Method for storing Luzhou-flavor liquor

A technology of strong-flavor liquor and hops, which is applied in the field of winemaking, can solve the problems of insufficient aroma, few choices of wine body design, and few types of basic wine sources, and achieves typical style, rich wine body design choices, and excellent wine body. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

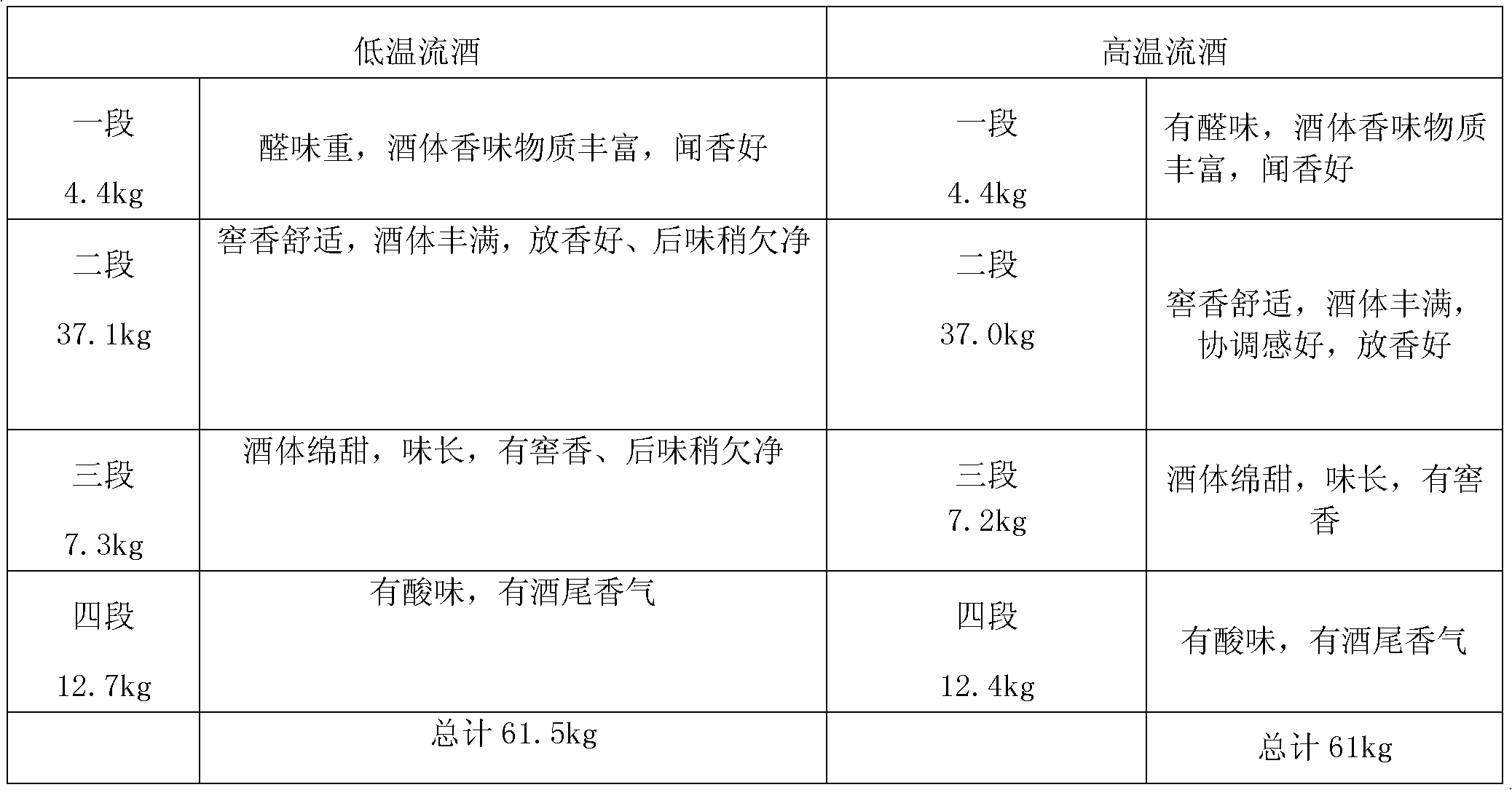

[0034] Embodiment one uses the method of the present invention to pick wine

[0035] 4.8M 3 The distiller's grains are evenly divided into 2 wine retorts for comparative experiments, and the conditions of the method are investigated:

[0036] (1) Take the wine at a lower temperature of the flowing wine:

[0037] a. Before distilling the wine, the water content of the distiller's grains should be controlled to 53% by means of ingredients. 3 , the air pressure of filling the retort is controlled at 0.03-0.035MPa, and the pressure of flowing wine is controlled at 0.02-0.25Mpa. Since the pressure will fluctuate, as long as it is within this range, the time of filling the retort is controlled at 45min, and the wine will start flowing 4 minutes after the plate is covered.

[0038] b. Take 4.4kg (equivalent to 60% vol) as a section of wine; the temperature is controlled at 25 degrees Celsius, and the aldehyde smell in the wine body is required to be removed. A large amount of alde...

Embodiment 2

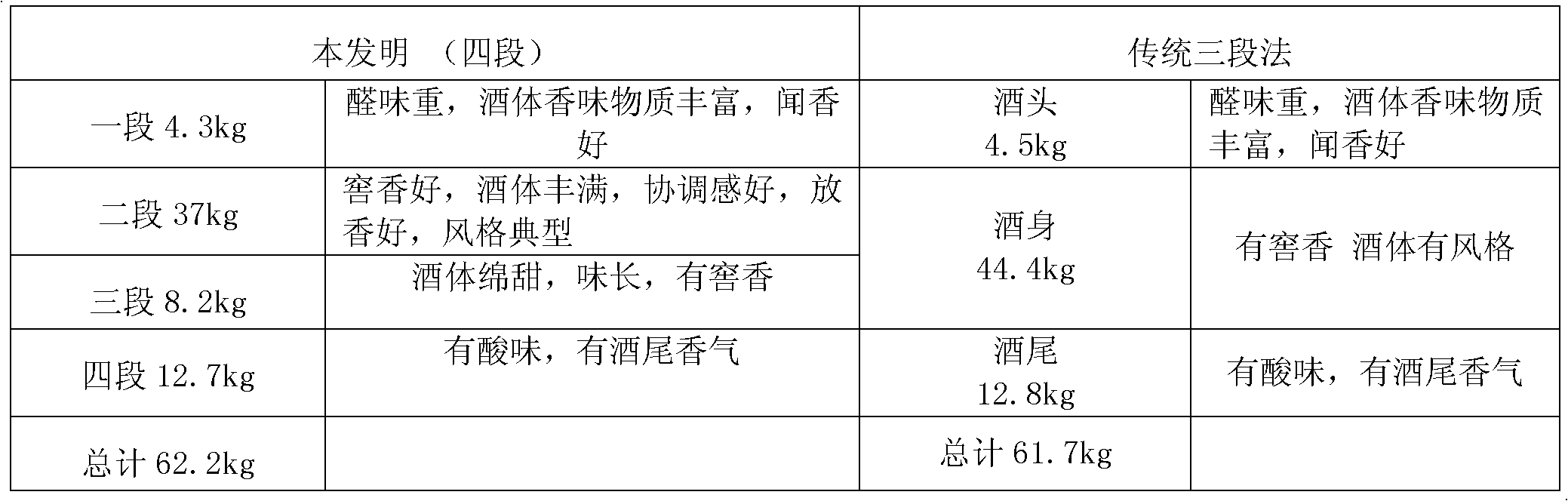

[0051] Embodiment two uses the method of the present invention to pick wine and contrasts with traditional method picking wine

[0052] 4.8M 3 The distiller's grains were evenly mixed and put into two wine retorts for comparative experiments. Except for the different number of wine harvesting stages, the rest of the conditions should be kept as consistent as possible.

[0053] (1) use the inventive method to pick wine

[0054] a. Before distilling the wine, the water content of the distiller's grains should be controlled to 53% by means of ingredients. 3 , the pressure of filling the retort is controlled at 0.03-0.035MPa, the pressure of flowing wine is controlled at 0.02-0.25Mpa, the time of filling the retort is controlled at 45min, and the wine starts to flow 4 minutes after the plate is covered.

[0055] b. Take 4.4kg (equivalent to 60% vol) as a section of wine; the temperature is controlled at 31 degrees Celsius, and the aldehyde smell in the wine body is required to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com