Polyester bottle trademark removing machine

A label-removing machine and polyester bottle technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as affecting quality, large damage, dull bottle body, etc., and solve labor difficulties , Overcoming damage and improving the cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, specific embodiment of the utility model is described in further detail.

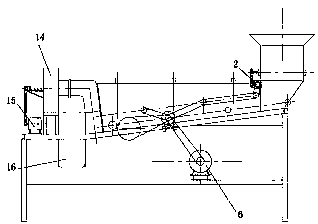

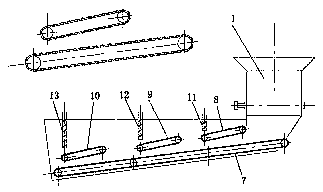

[0021] figure 1 It is the exterior view of the polyester bottle labeling machine of the present invention, the polyester bottle labeling machine is composed of a feeding part, a fuselage part and a discharging part, and the fuselage part includes a main drive motor 6, along the feeding port 1 The direction to the discharge port 16 is arranged in a slope form from high to low and rotates at a constant speed under the action of the main drive motor 6. The long chain group 7 with blades is arranged above the long chain group 7 and between the long chain group 7 The distance is not less than 20mm, under the action of the main drive motor 6, the short chain group with blades is opposite to the rotation direction of the long chain group 7 and faster than the rotation speed of the long chain group 7.

[0022] The above polyester bottle labeling machine, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com