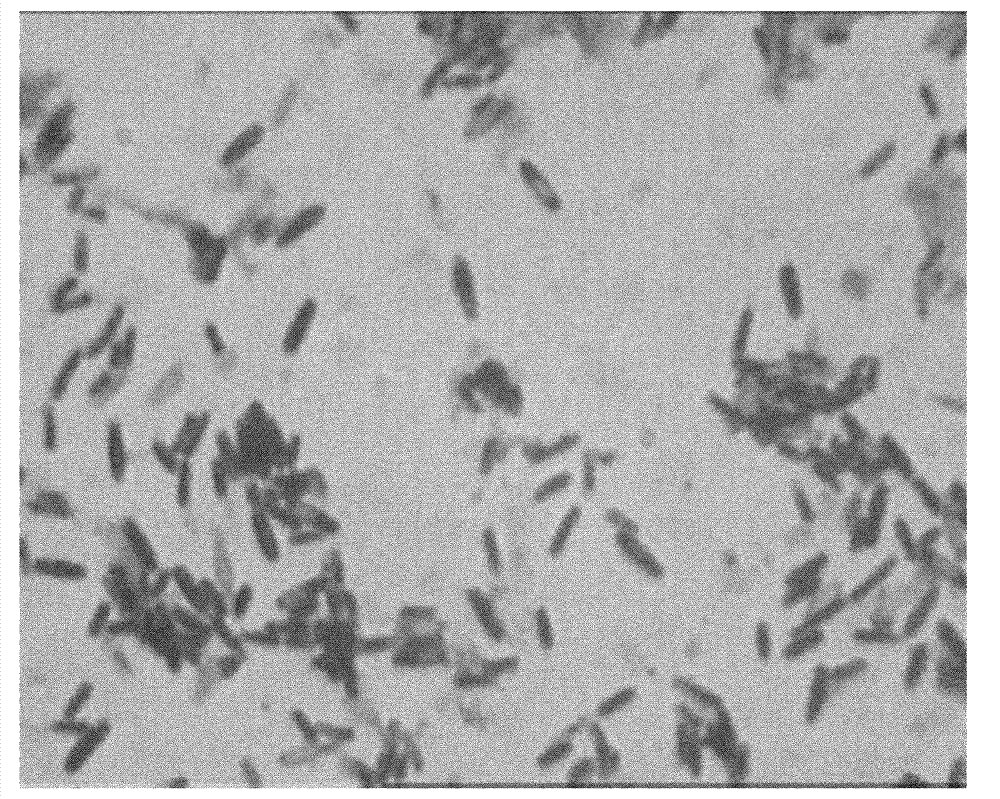

ActiveCN102140427AGood aroma productionQu Yi obviousBacteriaMicroorganism based processesFlavorChemistry

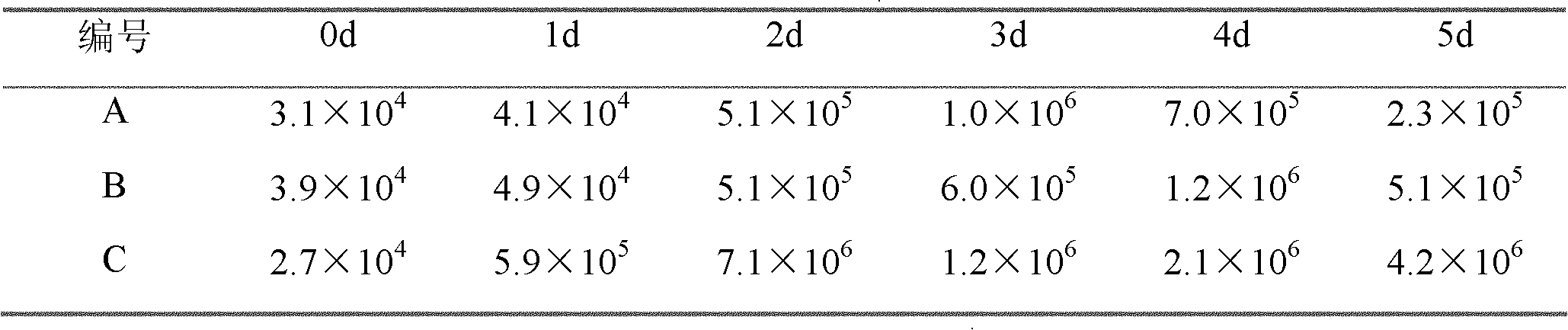

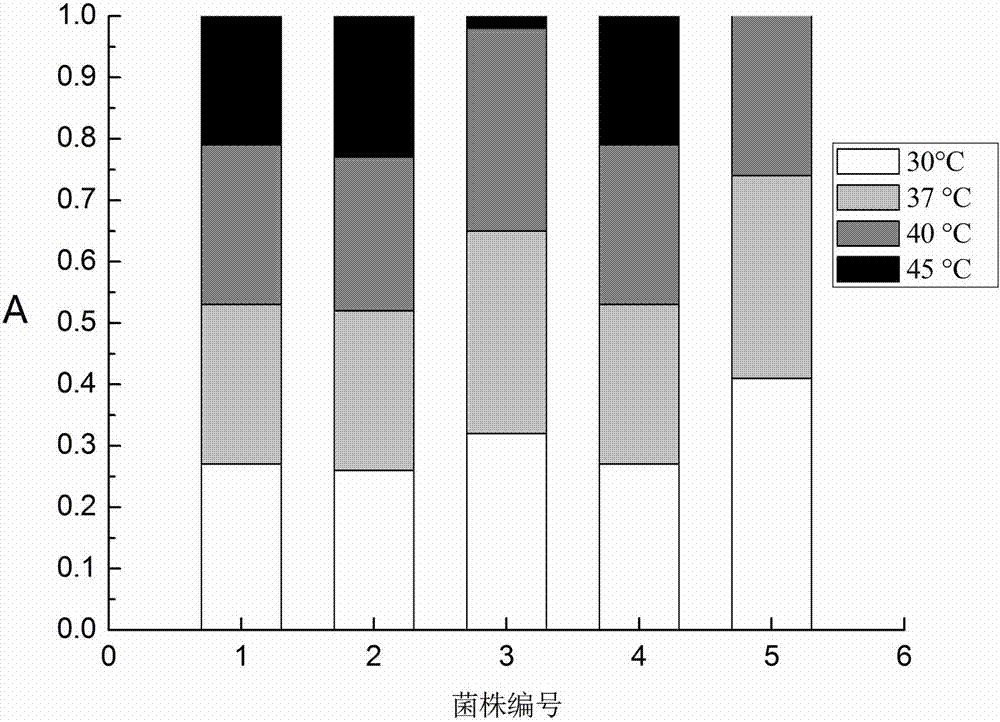

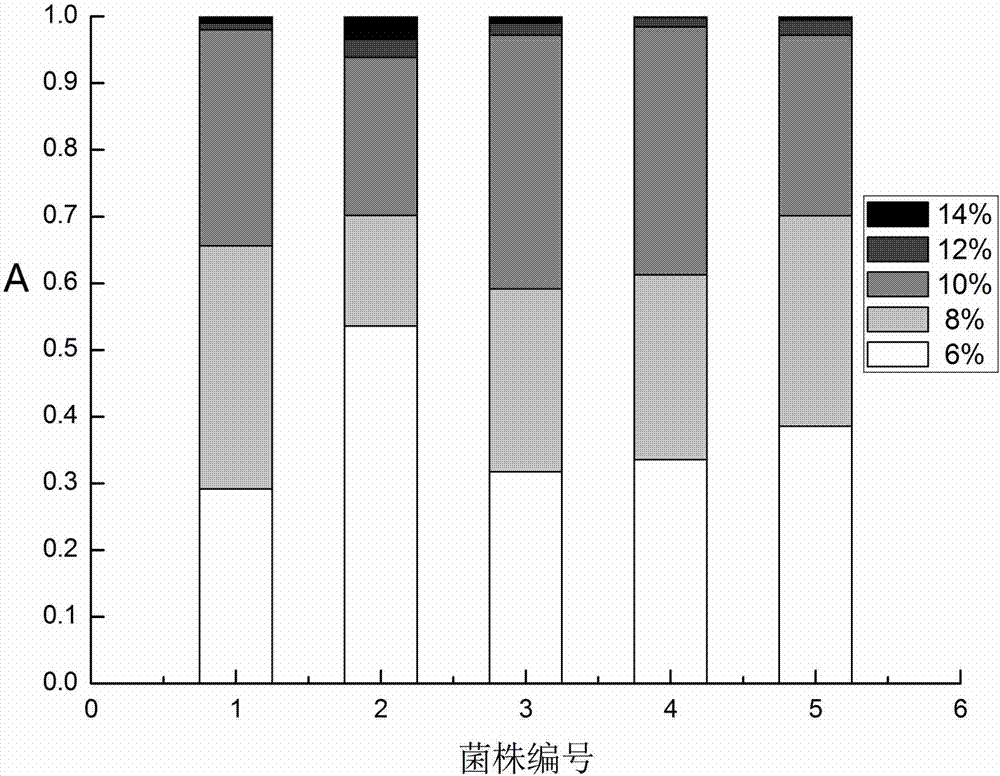

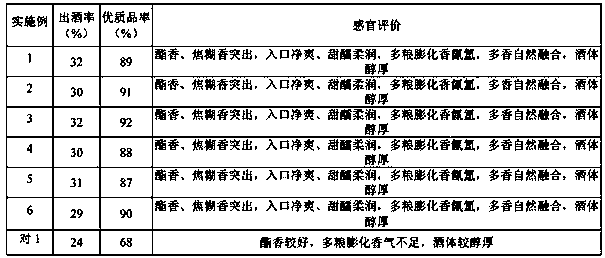

The invention relates to a method for preparing intensified daqu applied to nongjiang-flavor Chinese spirits from Bacillus thermophilus. The intensified daqu prepared by the method is high in fermentation speed, is added into a finished high-temperature starter for production, is used for brewing traditional Chinese spirits, can reduce the starter consumption in production, effectively solves the problem that fermented grains stacked in winter are difficult to heat, improves the spirit yield and premium quality good rate on the premise of keeping the flavor of the original spirits, can save massive brewing and fermentation equipment, manpower, field and energy, and has high use value.

Owner:湖北白云边酒业股份有限公司

Method for brewing oil-tea wine by using bio-enzymes

ActiveCN103981054ARaw materials are uniqueWith aromaMicroorganism based processesAlcoholic beverage preparationCamellia oleiferaDecomposition

The invention discloses a method for brewing an oil-tea wine by using bio-enzymes. The method comprises the following steps: (1) cleaning and impurity removal; (2) crushing and sieving; (3) mixing; (4) high-temperature enzyme deactivation; (5) multi-enzyme decomposition; (6) carbohydrate supplementation; (7) fermentation; (8) distillation; and (9) aging and packaging. The method disclosed by the invention is simple in process, less in investment, low in energy consumption, and easy to operate. The oil-tea wine prepared by using the method is bright and transparent, mellow and exquisite in taste and typical in style, and has no suspended matters and precipitates.

Owner:HUNAN ACAD OF FORESTRY

Hawthorn brandy and brewage method thereof

InactiveCN102337189AFruity harmonyTypical styleAlcoholic beverage preparationMicroorganism based processesManufacturing technologyBottle

The invention belongs to liquor manufacturing technologies, and discloses a hawthorn brandy and a brewage method thereof. The brandy is brewed with hawthorns as a main material. The method comprises technical processes of: material selecting, washing, crushing, pre-fermenting, separating and marc removing, brut fermenting, post-fermenting, distilling, raw hawthorn brandy obtaining, storing, brandy blending, storing, component regulating, freeze treating, filtering, bottle filling, checking, and finished product preparing. With the method provided by the invention, nutrients and health caring components are preserved, and the brandy is advantaged in a good taste.

Owner:宗坤

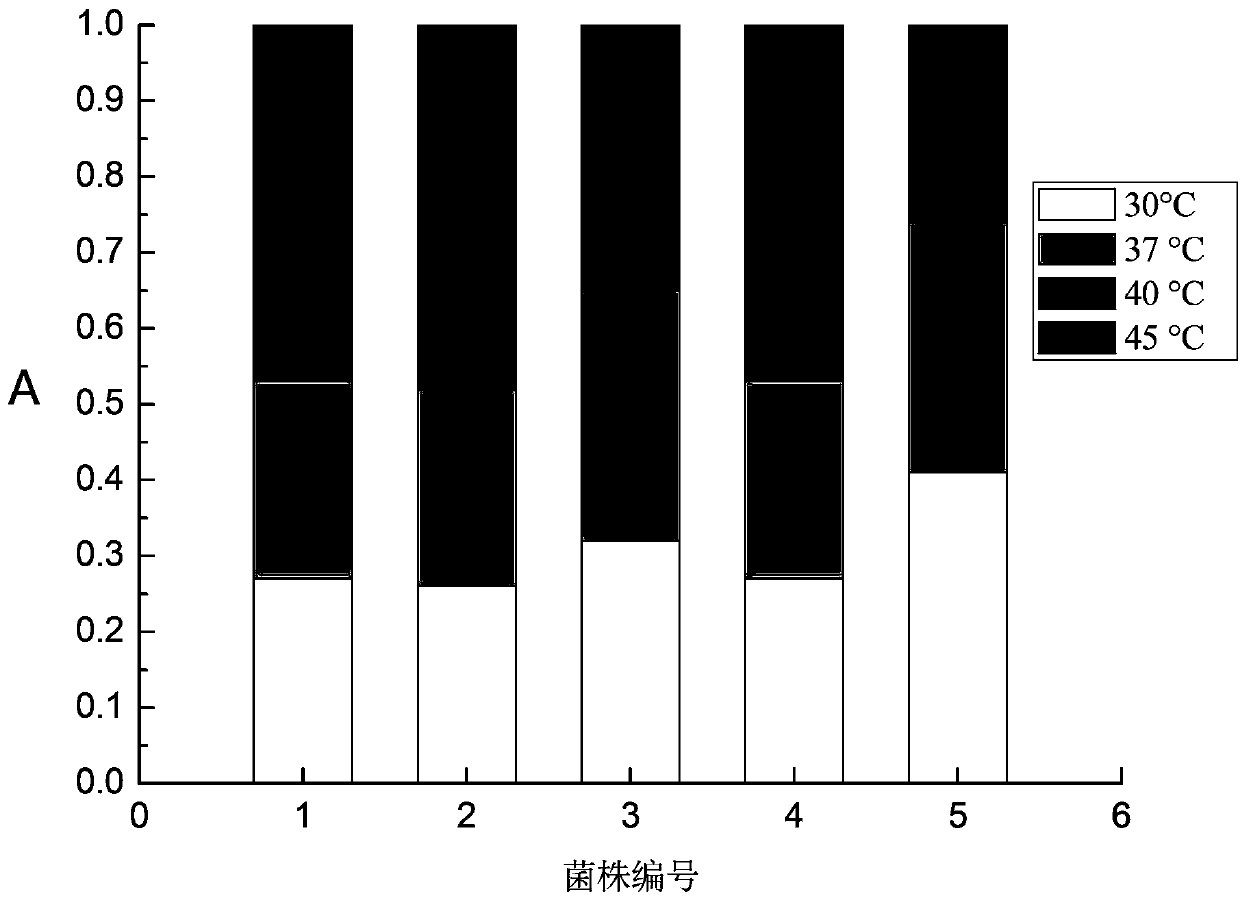

Low-yield fusel oil saccharomyces cerevisiae and application thereof in mechanical production of Xiaoqu base wine

ActiveCN107012103AThe entrance is sweetFragrance coordinationFungiMicroorganism based processesChemistrySaccharomyces cerevisiae

The invention discloses low-yield fusel oil saccharomyces cerevisiae. The classification name of the low-yield fusel oil saccharomyces cerevisiae is saccharomyces cerevisiae Y25, the saccharomyces cerevisiae Y25 is preserved in China Center For Type Culture Collection on February 20th, 2017, and the preservation number of the saccharomyces cerevisiae Y25 is CCTCC No. M2017049. When the saccharomyces cerevisiae Y25 is applied to the mechanical production of Xiaoqu base wine, the fusel oil content in the Xiaoqu base wine is lowered by 20.12% as compared with that in Xiaoqu base wine produced by a traditional method, and the produced Xiaoqu base wine is pure and coordinated in fragrance, mellow and sweet in taste, clean and refreshing in aftertaste and typical in style.

Owner:JING BRAND

Intensified baijiu daqu and production method and application thereof

ActiveCN111235067AMinimal ingredients addedAdd trace ingredientsBacteriaMicroorganism based processesMicroorganismHordeum vulgare

The invention discloses intensified baijiu daqu and a production method and application thereof. The intensified baijiu daqu is produced from the following raw materials in parts by weight: 100 partsof main raw materials, 4-5 parts of an accessory, 2-3 parts of a functional bacterial intensifier and 2-3 parts of mother qu; and the main raw materials are composed of wheat, barley and peas with a weight ratio ranging from 15:1:1 to 20:3:1, the accessory is distiller's dried grains, and the functional bacterial intensifier is produced by mixing bacillus velezensis, acinetobacter and sporosarcinaaccording to a weight ratio ranging from 1.0:0.5:0.5 to 1.0:1.0:1.0. In the intensified baijiu daqu, the microorganisms are diversified and high in content, and the quality of obtained baijiu is excellent.

Owner:HENAN YANGSHAO LIQUOR IND CO LTD +1

Sesame flavor liquor production technology

ActiveCN103484287AUnique styleDelicate styleAlcoholic beverage preparationMicroorganism based processesYeastFood flavor

A disclosed sesame flavor liquor production technology comprises: mixing yellow wine lees, liquor starter, bacterial starter, high-temperature massive raw starter and a flavor-producing yeast according to a ratio, stirring uniformly, stacking to culture bacterium, and forming a special yeast by secondary starter propagation, then mixing with sesame-flavor grain lees according to a ratio, stirring uniformly, wetting the materials at a high temperature, stacking at a high temperature, fermenting at a high temperature, and making liquor flow out at a high temperature to obtain the sesame-flavor liquor which is abundant in nutrition, unique in style, fine and smooth, mellow and typical. The technology is relatively simple, the quality is easy to control, and for manufacturers producing the sesame-flavor liquor, no equipment investment needs to be increased, while the production benefit is increased, and the added value of yellow wine lees is improved.

Owner:ANHUI XUANJIU GRP

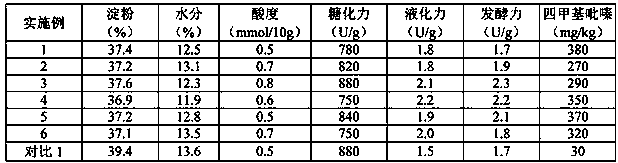

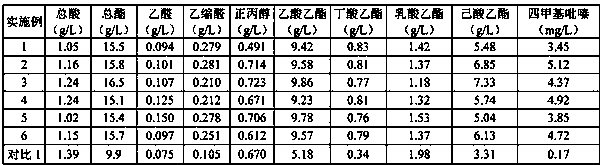

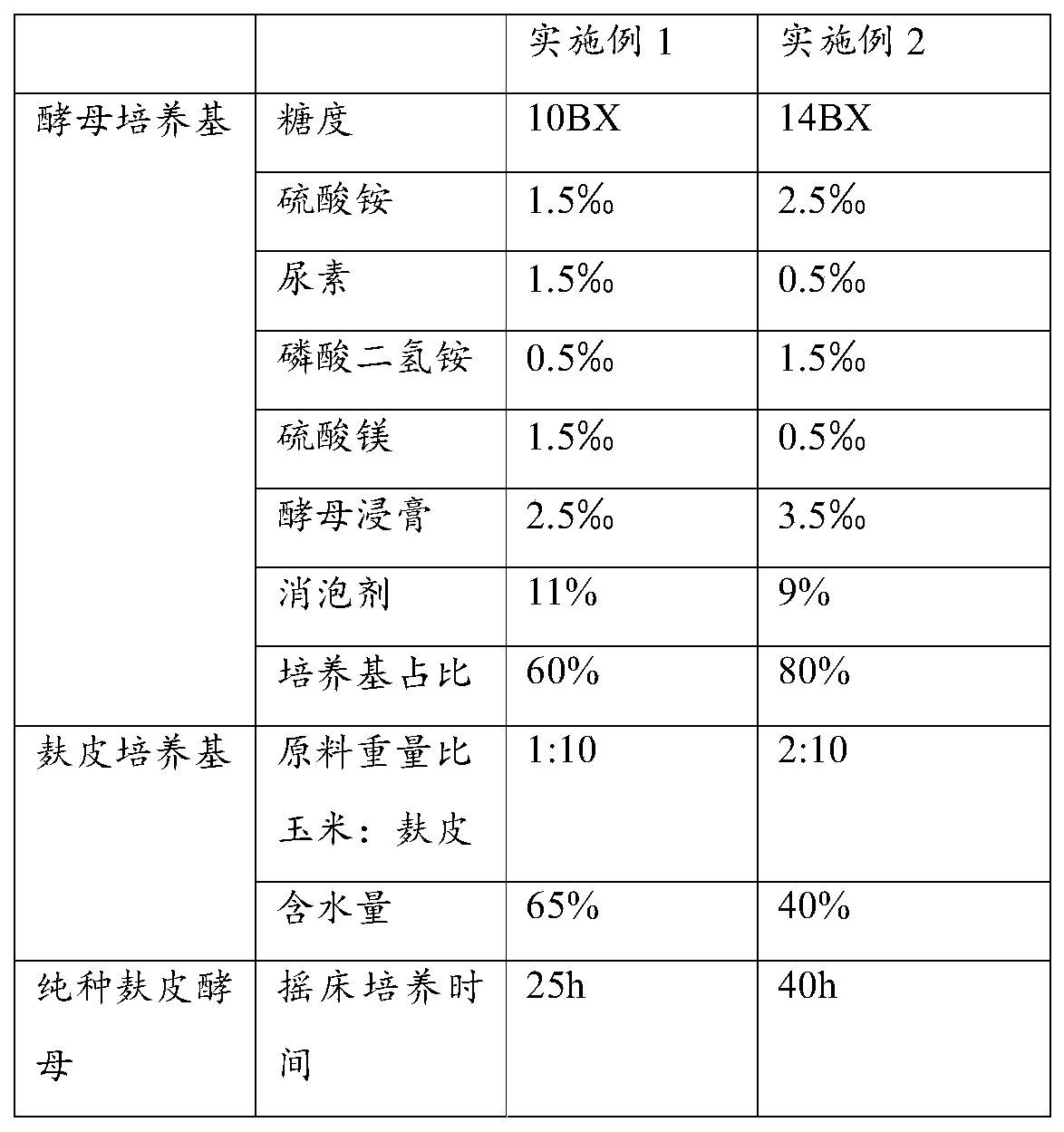

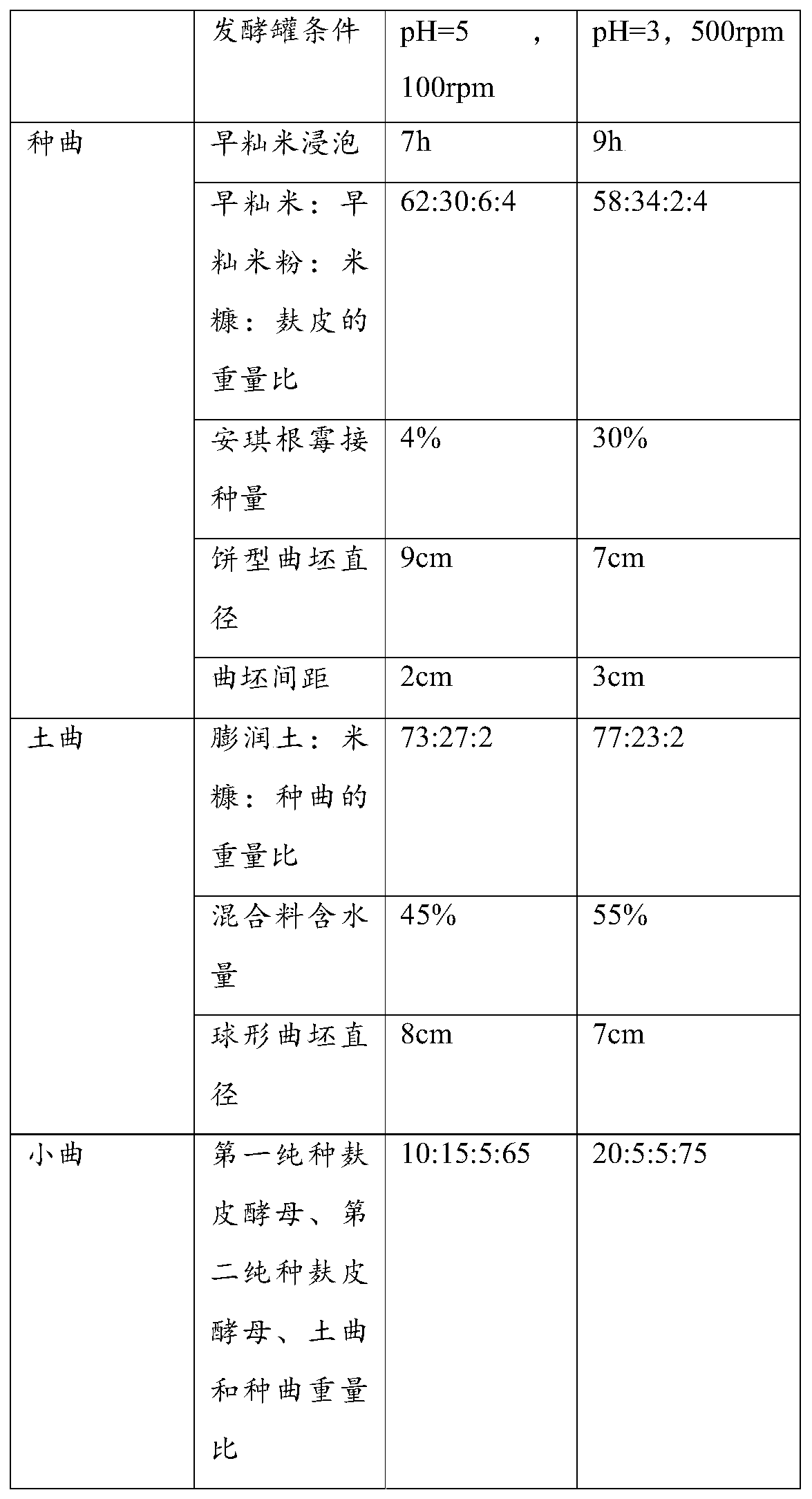

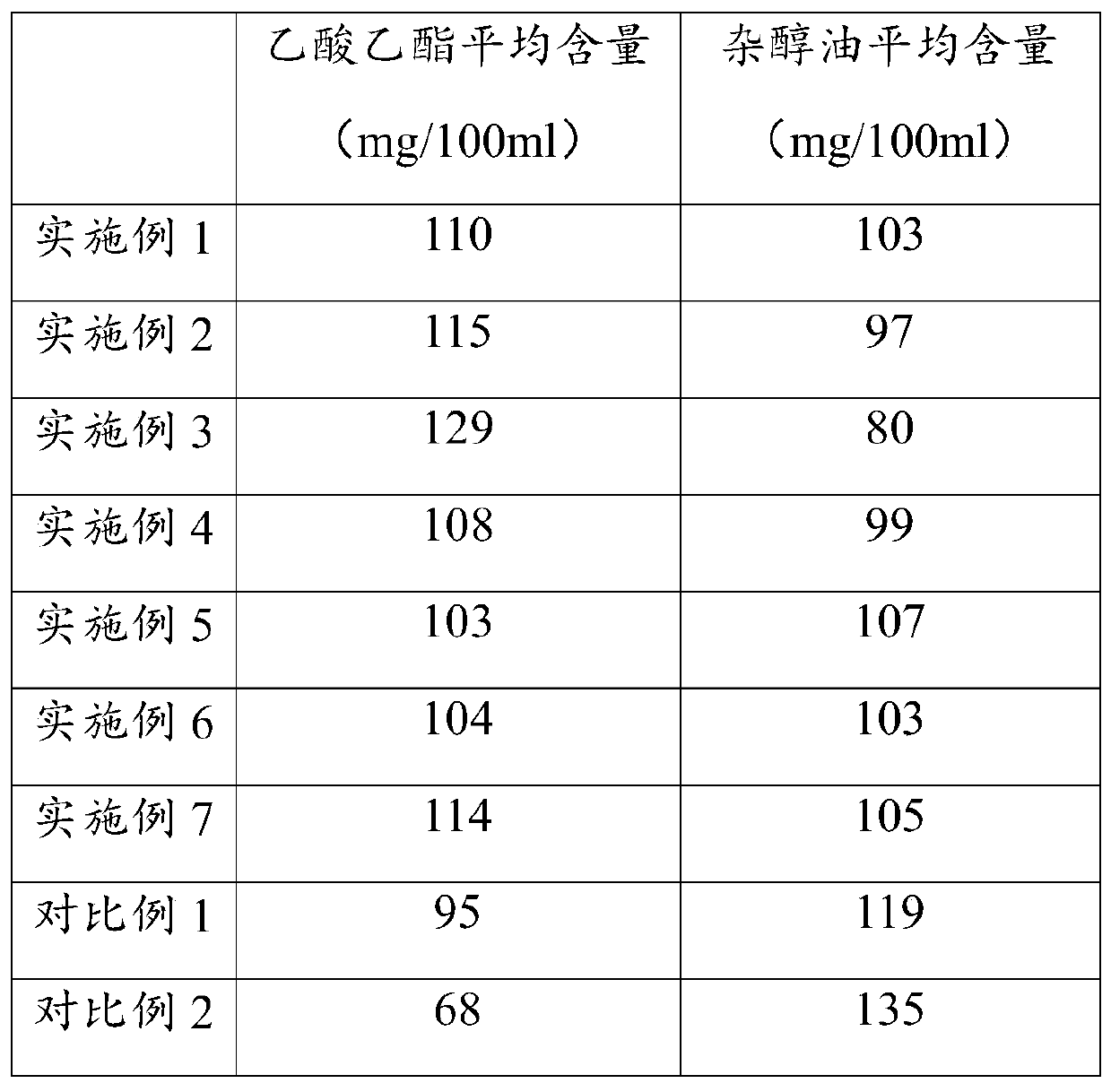

Koji for fermented baijiu, application, fen-favor koji baijiu and preparation method

PendingCN110106048AImprove playbackQuality improvementMicroorganism based processesAlcoholic beverage preparationAcetic acidYeast

The invention relates to the field of brewing technologies, and particularly relates to koji for fermented baijiu, application, fen-favor koji baijiu and a preparation method. The koji for the fermented baijiu is mainly prepared from first pure bran yeast, second pure bran yeast, traditional distiller's yeast and seed koji in a mass ratio of (10-20):(5-15):5:(65-75). The koji for the fermented baijiu adopts a combination of high-yield ethyl acetate yeast and low-yield fusel oil yeast, and the technical gap that in the prior art, there is no technology to achieve the aims of increasing the content of ethyl acetate in the baijiu and reducing the content of the fusel oil in the baijiu at the same time by using mixed yeast from the perspective of the koji is filled up. The preparation method of the fen-favor koji baijiu comprises the steps that the koji for the fermented baijiu is inoculated into a fermentation raw material for mixing, and after sequential cultivation saccharification, vinasse mixing, fermentation and distillation, the fen-favor koji baijiu is obtained.

Owner:JING BRAND

Flower fruit/vegetable honey wine and preparation method thereof

InactiveCN101649276BEnhance and exert medicinal valueHigh nutritional valueAlcoholic beverage preparationMicroorganism based processesFruit wineYeast

The invention discloses a flower fruit / vegetable honey wine and a preparation method thereof. The preparation method has the technique scheme that: taking advantages of nutritive characteristics and the like of a plurality of raw materials and auxiliary materials such as edible flowers, fruits (vegetables), black glutinous rice white glutinous rice and the like; using a pure saccharifying fermenting agent and an active dry yeast to carry out the compound fermentation with a plurality of raw materials and auxiliary materials; and using edible flower leaching liquor and cool fruit (vegetable) juice instead of brewing water so as to reduce the alcoholic strength of the yellow wine, increase the content of the dry extractive, increase the nutrients and the content of the yellow wine, enhance the health-care functions for beautifying and maintaining the face and improve the mouth feel. The honey wine tastes elegant, pure, sweet and thick, has peculiar flavor and has the characteristics of both yellow wines and fruit wines. The honey wine is a clear yellow wine having the advantages of elegant taste and health care, is suitable to drink in all seasons, and is especially suitable for women to drink.

Owner:刘名汉

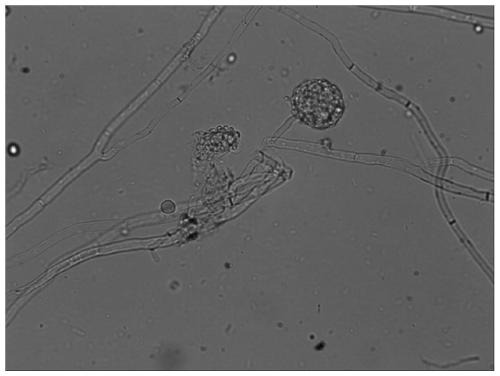

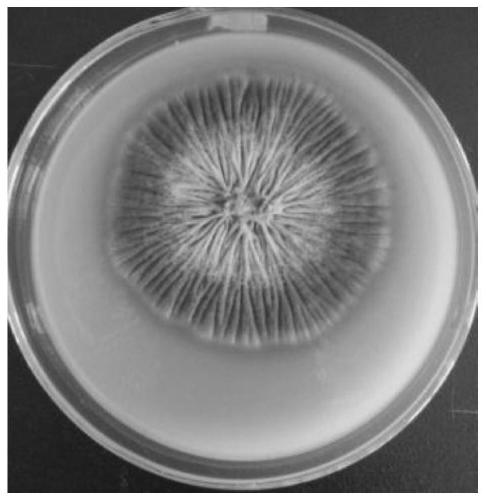

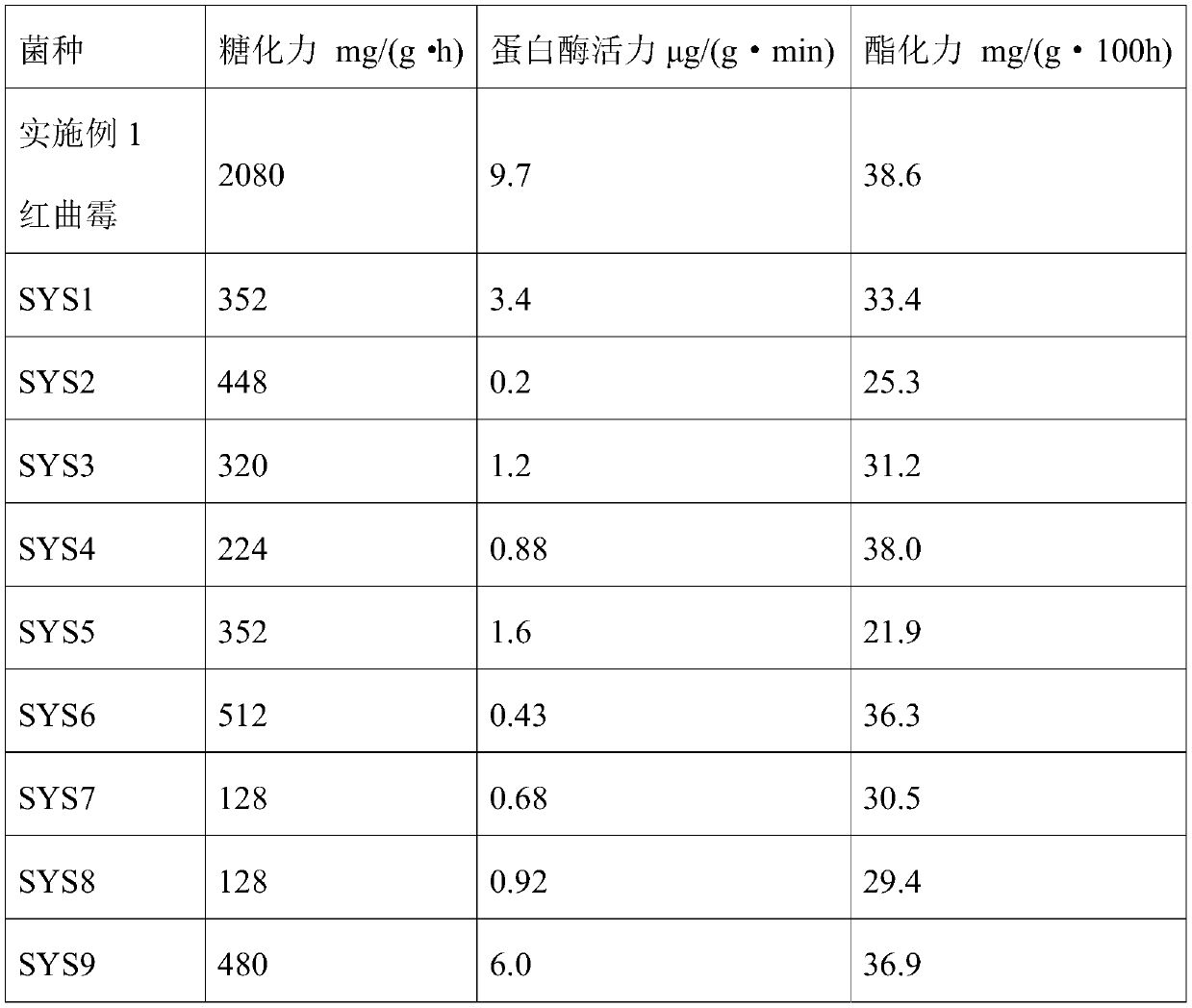

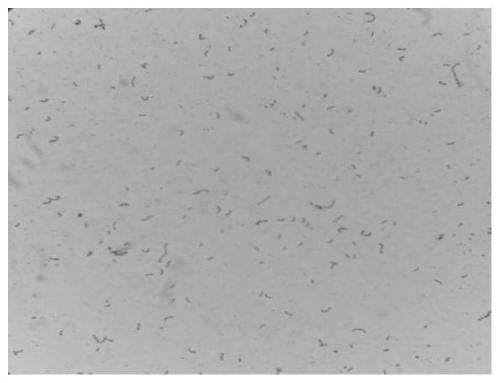

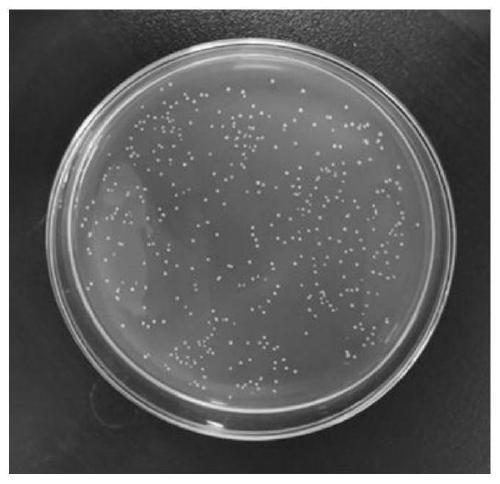

Monascus for high yield of saccharifying enzyme, esterifying enzyme and protease and isolated culture method and application thereof

ActiveCN110317734AHigh yieldImprove product qualityFungiMicroorganism based processesMicroorganismProteinase activity

The invention relates to monascus for high yield of a saccharifying enzyme, an esterifying enzyme and protease and an isolated culture method and application thereof. The monascus for high yield of the saccharifying enzyme, the esterifying enzyme and the protease is named as a Monascus anka T4 strain, the preservation unit is China General Microbiological Culture Collection Center, the preservation time is 25th February, 2019, the preservation number is CGMCC No.17074, and the address is No.3 the first yard, the eastern Beichen road, Chaoyang district, Beijing. The monascus has the good characteristic of high yield of the saccharifying enzyme, the esterifying enzyme and the protease, the obtained anka saccharifying power can reach up to 2,080 mg / (g h), the protease activity can reach up to9.7 microgram / (g min), and the esterifying power can reach up to 38.6 mg / (g 100h). The strain is of the great significance in increasing the baijiu brewing liquor yield and improving the product quality.

Owner:JIANGSU KINGS LUCK BREWERY

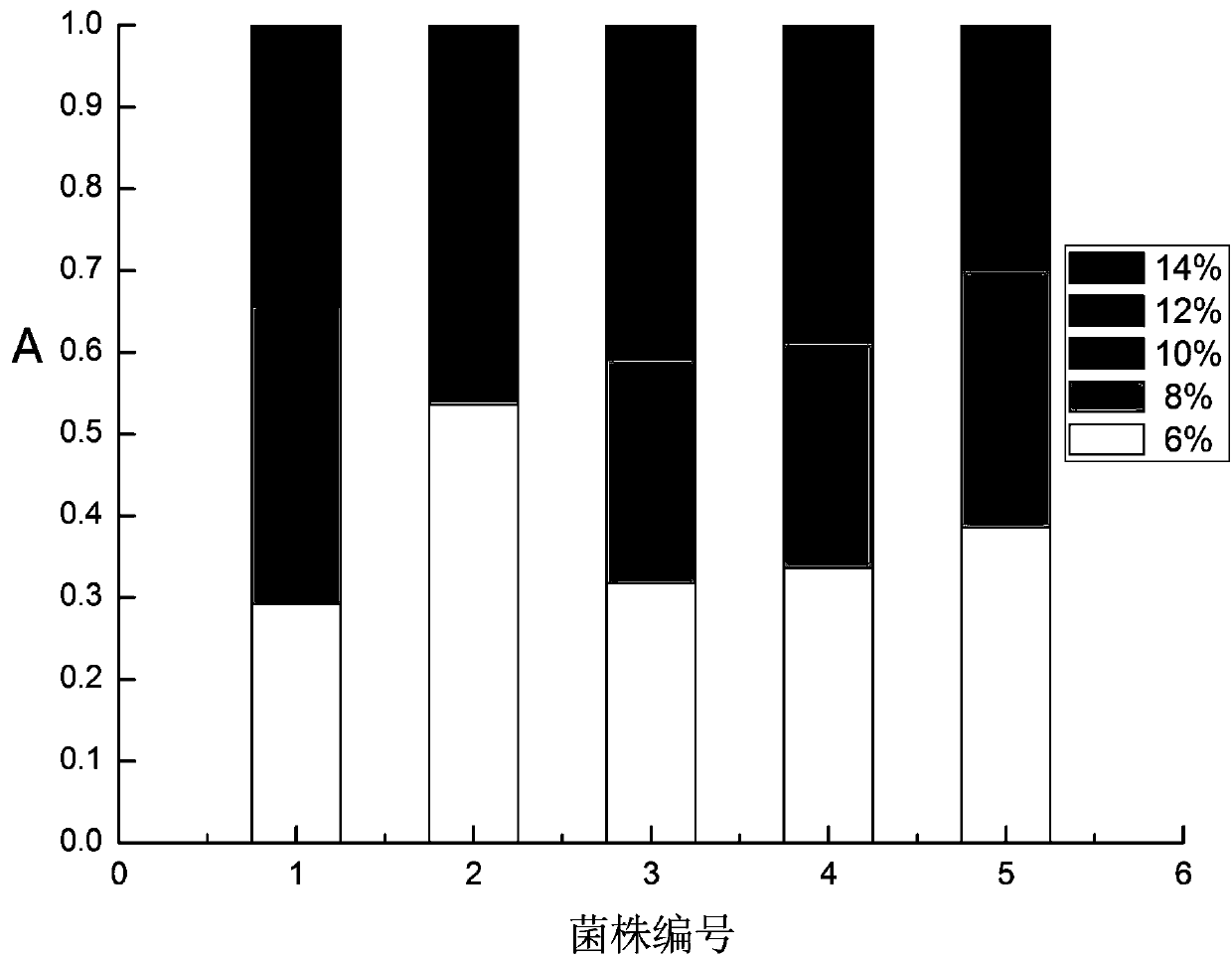

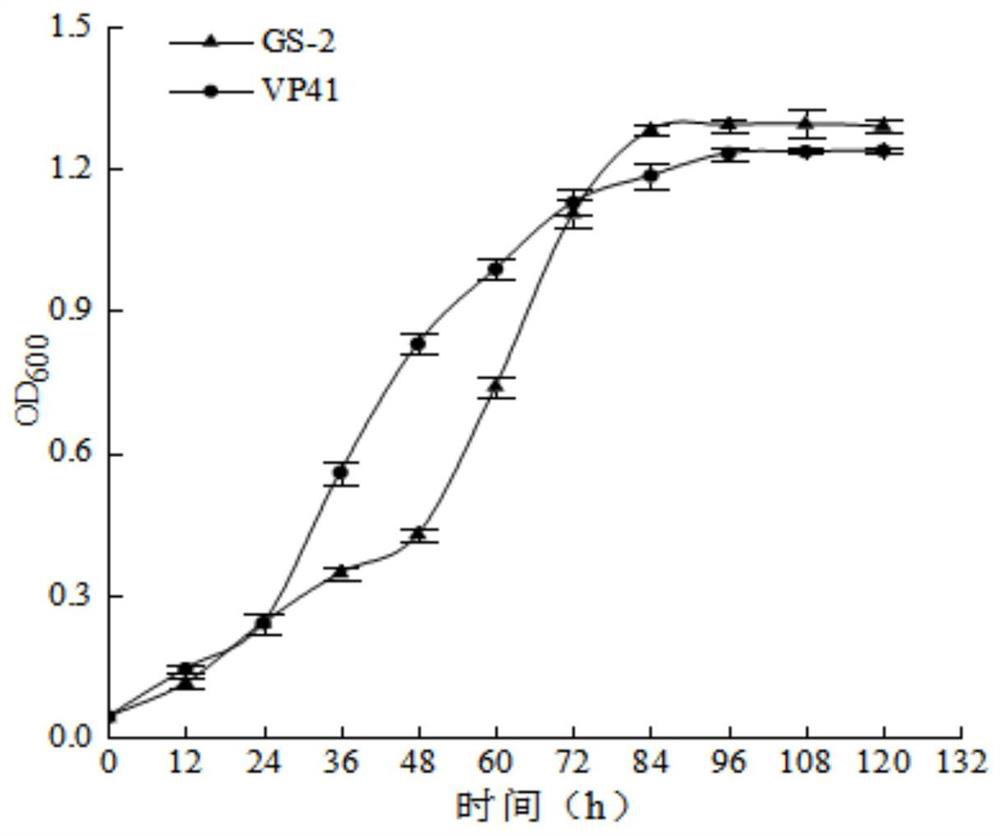

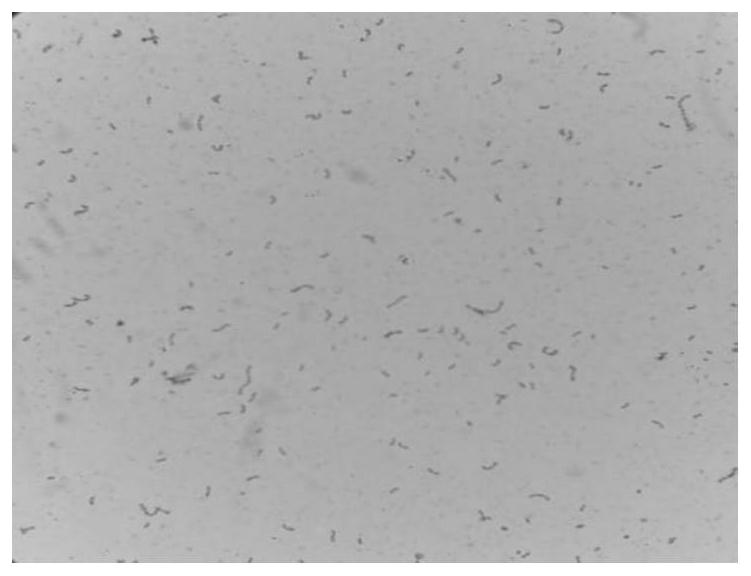

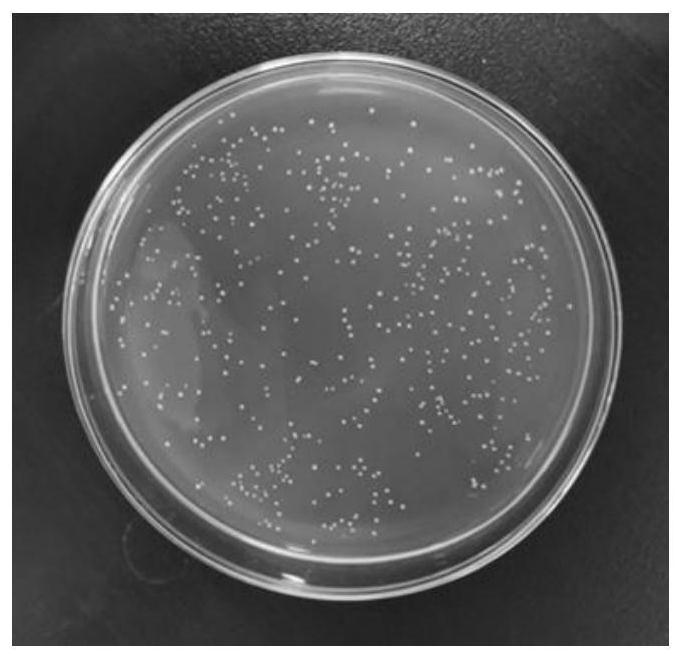

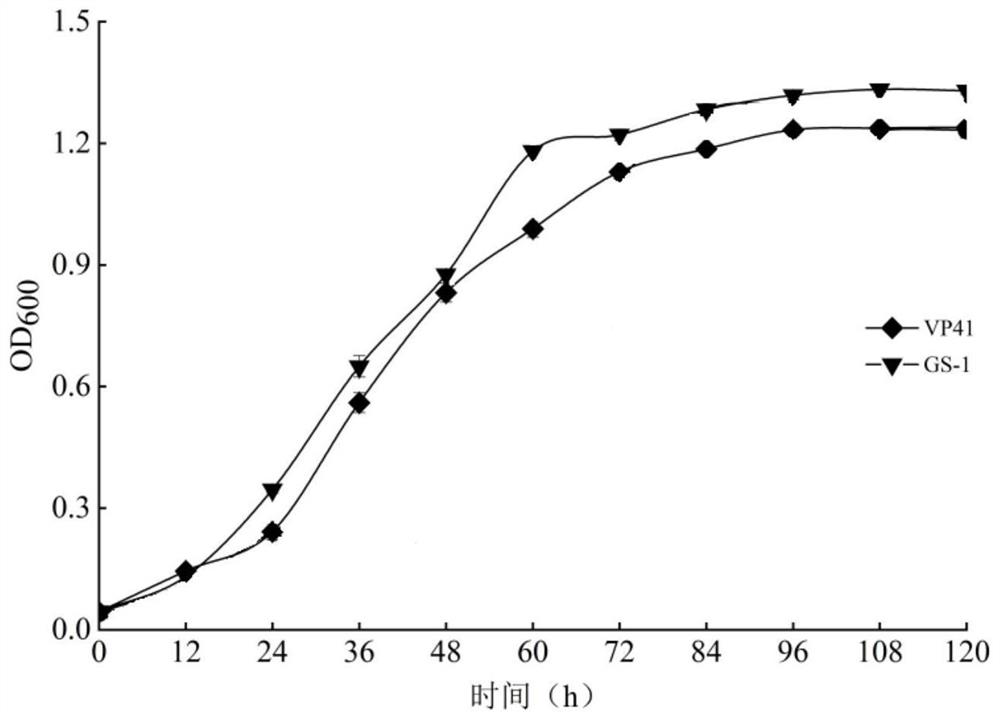

Malic acid-lactic acid fermentation strain for grape wine and application thereof

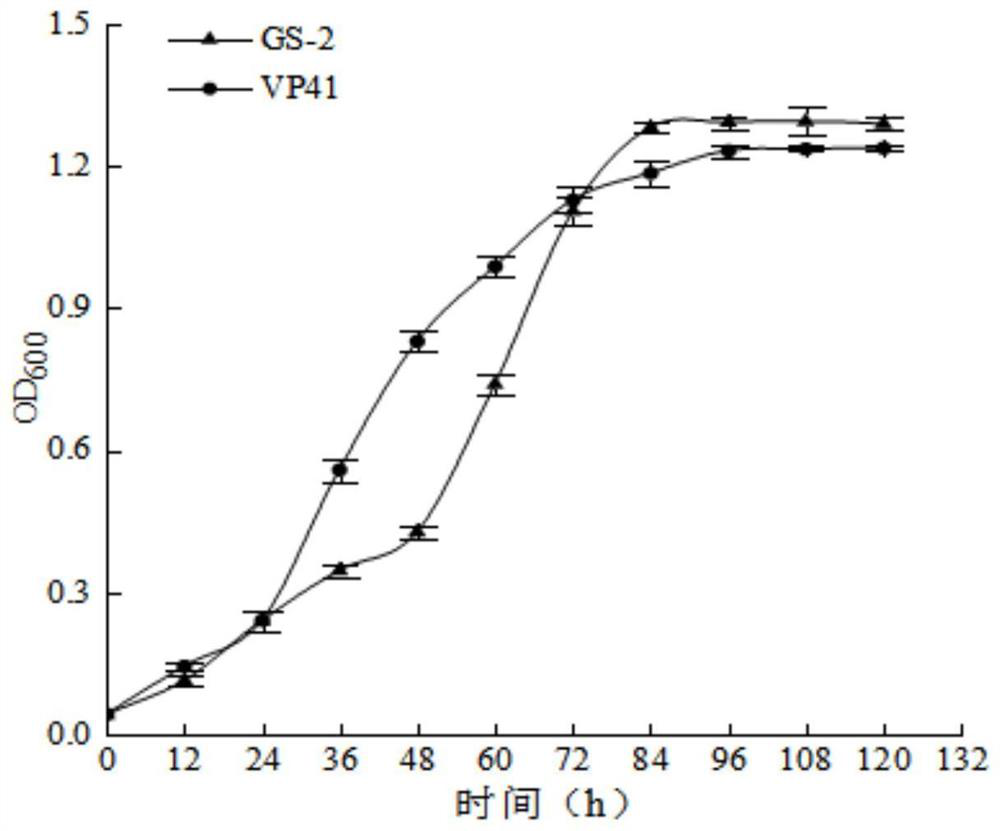

ActiveCN111205996AStrong acid-reducing abilityExcellent fermentation performanceBacteriaMicroorganism based processesLactic acid fermentationOenococcus

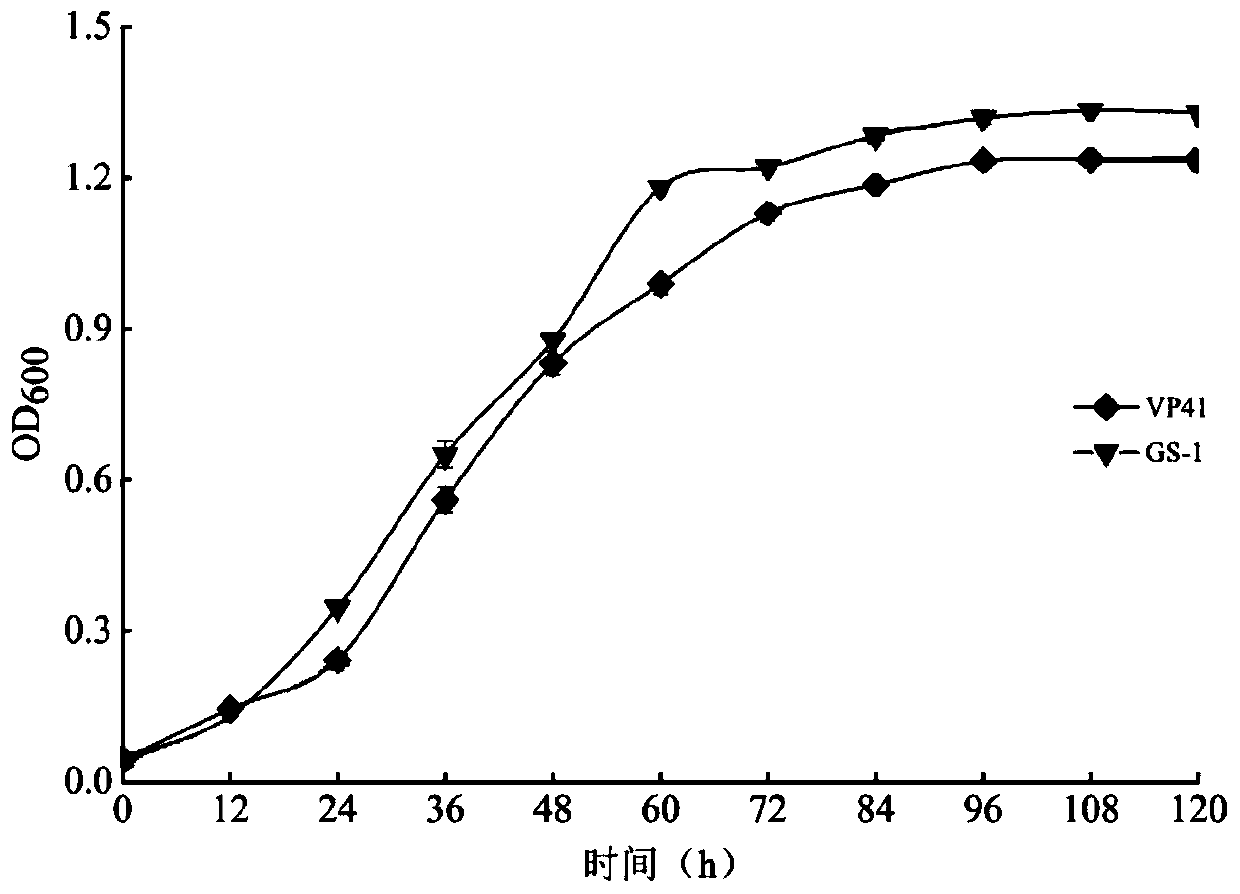

The invention discloses a malic acid-lactic acid fermentation strain for grape wine and an application thereof. The malic acid-lactic acid fermentation strain is classified and named as Oenococcus oeni (O.Oeni) GS-1, is preserved in China General Microbiological Culture Collection Center (CGMCC), and has a preservation number of CGMCC 18682 and a preservation date of October 14, 2019. The Oenococcus oeni (O. Oeni) GS-1 is inoculated into a grape wine sample after alcoholic fermentation is finished; fermentation can be started within 24 h under a condition that a fermentation temperature is 18-20 DEG C; and malic acid-lactic acid fermentation is completed within 9-10 d. Meanwhile, the Oenococcus oeni (O. Oeni) GS-1 has strong deacidification ability and excellent fermentation performance, can significantly improve the total amount of aroma compounds in a fermented wine sample, enriches flavor composition, brews dry red wine with typical style, and has good economic benefits and application prospects.

Owner:GANSU AGRI UNIV

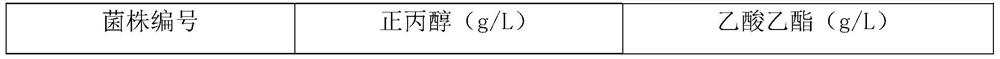

Kluyveromyces marxianus with low yield of n-propanol and application thereof in Fen-flavor Xiaoqu liquor

ActiveCN113278536ALong-term useReduce n-propanol contentFungiAlcoholic beverage preparationBiotechnologyPropanol

The invention discloses a low-yield n-propanol yeast, which is classified and named as Kluyveromyces marxianus Y245, is preserved in the China Center for Type Culture Collection on March 15, 2021, and has the preservation number of CCTCC NO: M2021225. The yeast is applied to production of fen-flavor Xiaoqu raw wine, the content of n-propanol in a wine body is reduced by 39.85% compared with that of a production control group, and the produced Xiaoqu raw wine is pure in fen-flavor, refreshing and clean in mouth, harmonious in fragrance and typical in style.

Owner:JING BRAND

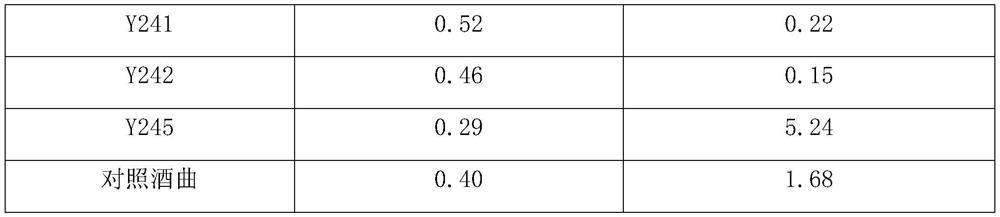

Method for reducing content of ethyl acetate in strong aromatic wine under mechanized production conditions

PendingCN111763588AHigh yieldReduce generationAlcoholic beverage preparationCellar toolsBiotechnologyWarm water

The invention discloses a method for reducing the content of ethyl acetate in strong aromatic wine under mechanized production conditions. The method comprises the steps of starting to pump yellow water five days before taking out of a cellar, taking 9900-12000 parts of hawthorn fermented grains in the cellar, mixing 2700-3300 parts of crushed unprocessed grains, adding warm water, uniformly stirring the warm water, adding 720-780 parts of steamed rice husk, and uniformly stirring the rice husk to obtain large hawthorn grains; adding 30-60 parts of steamed rice husk into 2000-2200 parts of fermented grains obtained after fermentation, and uniformly stirring the steamed rice husk to obtain double-round grains; firstly adding 50-100 parts of tail wine into a steaming bucket, then scatteringa small amount of steamed rice hulls at the bottom of the steaming bucket, and then putting large hawthorn grains or double-wheel grains into the steaming bucket; carrying out liquor steaming on the loaded large hawthorn grains so that the liquor steaming steam pressure is 4-10 Kpa and the liquor flowing speed is 3-4 Kg / min, removing the head and the tail, picking liquor according to the quality,and picking strong-aroma large hawthorn raw liquor; and steaming the loaded double-round grains, and performing picking to obtain the strong-flavor double-round raw wine. The ethyl acetate content ofthe raw wine is reduced to 400 mg / l or below, the superior product rate of the strong aromatic wine is increased by 15% or above, the cellar aroma is prominent, the wine tastes mellow, sweet and full,the aftertaste is fresh and clean, and the style is typical.

Owner:山东景芝白酒有限公司

Flavoring spirit preparation process

ActiveCN102382744ASimple production processReduce investmentAlcoholic beverage preparationFood flavorImpurity

A flavoring spirit preparation process belongs to the technical field of spirit brewing. The preparation process is characterized in that baked sesames are added in high-quality flavor five-grain base spirit, wherein the weight percent of the sesames in the spirit is 0.3-0.7%, then the mixture is placed in a pottery jar to be stored in seal, and is preserved in an underground storehouse for 15-20months; and the preparation process comprises: (1) selecting high-quality flavor spirit, (2) choosing high-quality sesames, (3) removing impurities, (4) drying, (5) soaking, (6) inspecting and entering a warehouse, and obtaining sesame-flavor white spirit. The white spirit preparation process of the invention is simple and easy to practice, is small on equipment input, is short in period, and is low in production cost, the quality of white spirit produced by the invention is stable, the color of the spirit is golden yellow, clear and transparent, and white spirit produced by the invention hascomfortable sesame smell, has imported liquor taste, is pure and long on after taste of sesame, is typical on sesame flavor, and can satisfy the requirement on high-grade spirit product in market.

Owner:GUBEICHUN GROUP

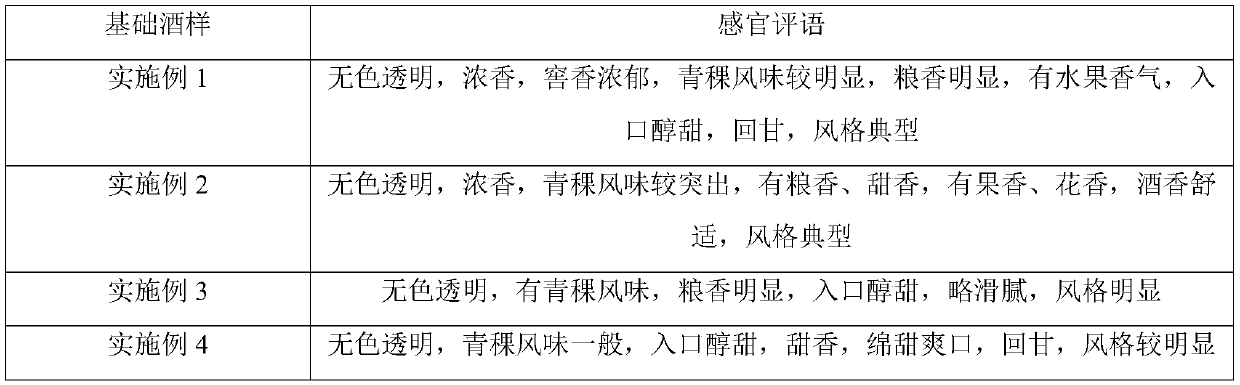

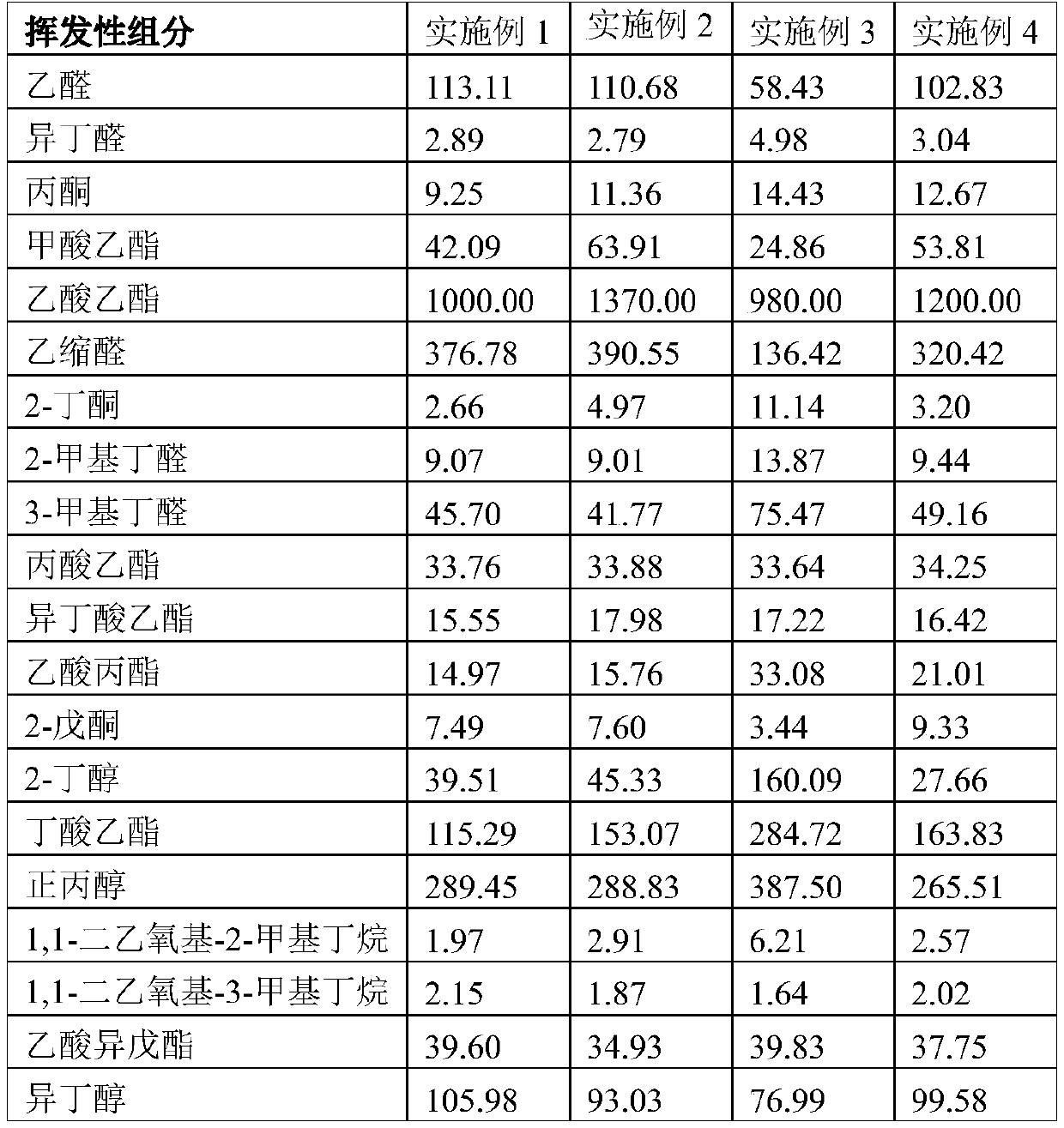

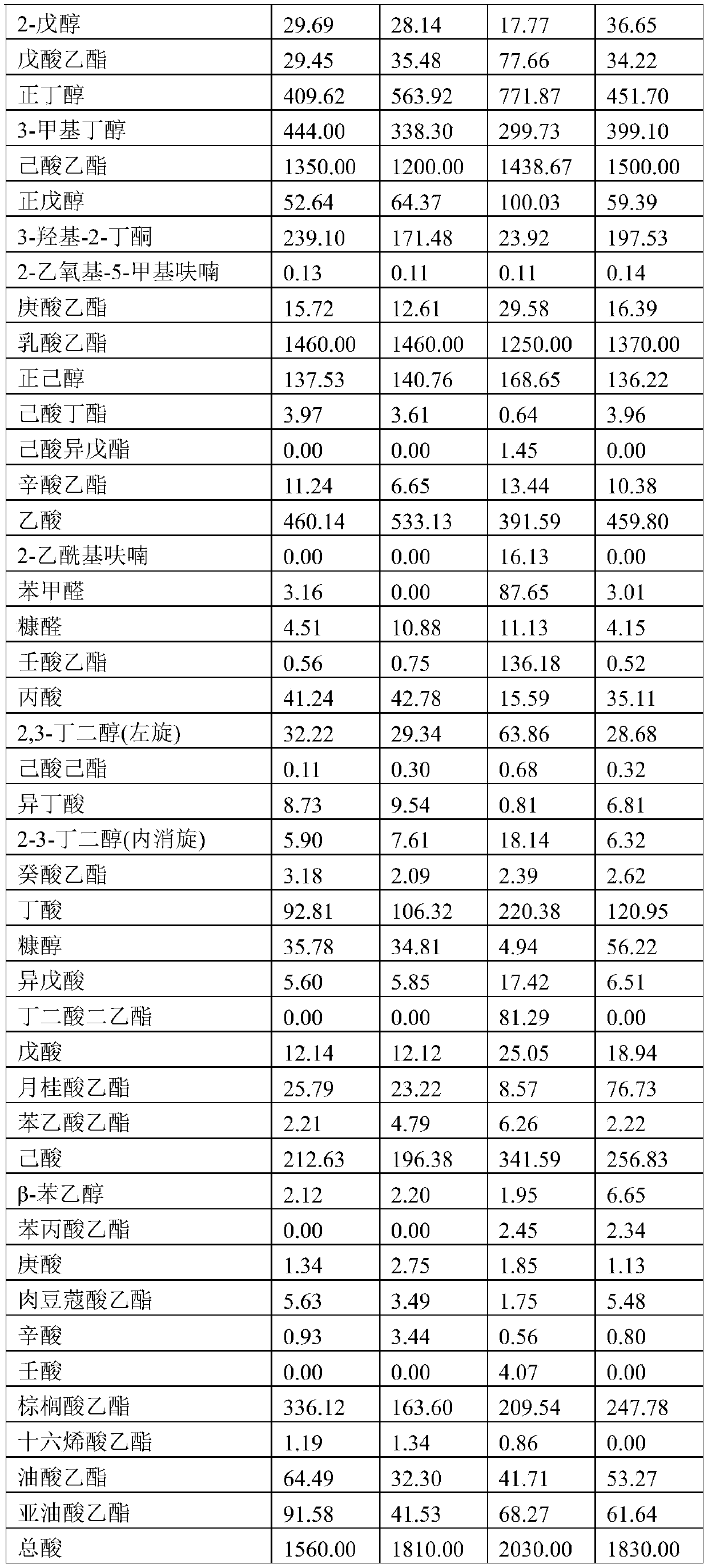

Luzhou-flavor highland barley wine and brewing method thereof

PendingCN110777034AImprove comfortIncrease sweetnessAlcoholic beverage preparationBiotechnologyYield (wine)

The invention belongs to the technical field of wine brewing and specifically relates to luzhou-flavor highland barley wine and a brewing method thereof. The technical problems to be solved are to provide the luzhou-flavor highland barley wine and the brewing method thereof. The brewing method includes the following steps: (1) uniformly mixing highland barley powder and sorghum flour to obtain wine-brewing raw grain, and adding water to moisturize materials; (2) mixing the moisturized raw grain with wine-brewing maternal fermented grains and steamed bran shells, performing steamer filling anddistillation, and obtaining fermented grains after steaming; (3) supplementing water into the fermented grains, adding Daqu after air drying, and obtaining luzhou-flavor highland barley fermented grains through pit entry fermentation; and (4) stirring the moisturized raw grain and the steamed bran shells into the luzhou-flavor highland barley fermented grains, performing distillation, collecting wine liquid, and obtaining the luzhou-flavor highland barley wine. The method is simple in brewing process, short in fermentation period, high in starch utilization, high in wine yield and low in production cost; and the prepared luzhou-flavor highland barley wine is typical in luzhou-flavor style, obvious in grain fragrance, pleasant in fruit fragrance, mellow and sweet in mouth-feel, comfortablein wine fragrance and sweet after taste.

Owner:LUZHOU PINCHUANG TECH CO LTD

Low Fusel Oil Yield Yeast and Its Application in Mechanized Production of Xiaoqu Liquor

ActiveCN107012103BThe entrance is sweetFragrance coordinationFungiAlcoholic beverage preparationBiotechnologyFusel alcohol

The invention discloses a strain of low-yield fusel oil yeast, which is classified as Saccharomyces cerevisiae Y25 and is preserved in the China Center for Type Culture Collection with a preservation date of February 20, 2017 and a preservation number of CCTCC NO: M2017049 ; The yeast is used in the production of mechanized Xiaoqu original wine, the content of fusel oil in it is reduced by 20.12% compared with the traditional method, and the produced Xiaoqu original wine has a pure fragrance, a soft and sweet taste, a harmonious aroma, a clean and refreshing finish, and a typical style.

Owner:JING BRAND

Malolactic fermentation (MLF) lactic acid bacteria strain with high yield of esterase and application thereof

ActiveCN111662838AIncrease expansionIncrease the fragranceBacteriaMicroorganism based processesBiotechnologyGrape wine

The invention discloses a malolactic fermentation (MLF) lactic acid bacteria strain with high yield of esterase and application thereof. The strain is classified and named as Oenococcus oeni (O.oeni)GS-2 collected in the China General Microbiological Culture Collection center (CGMCC) on October 14, 2019 with the collection number of CGMCC 18683. A grape wine sample is inoculated with the O.oeni GS-2 after alcohol fermentation is finished; and MLF can be completed within 12-14 d under the condition that the fermentation temperature is 18-20 DEG C, the fermentation perofrmnace is excellent, thetotal amount of ester aroma compounds in the fermented wine sample can be remarkably increased, the fruit aroma is improved, dry red wine with a typical style is brewed, and good economic benefits and application prespects are achieved.

Owner:GANSU AGRI UNIV

Preparation method of coconut wine

InactiveCN103666916ARealize comprehensive utilizationGood bouquetAlcoholic beverage preparationMicroorganism based processesEconomic benefitsCoconut Flavor

The invention discloses a preparation method of coconut wine. The preparation method is characterized by comprising the processing technological procedures of taking fresh fruit, juicing, mixing sugar acid, sterilizing, inoculating, fermenting, freezing, removing sediment, blending with brandy, bottling, checking, and finishing. The product is clear and glossy, can produce fine and smooth bubbles when injected in a cup, has good wine aroma and coconut flavor, and is mellow and normal in taste, cool, tasty and refreshing, and classic in style. The preparation method implements comprehensive utilization of the coconut raw material; the product is deeply popular with consumers; the better economic benefits can be achieved.

Owner:周瑞保

Method for preparing intensified daqu applied to nongjiang-flavor Chinese spirits

ActiveCN102140427BGood aroma productionStrong aromaBacteriaMicroorganism based processesBrewingChemistry

The invention relates to a method for preparing intensified daqu applied to nongjiang-flavor Chinese spirits from Bacillus thermophilus. The intensified daqu prepared by the method is high in fermentation speed, is added into a finished high-temperature starter for production, is used for brewing traditional Chinese spirits, can reduce the starter consumption in production, effectively solves theproblem that fermented grains stacked in winter are difficult to heat, improves the spirit yield and premium quality good rate on the premise of keeping the flavor of the original spirits, can save massive brewing and fermentation equipment, manpower, field and energy, and has high use value.

Owner:湖北白云边酒业股份有限公司

A kind of method of biological enzyme brewing camellia oleifera wine

ActiveCN103981054BRaw materials are uniqueWith aromaAlcoholic beverage preparationMicroorganism based processesCamellia oleiferaDistillation

The invention discloses a method for brewing an oil-tea wine by using bio-enzymes. The method comprises the following steps: (1) cleaning and impurity removal; (2) crushing and sieving; (3) mixing; (4) high-temperature enzyme deactivation; (5) multi-enzyme decomposition; (6) carbohydrate supplementation; (7) fermentation; (8) distillation; and (9) aging and packaging. The method disclosed by the invention is simple in process, less in investment, low in energy consumption, and easy to operate. The oil-tea wine prepared by using the method is bright and transparent, mellow and exquisite in taste and typical in style, and has no suspended matters and precipitates.

Owner:HUNAN ACAD OF FORESTRY

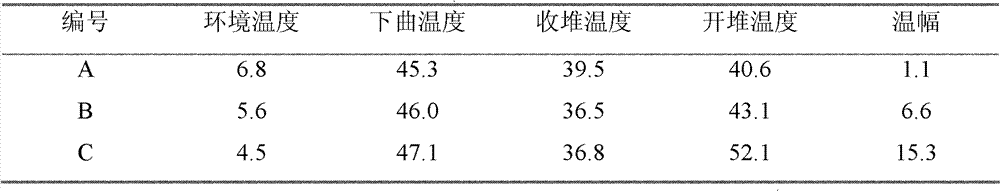

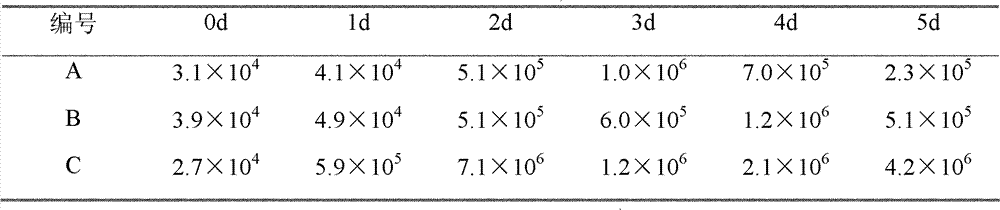

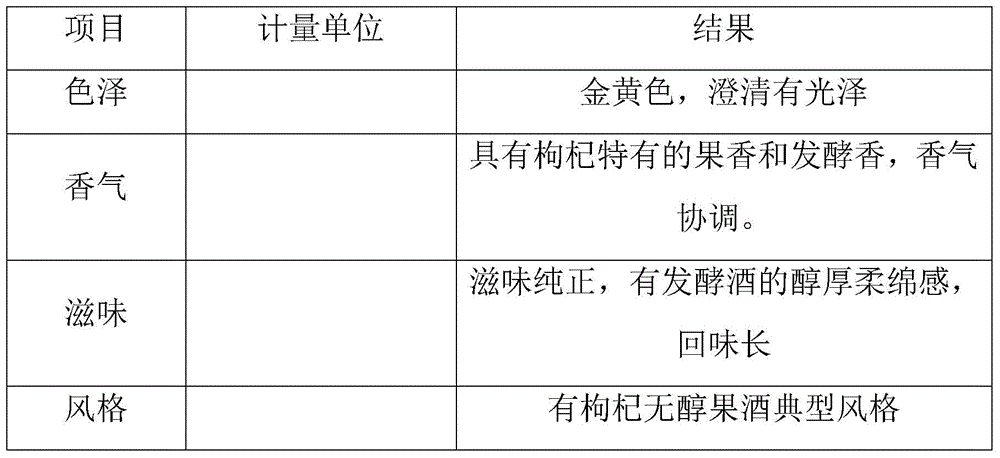

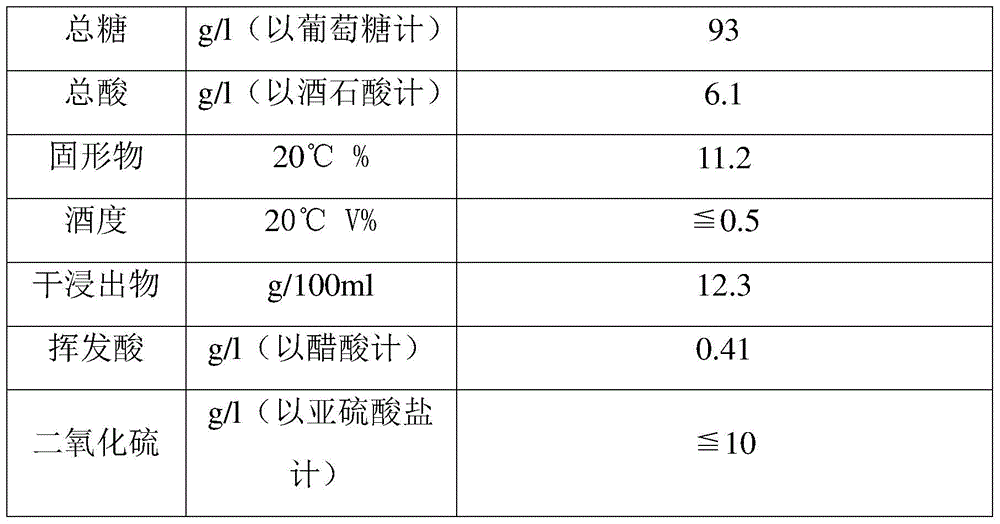

A kind of production technology of non-alcoholic wolfberry fruit wine

The invention relates to a production technology of alcohol-free wolfberry fruit wine. The technology comprises the following steps: choosing dry wolfberry fruits as a raw material, cleaning, rehydrating, crushing, extracting to obtain an extract juice, carrying out enzyme treatment, adjusting components, and carrying out low temperature fermentation, or choosing fresh wolfberry fruits as a raw material, cleaning, crushing, dipping, carrying out enzymatic hydrolysis, adjusting components, and carrying out peel-containing low temperature fermentation; and separating when the alcohol degree reaches 3-7% and the sugar content is 60-80g / l in order to remove wine lees or peel residues, filtering the obtained wolfberry fruit wine to remove yeast in order to stop fermentation, ageing, carrying out vacuum rotary evaporation to remove alcohol in order to make the alcohol degree smaller than 0.5%, blending the alcohol-removed fruit wine, and filtering to obtain the alcohol-free wolfberry fruit wine. The technology reserves the original nutrition of the fruit juice, gives a certain fermentation flavor by using a biological technique, controls the alcohol-free wolfberry fruit wine to be a fruit juice beverage with a low ethanol content, and provides rich various nutritional components in the wolfberry fruit for people.

Owner:曹广江

Flavoring spirit preparation process

ActiveCN102382744BSimple production processReduce investmentAlcoholic beverage preparationFood flavorImpurity

Owner:GUBEICHUN GROUP

Method for producing acerbity-removing persimmon wine

ActiveCN101215498BReduce astringencyTypical styleMicroorganism based processesAlcoholic beverage preparationAlcoholAdditive ingredient

The invention discloses a production method for persimmon wine to remove acerbity, which comprises the following procedures: (1) selecting fruits, cleaning and beating; (2) protecting the color; (3) enzymolysising; (4) removing acerbity and clarifying; (5) adjusting ingredient; (6) fermenting; (7) ageing; (8) filtering, filling in bottles and sterilizing; (9) stocking, wherein removing acerbity and clarifying is completed via charging 0.3-0.6g gelatin into one kilogram persimmon juice, standing for 30-40 minutes, clarifying and filtering. The invention protects the color of persimmon juice and reduces oxidation by adding ascorbic acid and citrate, applies gelatin to remove acerbity and clarify, which can effectively remove acerbity and suspended granules in persimmon juice and enable persimmon wine without acerbity and to be easily clarified,) and employs brewing dry yeast to ferment at higher temperature, which has short ferment period. The persimmon wine is clear, transparent, lucidus and free of sediment, which has typical style, good taste, pure flavour, coordinated alcohol and acerbity, full wine body, tasty, good aftertaste, no objectionable odour, fresh persimmon flavour and wine flavour.

Owner:ZHONGKAI UNIV OF AGRI & ENG

A kind of wine malic acid-lactic acid fermentation strain and application thereof

ActiveCN111205996BTypical styleStrong acid-reducing abilityBacteriaMicroorganism based processesBiotechnologyMicroorganism

Owner:GANSU AGRI UNIV

A kind of esterase-producing malic acid-lactic acid fermentation lactic acid bacteria strain and application thereof

ActiveCN111662838BIncrease expansionIncrease the fragranceBacteriaMicroorganism based processesLactobacillusMicroorganism

The invention discloses an esterase-producing malic-lactic-acid-fermenting lactic acid bacteria strain and its application, which is classified as Oenococcus oeni (O.oeni) GS-2, and is preserved in China Microbiological Cultures Preservation Management Committee Common Microorganisms Center, the preservation number is: CGMCC 18683, and the preservation date is October 14, 2019. The Oenococcus oeni (O.oeni) GS-2 of the present invention is inoculated in the wine sample after the alcoholic fermentation ends, and the fermentation temperature is Under the condition of 18-20℃, malo-lactic acid fermentation can be completed in 12-14 days, and the fermentation performance is excellent, which can significantly increase the total amount of ester aroma compounds in the fermented wine sample, enhance the fruit aroma, and brew a typical style of dry red wine , has good economic benefits and application prospects.

Owner:GANSU AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com