Integrated joint bicycle frame, electric bicycle frame and electric moped frame

An electric moped, integrated technology, applied in the field of manufacturing, can solve the problems of lack of welders, high labor costs of welders, high cost of the frame, etc., and achieve the effects of reducing costs, saving energy, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

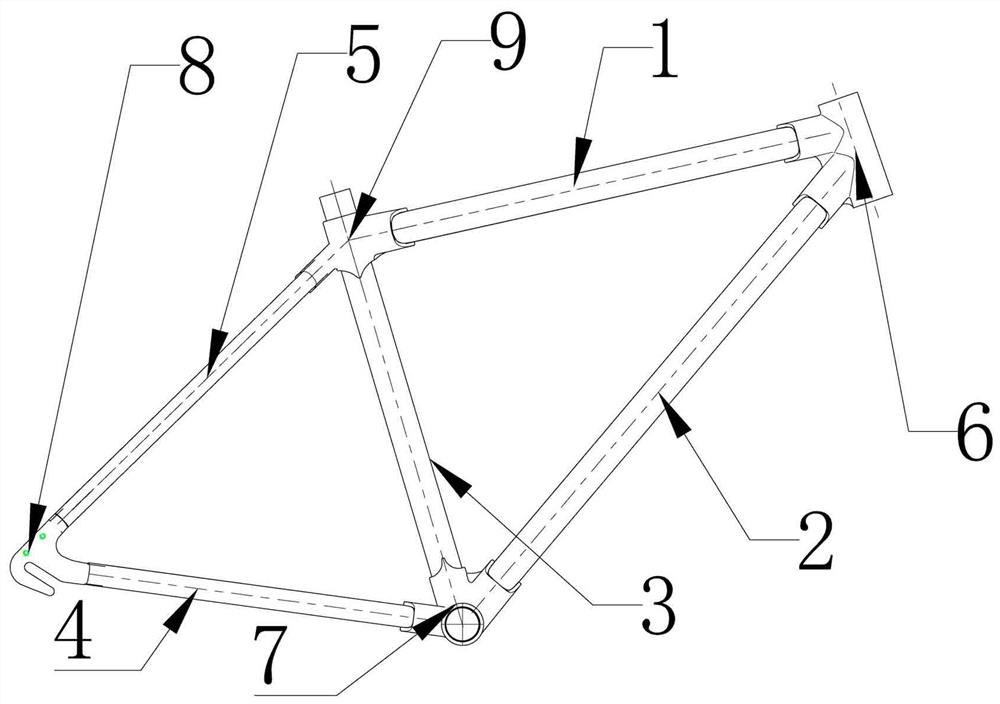

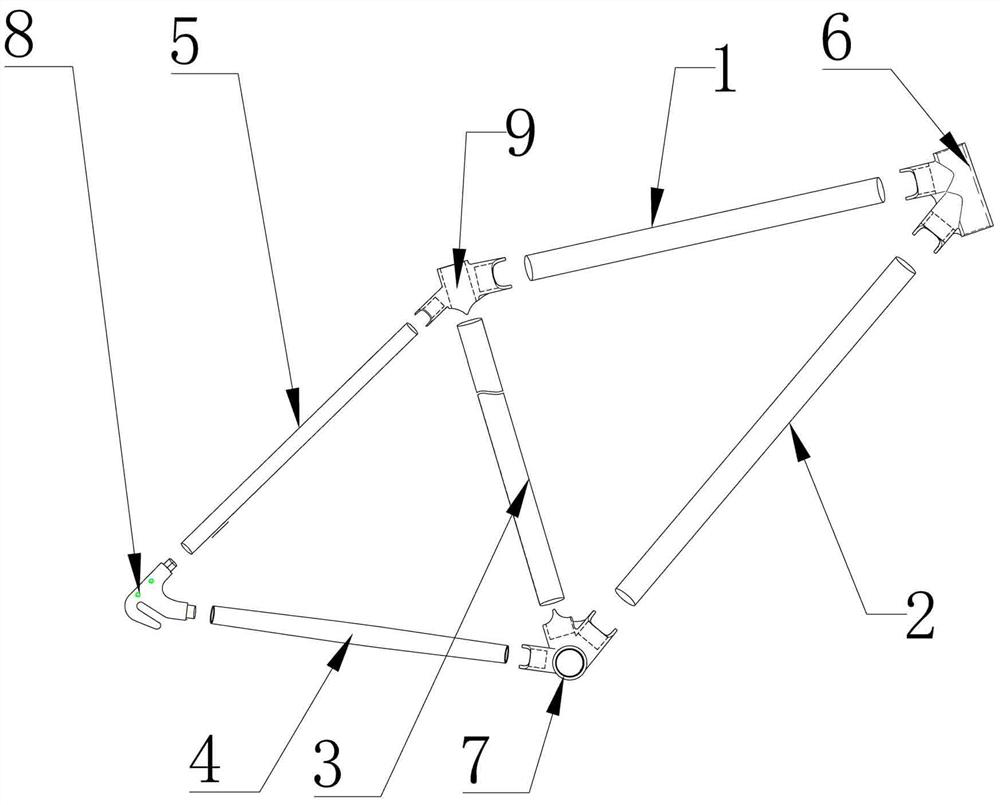

[0021] Such as Figure 1-2 As shown, the integrated joint bicycle, electric vehicle, and electric bicycle frame of the present invention include an upper tube 1, a lower tube 2, a middle tube 3, a flat fork 4 and a vertical fork 5, and wherein it also includes an integrated head pipe joint 6 , one-piece bottom bracket joint 7, one-piece middle pipe joint 9 and one-piece rear drop claw 8; one end of the upper pipe 1 is socketed with the head pipe joint 6, and the other end is socketed with the middle pipe joint 9; the lower pipe 2 One end is socketed with the head pipe joint 6, and the other end is socketed with the bottom bracket joint 7; the middle pipe 3 passes through the middle tube joint 9, and the lower end is socketed with the bottom bracket joint 7; one end of the flat fork 4 is connected with the bottom bracket joint The joint 7 is socketed, and the other end is socketed with the rear hook 8; the upper end of the vertical fork 5 is socketed with the middle pipe joint ...

Embodiment 2

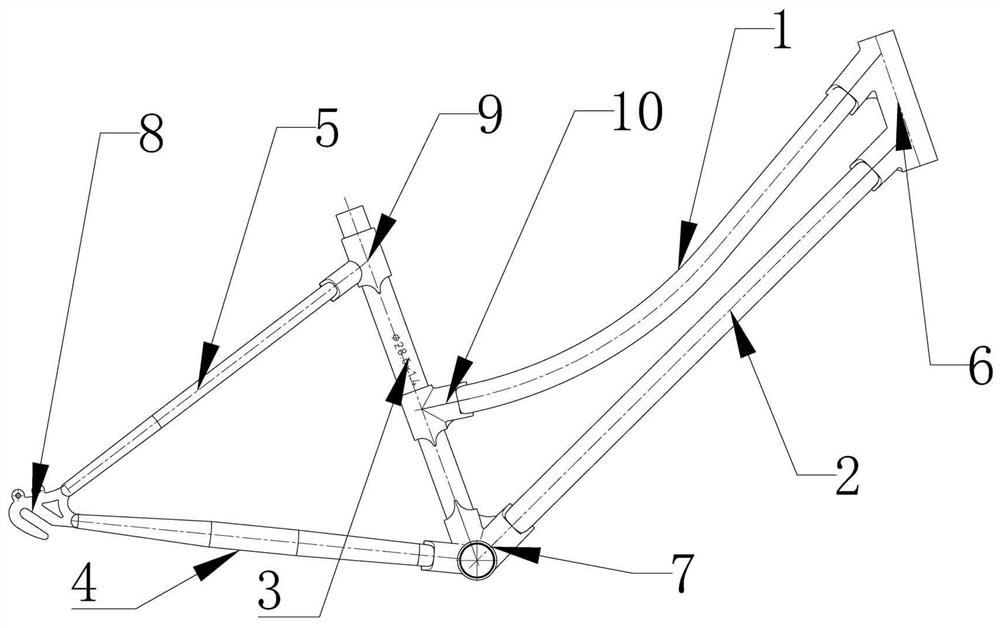

[0028] Such as Figure 3-4 As shown, the integrated joint bicycle, electric vehicle, and electric bicycle frame of the present invention include an upper tube 1, a lower tube 2, a middle tube 3, a flat fork 4 and a vertical fork 5, and wherein it also includes an integrated head pipe joint 6 , one-piece bottom bracket joint 7, one-piece middle pipe joint 9, one-piece upper pipe joint 10 and one-piece rear drop claw 8; Socketing; one end of the lower pipe 2 is socketed with the head pipe joint 6, and the other end is socketed with the bottom bracket joint 7; the middle pipe 3 passes through the middle pipe joint 9 and the upper pipe joint 10, and the lower end is connected with the bottom bracket joint 7 Socketing; one end of the flat fork 4 is socketed with the bottom bracket joint 7, and the other end is socketed with the rear hook 8; the upper end of the vertical fork 5 is socketed with the middle pipe joint 9, and the lower end is socketed with the rear hook 8; The socketi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com