Luzhou-flavor highland barley wine and brewing method thereof

A technology of Luzhou-flavored highland barley wine, which is applied in the field of wine making, can solve the problems of high energy consumption and production cost, long cellar fermentation cycle, and large amount of moistening water, so as to shorten the fermentation cycle, improve starch utilization rate and output The effect of alcohol rate and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

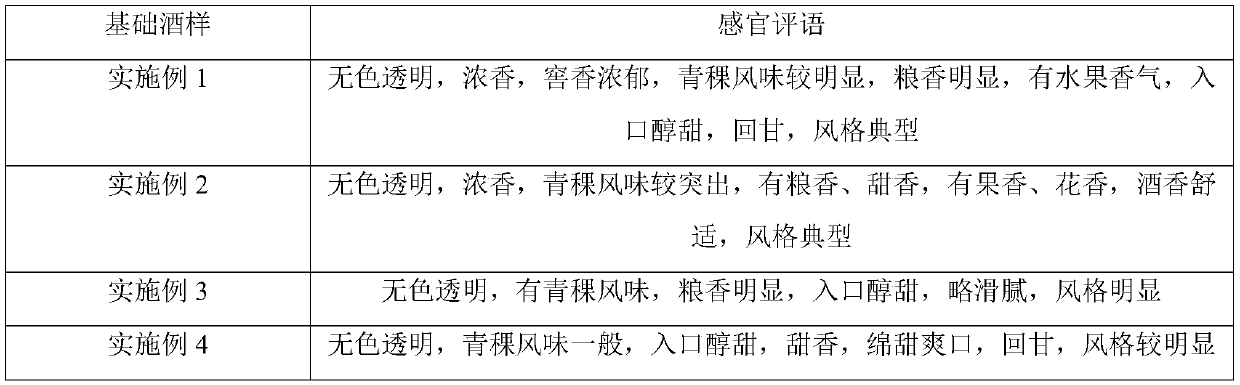

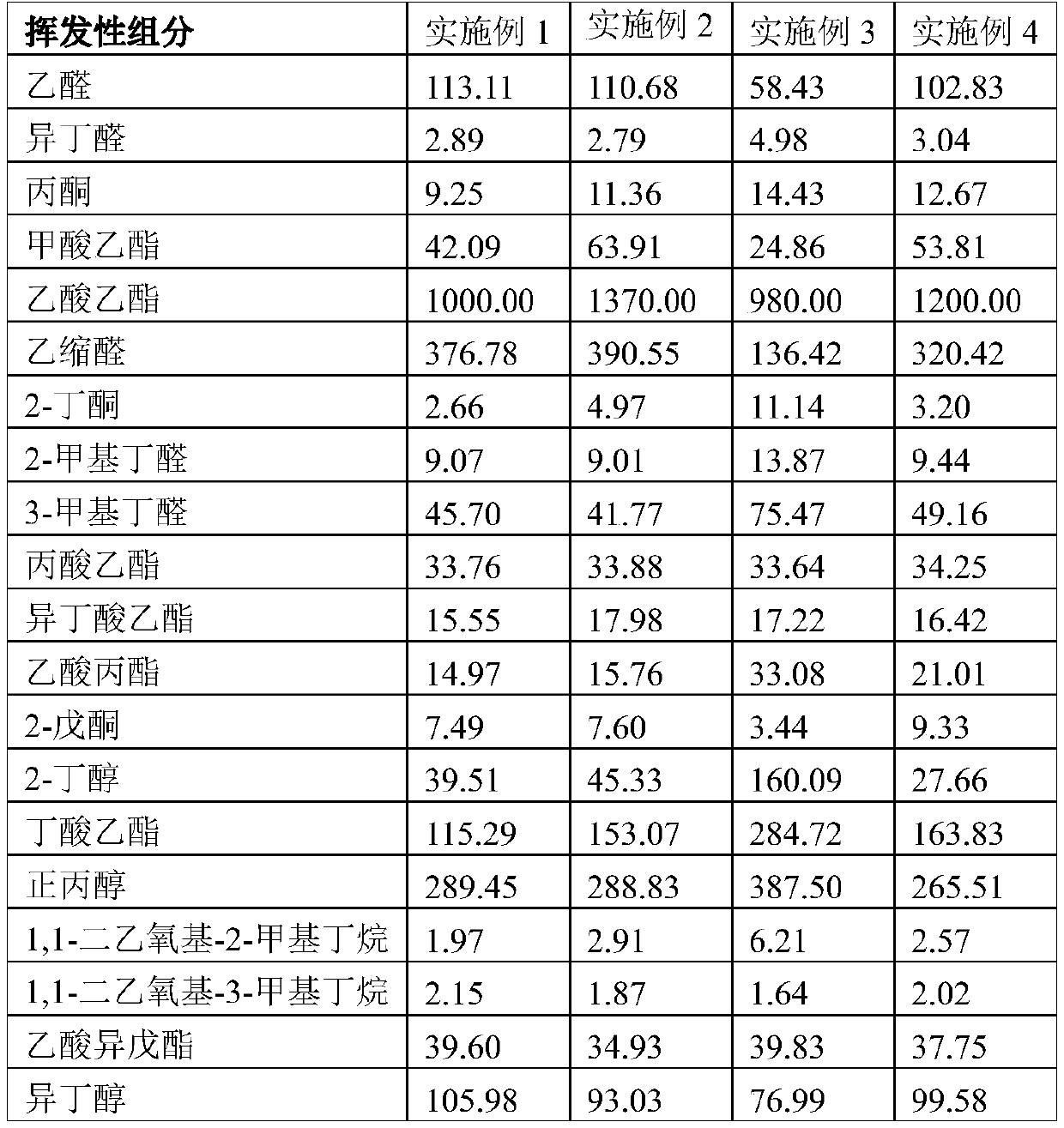

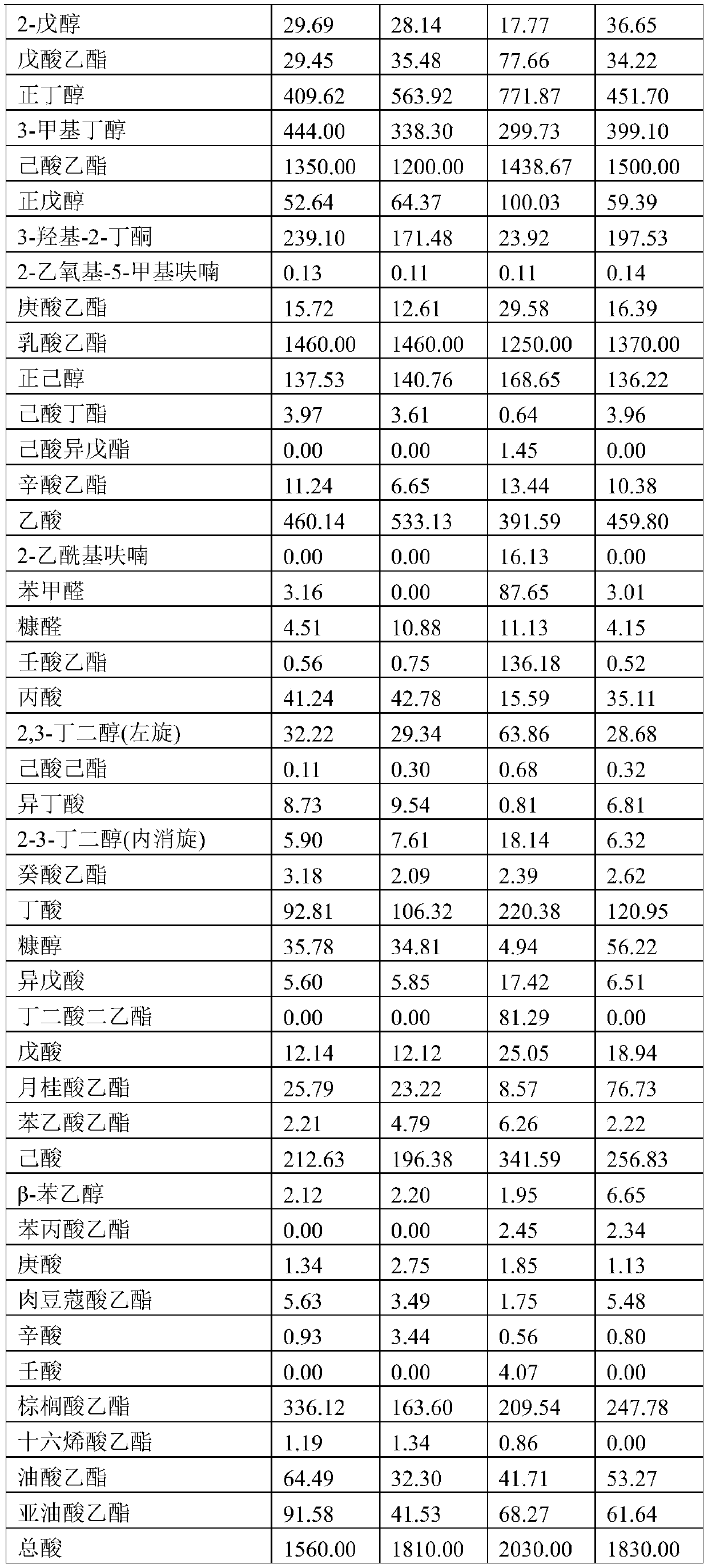

Examples

Embodiment 1

[0039] Grind 200kg of highland barley and 50kg of sorghum and mix them evenly to obtain the raw grain for brewing, then add 163kg of hot water at a temperature of 55°C, stir evenly, and pile up the moistening materials for 4 hours. Then, mix the moistened brewing grains with 500kg of grains and 100kg of bran husks evenly, put them in a retort and distill for 140 minutes, the temperature of the wine is 28°C, after the retort, add 100kg of hot water at a temperature of 60°C to the grains, and stir After uniformity, spread and air until the temperature of grain grains is 20°C, mix in 40kg of medium-high temperature Daqu, and put it into the cellar for fermentation for 60 days. That is to obtain Luzhou-flavor highland barley wine.

Embodiment 2

[0041]Grind 300kg of highland barley and 60kg of sorghum and mix them evenly to obtain the raw grain for brewing, then add 250kg of hot water at a temperature of 60°C, stir evenly, and pile up the moistening materials for 3.5 hours. Then, mix the moistened raw wine grains with 1000kg of grains and 90kg of bran husks evenly, put them in a retort and distill for 150min at a temperature of 25°C. After uniformity, spread out to the temperature of grain grains at 24°C, mix in 70kg of medium-high temperature Daqu, and ferment in cellars for 55 days. Control the fermentation temperature at 14-35°C. After fermentation, mix in raw wine grains and bran husks in proportion, and steam the wine in a retort That is to obtain Luzhou-flavor highland barley wine.

Embodiment 3

[0043] 150kg of highland barley and 150kg of sorghum were crushed and mixed evenly to obtain the raw grain for brewing, and then 180kg of hot water at a temperature of 70°C was added, mixed evenly, and the materials were piled up for 3.5 hours. Then, mix the moistened raw wine grains with 1350kg of grains and 105kg of bran husks evenly, put them in a retort and distill for 120min at a temperature of 35°C. After uniformity, spread out to the temperature of the grain grains at 18°C, mix in 50kg of medium-high temperature Daqu, and ferment in the cellar for 45 days. That is to obtain Luzhou-flavor highland barley wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com