Automatic conveying and feeding system for pig farm

An automatic conveying and feeding system technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of labor-intensive pig houses, harsh working environment, random inaccuracy of feeding amount, and inability to achieve accurate feeding, etc. , to achieve the effect of increasing the benefit of the pig farm, facilitating the management of the pig farm, and improving feeding efficiency and benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

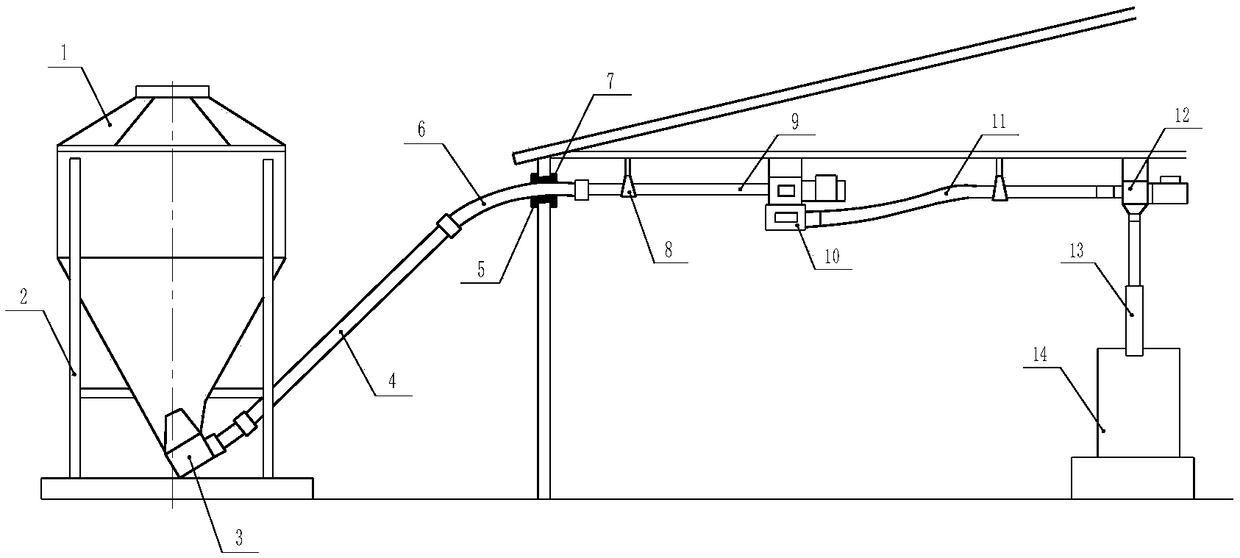

[0015] An automatic conveying and feeding system for pig farms, including: a material tower 1, a bracket 2, a first screw tail frame 3, a feeding inclined pipe 4, a left sleeve 5, a feeding elbow 6, a right sleeve 7, a hanging Frame 8, feeding straight pipe 9, second screw tail frame 10, branch pipe 11, screw drive unit 12, feeding pipe 13 and feeding tank 14, the material tower 1 is fixedly installed on the support 2, the described The first spiral tailstock 3 is installed at the bottom of the material tower 1, one end of the described material delivery inclined pipe 4 is connected with the first spiral tailstock 3 and the other end of the material delivery inclined pipe 4 is connected with the material delivery elbow 6, the described The left sleeve 5 and the right sleeve 7 are buckled together and installed on the feeding elbow 6, one end of the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com