Automatic drilling and milling machine for chain connecting pin shaft

A technology of automatic drilling and connecting pins, which is applied in the direction of metal processing machinery parts, clamping, supporting, etc., to ensure product quality, realize automation, and solve the effects of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

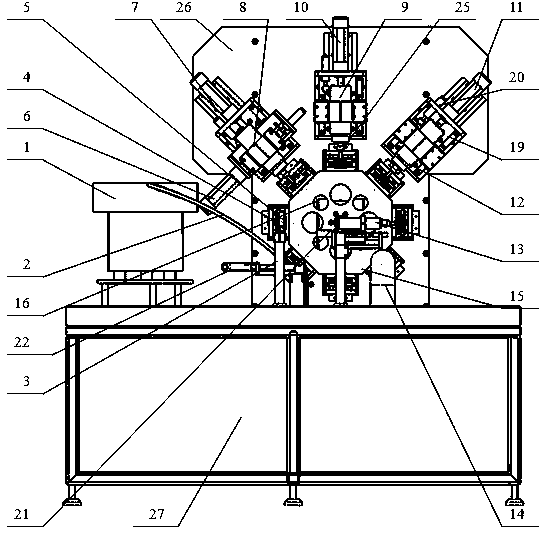

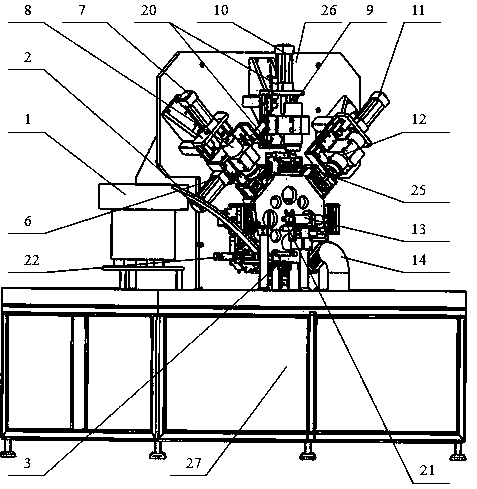

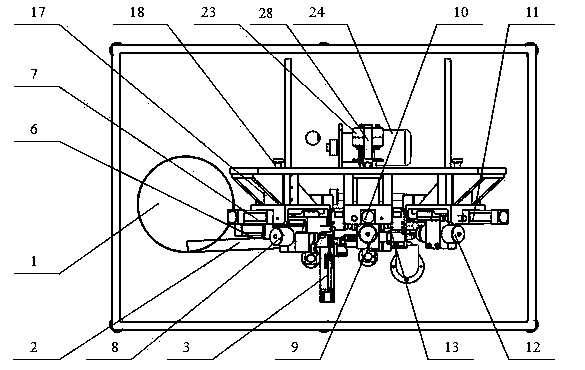

[0046] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0047]The present invention solves this problem very well, realizes the fully automatic production process of parts processing, and completes the parts that originally required a large number of manual operations and multiple processes to complete at one time, greatly improving production efficiency and product quality.

[0048] The specific working process of the technology of the present invention is: a vibrating plate installed on the left side of the equipment vibrates and arranges the pin shaft round rods to be processed into the feeding guide rail 2, and is separated by the material distribution mechanism 22 at the material inlet, and then is placed on the The material cylinder 3 is pushed into the facing clamping fixture 5, the octagonal station turntable 15 rotates with the precision cam divider 16 driven by the motor 23, and the bar material is driven to the nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com