Method for producing white spirit

A production method and liquor technology, applied in the field of liquor production, can solve the problems of long fermentation period, large amount of koji used, large saccharification site, etc., and achieve the effect of harmonizing liquor body and increasing the refreshing sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

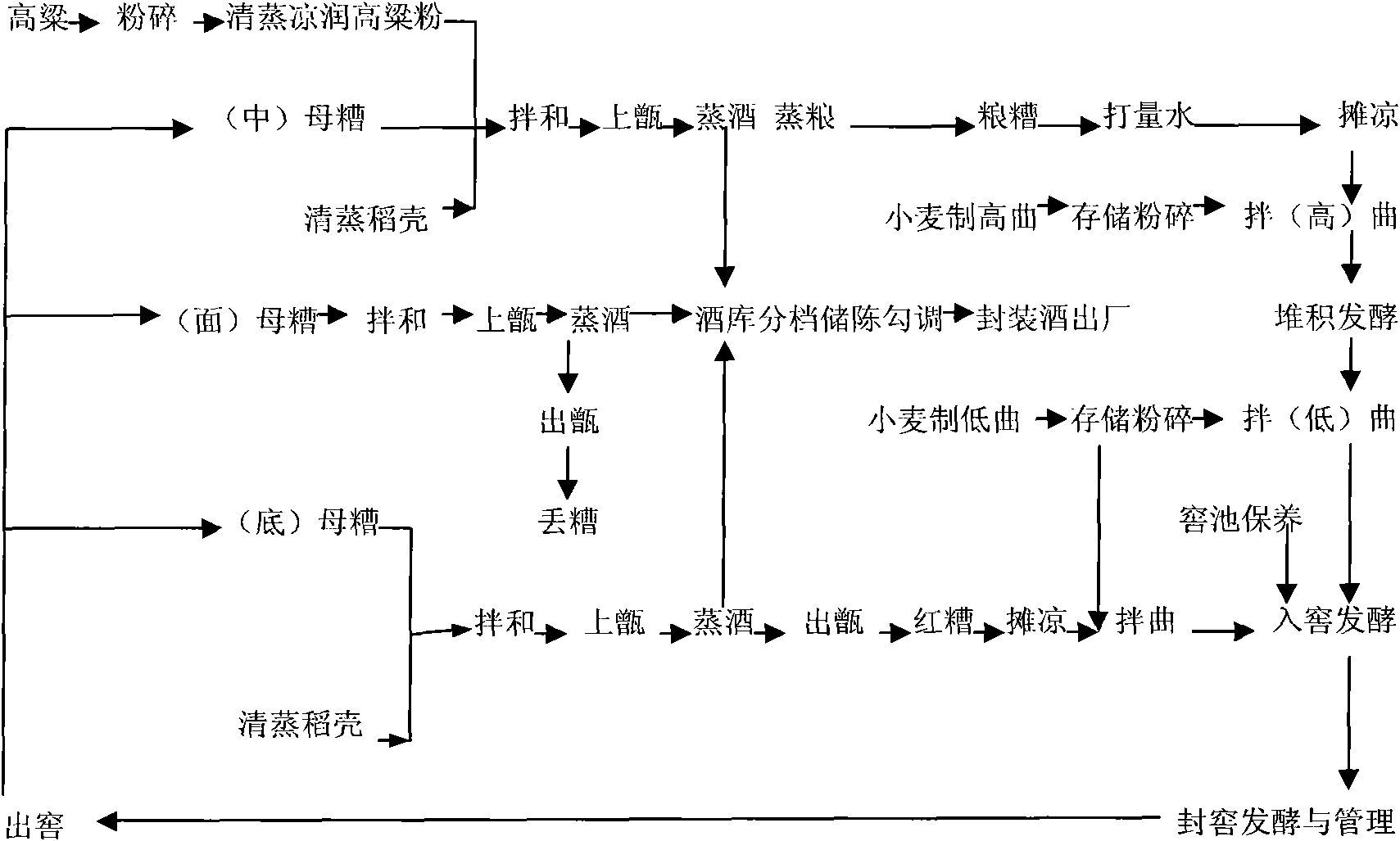

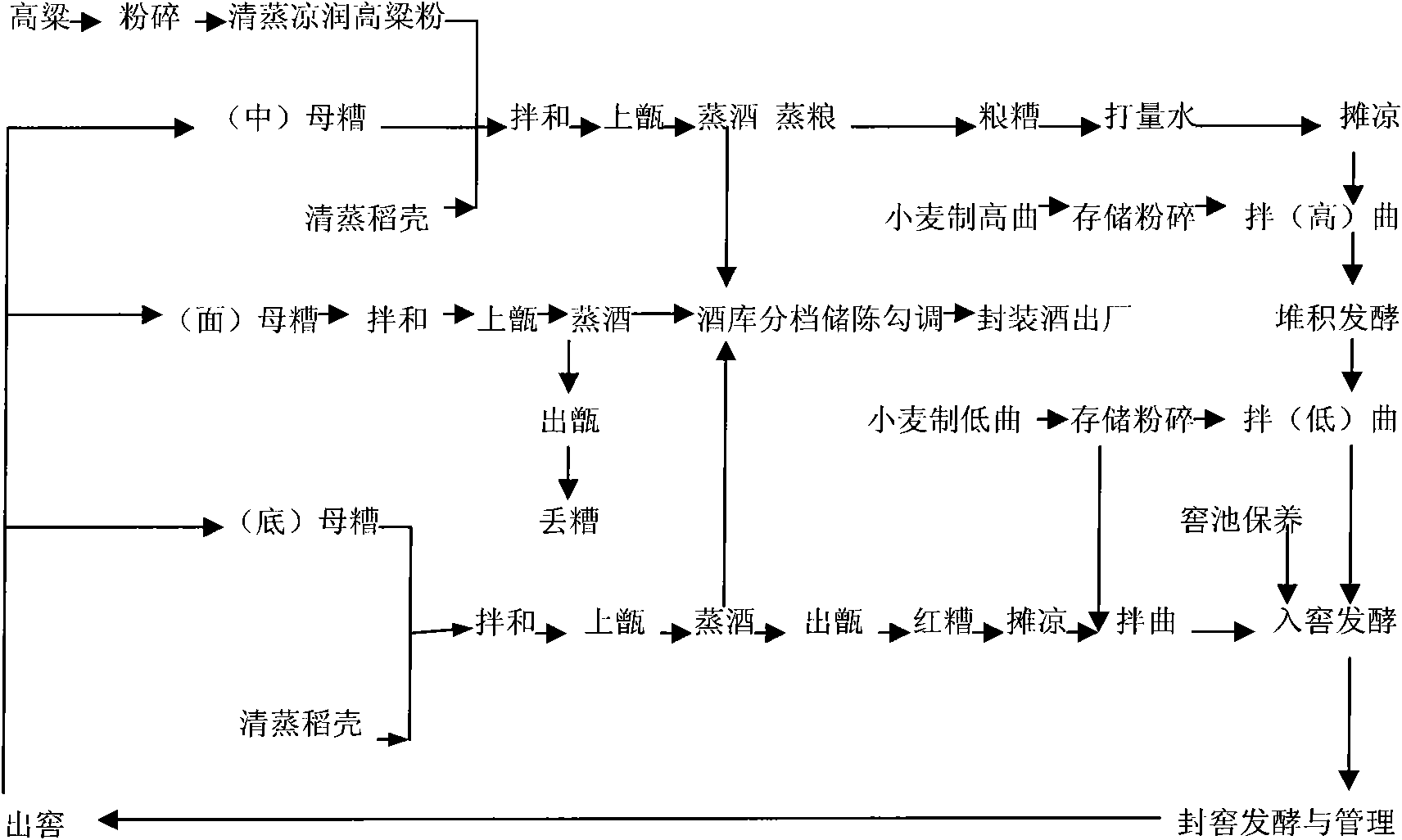

Method used

Image

Examples

Embodiment Construction

[0032] Production method of liquor:

[0033] 1. Requirements and processing of raw and auxiliary materials

[0034] The green sorghum (rice) for brewing this wine requires full grains, no mildew, no insects, no pesticide residues, impurity content below 1.5%, moisture ≤ 15%, starch content ≥ 62%, broken particle size 4-8 petals, 40-mesh sieve fine powder ≤ 15%; to make it easy to gelatinize during cooking, and to increase the contact surface between grain powder and koji powder, etc., to create good conditions for saccharification and fermentation.

[0035] Pre-steaming and moistening of sorghum (rice) ingredients: pre-steam sorghum (rice) for about 30 minutes until the steam has no peculiar smell; , respectively add 80-100 ℃ hot water to moisten the material, the amount of water depends on the water content of the wine grains, generally 60-80kg of water is added to each pile.

[0036] Rice husk steaming: Rice husk must be thoroughly steamed before use, usually for more than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com