Pitter for green and red peppers

A technology of green and red peppers and outer drums, which is applied in the fields of application, food processing, food science, etc., can solve the problems that it is difficult to meet the requirements of food processing, the separation quality cannot be guaranteed, and the hygienic conditions cannot be guaranteed, so as to achieve hygienic Guaranteed conditions, high production efficiency, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

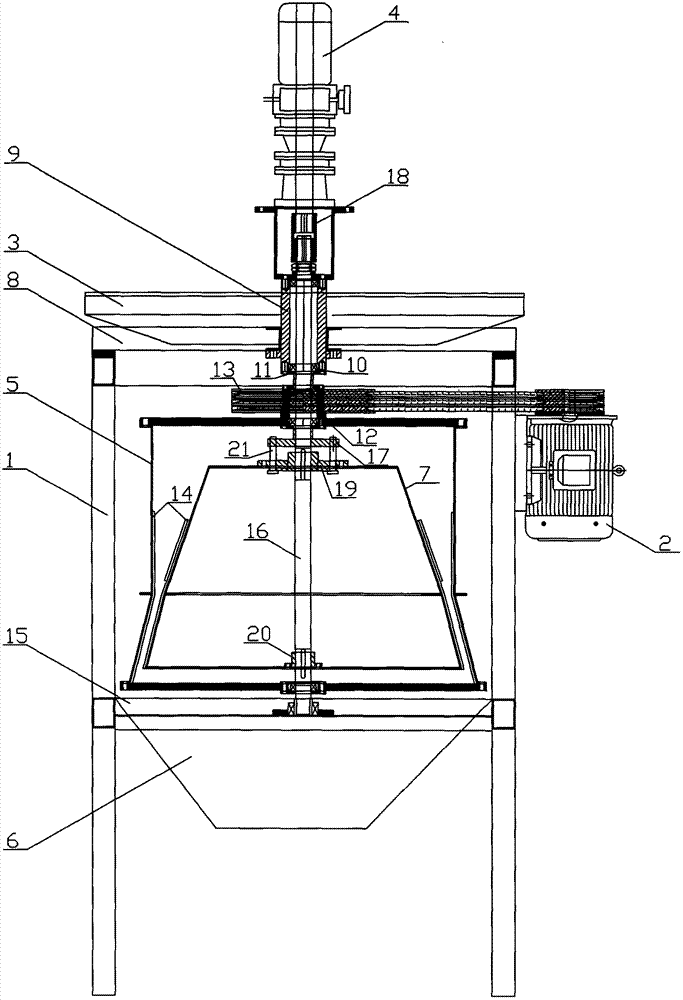

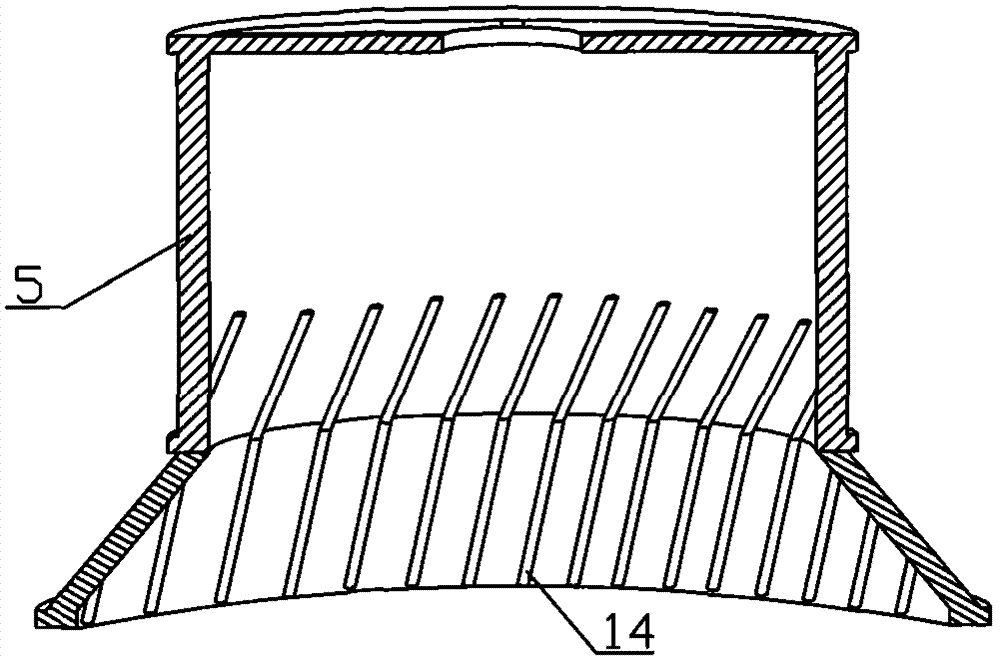

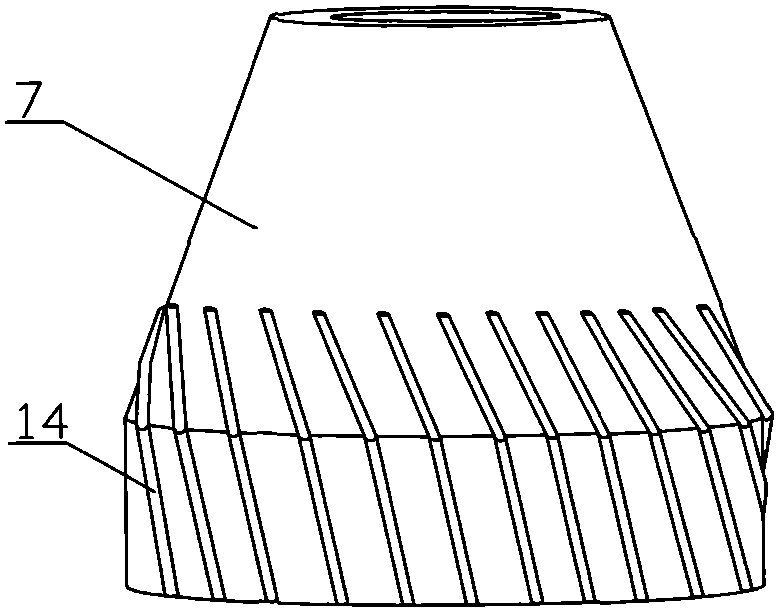

[0013] Specific implementation methods: such as Figure 1 to Figure 3 As shown, the green and red pepper rubbing machine includes a support 1, an outer drum motor 2, a feed inlet 3, an inner drum motor 4, an outer drum 5, a discharge port 6 and an inner drum 7, and a There is an outer drum motor 2; a feed inlet 3 is provided on the top of the support 1; an outer drum fixing frame 8 is arranged on the bracket 1 at the bottom of the feeding port 3; a main bearing cylinder 9 is arranged on the outer drum fixing frame 8; The bearing cylinder 9 is provided with an inner roller bearing 10 and an outer roller bearing 11, the inner roller bearing 10 is placed above the outer roller bearing 11, and the outer ring of the inner roller bearing 10 and the outer ring of the outer roller bearing 11 are respectively fixed on the main bearing On the inner wall of the drum 9; the inner drum motor 4 is arranged on the top of the main bearing drum 9, and the outer drum 5 is suspended at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com