Patents

Literature

34results about How to "Solve labor difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

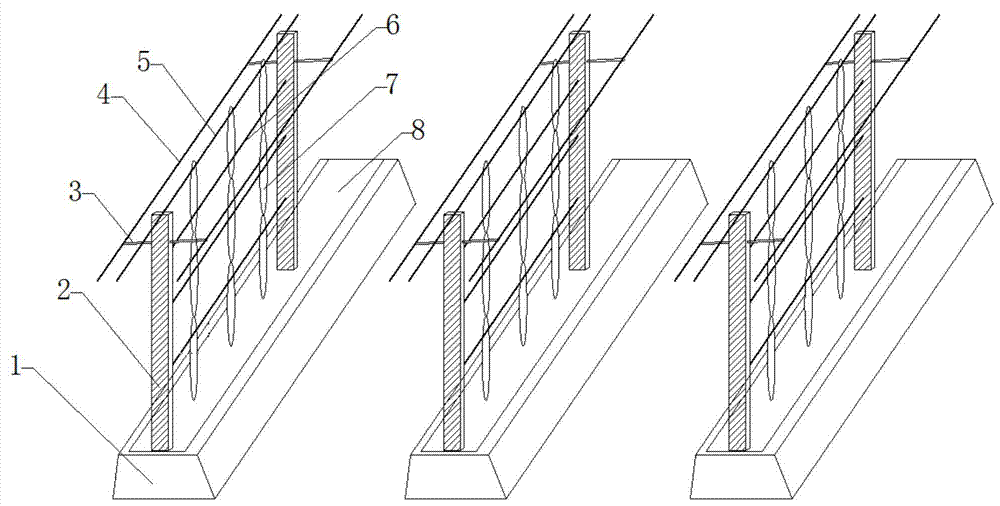

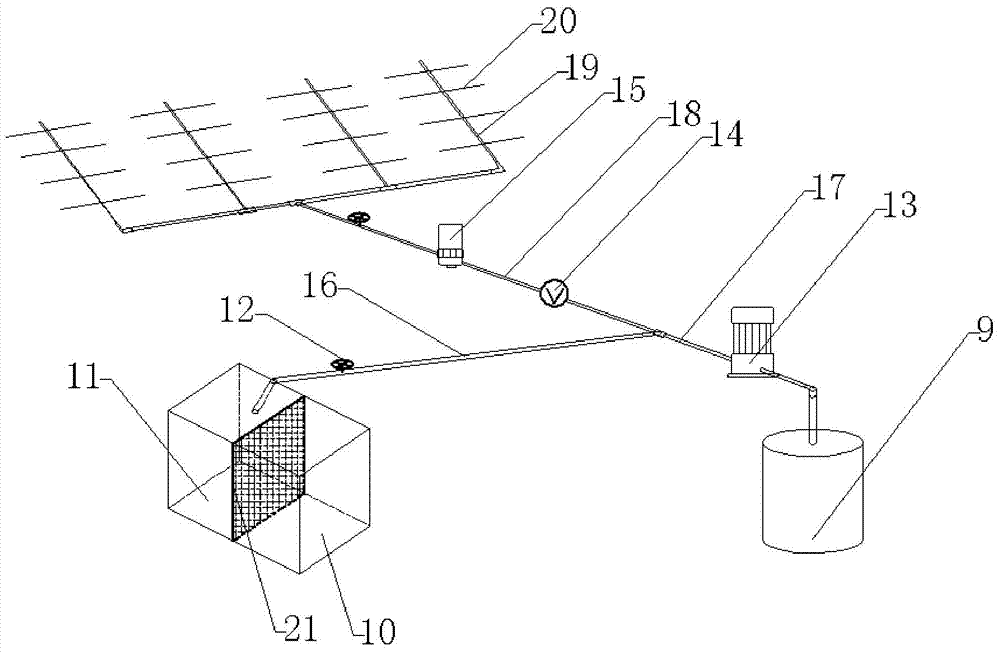

Pitaya high-quality and high-yield cultivation method adopting water and fertilizer integrated fertigation technology

InactiveCN104737743ALabor savingSolve labor difficultiesFertilising methodsHorticultureEchinocereus enneacanthusFrost

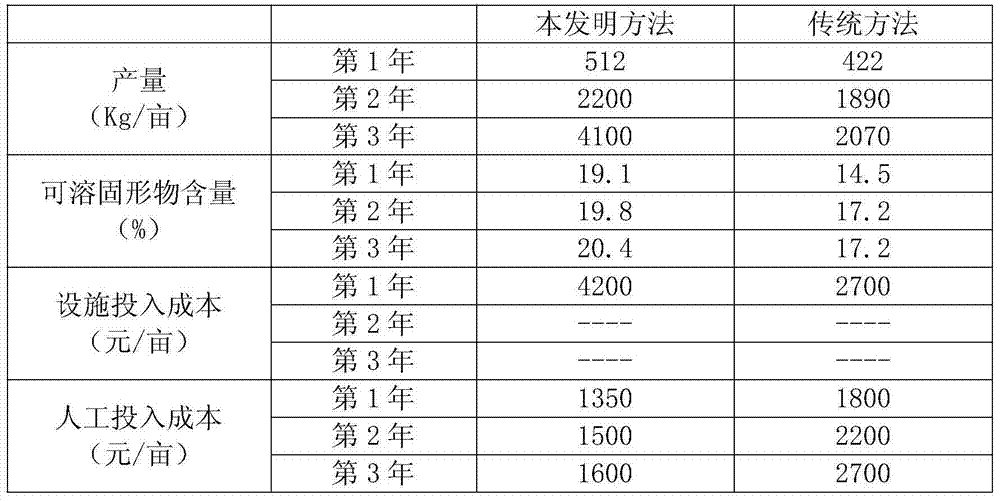

The invention discloses a pitaya high-quality and high-yield cultivation method adopting a water and fertilizer integrated fertigation technology. The method comprises the steps of screening of cultivated varieties, seedling cultivation, soil preparation, planting line and belt fabrication, bent frame building with stand columns, trickle irrigation system laying, plastic film mulching, seedling planting, irrigation, fertilization, trimming, clipping, flower thinning, fruit sorting, pest control, plastic film mulching for protection against frost and the like. According to the method, the pitaya variety of a self-pollination type is adopted as the cultivated variety, the fence planting mode and the fertigation technology are adopted, the investment in labor cost such as in pollination, weed control and fertilization is greatly saved, the lighting effect for pitaya is improved, the fertile fruit percentage is effectively raised, the fruit quality is effectively improved, the fertilizer using efficiency is raised to the maximum extent, the input-output cycle is short, the output is high, and the pitaya cultivation technology is worthy of being promoted widely.

Owner:GUANGXI JIN HONG GUO AGRI COMPREHENSIVE DEV CO LTD

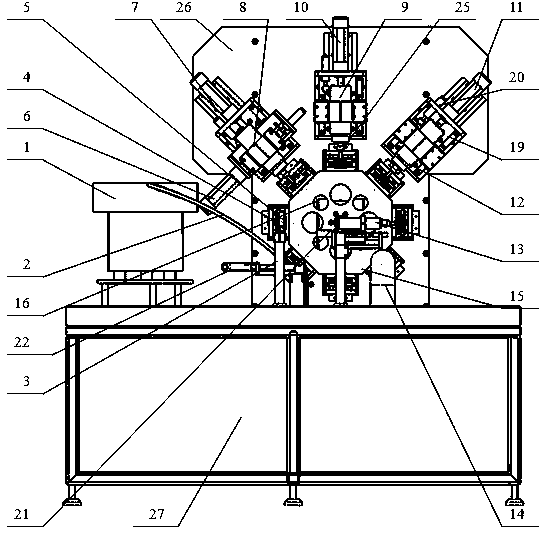

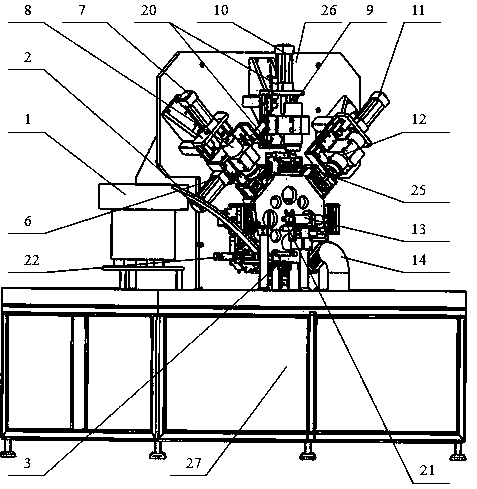

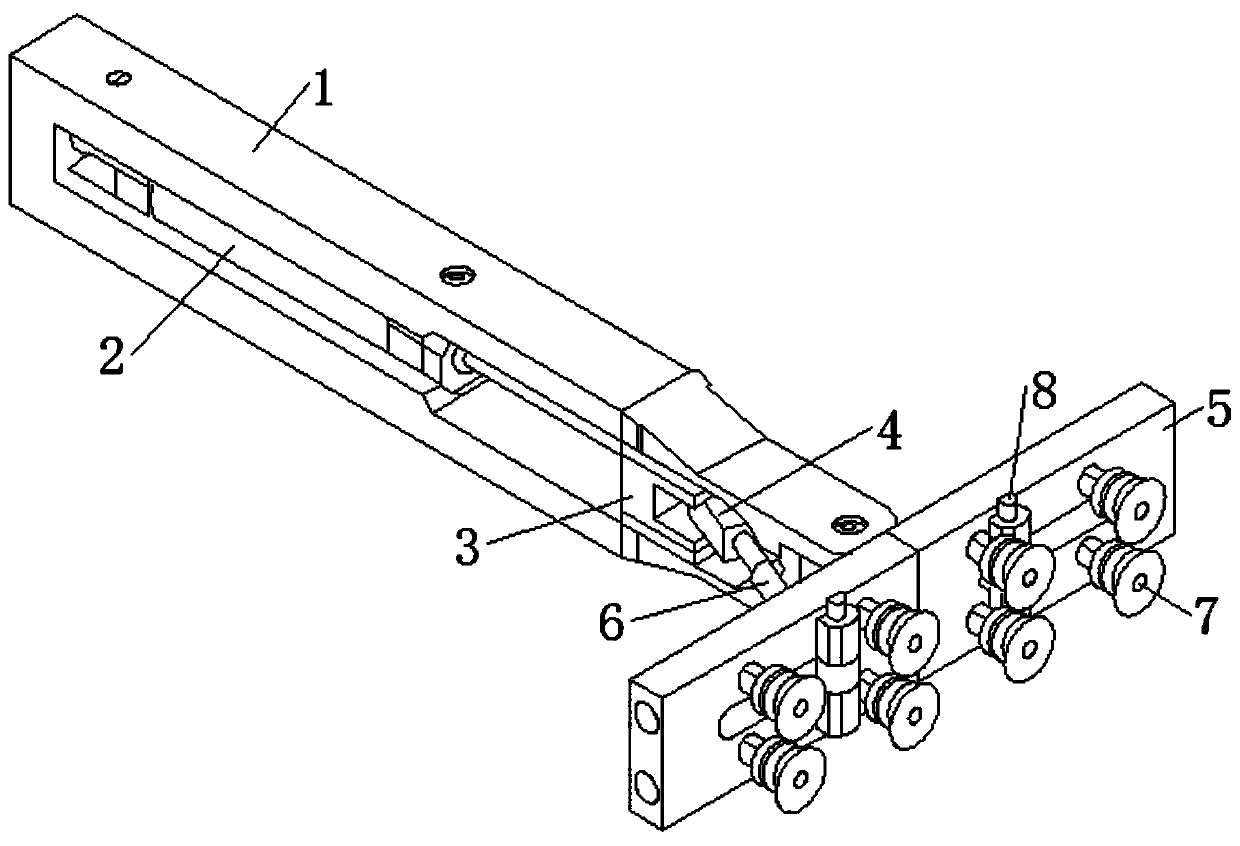

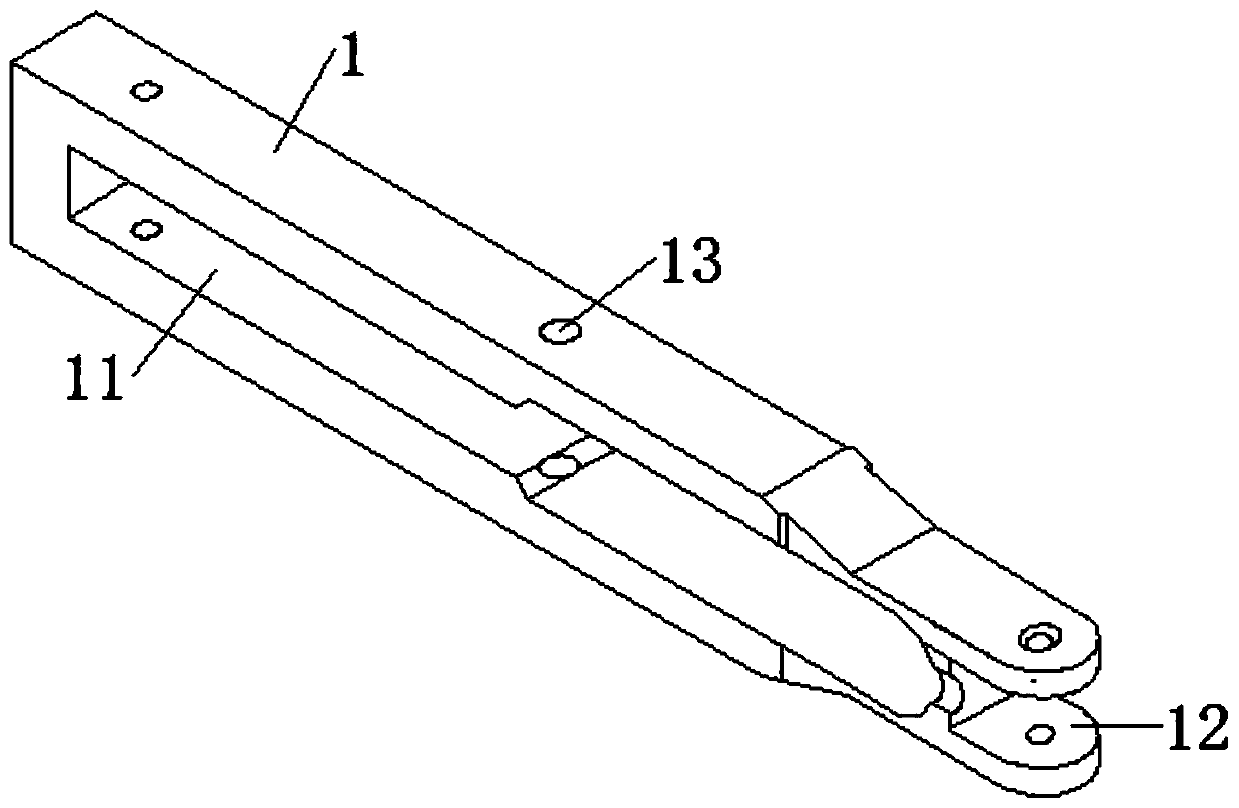

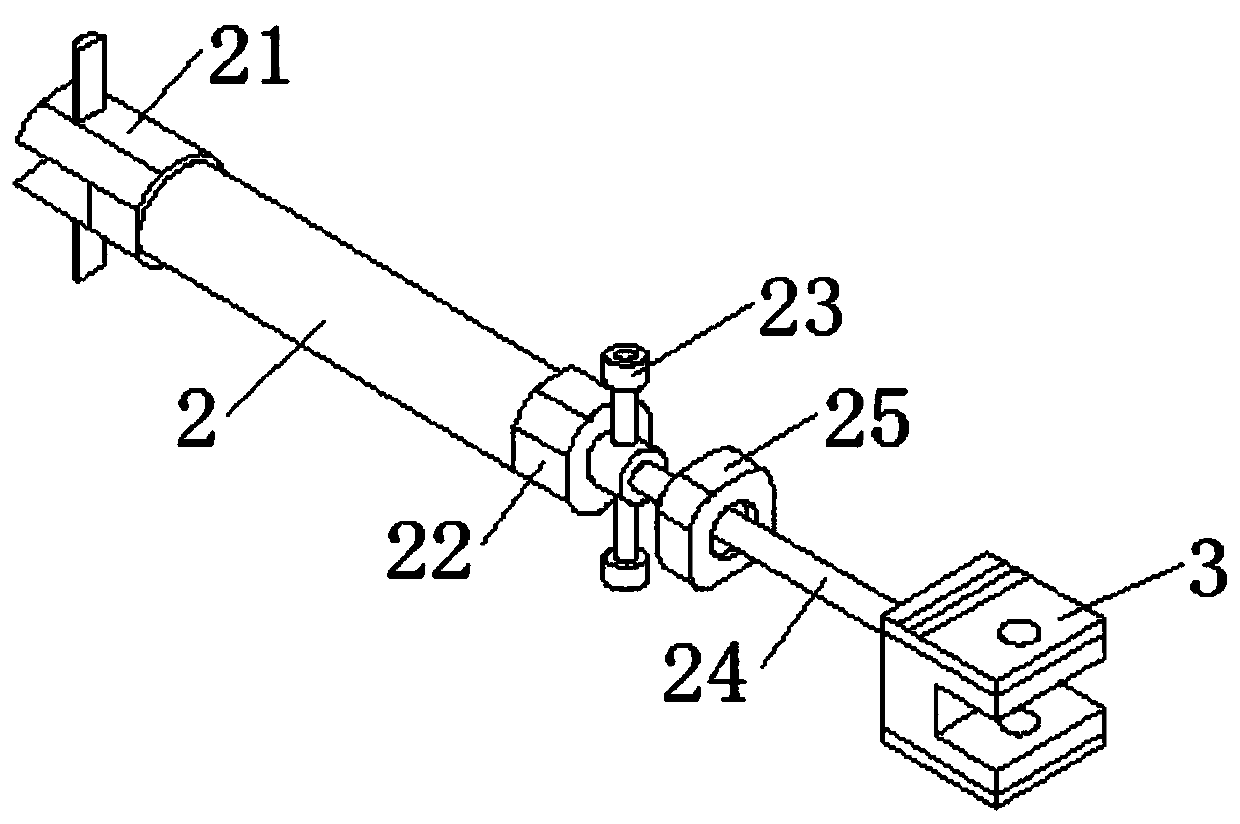

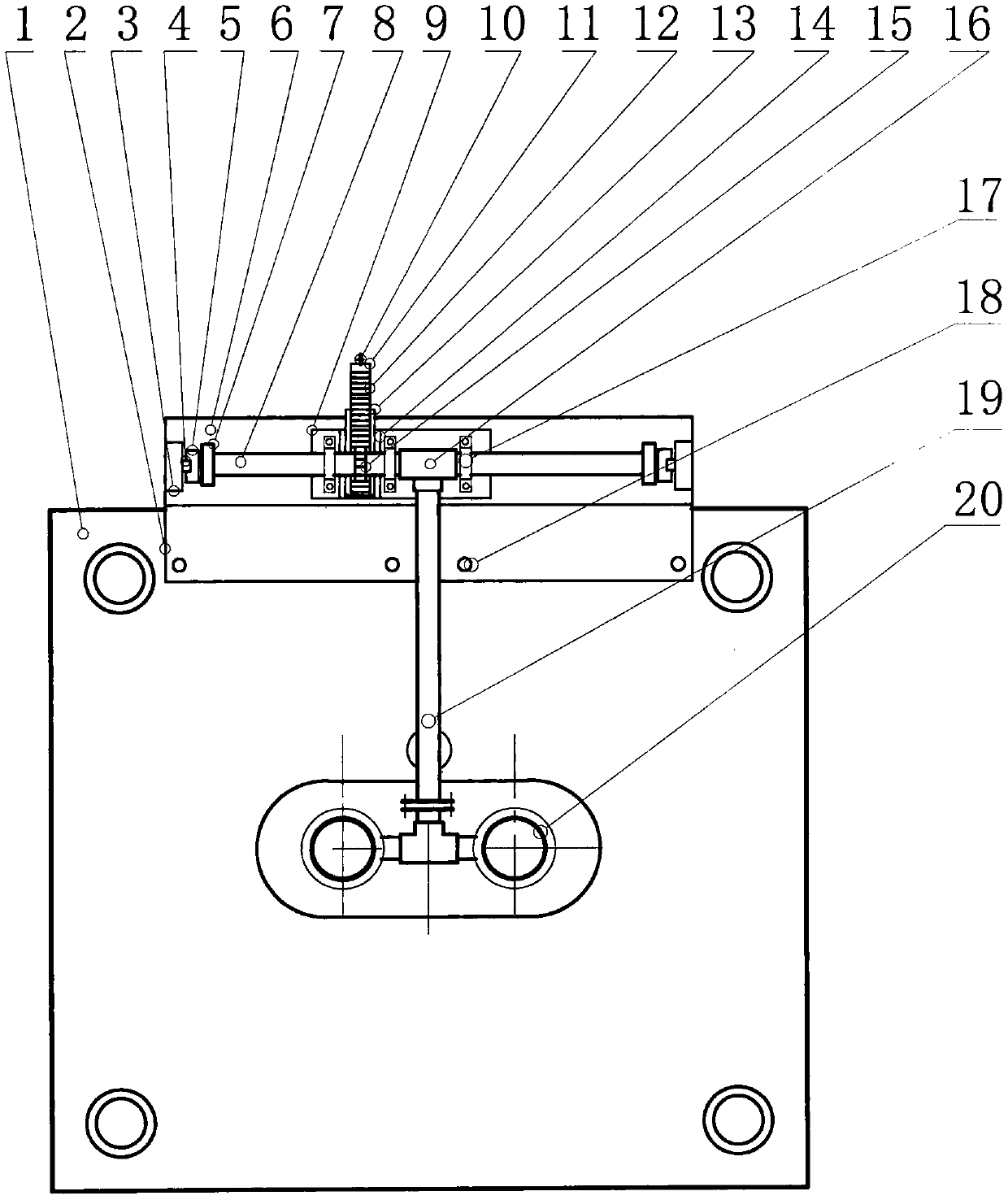

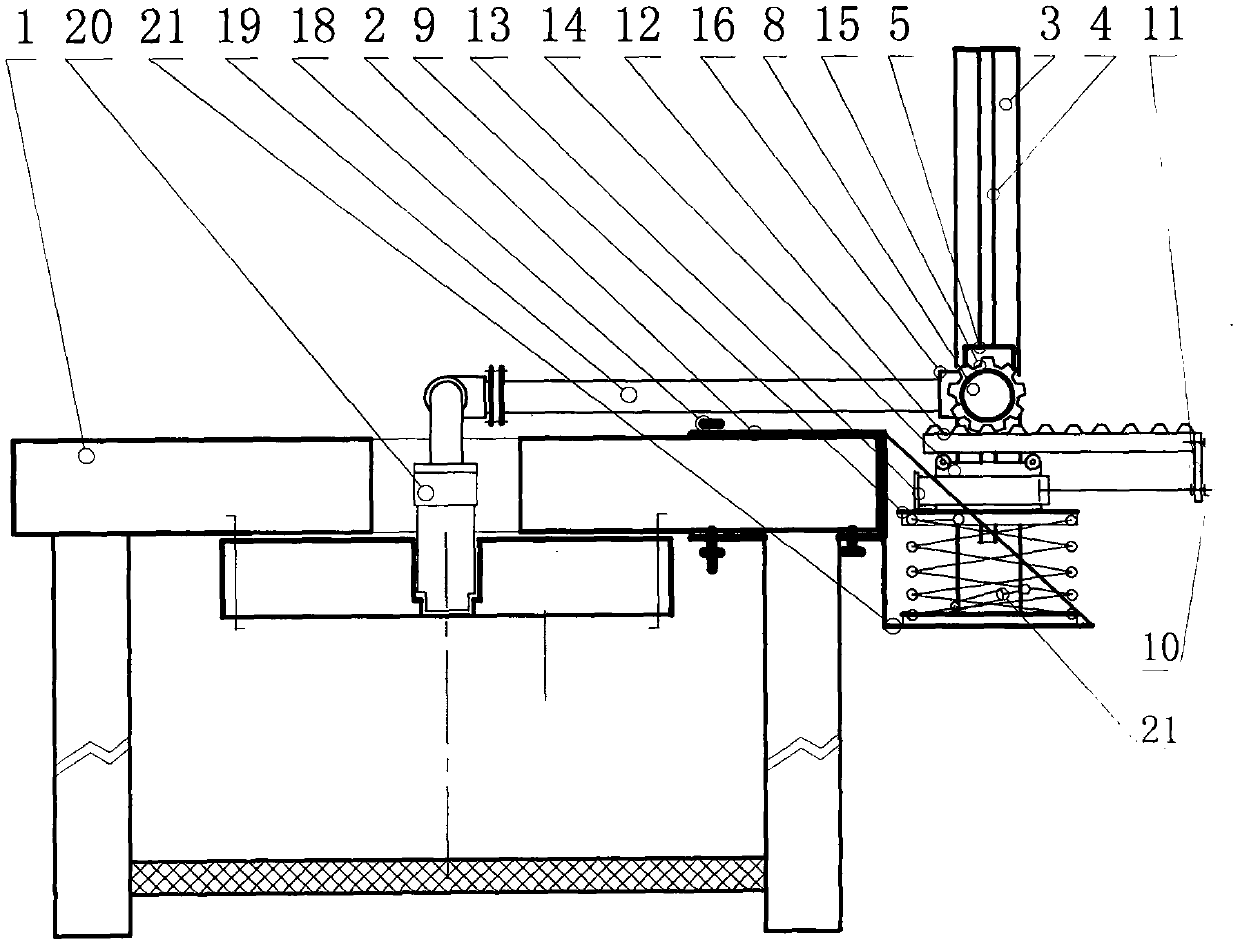

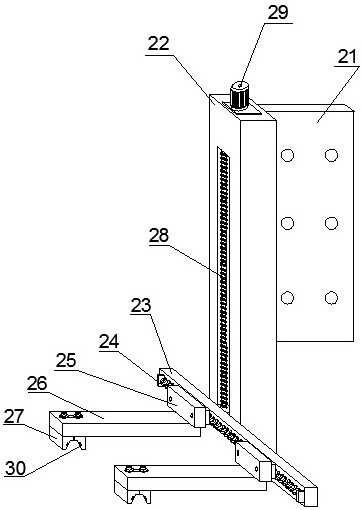

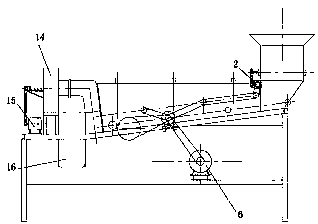

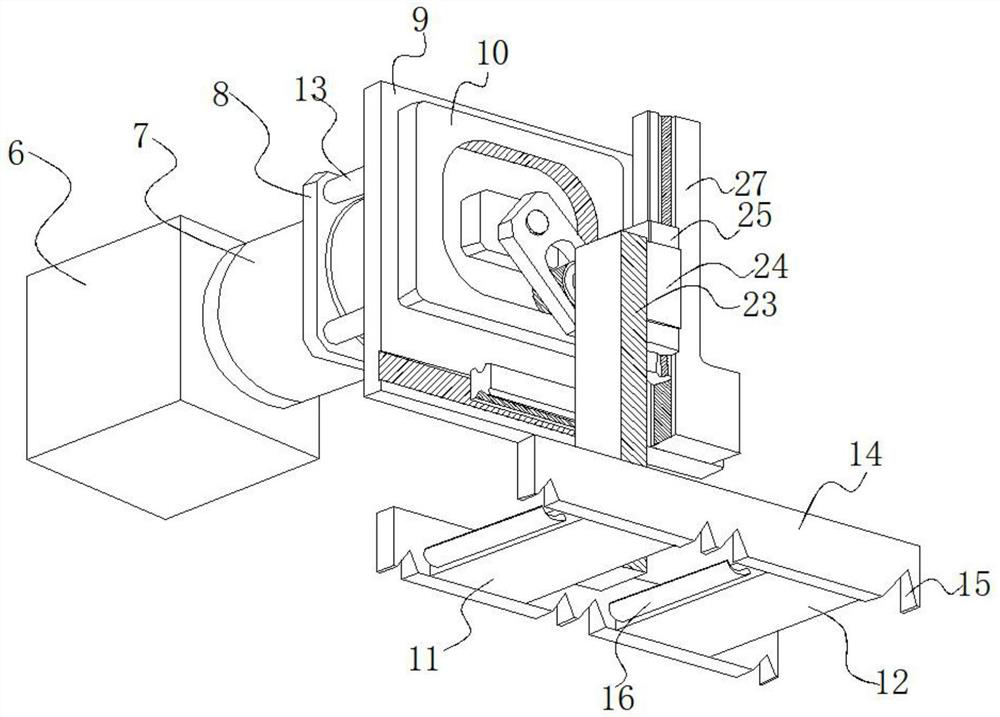

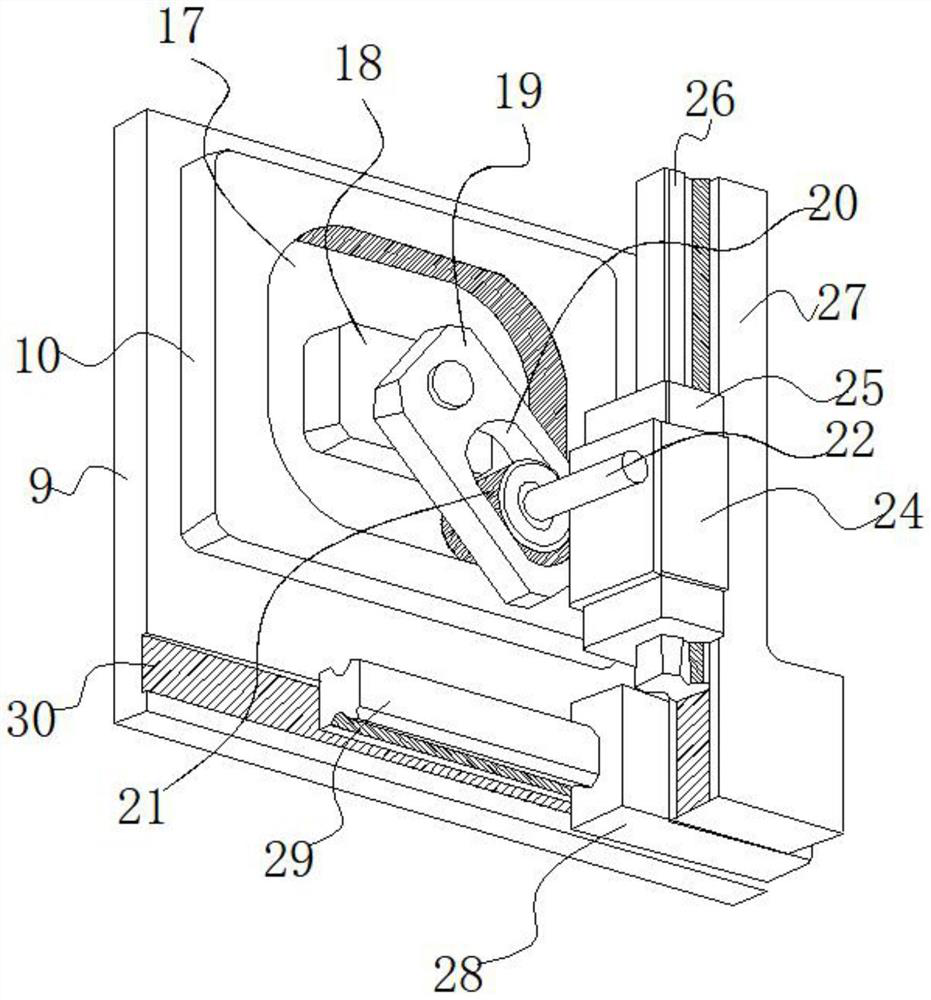

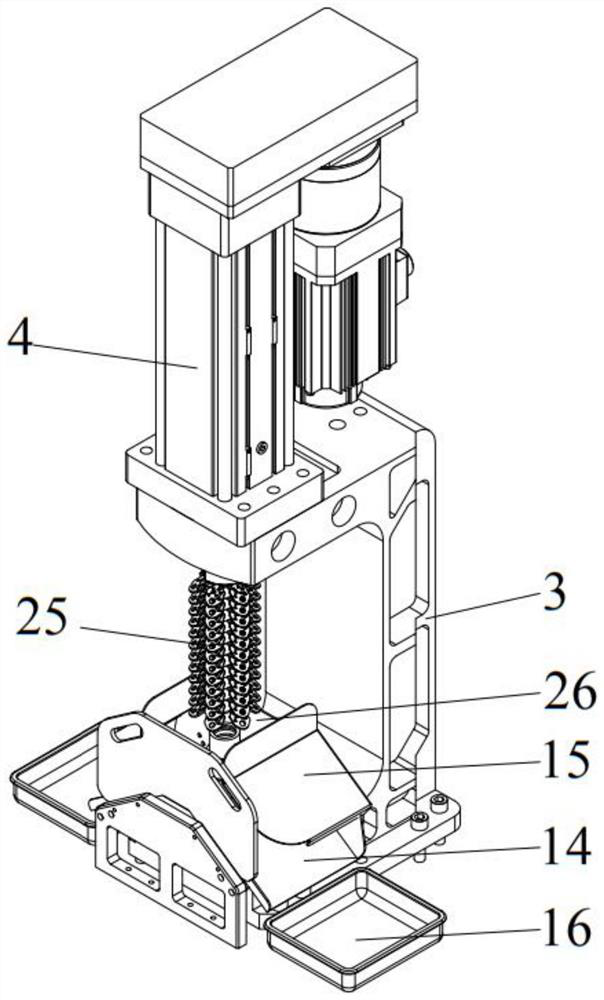

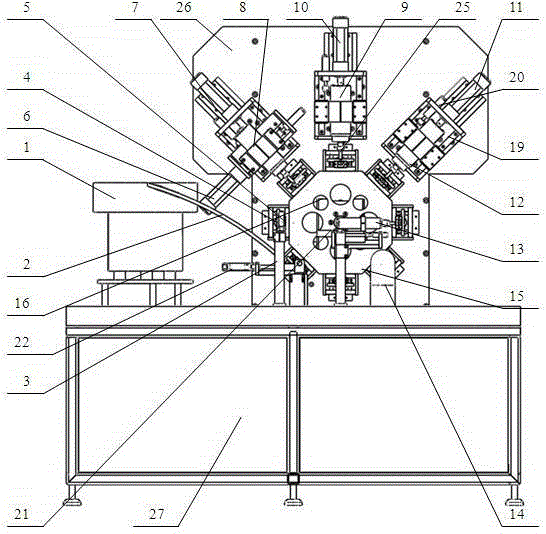

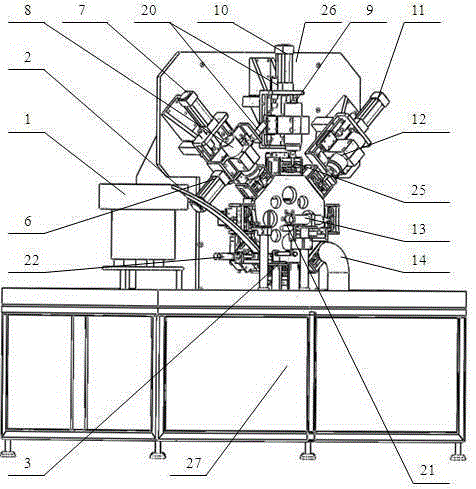

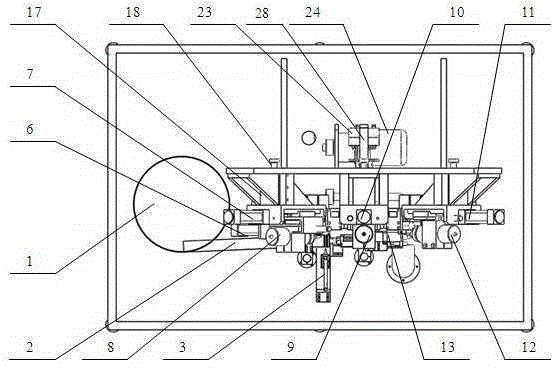

Automatic drilling and milling machine for chain connecting pin shaft

InactiveCN103921121AAchieving installation design complex issuesSolve the labor-intensiveOther manufacturing equipments/toolsMetal working apparatusEngineeringCam

An automatic drilling and milling machine for a chain connecting pin shaft is mounted on a rack table face, the automatic drilling and milling machine comprises a vibration disc, a feeding guide rail, an air cylinder, clamping jigs, a flat table milling mechanism, a central hole drilling mechanism, a small hole drilling mechanism, a chamfering mechanism, an octagonal eight-station rotating disc, a precise cam indexer, an electric motor and an automatic drilling and milling machine body support. The octagonal eight-station rotating disc is arranged on the front side of the automatic drilling and milling machine body support, the precise cam indexer is arranged behind the octagonal eight-station rotating disc, the electric motor is arranged on the rear side of the automatic drilling and milling machine body support, the electric motor is provided with a compressed air flow divider, the vibration disc is arranged on one side of the octagonal eight-station rotating disc, the eight clamping jigs are mounted on the octagonal eight-station rotating disc, the flat table milling mechanism, the central hole drilling mechanism and the small hole drilling mechanism are arranged on the upper side of the octagonal eight-station rotating disc, and the chamfering mechanism is mounted on the front side of the octagonal eight-station rotating disc. According to the technology, the full-automatic production process of part machining is achieved, and production efficiency and product quality are improved greatly.

Owner:肖闯

Erigeron breviscapus planting and field managing method

InactiveCN103988706AGuaranteed small investmentSolve labor difficultiesHorticultureDiseaseTotal investment

An erigeron breviscapus planting and field managing method belongs to a medicinal plant cultivating technique. By the erigeron breviscapus planting and field managing method, the whole planting process of erigeron breviscapus can be managed and controlled through subtle changes of the procedures such as land selecting, ploughing, ditching, film covering, seed dressing, sowing, fertilizing, weed removing, watering, and disease preventing. Thus, the most serious problems in an existing erigeron breviscapus planting process are solved, the emergence rate is greatly improved, and the mortality is reduced. Physical and manual weed removal is utilized in the whole planting process, so that the weed removal cost is greatly reduced, and the difficulty with labor using is solved. The most serious problem of root rot, the most headache, is fundamentally solved. Small investment, large output and high yield of farmers are guaranteed. Calculated by per acre, the total investment is 3000 yuan, the output generally reaches 3000-4500kg; if the price is 3 yuan per kilogram, the gain is 9000-135000 yuan, and the net income is 6000-9000 yuan.

Owner:云南绿高生物科技有限公司

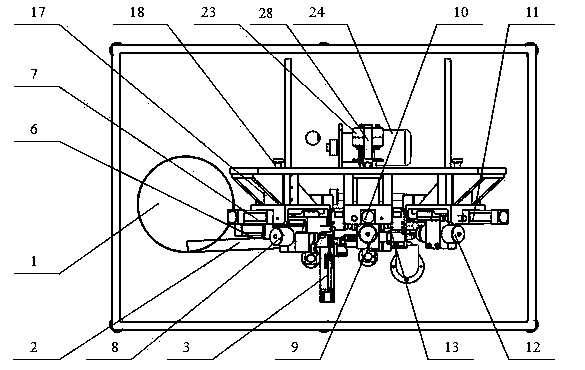

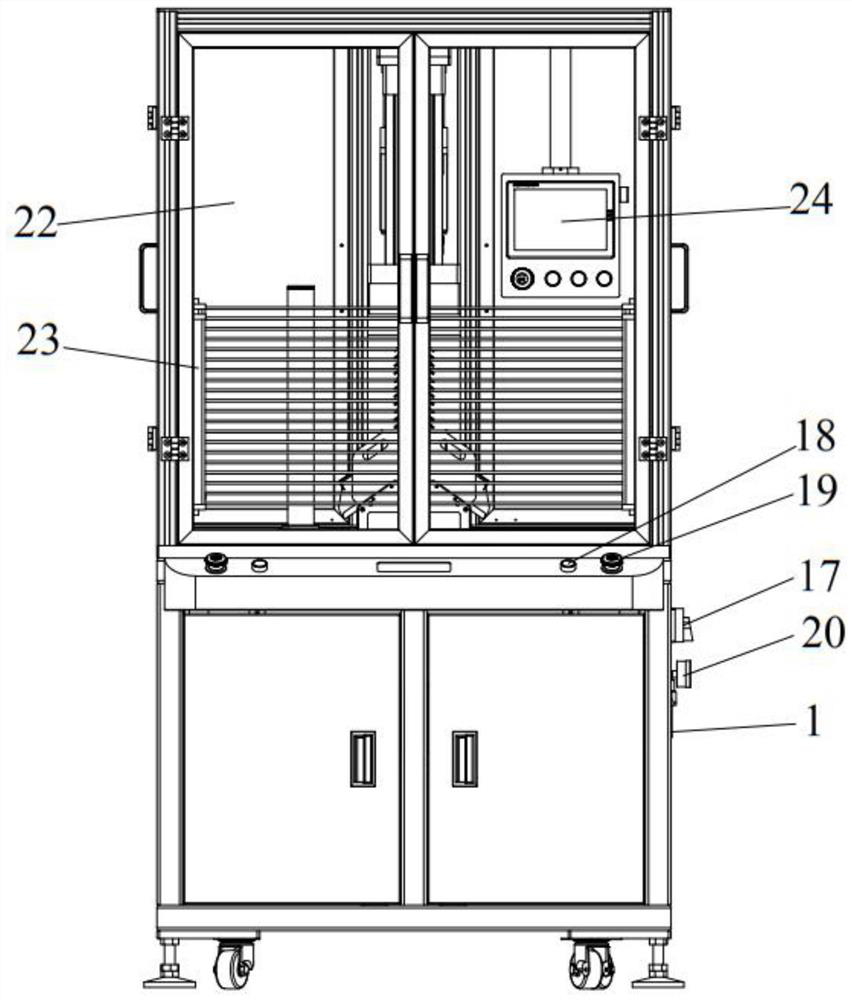

Intelligent planting greenhouse and control method

ActiveCN108901474AReduce labor costsLower quality requirementsClimate change adaptationGreenhouse cultivationSocial benefitsGreenhouse

The invention relates to an intelligent planting greenhouse and a control method. The intelligent planting greenhouse comprises a pinnacled greenhouse body, a top rectangular frame, a greenhouse door,a control box, a monitoring unit, an outer sunshade curtain, an inner sunshade curtain, etc. The control method comprises the following steps: acquiring the information of indoor and outdoor environments through sensors, and controlling an executing mechanism according to the acquired information. The intelligent planting greenhouse and the control method provided by the invention have the following advantages: the labor cost of a large-scale planting greenhouse can be effectively reduced; the degree of automation is high; high practicability is achieved; and certain economic benefits and social benefits can be generated.

Owner:HEBEI NORMAL UNIV

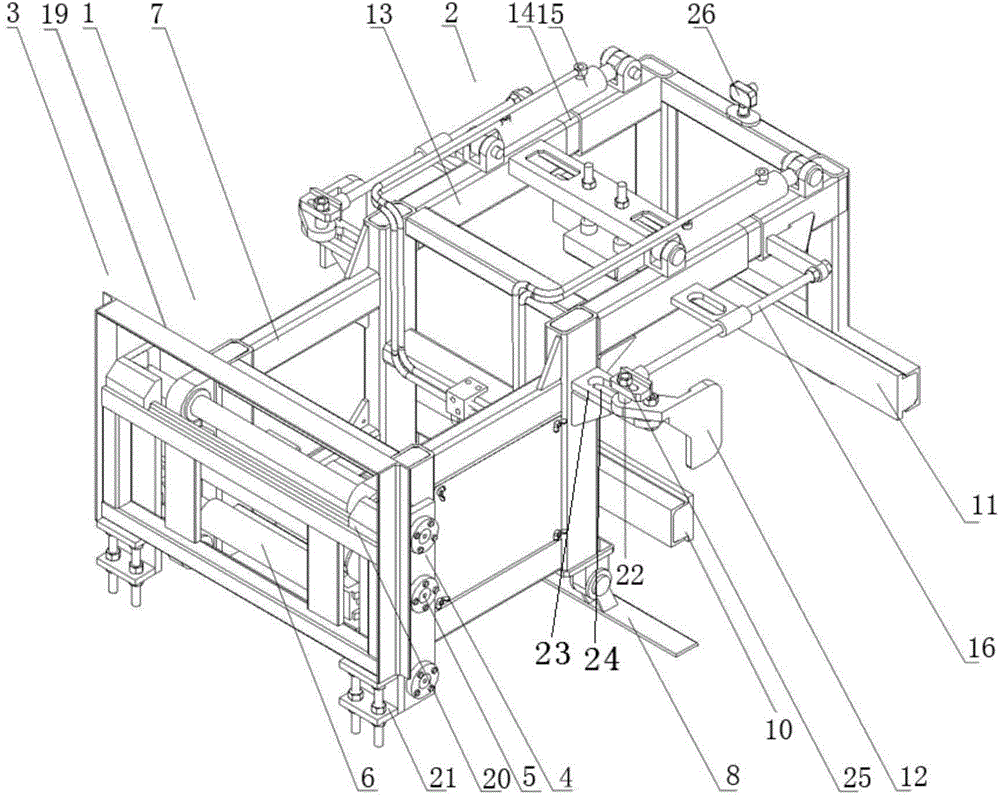

Forklift truck accessory for assembling and disassembling ceramic tiles

InactiveCN103979462AFunction increaseImprove efficiencyLifting devicesElectronic control systemMaterial consumption

The invention relates to a forklift truck accessory for assembling and disassembling ceramic tiles; two support frames are respectively and fixedly arranged at the two sides of a forklift truck connecting device; a lateral movement mechanism comprises a sliding shaft and an oil cylinder I; a clamp arm extension frame sheathes the sliding shaft; a support mechanism comprises a support arm which is connected with an oil cylinder II; a clamping block I is arranged on the clamp arm extension frame; two fixed arms are respectively arranged at the two sides of the top of the clamp arm extension frame; a telescopic arm is sheathed in each fixed arm; an oil cylinder III is connected between the each fixed arm and the corresponding telescopic arm; the two ends of each oil cylinder III are respectively fixedly arranged on the corresponding fixed arm and the corresponding telescopic arm; a clamping block II is connected to the lower end of each telescopic arm; the side of each telescopic arm is fixedly provided with a linkage rod; the tail end of each linkage rod is connected with a clamp arm; the oil cylinder I, the oil cylinder II and the oil cylinders III are respectively connected with an oil supply and distribution integrated valve and an oil cylinder control integrated valve by oil pipes; the oil supply and distribution integrated valve and the oil cylinder control integrated valve are respectively connected with an electronic control system. The forklift truck accessory has the beneficial effects of being simple, reliable, free from maintenance, low in material consumption and manufacturing cost, high in efficiency, stable, reliable and remarkable in economical benefit.

Owner:马志新

Egg knocking-free technology for preserved egg production

InactiveCN111838575AIncrease production speedReduce man-made damagePolysaccharide/gum food ingredientsBiotechnologyAnimal science

The invention relates to preserved egg production, and discloses an egg knocking-free technology for preserved egg production, which comprises the following steps: (1) putting fresh duck eggs into a preserved egg pickling solution, and soaking for 2-3 hours so that cracks on cracked eggs are clearly visible; (2) taking out the soaked duck eggs, washing the surfaces of the duck eggs with an egg washing machine, and taking out all cracked eggs through optical detection. The method has the beneficial effects that the production speed of the preserved eggs is increased, the artificial damage of the fresh duck eggs during egg beating is reduced, the labor is saved, the cost is reduced, and the problem of difficulty in labor of enterprises is effectively solved.

Owner:周玉军

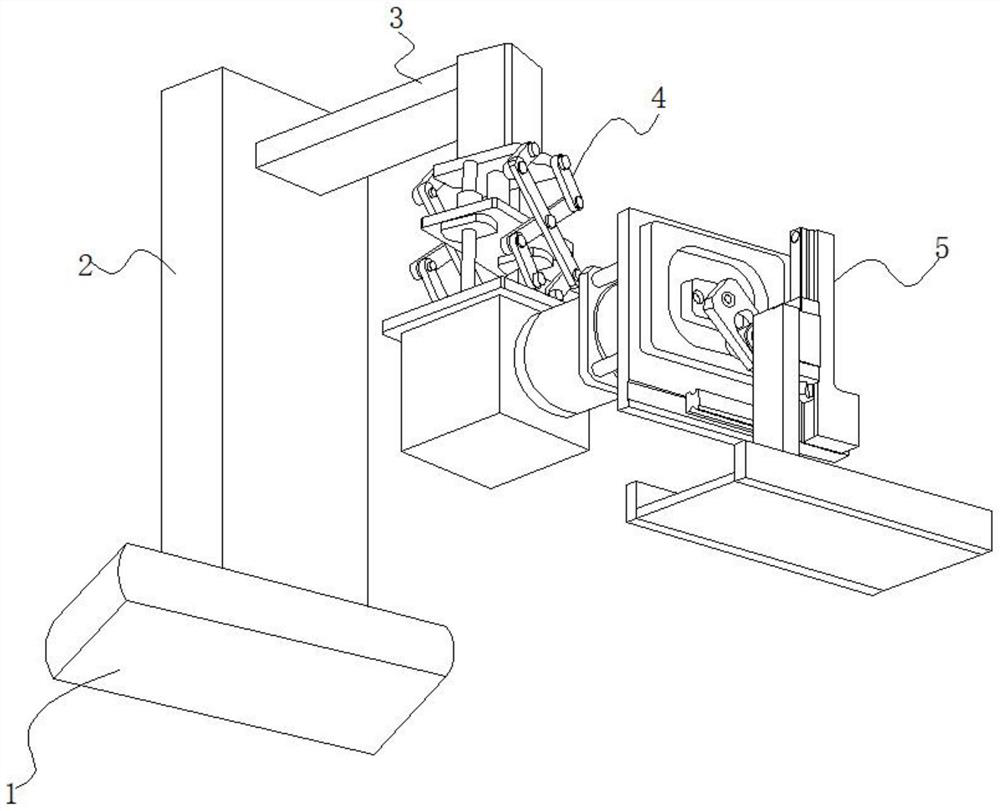

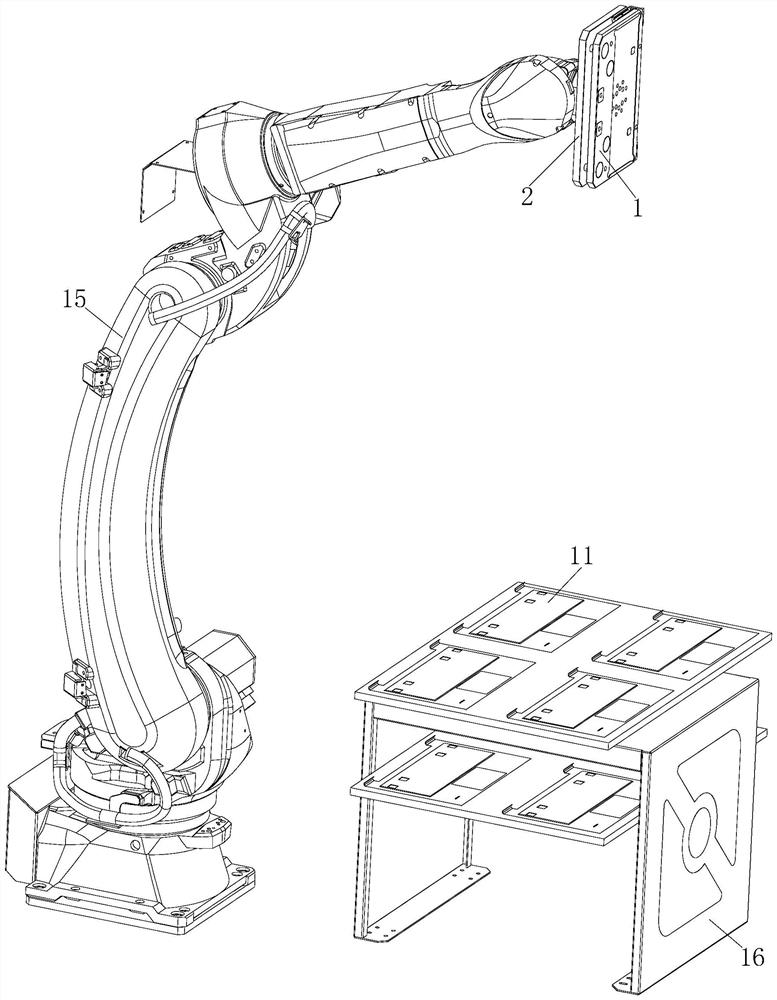

An Efficient CNC Machining Robot Arm

Owner:苏州明俊设备制造有限公司

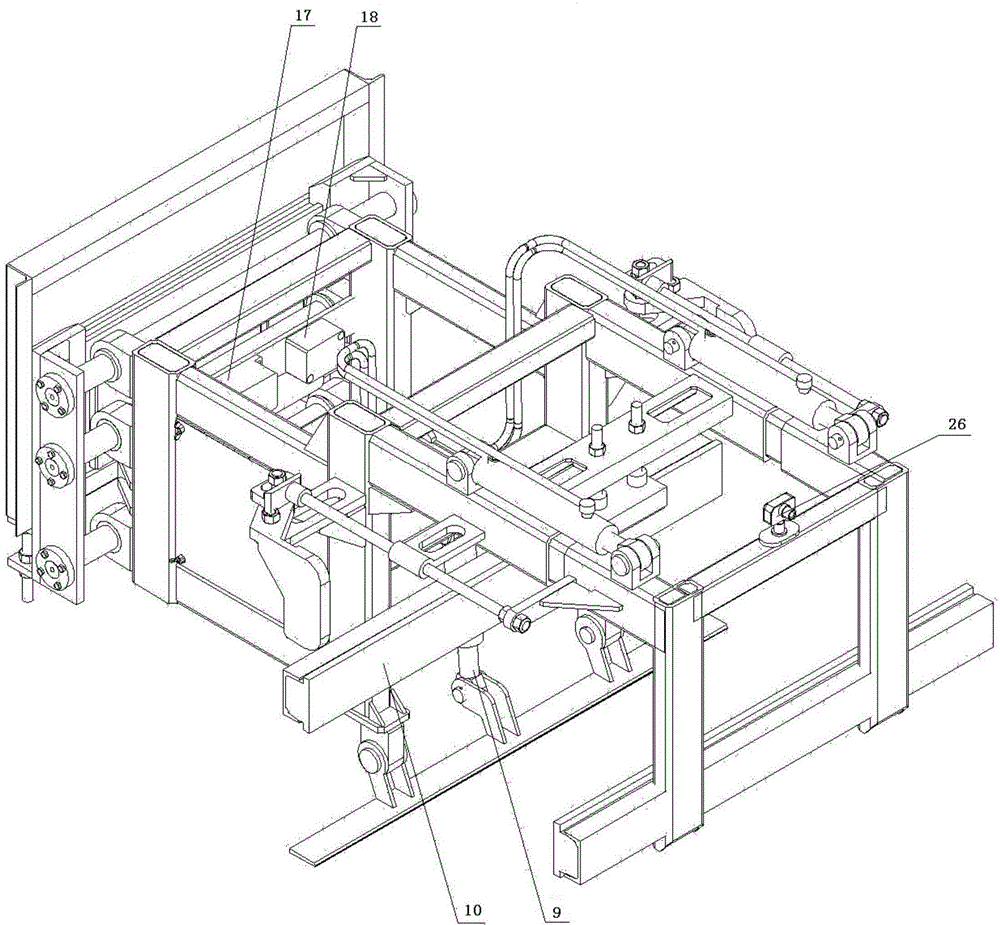

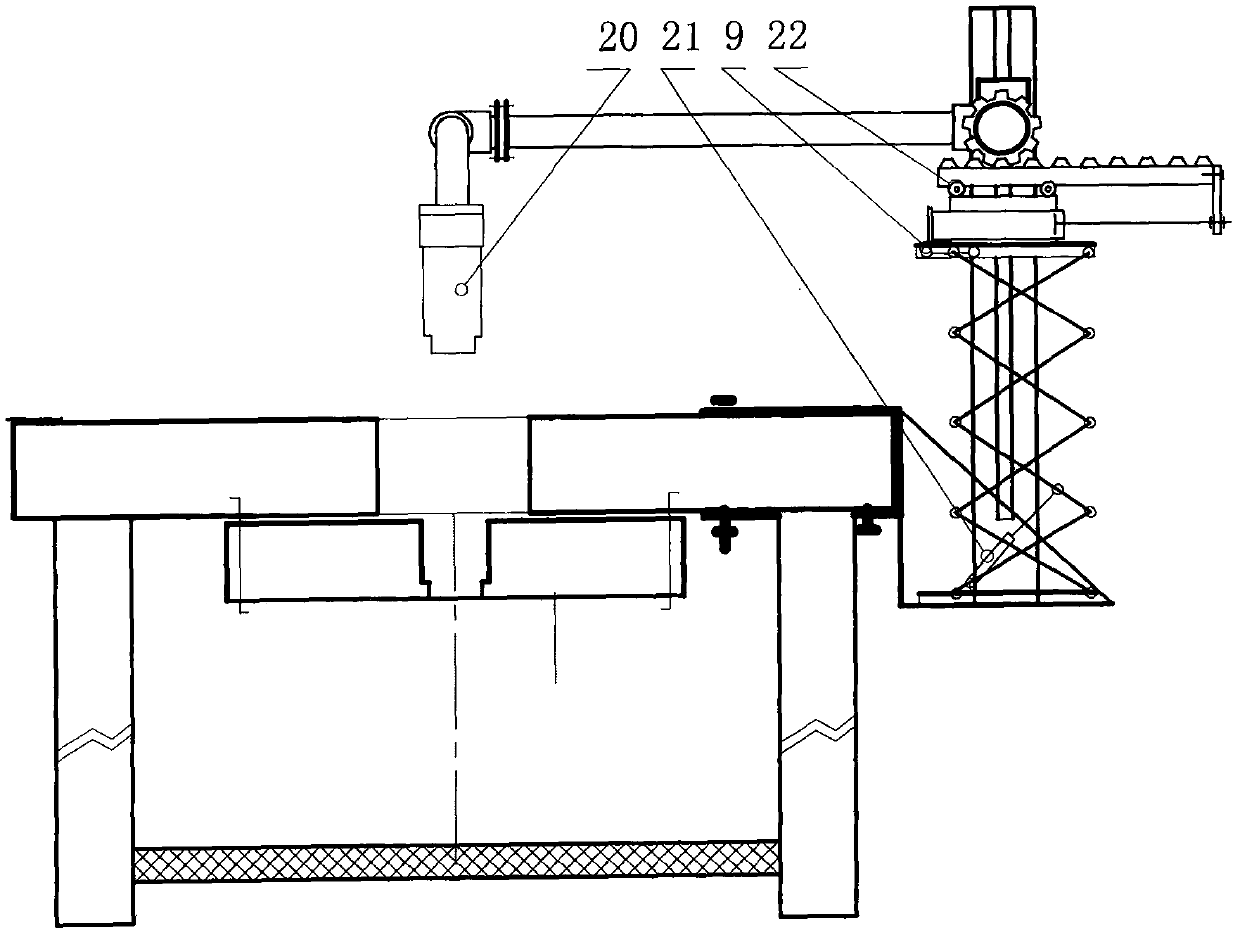

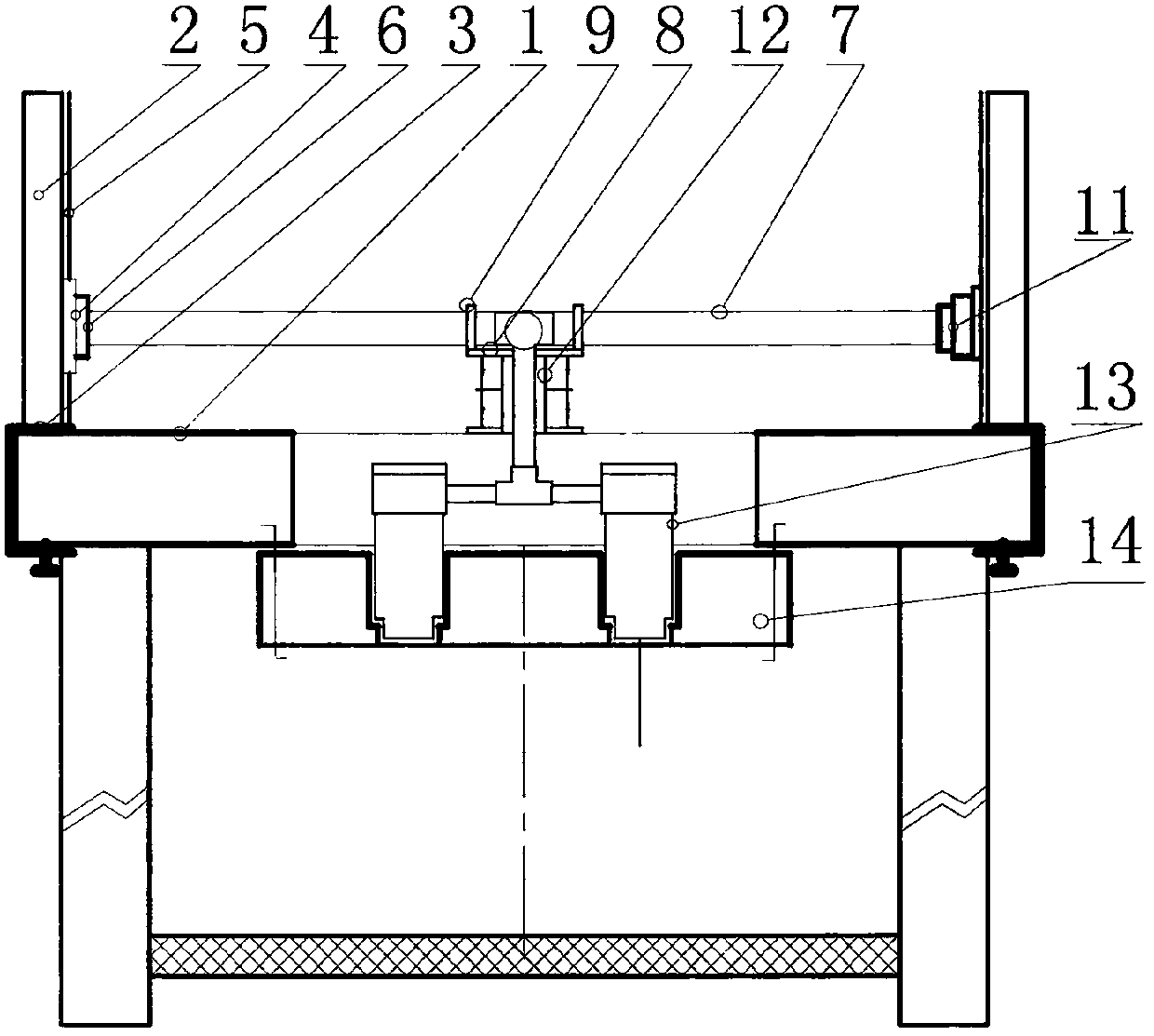

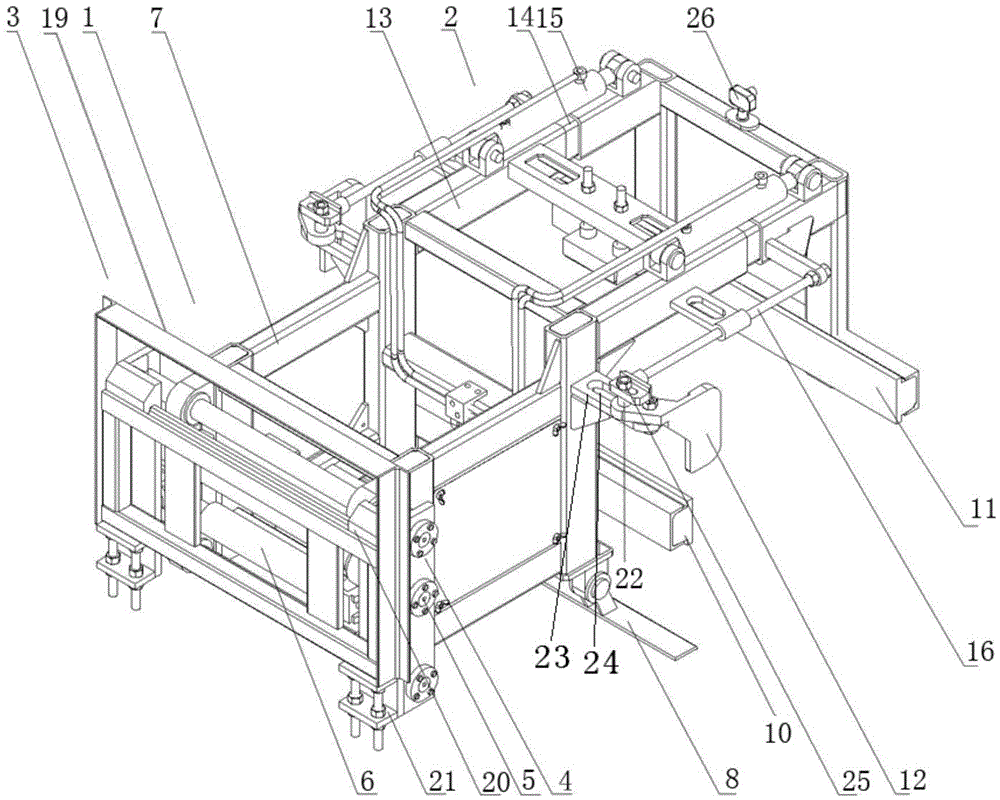

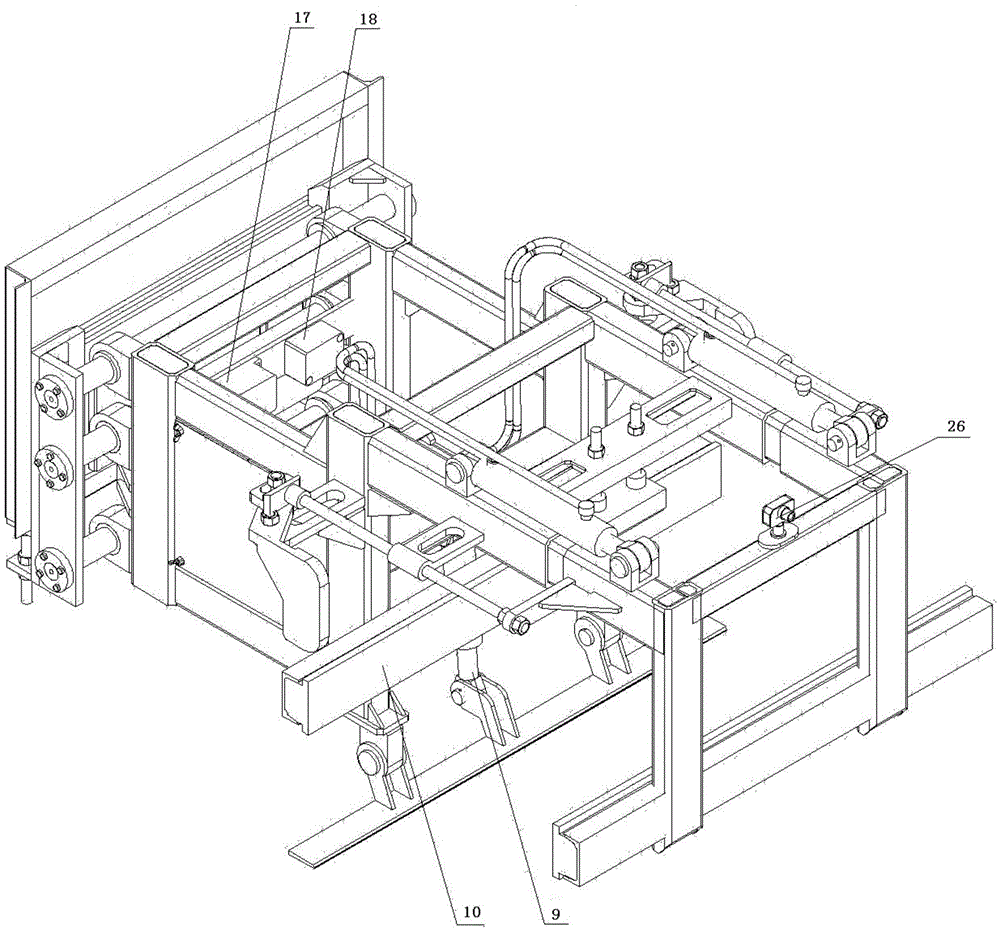

Overturning equipment for simple gravity casting machine

InactiveCN110369695ARaise the gradeFacilitate automatic castingMould handling equipmentsMarine engineeringAlloy

Overturning equipment for a simple gravity casting machine comprises a positioning mechanism, a lifting mechanism, overturning mechanisms and a control mechanism. A positioning frame is arranged on anupper die table. A positioning platform is arranged at the lower end of the positioning frame. Guide columns, guide rails and overturning shafts are correspondingly arranged on the two sides of the positioning platform. A lifting platform is arranged on the positioning platform. A lifting oil cylinder is arranged in the lifting platform. Bearing seats are arranged on the lifting platform. Rack frames are arranged in the two bearing seats. The overturning mechanisms are arranged on the rack frames. According to the overturning equipment for the simple gravity casting machine, the positioning frame is arranged on the upper die table, the overturning equipment is suitable for an original lower movable die gravity casting machine, also suitable for a modern upper movable die gravity casting machine, automatic casting of a spoon machine is facilitated, and direct installation is facilitated; the automation equipment which repetitively uses gates is more popular and intelligent; and the equipment has low investment and also increases the process yield of aluminum alloy metal die gravity casting products.

Owner:WUXI XIYANGKANG SCI & TECH

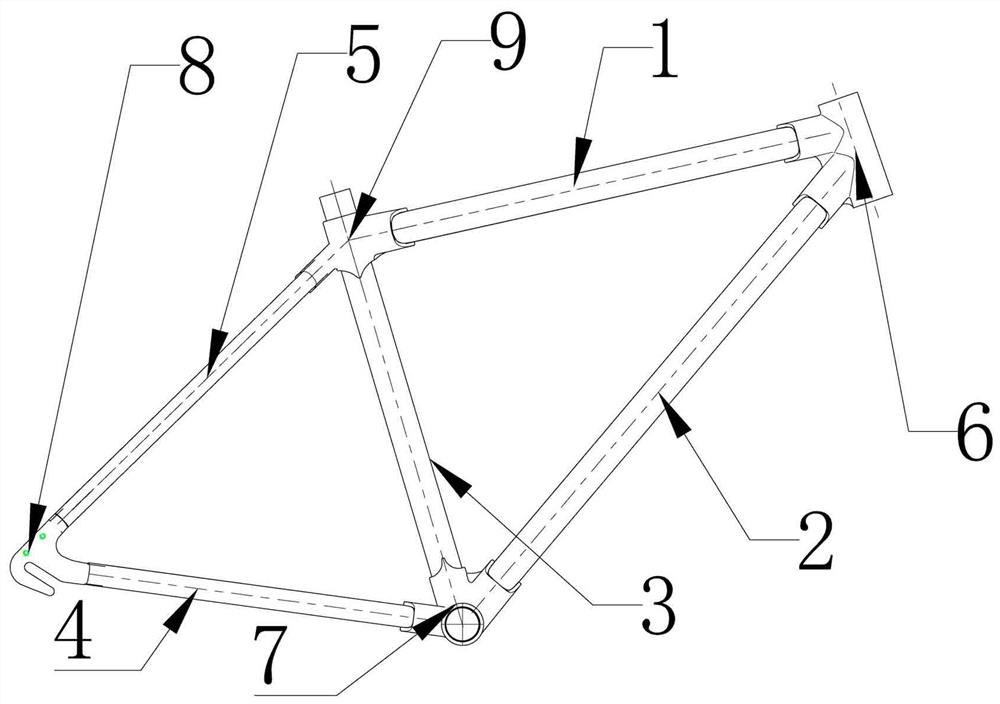

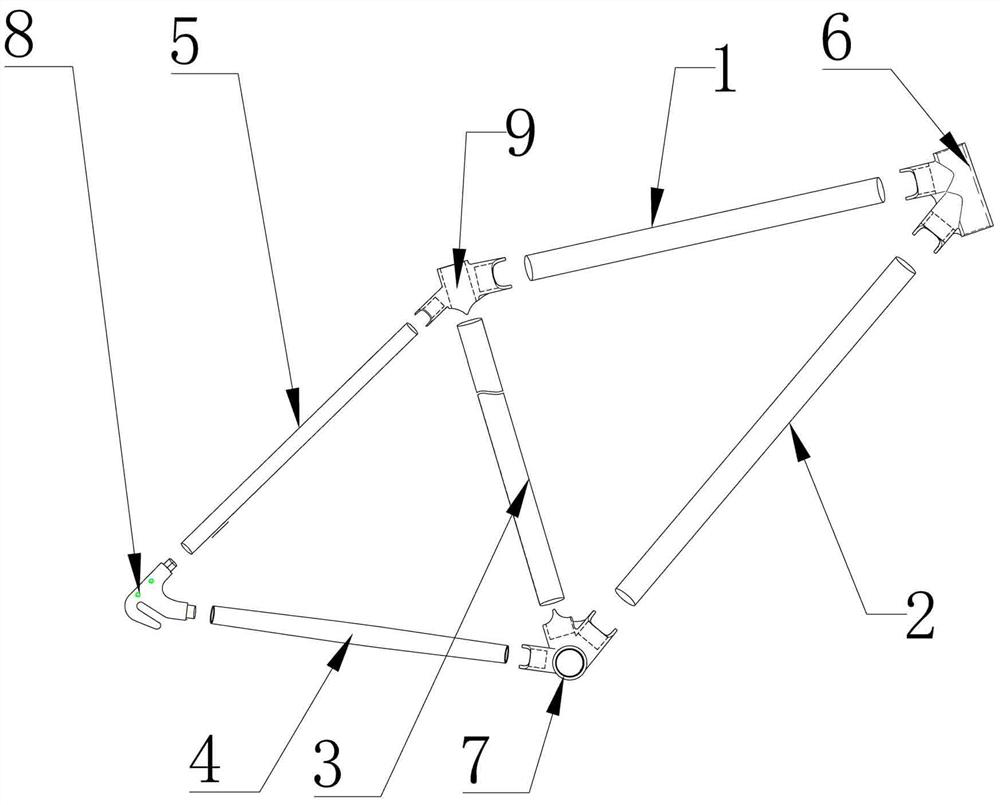

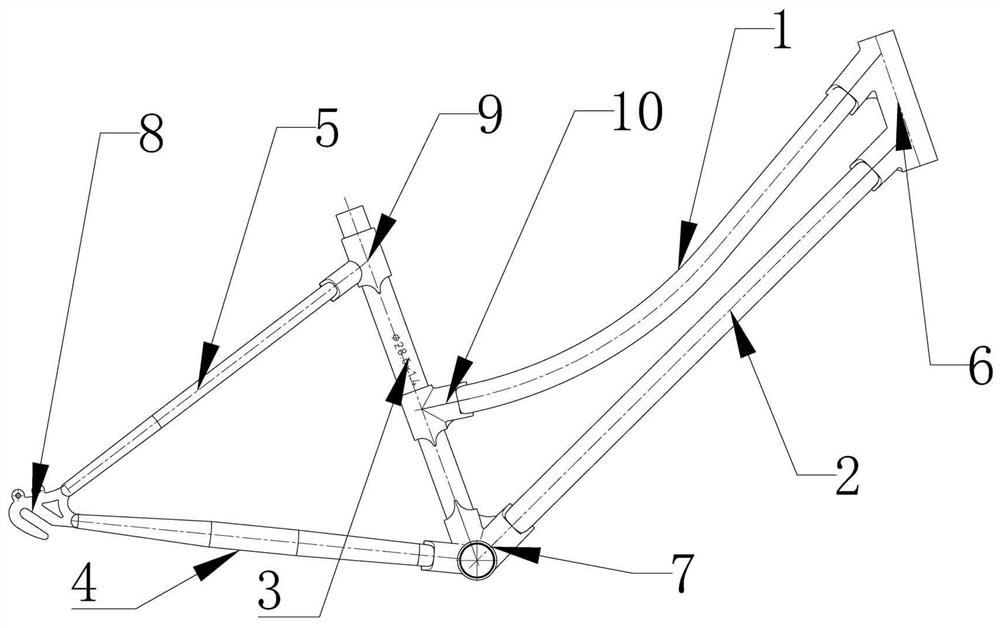

Integrated joint bicycle frame, electric bicycle frame and electric moped frame

The invention discloses an integrated connector bicycle, electric vehicle and electric moped frame which comprises an upper pipe, a lower pipe, a middle pipe, a bottom fork and a vertical fork and further comprises an integrated head pipe connector, an integrated five-way connector, an integrated middle pipe connector and an integrated rear hook claw. One end of the upper pipe is sleeved with the head pipe joint, and the other end is sleeved with the middle pipe joint; one end of the lower pipe is sleeved with the head pipe joint, and the other end is sleeved with the five-way joint; the middle pipe penetrates through the middle pipe joint, and the lower end is sleeved with the five-way joint; one end of the bottom fork is sleeved with the five-way joint, and the other end is sleeved with the rear hook claw; the upper end of the vertical fork is sleeved with the middle pipe joint, and the lower end is sleeved with the rear claw; the sleeving positions are bonded and fixed through adhesives, and the middle pipe and the middle pipe connector are bonded and fixed through adhesives. Or an upper pipe joint sleeved on the middle pipe is additionally arranged on the middle pipe. The frame is free of welding, high in strength, easy and convenient to assemble, high in production efficiency and low in cost; and meanwhile, a foundation is laid for later automatic production.

Owner:吴志华 +1

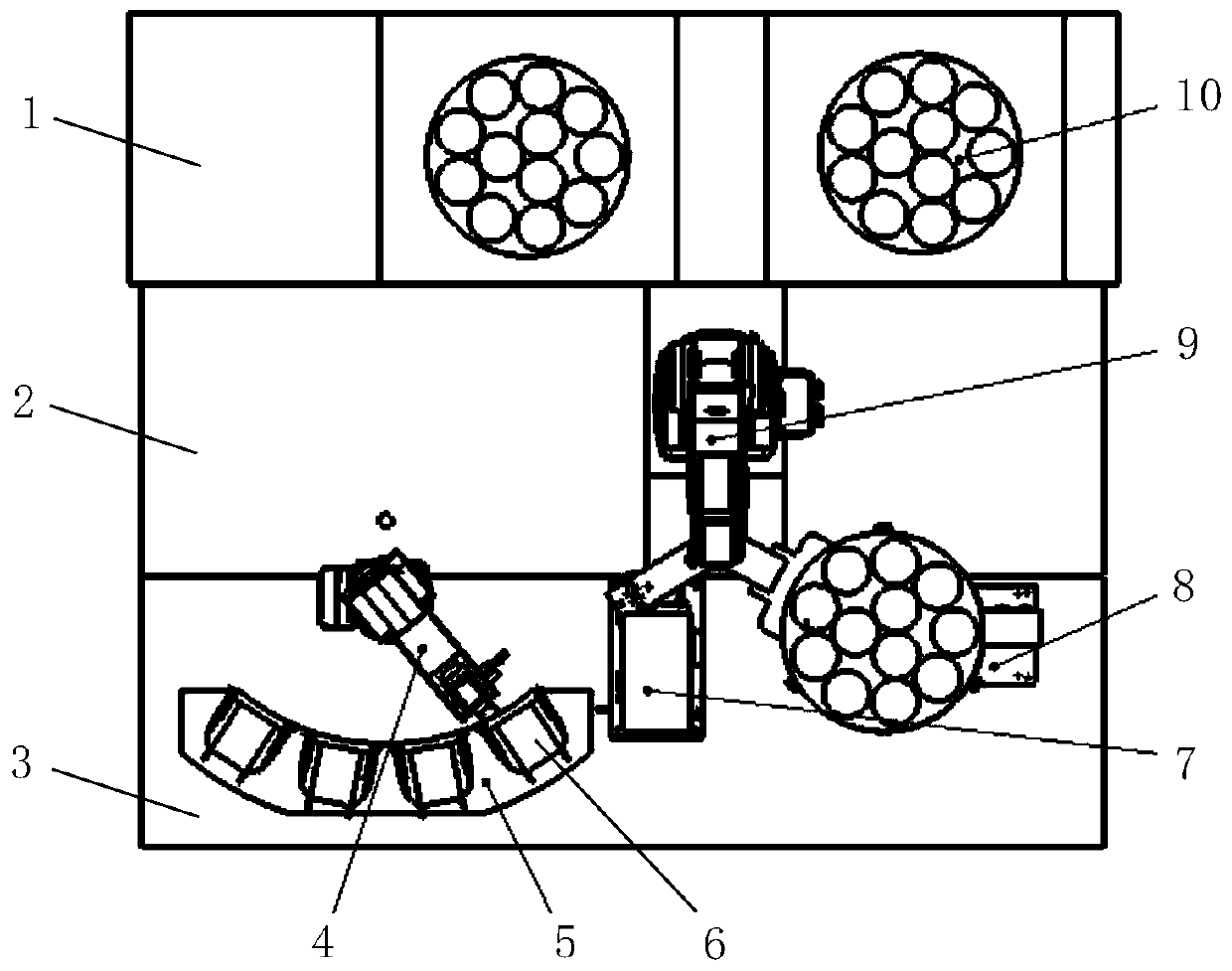

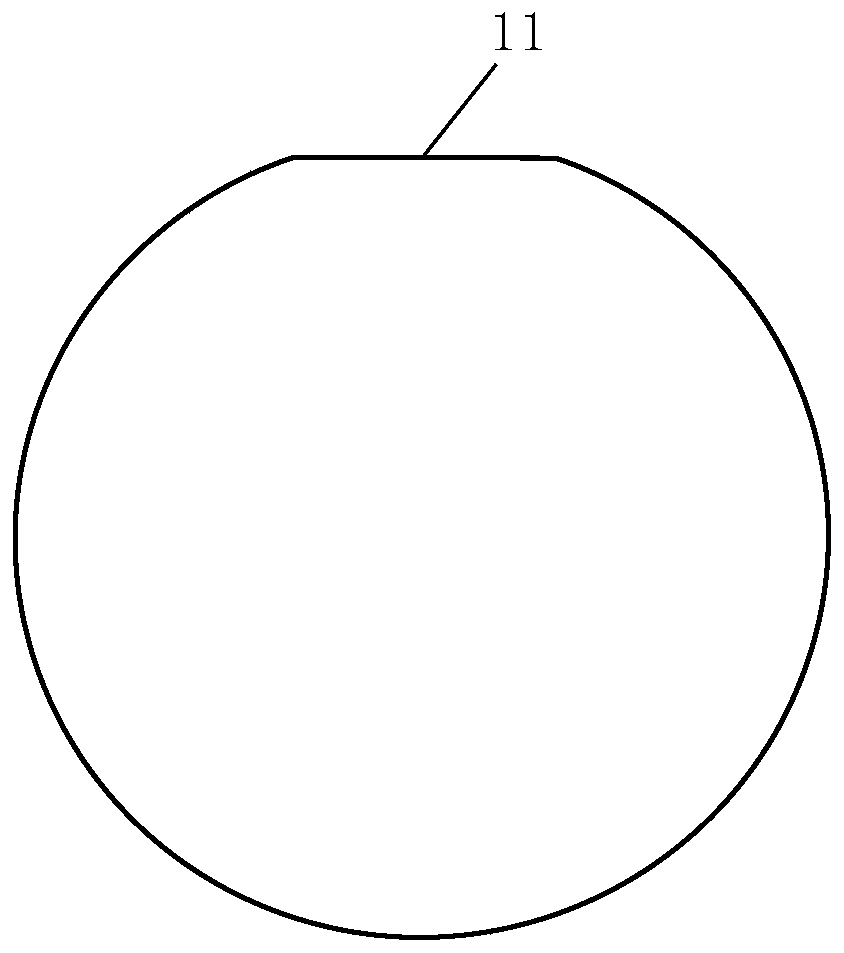

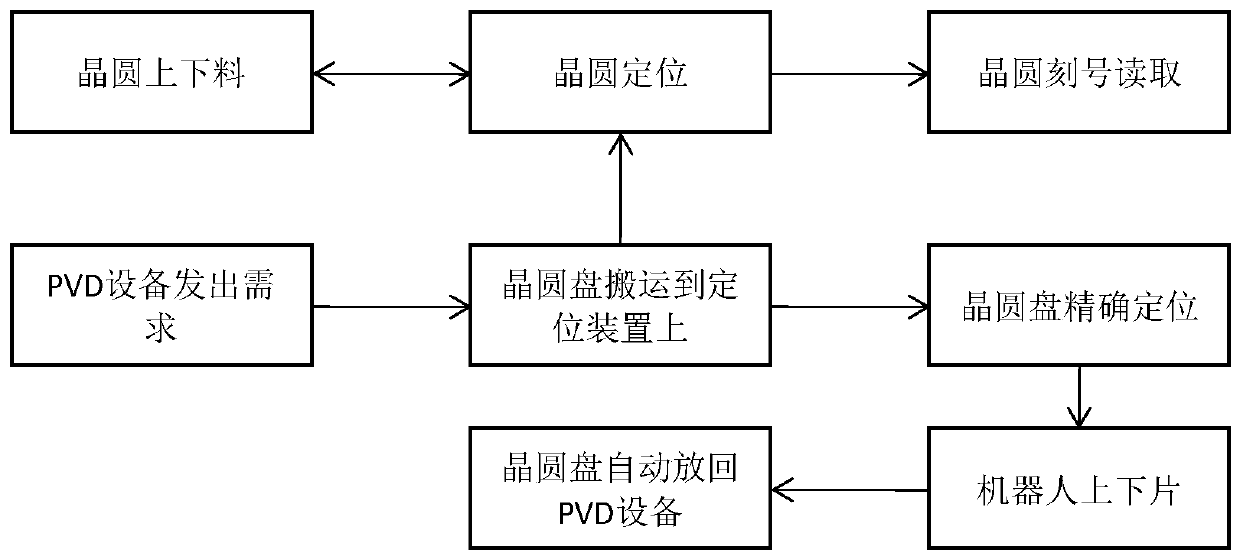

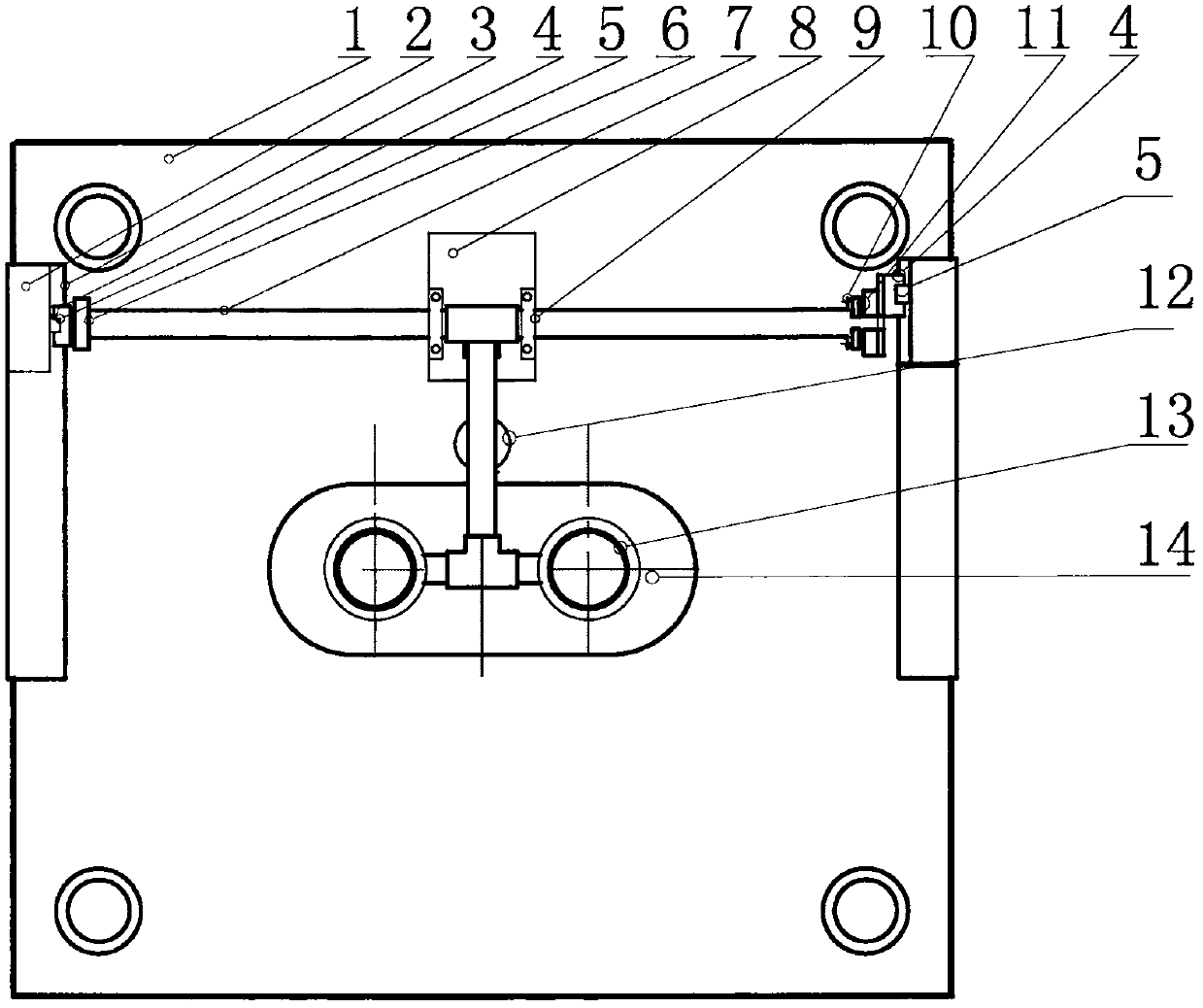

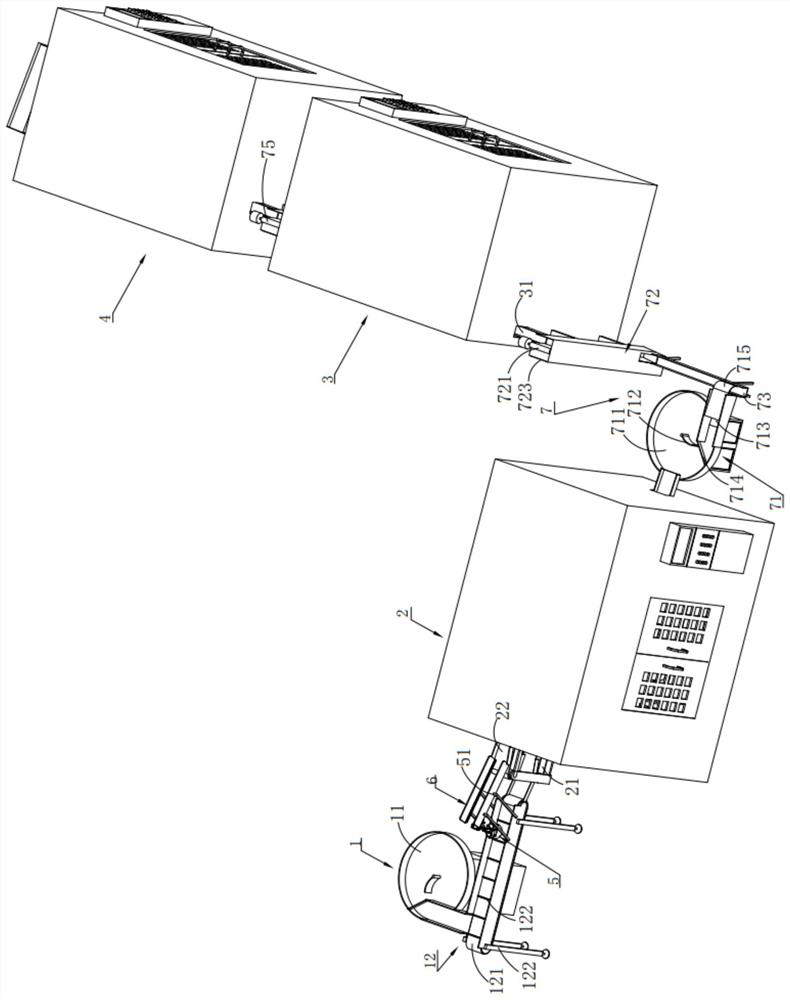

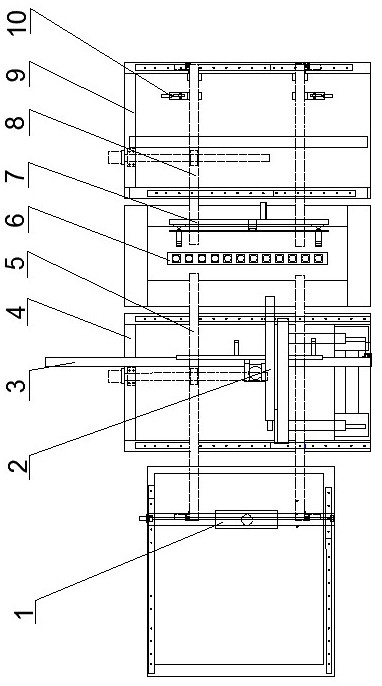

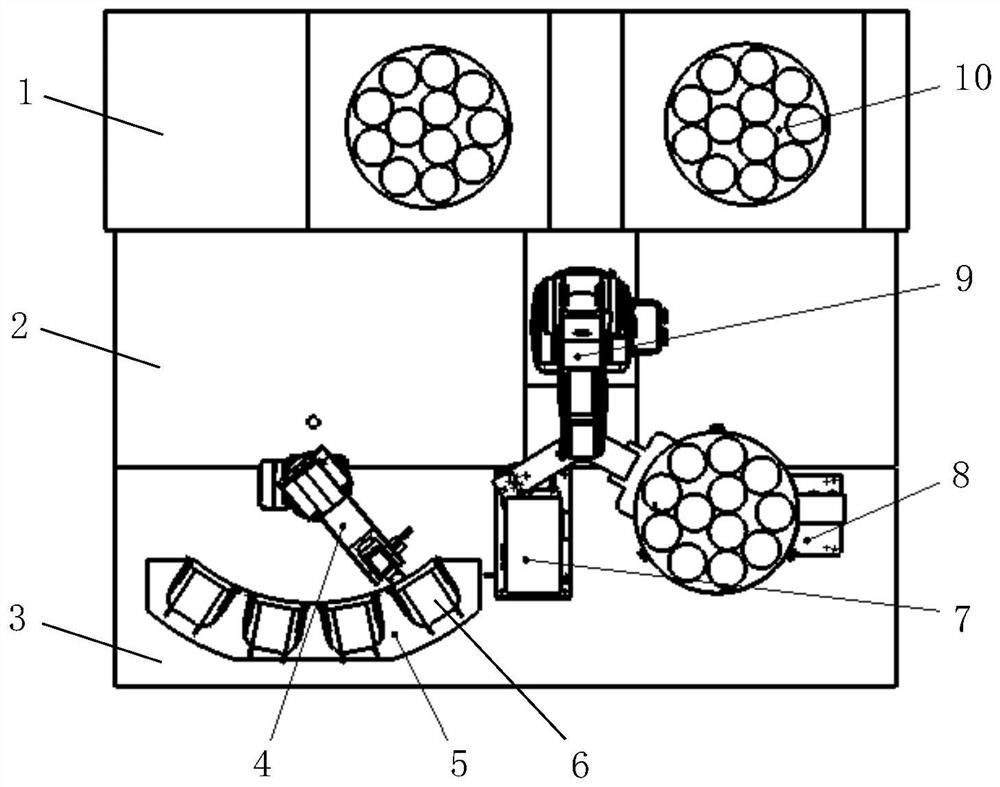

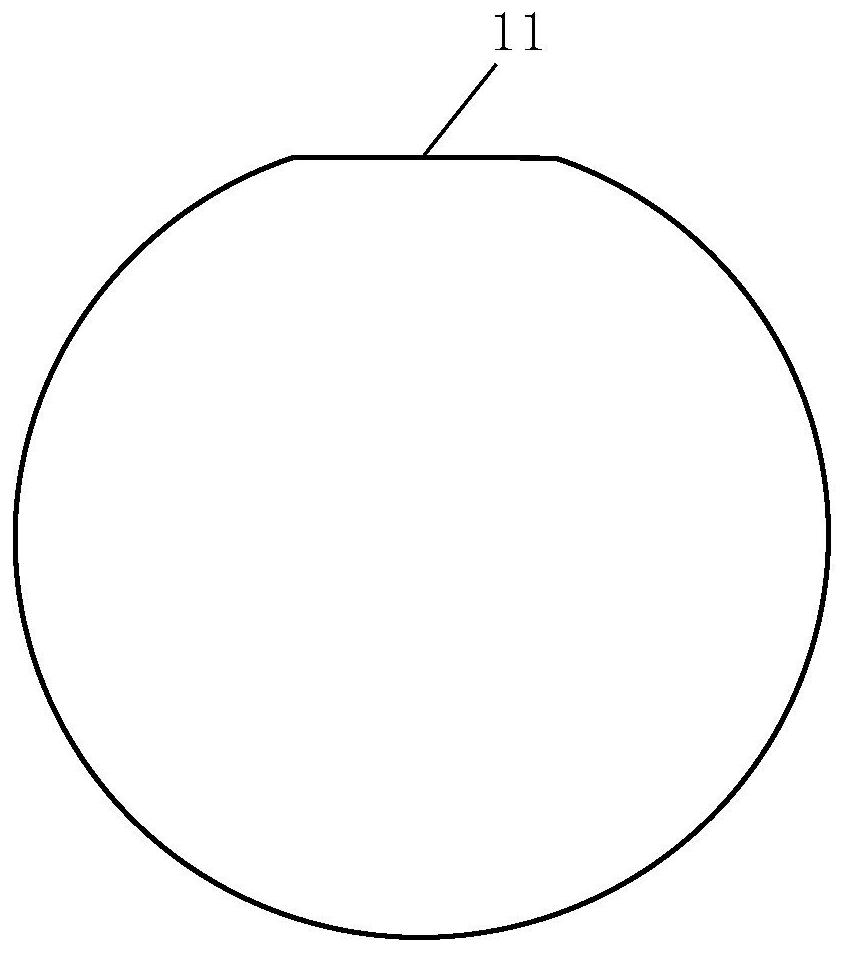

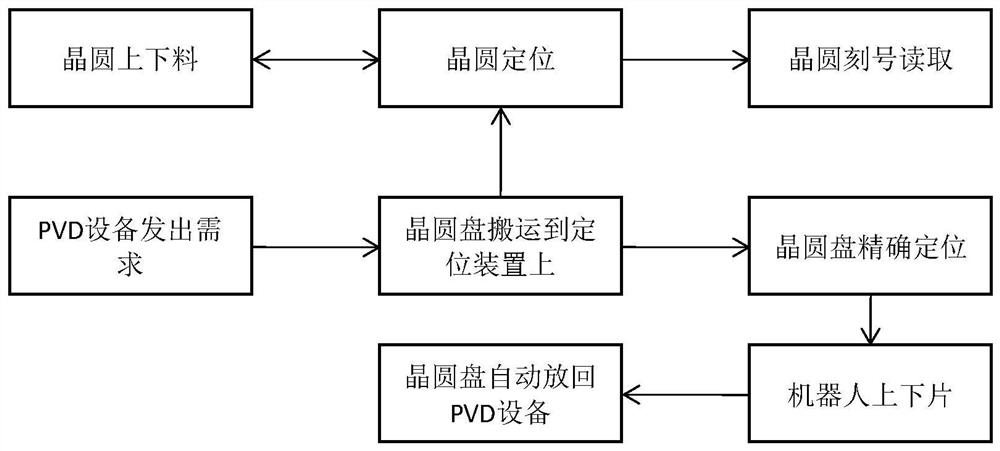

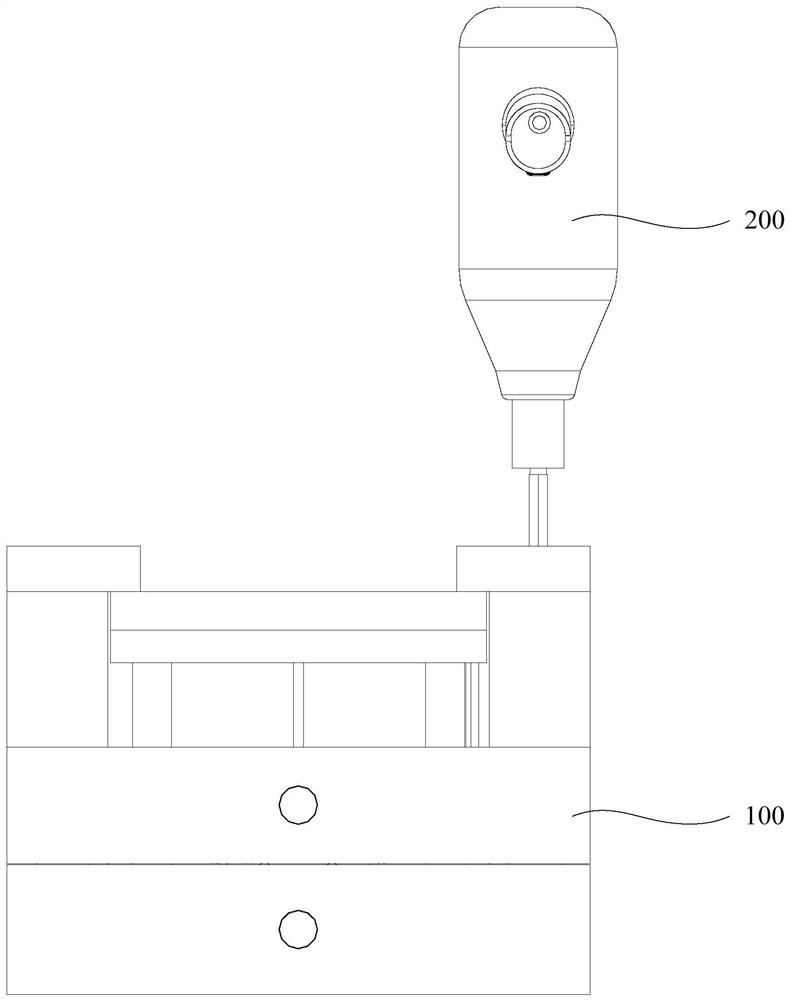

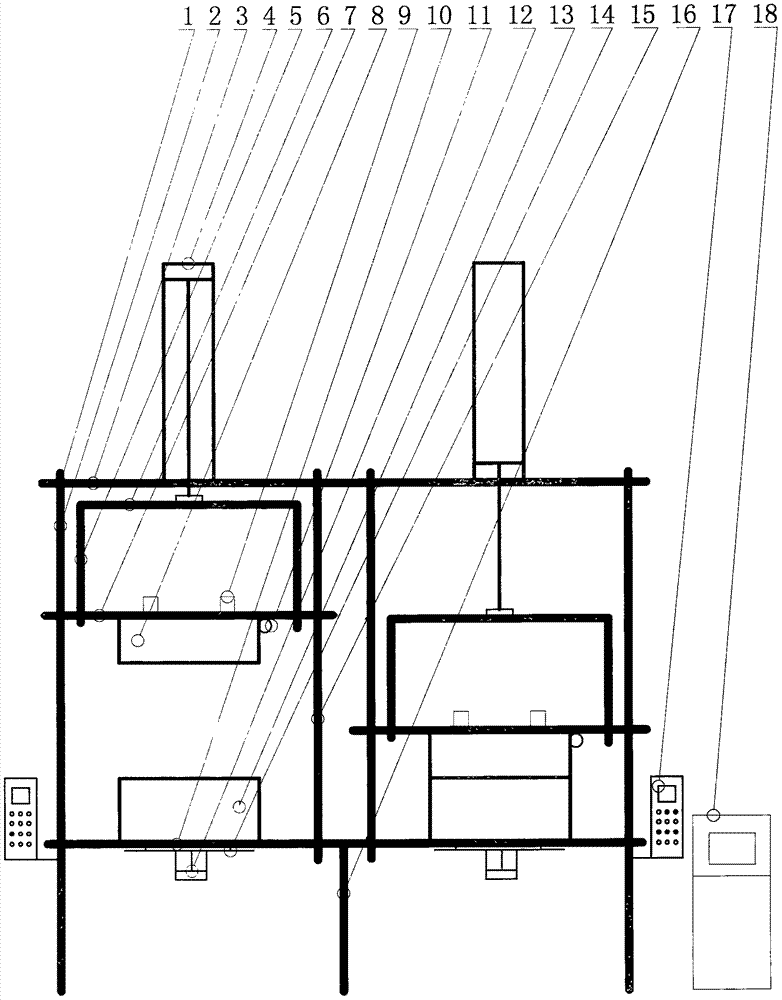

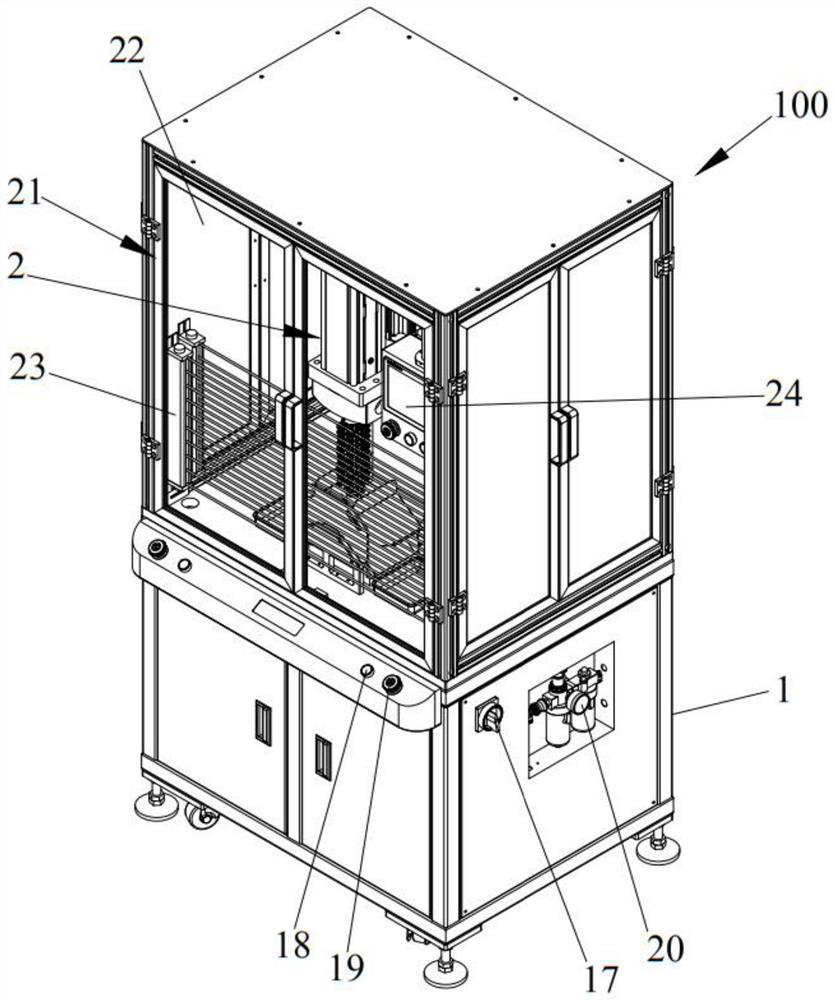

Automatic wafer loading and unloading system

ActiveCN111029287AEnsure consistencyAvoid Wafer ContaminationSemiconductor/solid-state device manufacturingConveyor partsPhysicsStorage cell

The invention discloses an automatic wafer loading and unloading system. The system comprises a storage unit integrated on process equipment, a wafer positioning unit, a wafer disc positioning unit and a wafer disc storage unit. A first loading unit is adopted to transmit wafer discs before and after the process between the wafer disc storage unit and the wafer disc positioning unit, and a secondloading unit is adopted to transmit wafers before and after the process among the wafer disc positioning unit, the wafer positioning unit and a storage unit. According to the system, the efficiency ofthe whole production process can be improved, wafer pollution is avoided, the percent of pass of the wafers placed in the wafer disc is improved, and the rejection rate of the wafers is reduced.

Owner:SHANGHAI FORESIGHT ROBOTICS CO LTD

Double Riser Lifting and Turning Device for Gravity Casting Machine

The invention discloses a double-riser lifting and overturning device for a gravity casting machine. The device comprises a lifting mechanism and an overturning mechanism, and further comprises two positioning frames arranged on the gravity casting machine; a mold is arranged below the gravity casting machine; lifting columns are arranged on the positioning frames; a rail is arranged on the lifting columns; slide blocks are arranged on the rail; the overturning mechanism is arranged in the slide blocks; a lifting table and a front end oil cylinder are arranged below the overturning mechanism; a lifting oil cylinder is arranged in the lifting table; the overturning mechanism comprises an overturning bearing arranged on one slide block, and a rotating oil cylinder arranged on the other slide block; overturning shafts are arranged in the overturning bearing and the rotating oil cylinder; bearing bases are arranged in the overturning shafts; riser frames are arranged in the bearing bases; and risers are arranged on two sides of the front ends of the riser frames. The lifting table arranged below the riser frames is adopted to support the overturning mechanism, and the front end oil cylinder arranged in front of the lifting table is adopted to support the riser frames, so that the risers are overturned again after vertically leaving frame a metal mold, the radian influence on direct overturning by riser cavities of the metal mold is effectively prevented, and the investment is low.

Owner:青岛盛森铸造有限公司

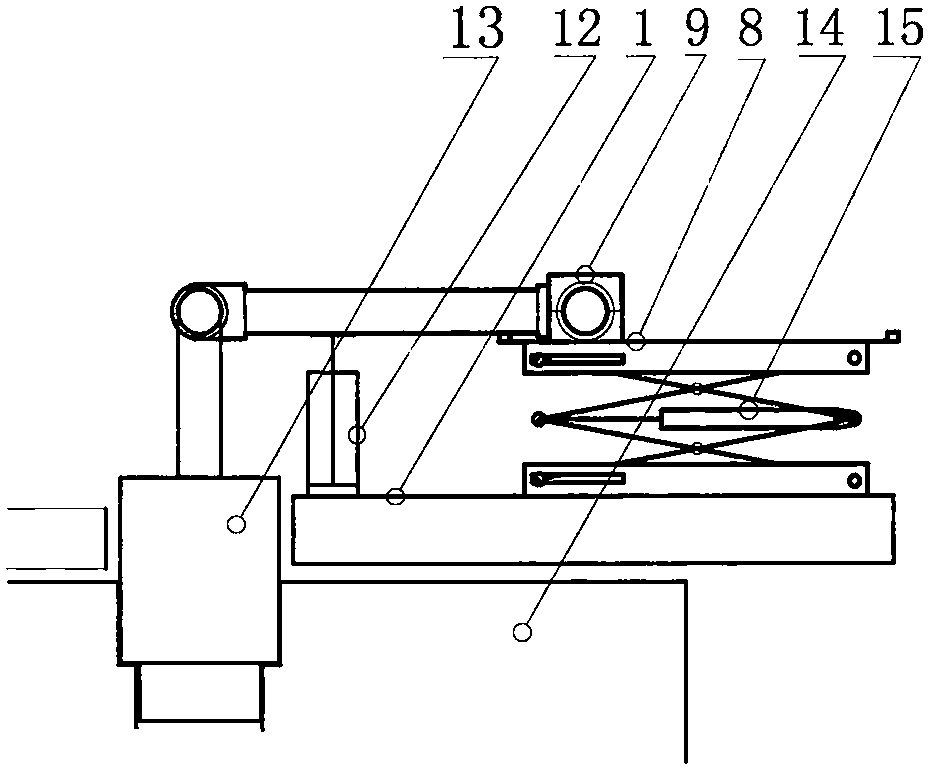

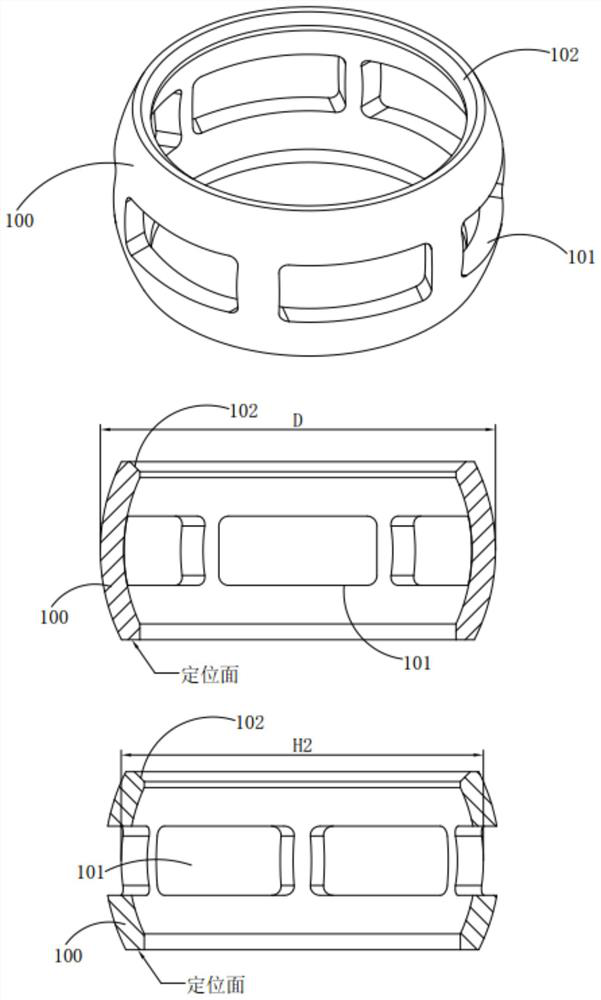

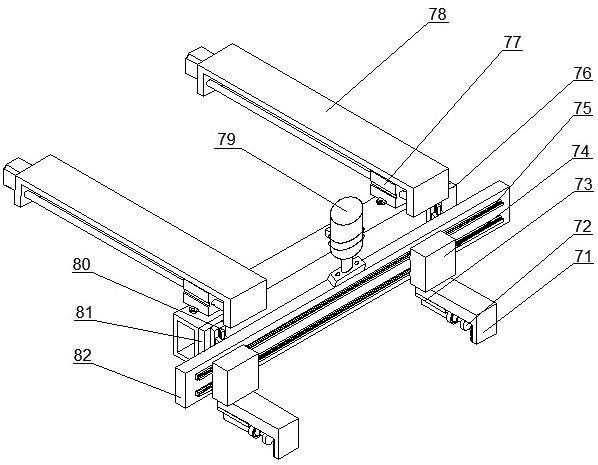

Automatic production line and process of inner joint holder

ActiveCN111761461ARealize automatic feedingEasy to detectGrinding machinesGrinding feedersProduction lineMachine

The invention provides an automatic production line and a process of an inner joint holder. The automatic production line comprises a feeding system, a window processing system, an outer circle processing system, an inner diameter processing system, a turning system and a conveying unit; holders to be processed are gradually conveyed to the turning system for detection after being sorted by the feeding system, wherein the holder with a positioning surface facing down is directly conveyed to a first feeding unit, and the holder with a positioning surface facing up can realize automatic feedingand detection of the positioning surface by adding the automatic feeding and the turning system before a grinding window process as well as the holder with the positioning surface facing up is conveyed to the window processing system for grinding window processing after being turned automatically; and the holder is conveyed to the outer circle processing system and a subsequent inner hole processing system by a lifting unit, so as to realize one person operating a plurality of machines, reduce labor intensity, improve production efficiency, and reduce the turnover cycle of workpieces.

Owner:ZHEJIANG KAIDI AUTOMOTIVE PARTS IND

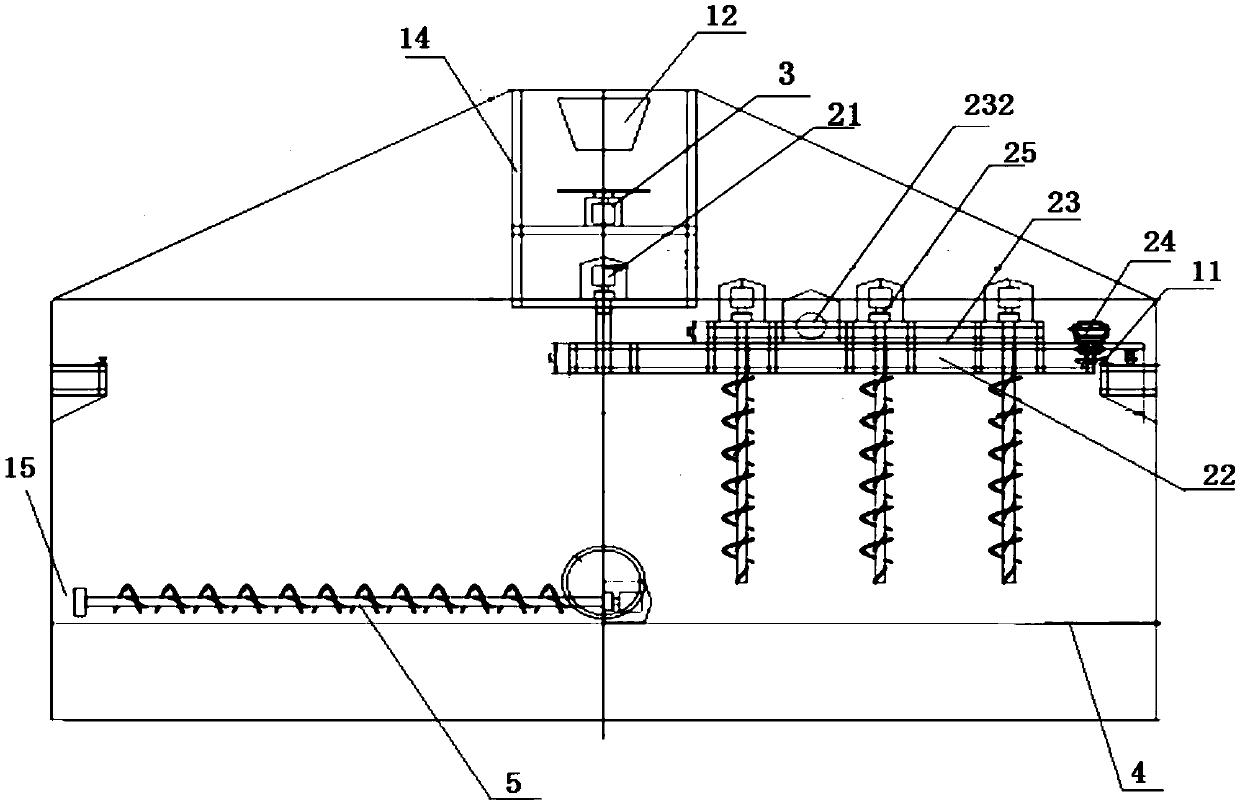

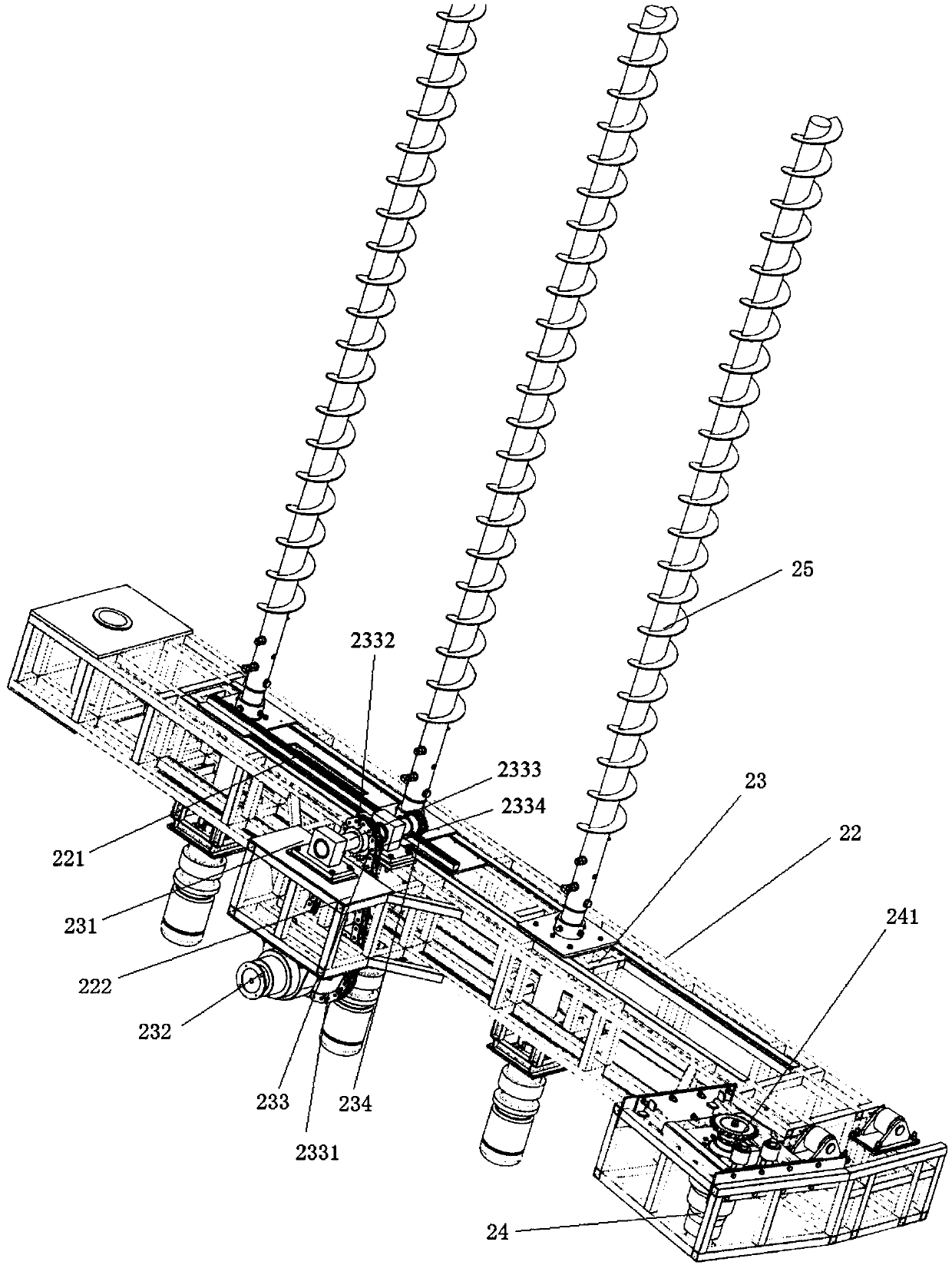

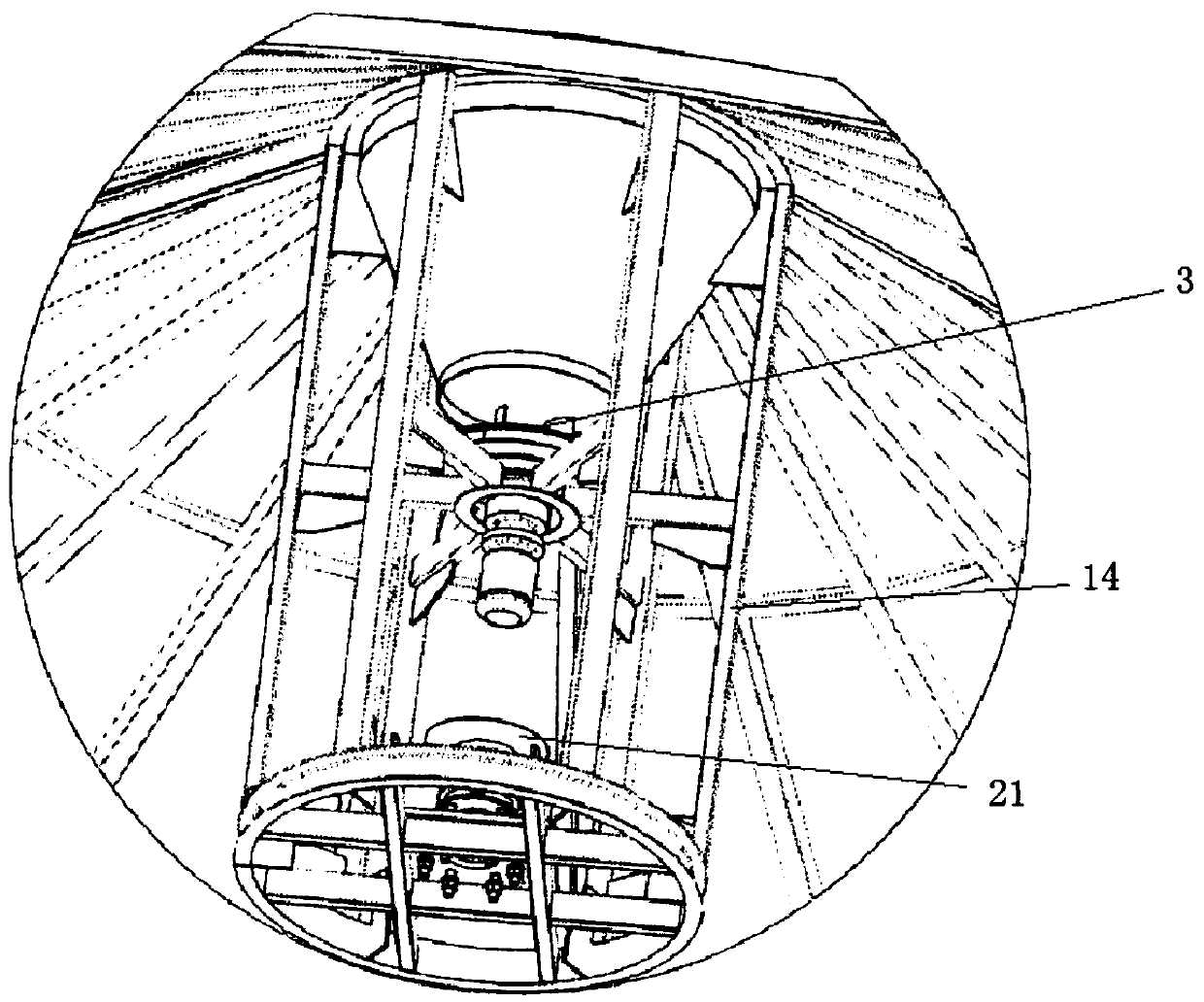

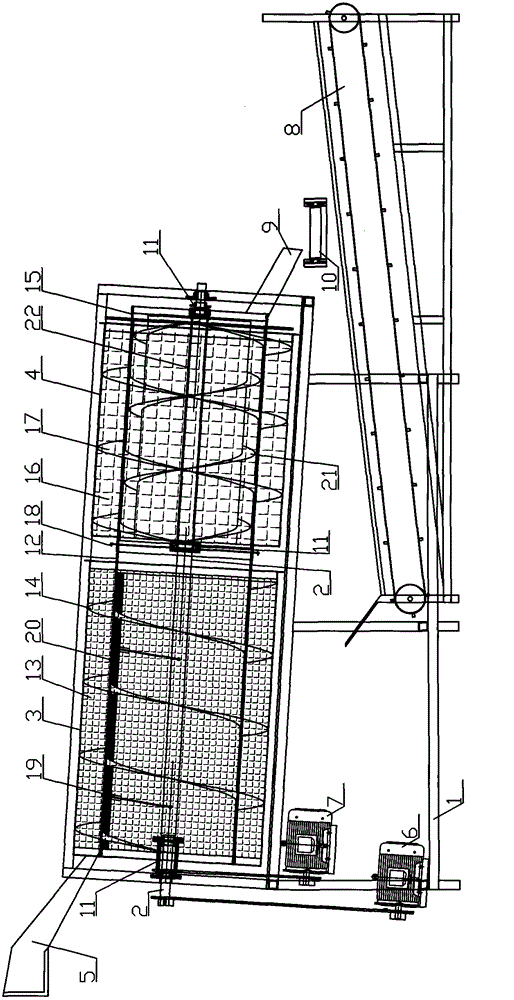

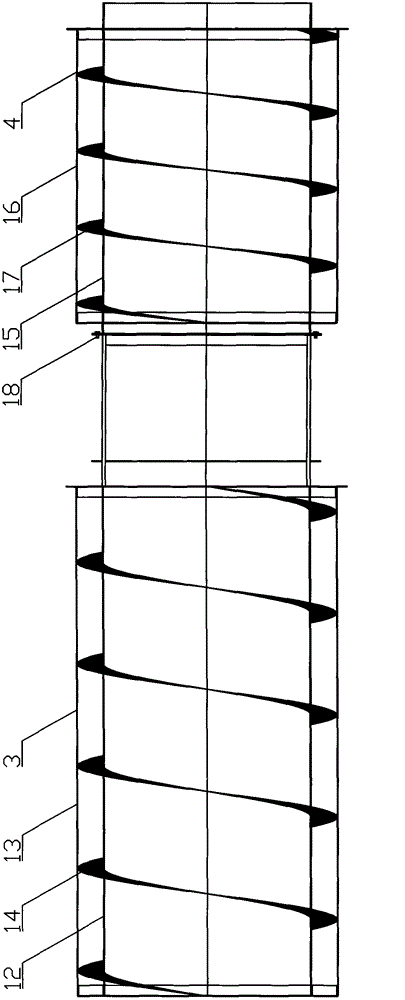

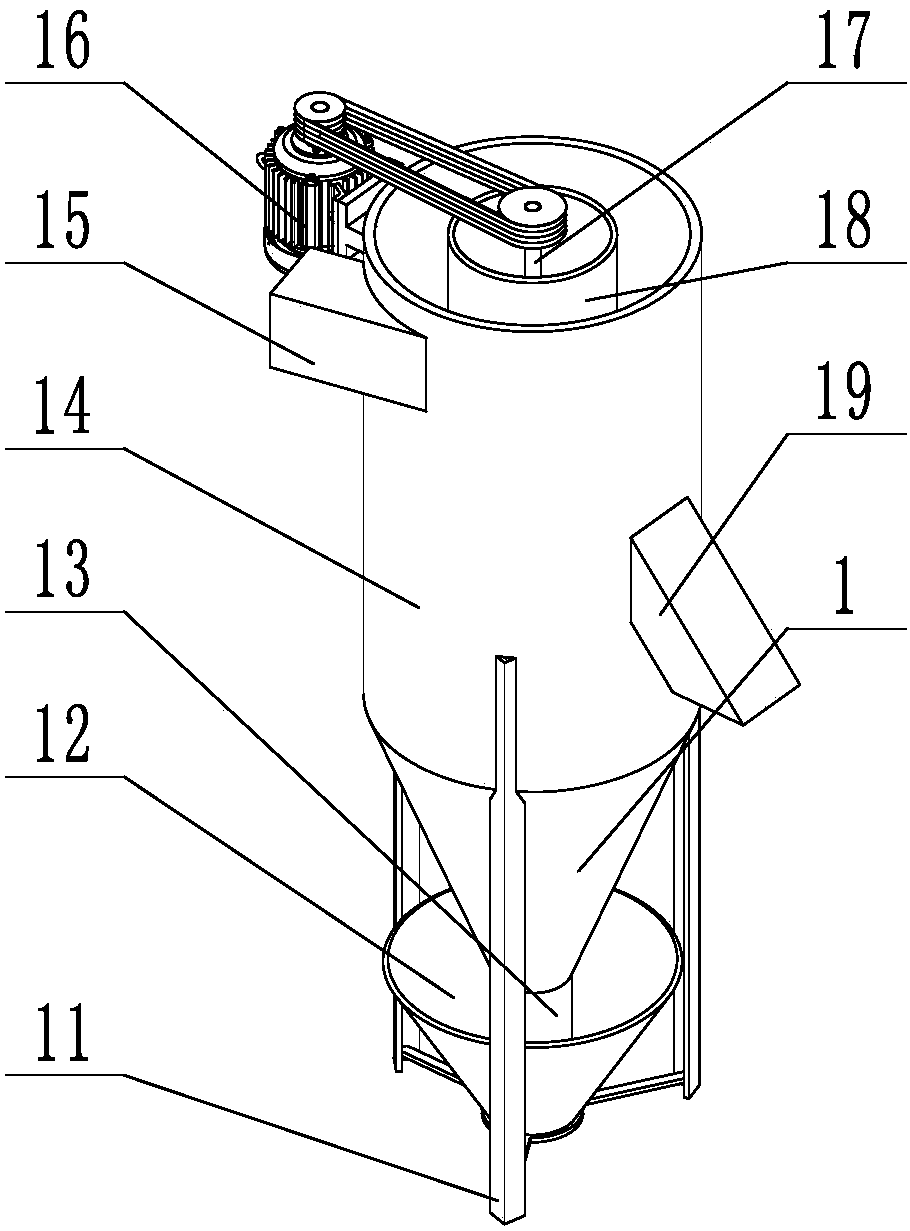

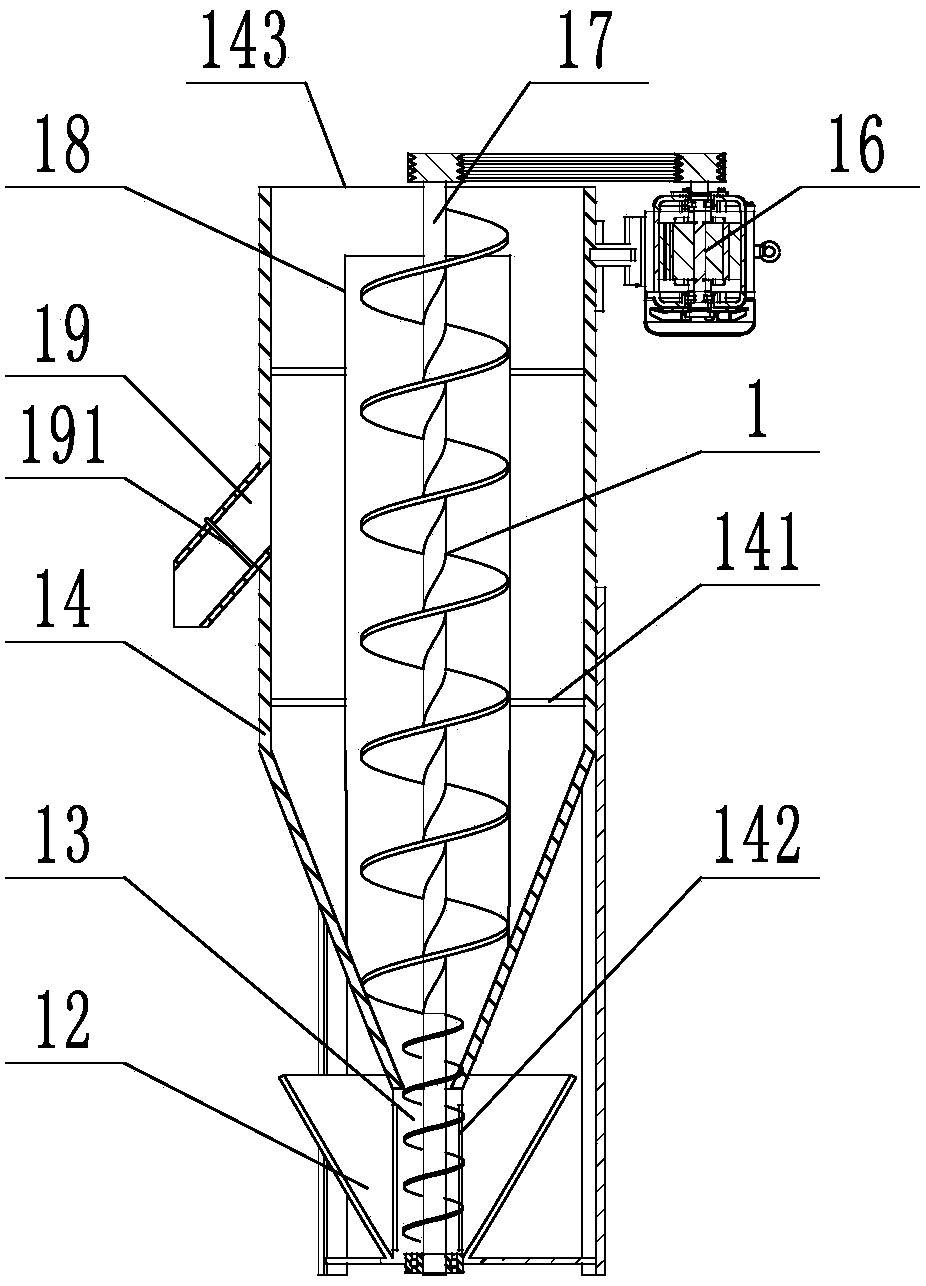

Air-drying bin

PendingCN109566732AEffective cooling and dehumidificationReduce the temperatureAgriculture tools and machinesClimate change adaptationEngineeringScrew conveyor

The invention relates to an air-drying bin. The air-drying bin comprises a bin body, a track, a screw conveyor travelling unit in transmission connection with the track, a projecting disc, a ventilating plate and a feeding unit; and the projecting disc is arranged on the lower part of a feeding inlet of the bin body, the track is arranged on the inner wall of the bin body, the ventilating plate isarranged at the bottom of the bin body, a space is reserved between the ventilating plate and the ground, the ventilating plate is provided with ventilating holes distributed perpendicular to the plate surface, and the feeding unit is arranged on the ventilating plate. The air-drying bin has the beneficial effects that the problem of difficult labor using is solved, the used labor can be reducedsignificantly, and the grain crushing phenomenon is lowered significantly; and the cost of corresponding drying equipment is also reduced.

Owner:JIANGSU PROVINCIAL AGRI RECLAMATION & DEV CO LTD

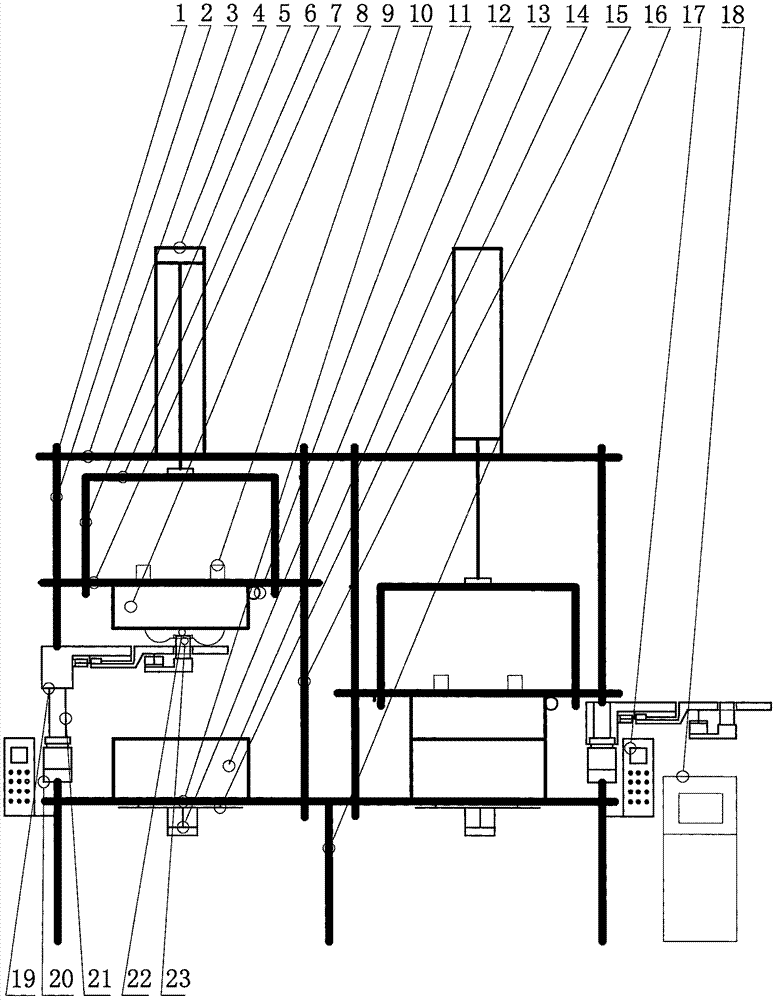

A fully automatic laminate spot welding production device and its application method

ActiveCN110039165BSolve labor difficultiesIncrease productivityResistance welding apparatusProduction lineStructural engineering

The invention relates to a full-automatic laminate spot welding production device and its application method, comprising a laminate translation machine, a rib feeding device, a reinforcing conveyor, a front frame, a front conveyor belt, a gantry welding machine, a board grabbing device, a rear Conveyor belts, rear racks and shelf turners. The laminate translation machine, the front frame, the gantry welder, and the rear frame are connected in sequence, the front conveyor belt is arranged on the front frame, and the laminate translation machine and the gantry welder are connected front and rear, and the gantry welder and the rear frame They are installed on the rear side of the front frame in turn, the plate grabbing device is set behind the gantry welding machine, the rear conveyor belt is set on the rear frame to connect with the plate grabbing device, and the laminate turning machine is set above the rear frame, close to the rear end of the rack. The production equipment of shelf laminates is integrated into one production line, which improves production efficiency, is safe and reliable, saves energy, and solves the problem of difficult labor in the production plant.

Owner:常熟市江龙智能科技有限公司 +1

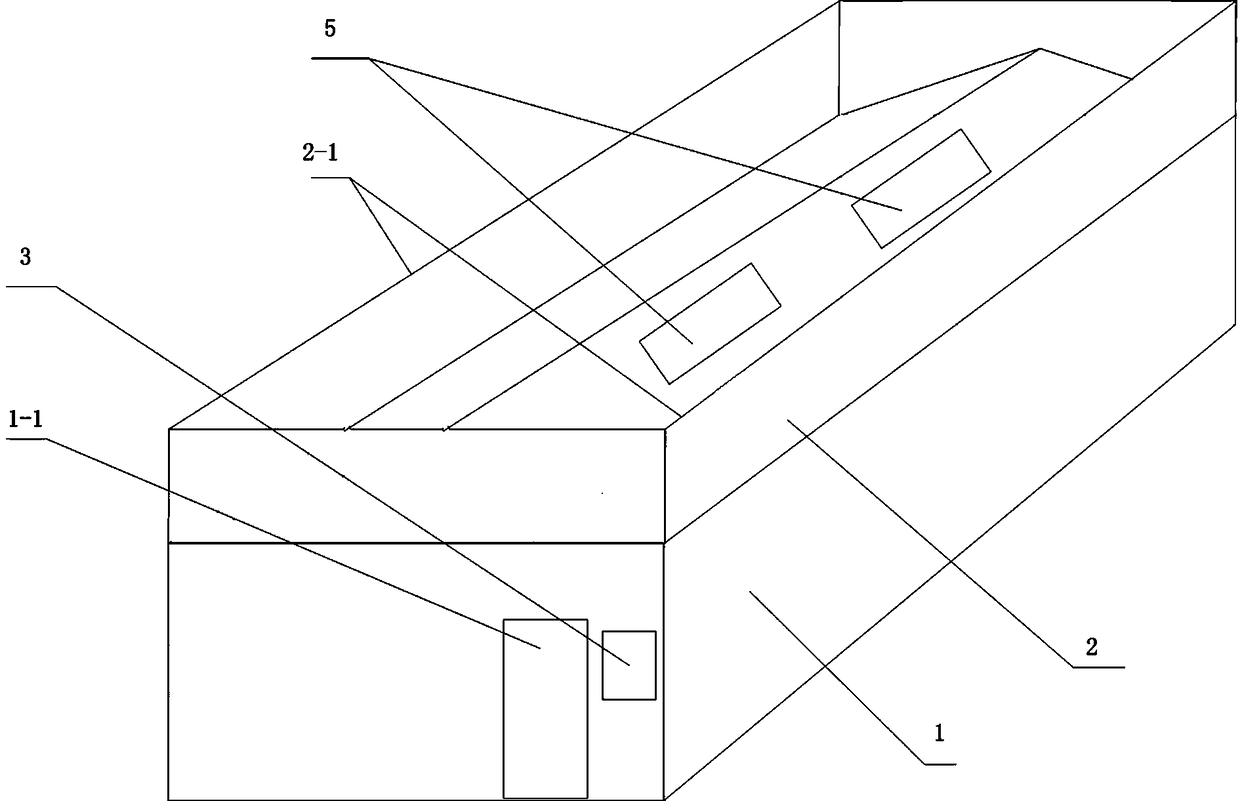

Stand column prefabrication construction process

InactiveCN113001749AGuarantee the appearance qualityIntrinsic Quality GuaranteeDischarging arrangementFeeding arrangmentsSheet steelArchitectural engineering

The invention provides a stand column prefabrication construction process. The stand column prefabrication construction process comprises the following steps of 1, selecting stand column steel bar machining equipment; 2, machining a grout sleeve; 3, conducting steel bar machining; 4, installing auxiliary equipment; 5, hoisting a stand column steel framework; step 6, machining a stand column sheet steel form; step 7, assembling the sheet steel form and putting the stand column steel framework into the sheet steel form; 8, installing a concrete pouring platform and pouring concrete; and 9, removing the sheet steel form and conducting concrete curing and storage. Compared with the prior art, the stand column prefabrication construction process has the following beneficial effects that the appearance quality and the inner quality of a prefabricated stand column, the accuracy of a connecting sleeve, the positioning accuracy of connected steel bars and the like are ensured, environmental protection is enhanced, the problem of labor difficulty is solved, the industrialization skills of workers are improved, and the construction period is shortened.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD +1

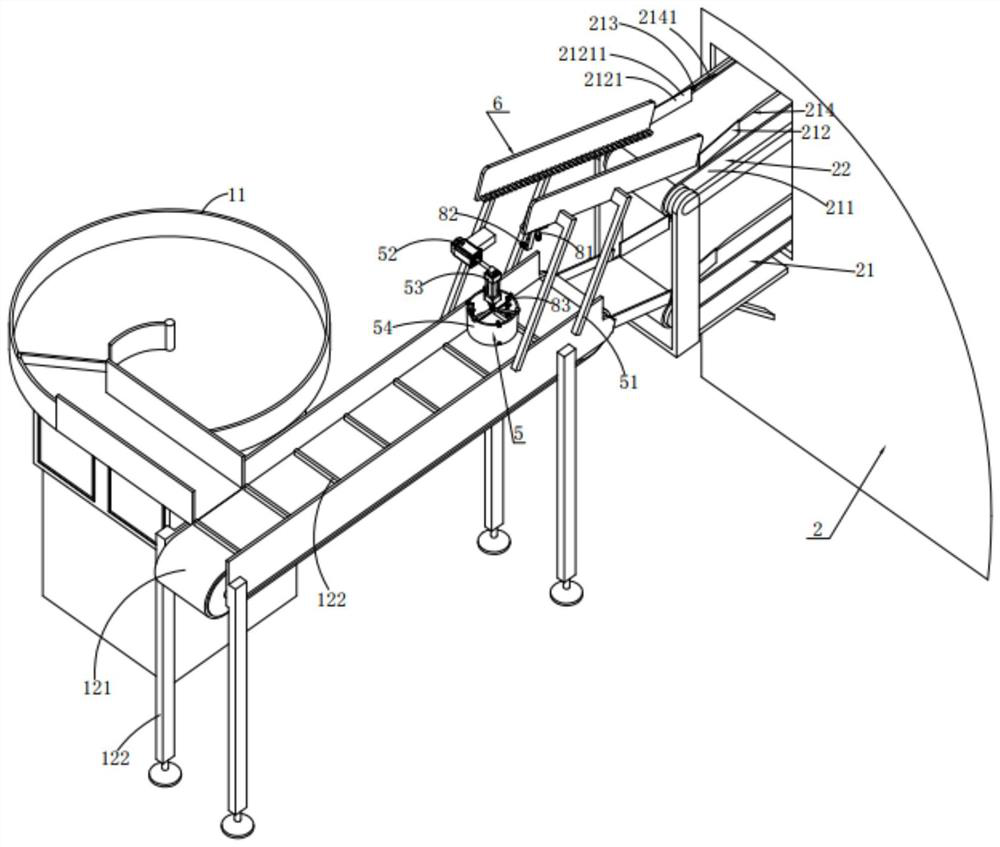

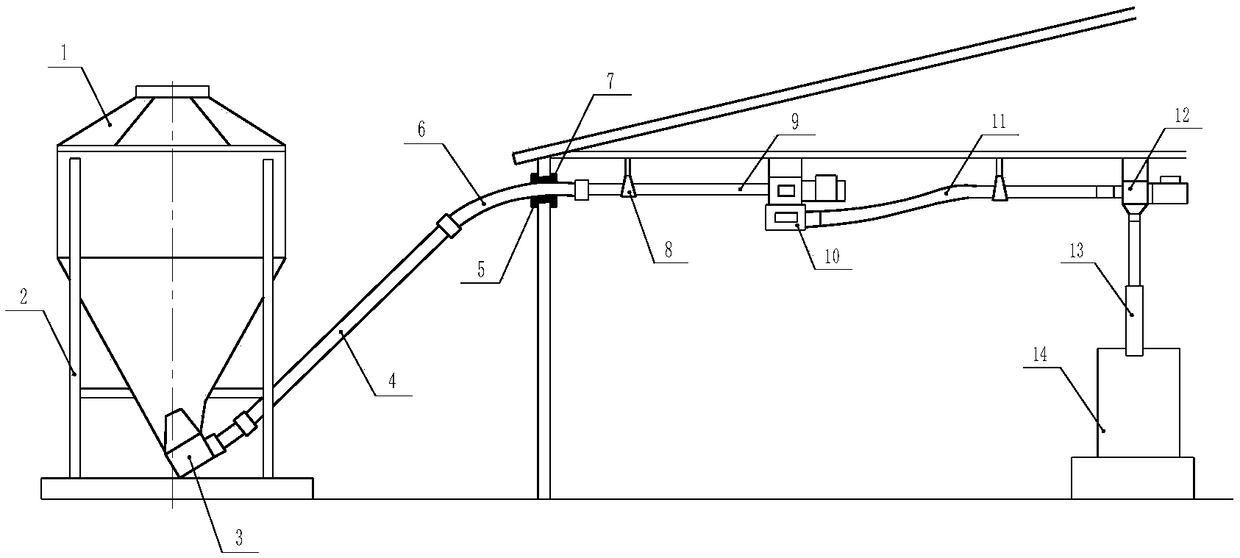

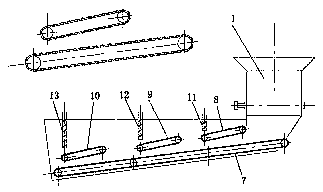

Automatic conveying and feeding system for pig farm

The invention discloses an automatic conveying and feeding system for a pig farm. The automatic conveying and feeding system for the pig farm is characterized in that a feed tower is fixedly arrangedon a bracket, a first spiral tail frame is arranged on the bottom of the feed tower, one end of a feed conveying inclined tube is connected with the first spiral tail frame, the other end of the feedconveying inclined tube is connected with a feed conveying elbow tube, a left sleeve and a right sleeve are buckled together and arranged on the feed conveying elbow tube, one end of a feed conveyingstraight tube is connected with the feed conveying elbow tube, the other end of the feed conveying straight tube is connected with a second spiral tail frame, the feed conveying straight tube is arranged on a top plate through a hanging frame, a spiral driving unit is connected with the second spiral tail frame through a tapoff tube, the spiral driving unit is arranged on the top plate, a discharge pipe is arranged in an outlet of the spiral driving unit, and a rearing trough is located under the discharge pipe. The automatic conveying and feeding system for the pig farm has the advantages that the structure is simple, not only can the problem of difficult recruitment and employment be effectively solved, but also the expenditure can be greatly saved, and the benefit of the pig farm can begreatly increased, and the system has dual effects of improving the feeding efficiency and benefits simultaneously.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

Wafer automatic loading and unloading system

ActiveCN111029287BEnsure consistencyAvoid pollutionSemiconductor/solid-state device manufacturingConveyor partsCircular discProcess equipment

Owner:SHANGHAI FORESIGHT ROBOTICS CO LTD

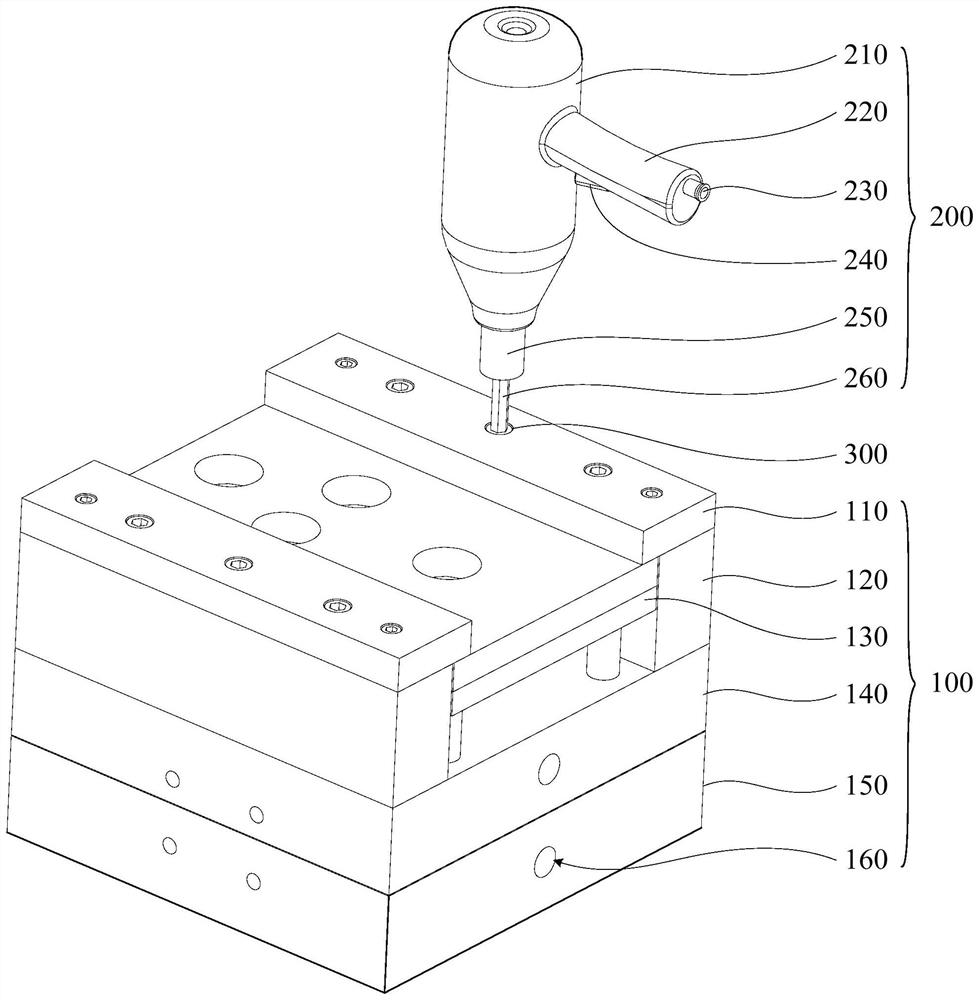

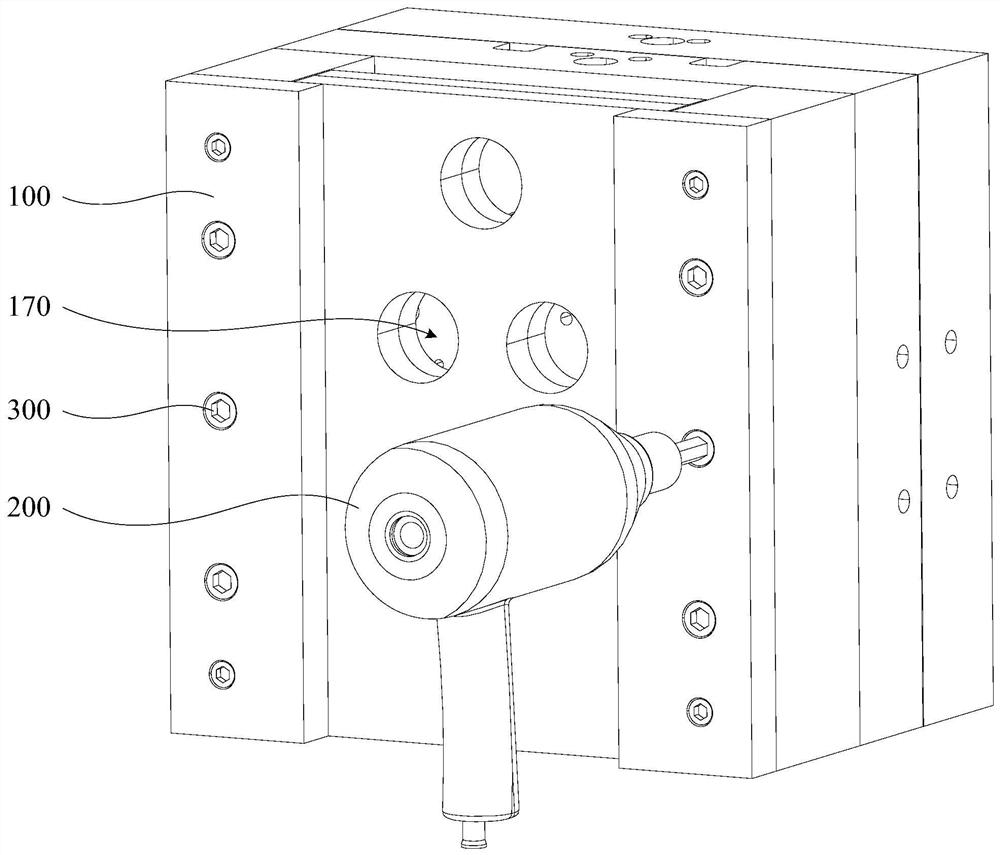

Mould dismounting system and mould processing equipment

InactiveCN111922965ASolve the disassembly problemSolve labor difficultiesPower driven toolsMetal-working hand toolsProcess equipmentEngineering

The invention relates to a mould dismounting system and mould processing equipment. The mould dismounting system comprises a mould and a pneumatic wrench, wherein a plurality of screws are arranged onthe dismounting mould; the pneumatic wrench is used for dismounting the screws; the dismounting mould is equipped with at least three mould bodies; each mould body is fixed with other at least one mould body through at least two screws; each screw is in screw joint to at least two mould bodies; a slot hole is formed in at least one dismounted mould body; the dismounted pneumatic wrench is equipped with a body, a connecting hole and a screw detachably mounted in the body; the connecting hole communicates with the body; and the screw is matched with the screw. The mould dismounting system solves the dismounting problem of a screw high-strength locking mould; while screws on the moould are dismounted, an iron tube and an Allen key do not need to use, and only one person can solve the problem; and moreover, a powerful male worker is unnecessary and a common female worker also can accomplish the operation, so that the problem that employment is difficult at present is favorably solved, andtherefore, the mould dismounting system is especially suitable for dismounting a large mould.

Owner:东莞市闻誉实业有限公司

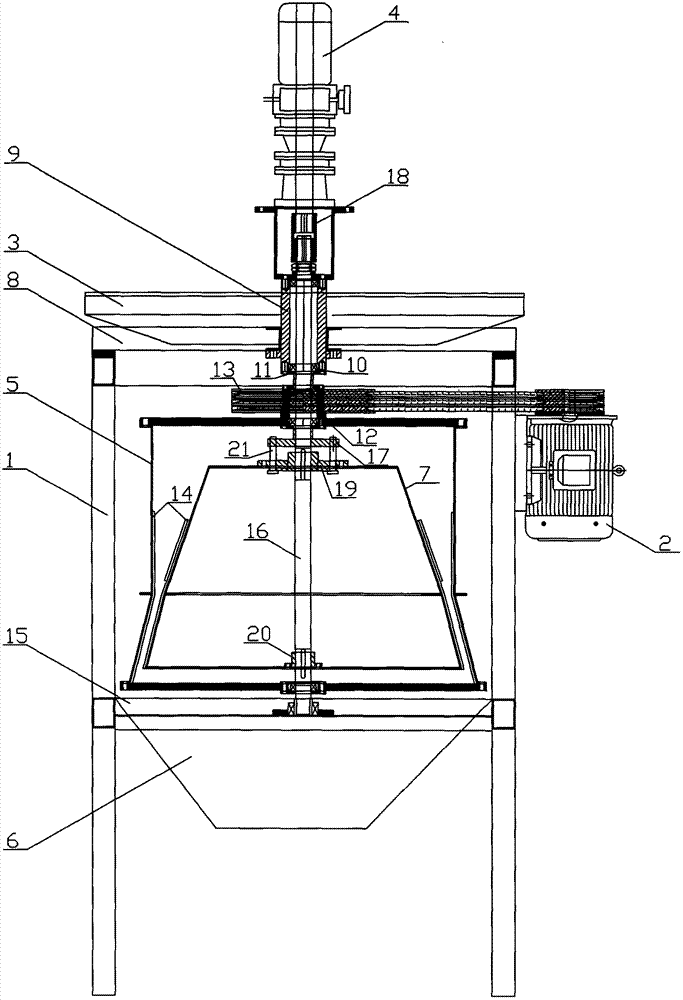

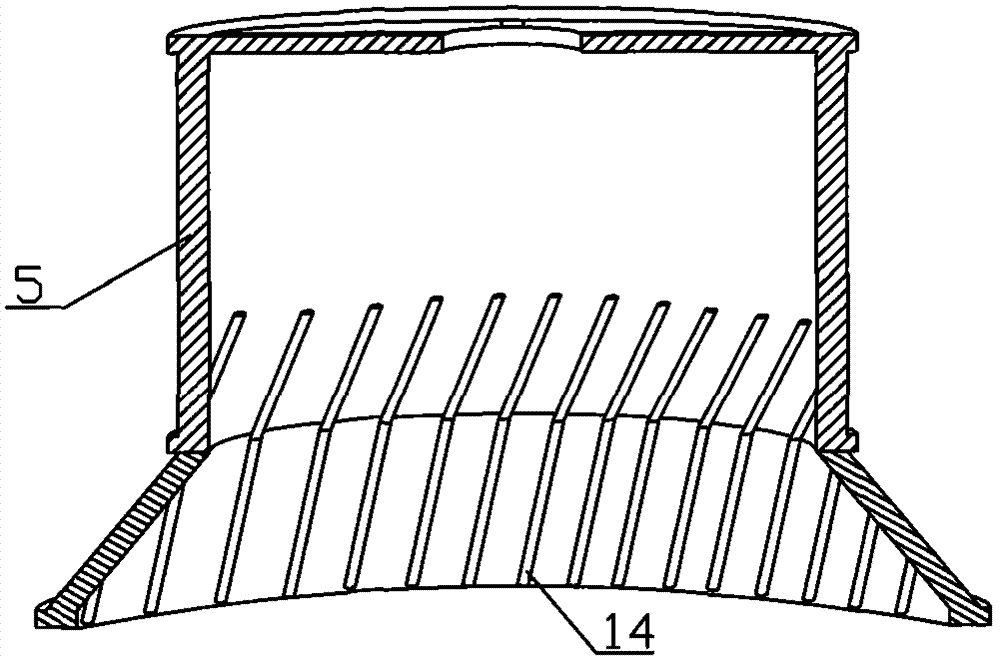

Separation device for green pepper surface and green pepper nucleus

ActiveCN103170451BImprove working environmentIncrease productivitySievingScreeningRotational axisWorking environment

Owner:TUOKETUO HONGCHANG MACHINERY MFG

Polyester bottle trademark removing machine

InactiveCN102601088BSolve labor difficultiesImprove cleaning rateHollow article cleaningPolyesterTrademark

A polyester bottle trademark removing machine belongs to the field of manufacture of machinery and consists of a feeding portion, a machine body and a discharging portion. The machine body comprises a main transmission motor, a long chain set and a short chain set group, wherein long chain set is arranged in a slope manner from high to low along a feeding opening to a discharging opening, rotates at constant speed under actions of the main transmission motor and is provided with a blade, and the short chain set group is arranged above the long chain set, the distance between the long chain set and the short chain set group is not smaller than 20mm, the rotation direction of the short chain set group is opposite to that of the long chain set under the actions of the main transmission motor, the rotation speed of the short chain set group is faster than that of the long chain set, and the short chain set group is provided with blades. The polyester bottle trademark removing machine is used for removing trademarks of polyester bottles, in the design, the problem that employment is difficult in the polyester recycling and processing industry can be resolved, work efficiency is improved, running cost of enterprises is lowered, and the shortcomings that products in the prior art are high in loss, bottle bodies are not glossy, and quality is affected are overcome. The polyester bottle trademark removing machine is free of loss, and removing rate of trademark paper is increased.

Owner:于立海

Mechanical dredging device for cleaning sludge in small river channel

InactiveCN114197560AImprove stabilityAvoid the phenomenon of collapse and tiltSoil-shifting machines/dredgersRiver routingSludge

The mechanical dredging device comprises a moving part, a supporting stand column is arranged at the top of the moving part, a supporting transverse plate is arranged at the top of one side of the supporting stand column, and a lifting extraction part is arranged at the end, away from the supporting stand column, of the supporting transverse plate; and a mud taking part is arranged below the lifting extraction part. The device has the beneficial effects that the sludge taking part below is driven through the lifting work of the lifting extraction part, the sludge taking part effectively dredges sludge in a river channel, labor force caused by manual operation is reduced, the sludge shoveled out of the river channel can be conveniently lifted up through the lifting work of the lifting lifting part, and the drainage effect in the river channel is improved.

Owner:王梦娇

Gravity casting machine with sunken portion detector

InactiveCN107350461AEasy to placeIncrease incomeCasting safety devicesFoundry mouldsEngineeringMechanical engineering

A gravity casting machine with a sag detector is characterized in that it includes a frame mechanism, an upper movable mold mechanism, a mechanical detection mechanism, and a control mechanism; the frame mechanism is provided with an upper machine plate and a lower template in the gravity casting machine , machine foot, the both sides of described upper machine plate and lower formwork are provided with side column, middle column; Described upper movable mold mechanism includes being provided with oil cylinder, top plate, support, upper formwork on upper machine plate; Said machine The detection mechanism is provided with a mechanical arm on the front side column, and a sag detector is provided in the arm support of the mechanical arm; the control mechanism is provided with a control box and a hydraulic system on the frame mechanism; The advanced upper movable mold mechanism replaces the original lower movable mold mechanism, which effectively reduces the operating surface of the upper mold, which is convenient for core workers to place the pouring riser by themselves, and reduces safety addiction; the sag detector is used to contact the sag detection point to detect and judge it , On-line replacement of manual pick-up and detection, realizing intelligent production and reducing product costs.

Owner:WUXI XIYANGKANG SCI & TECH

A forklift attachment for loading and unloading ceramic tiles

InactiveCN103979462BFunction increaseImprove efficiencyLifting devicesElectronic control systemMaterial consumption

The invention relates to a forklift truck accessory for assembling and disassembling ceramic tiles; two support frames are respectively and fixedly arranged at the two sides of a forklift truck connecting device; a lateral movement mechanism comprises a sliding shaft and an oil cylinder I; a clamp arm extension frame sheathes the sliding shaft; a support mechanism comprises a support arm which is connected with an oil cylinder II; a clamping block I is arranged on the clamp arm extension frame; two fixed arms are respectively arranged at the two sides of the top of the clamp arm extension frame; a telescopic arm is sheathed in each fixed arm; an oil cylinder III is connected between the each fixed arm and the corresponding telescopic arm; the two ends of each oil cylinder III are respectively fixedly arranged on the corresponding fixed arm and the corresponding telescopic arm; a clamping block II is connected to the lower end of each telescopic arm; the side of each telescopic arm is fixedly provided with a linkage rod; the tail end of each linkage rod is connected with a clamp arm; the oil cylinder I, the oil cylinder II and the oil cylinders III are respectively connected with an oil supply and distribution integrated valve and an oil cylinder control integrated valve by oil pipes; the oil supply and distribution integrated valve and the oil cylinder control integrated valve are respectively connected with an electronic control system. The forklift truck accessory has the beneficial effects of being simple, reliable, free from maintenance, low in material consumption and manufacturing cost, high in efficiency, stable, reliable and remarkable in economical benefit.

Owner:马志新

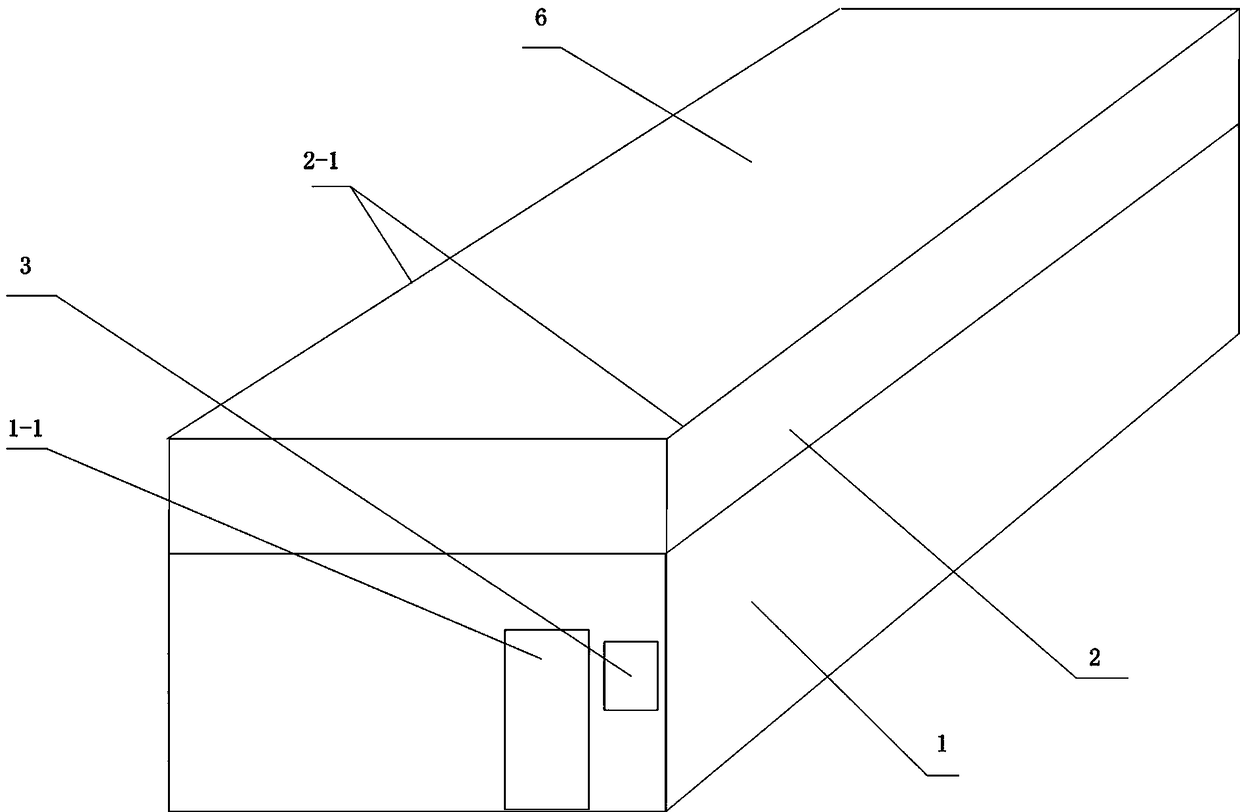

Upper movable mold gravity casting machine with simple structure

InactiveCN107377954AImprove work efficiencySolve labor difficultiesFoundry mouldsFoundry coresEngineeringMiddle column

A gravity casting machine with a simple upper movement mode, characterized in that it includes a frame mechanism, an upper movable mold mechanism, and a control mechanism; the frame mechanism is provided with an upper machine plate, a lower template, and machine feet in the gravity casting machine , both sides of the upper machine plate and the lower formwork are provided with side columns and middle columns; the upper movable mold mechanism includes an oil cylinder, a top plate, a support, and an upper formwork on the upper machine plate; the control mechanism is in The frame mechanism is equipped with a control box and a hydraulic system; the upper movable mold mechanism installed on the upper machine plate is used to replace the original lower movable mold mechanism, which effectively reduces the operating surface of the upper mold and facilitates the core worker to place the riser by himself. Reduce safety addiction; adopt the lower ejection device installed under the lower template, which is beneficial for the product to be separated from the lower mold first, which is beneficial to energy saving and further achieves automation; adopting the original gravity casting machine in the lower motion mode for transformation can save investment , Reduce waste and reduce product costs.

Owner:WUXI XIYANGKANG SCI & TECH

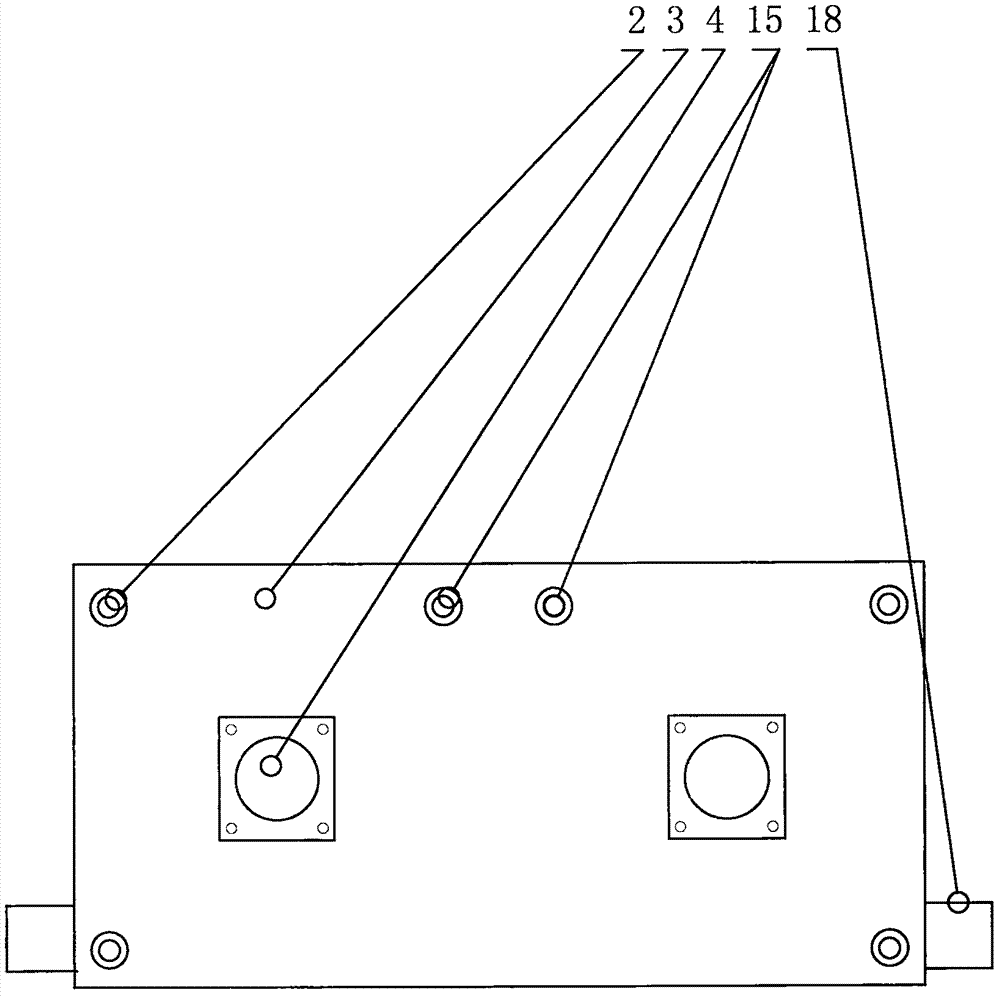

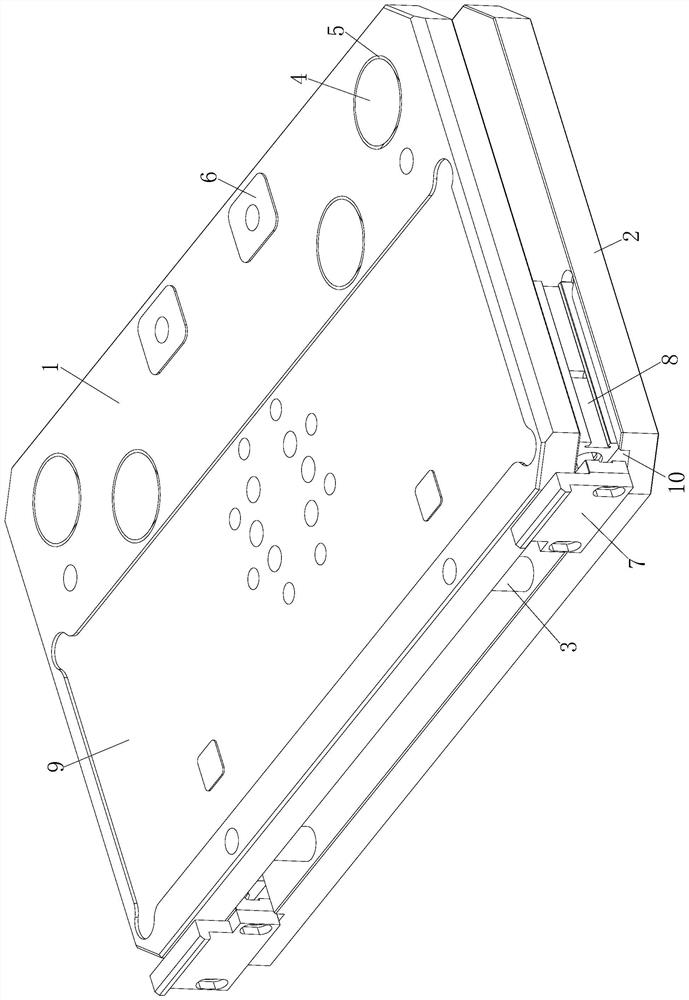

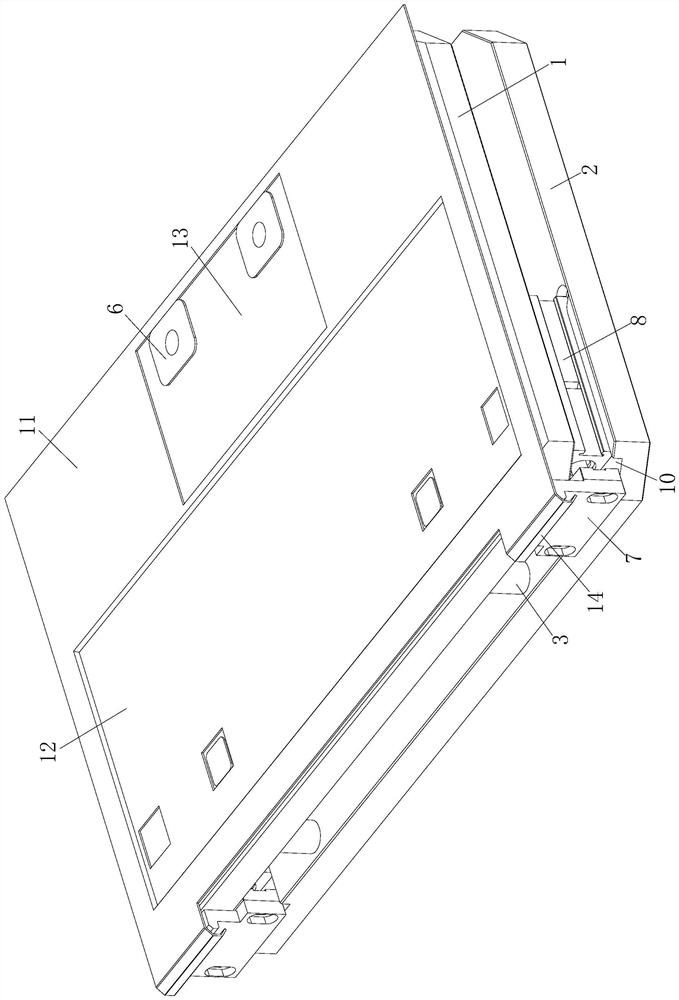

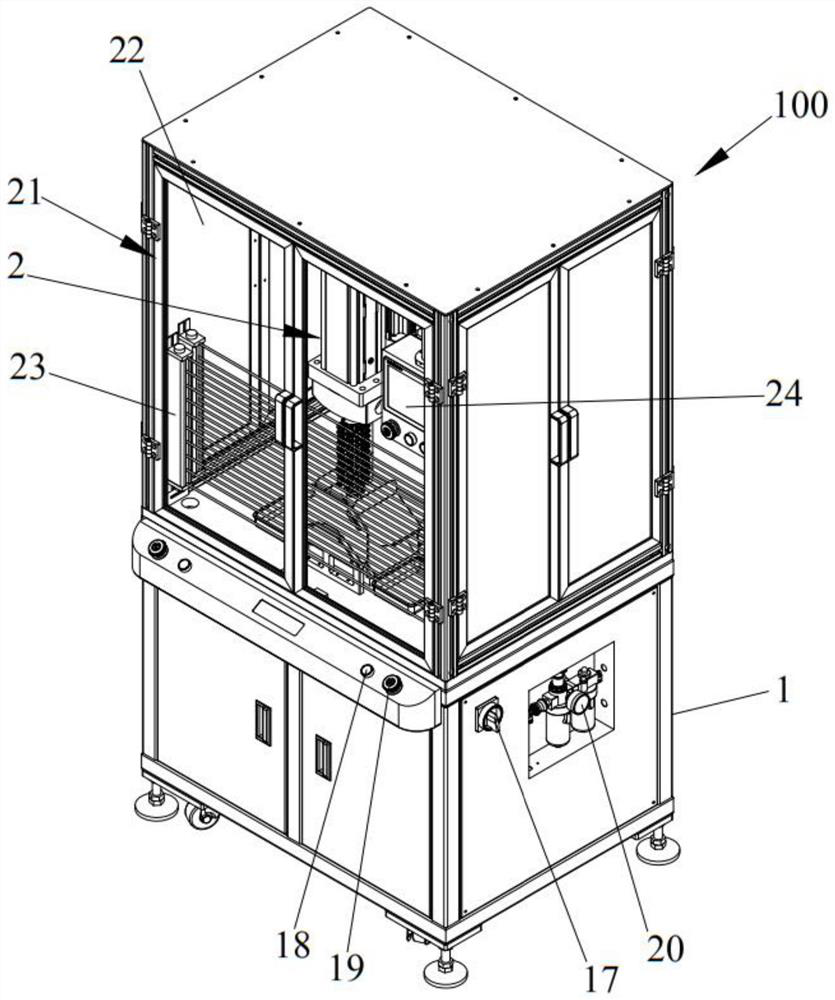

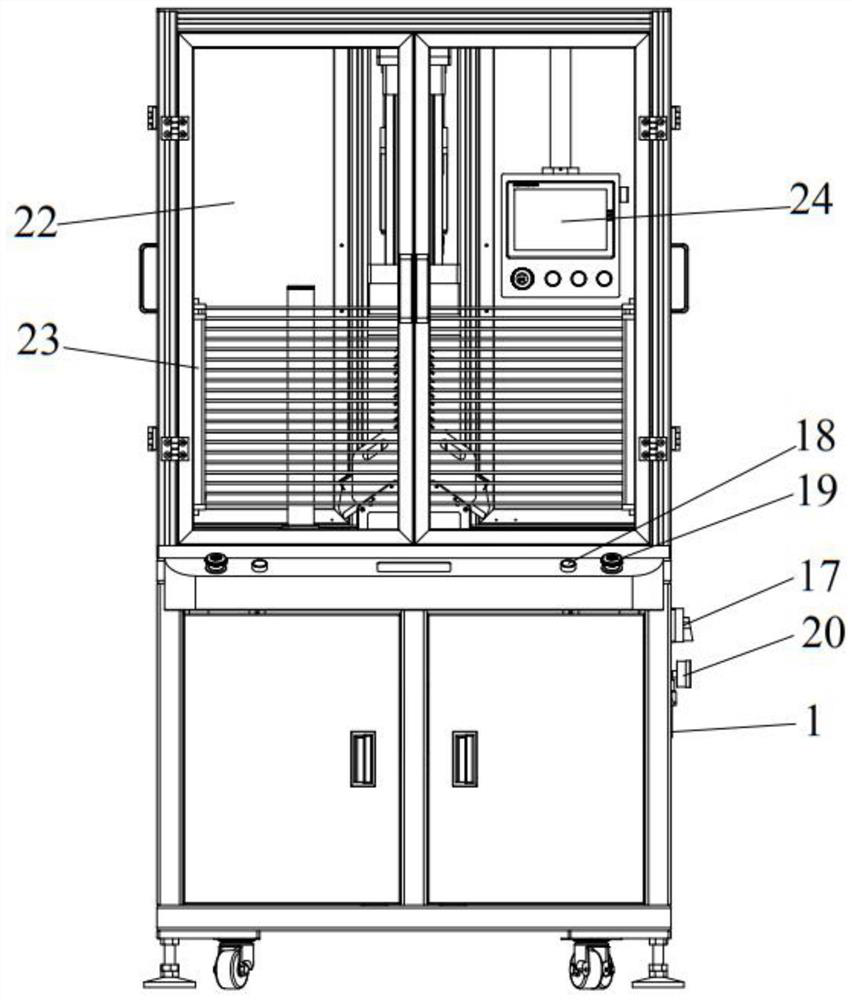

Polishing equipment and polishing method for notebook keyboard shell and polishing clamping jaw assembling method

PendingCN114734324ASolve labor difficultiesReduce work injury rateEdge grinding machinesPolishing machinesEngineeringGrinding

The invention relates to a grinding device and method for a notebook keyboard shell and a grinding clamping jaw assembling method, and belongs to the field of grinding and polishing of die-casting products. The device comprises a grinding clamping jaw, a grinding mechanism, a robot and a material table, and is structurally characterized in that the grinding clamping jaw is installed on the robot, the robot is matched with the grinding mechanism and the material table, and the grinding clamping jaw comprises an upper fixing plate, a lower fixing plate, equal-height positioning columns, suction cups, suction cup positioning holes, a fixing block, a profiling block and a double-shaft air cylinder; the upper fixing plate and the lower fixing plate are connected through the equal-height positioning column, the suction cup positioning hole is formed in the upper fixing plate, the head end of the suction cup is arranged on the lower fixing plate, the tail end of the suction cup is located in the suction cup positioning hole, the fixing block is arranged on the upper fixing plate, the double-shaft air cylinder is arranged on the lower fixing plate, and the double-shaft air cylinder is arranged on the lower fixing plate. The profiling block is arranged on the double-shaft air cylinder and matched with the fixing block, and the lower fixing plate is installed on the robot.

Owner:杭州龙砺智能科技有限公司

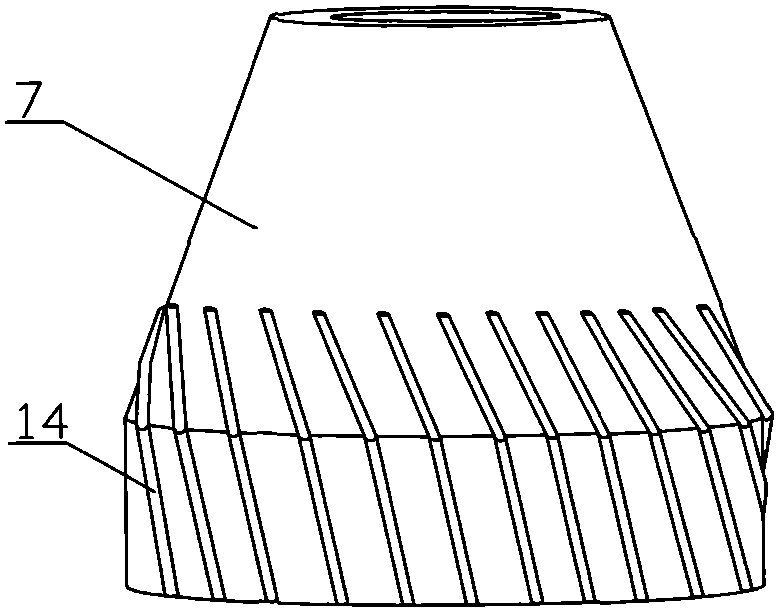

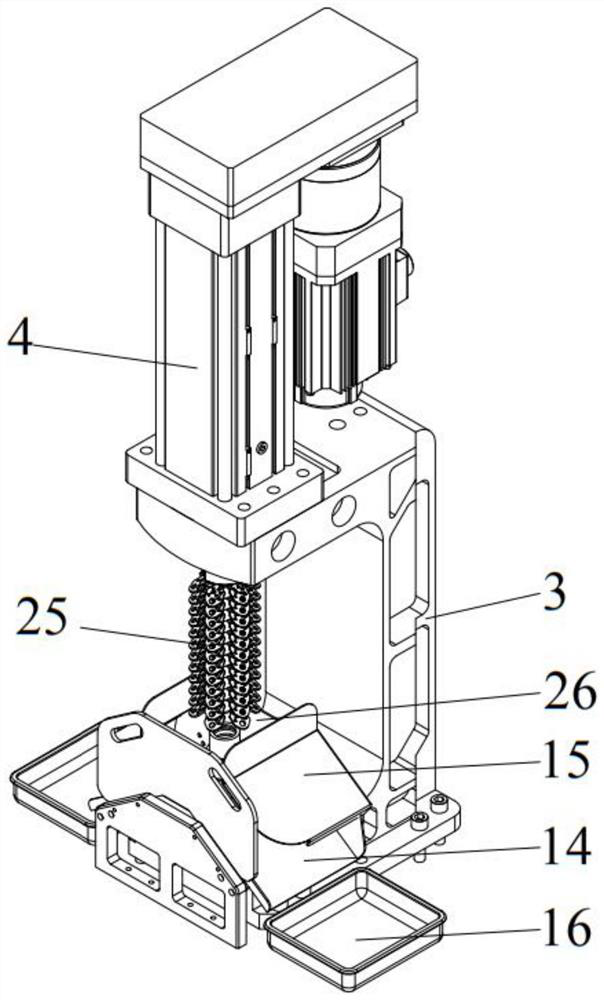

A jewelry copper tree cutting equipment

The invention discloses a jewelry copper tree cutting equipment, which relates to the technical field of jewelry cutting. On the equipment body, the lift drive device is fixedly connected to the upper end of the support base, the output end of the lift drive device is set downward, and the clamp base is fixedly connected to the output end of the lift drive device. The ring cutter is fixedly connected to the lower end of the support seat, and the annular cutter is fixedly connected to the knife seat and is arranged opposite to the clamp seat. The ornament copper tree cutting equipment provided by the invention saves manpower and improves the cutting efficiency.

Owner:温剑波

Pitter for green and red peppers

ActiveCN103202521BImprove working environmentIncrease productivityFood treatmentEngineeringMechanical engineering

The invention discloses a pitter for green and red peppers. The pitter comprises a support, an outer rotary drum motor, a feeding port, an inner rotary drum motor, an outer rotary drum, a discharging port and an inner rotary drum. The outer rotary drum motor is arranged on the side wall of the support; the feeding port is arranged at the top of the support; an outer rotary drum fixing frame is arranged on the support at the bottom of the feeding port; a main bearing drum is arranged on the outer rotary drum fixing frame; the inner rotary drum motor is arranged at the top of the main bearing drum; the outer rotary drum is suspended at the bottom of the main bearing drum; an inner rotary drum fixing frame is arranged on the support on the lower portion of the outer rotary drum; the discharging port is fixed on the support below the inner rotary drum fixing frame; and the inner rotary drum is movably arranged in an inner cavity of the outer rotary drum. The pitter for green and red peppers has the advantages of being high in production efficiency, good in separation effect and reliable in product quality.

Owner:TUOKETUO HONGCHANG MACHINERY MFG

A chain link pin shaft automatic drilling and milling machine

InactiveCN103921121BAchieving installation design complex issuesSolve the labor-intensiveOther manufacturing equipments/toolsMetal working apparatusEngineeringCam

An automatic drilling and milling machine for a chain connecting pin shaft is mounted on a rack table face, the automatic drilling and milling machine comprises a vibration disc, a feeding guide rail, an air cylinder, clamping jigs, a flat table milling mechanism, a central hole drilling mechanism, a small hole drilling mechanism, a chamfering mechanism, an octagonal eight-station rotating disc, a precise cam indexer, an electric motor and an automatic drilling and milling machine body support. The octagonal eight-station rotating disc is arranged on the front side of the automatic drilling and milling machine body support, the precise cam indexer is arranged behind the octagonal eight-station rotating disc, the electric motor is arranged on the rear side of the automatic drilling and milling machine body support, the electric motor is provided with a compressed air flow divider, the vibration disc is arranged on one side of the octagonal eight-station rotating disc, the eight clamping jigs are mounted on the octagonal eight-station rotating disc, the flat table milling mechanism, the central hole drilling mechanism and the small hole drilling mechanism are arranged on the upper side of the octagonal eight-station rotating disc, and the chamfering mechanism is mounted on the front side of the octagonal eight-station rotating disc. According to the technology, the full-automatic production process of part machining is achieved, and production efficiency and product quality are improved greatly.

Owner:肖闯

Ornament copper tree cutting equipment

The invention discloses ornament copper tree cutting equipment, and relates to the technical field of ornament cutting. The ornament copper tree cutting equipment comprises an equipment body and a cutting device, wherein the cutting device comprises a supporting seat, a lifting driving device, a clamp seat, a tool apron and an annular cutter; the supporting seat is fixedly connected to the equipment body, and the lifting driving device is fixedly connected to the upper end of the supporting seat; the output end of the lifting driving device is arranged downwards, and the clamp seat is fixedly connected to the output end of the lifting driving device; the lifting driving device can drive the clamp seat to move up and down; the tool apron is fixedly connected to the lower end of the supporting seat; and the annular cutter is fixedly connected to the tool apron and arranged opposite to the clamp seat. According to the ornament copper tree cutting equipment, manpower is saved, and the cutting efficiency is improved.

Owner:温剑波

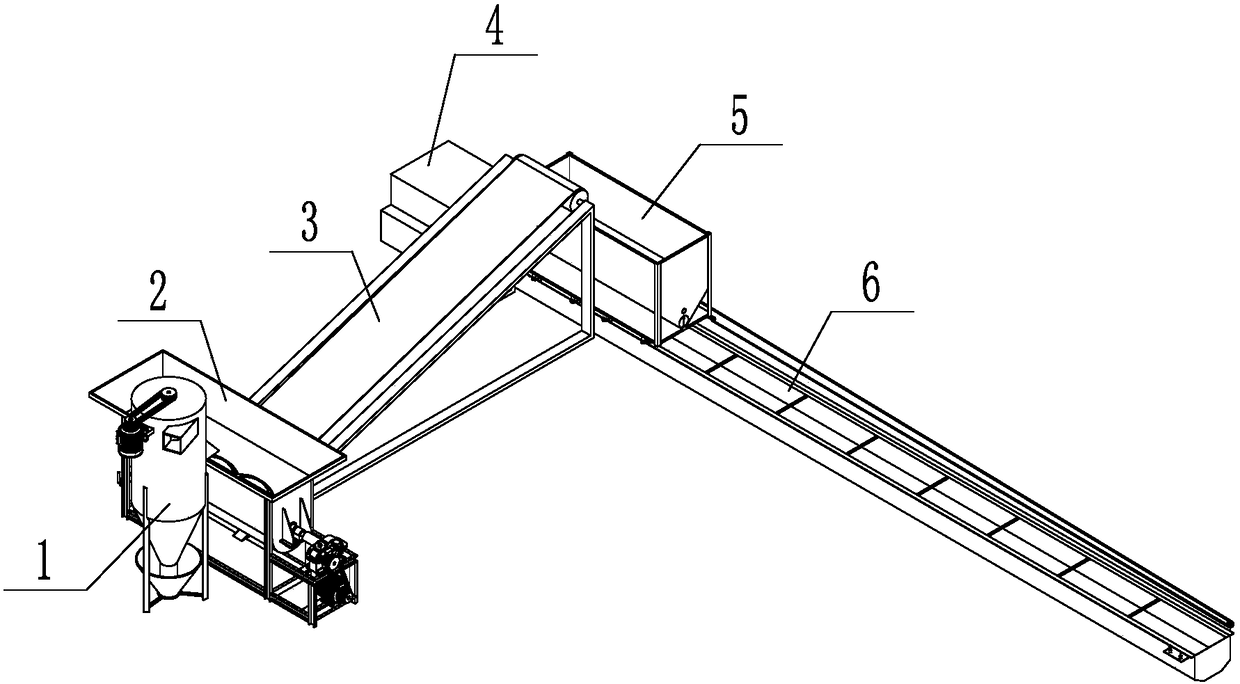

An automatic feeding system for ruminants

InactiveCN105766680BSolve labor difficultiesAutomatic feedingAnimal feeding devicesEngineeringAdverse effect

The invention discloses an automatic ruminant feeding system, and relates to the technical field of animal breeding. The automatic ruminant feeding system comprises a conveying belt, a concentrate mixer, a blender, a control cabinet, a feeder and a feeding assembly, wherein the conveying belt comprises an upper drum, a mounting frame, a belt, a third motor and a lower drum; the upper drum and the lower drum are arranged on the mounting frame; the upper drum and the lower drum are connected through the belt; the lower drum is connected with the third motor; the discharging hole of the concentrate mixer is formed above a blending barrel of the blender; the lower drum of the conveying belt is arranged below a sealing cover on the lower part of the blender; the conveying belt is arranged between the blender and the feeding assembly; the feeder is arranged on a guide rail of the feeding assembly; one end of the feeding assembly is provided with the control cabinet. By adopting the automatic ruminant feeding system, the problems of low breeding automation degree, high labor cost, and adverse effects on ruminant feeding due to manual or mechanical causes in a breeding enterprise can be solved.

Owner:JINAN ZHANGJING ANIMAL HUSBANDRY TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com