Overturning equipment for simple gravity casting machine

A gravity casting machine and equipment technology, applied in the field of aluminum alloy casting, can solve the problems affecting the automatic casting of the spoon machine, troublesome installation, large volume, etc., and achieve the effect of improving the process yield, convenient direct installation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

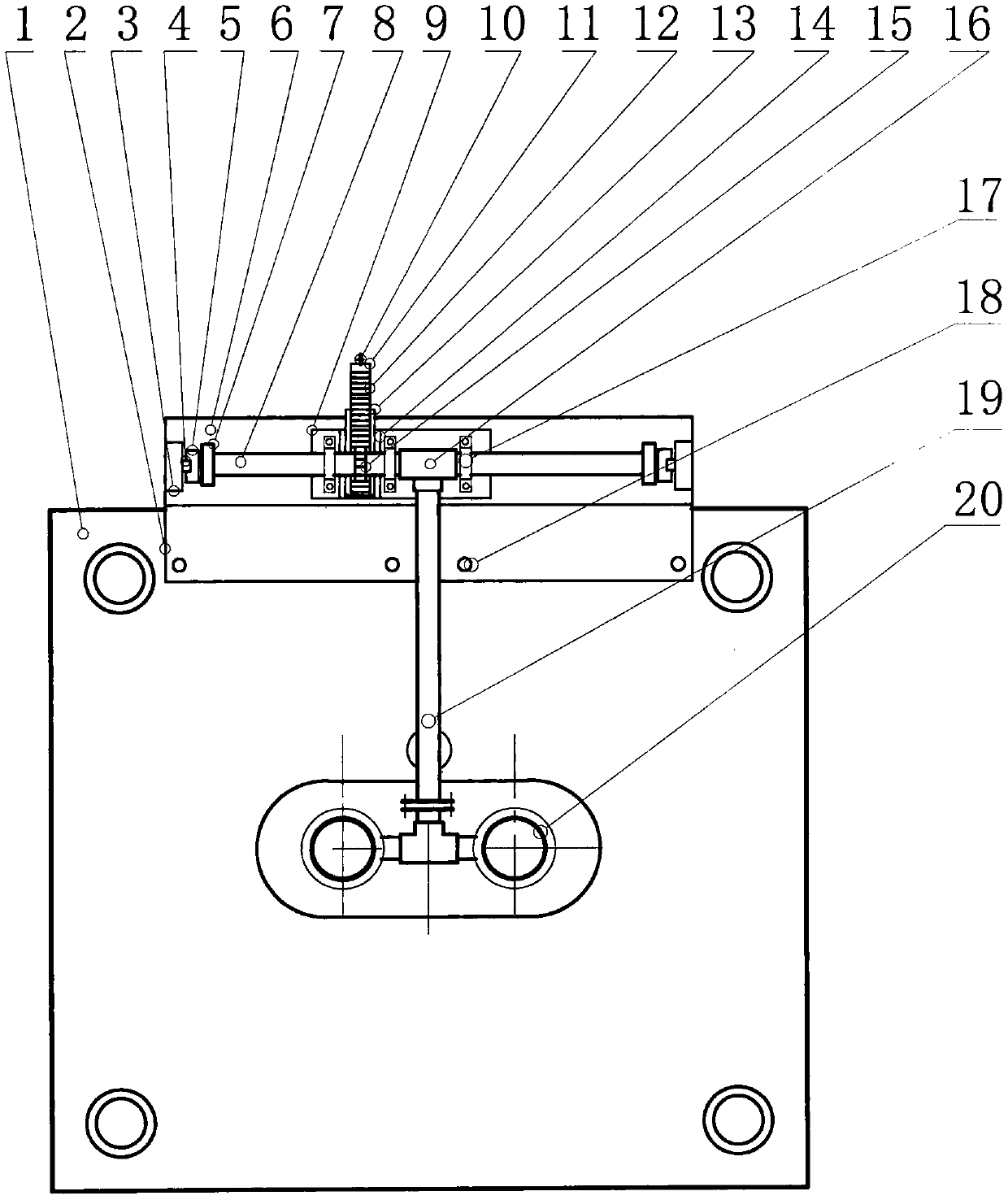

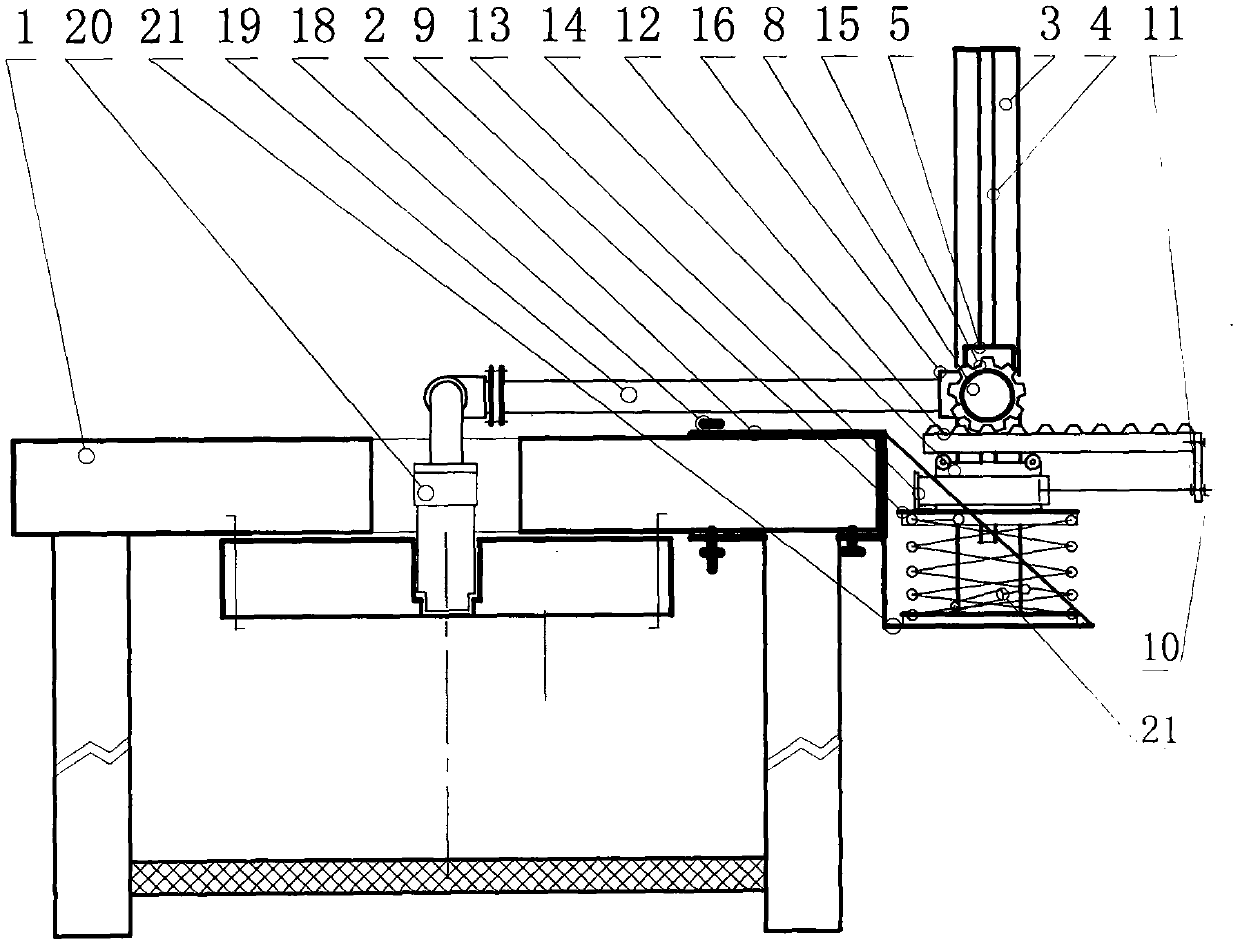

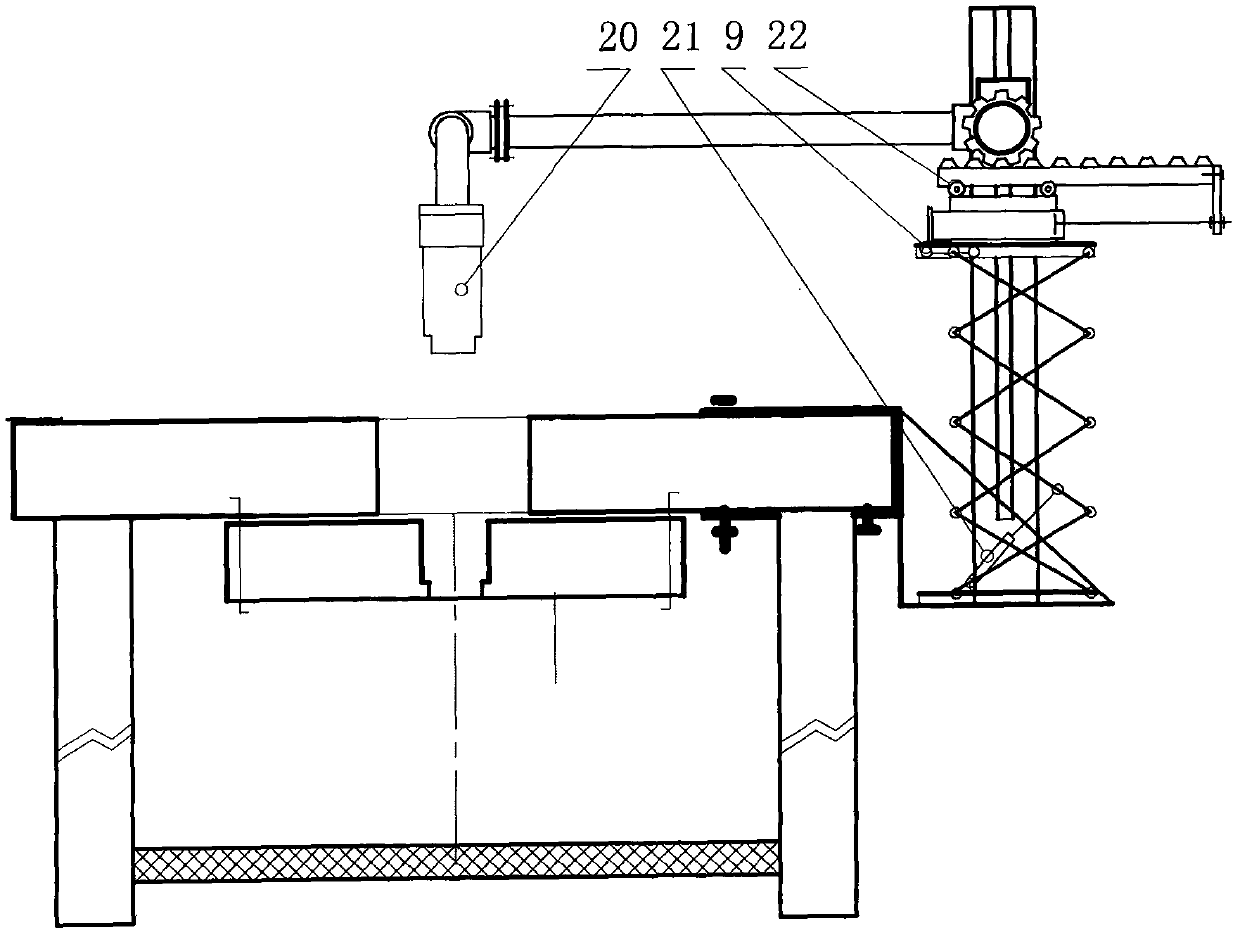

[0017] The specific implementation manners in this application will be further described below in conjunction with the accompanying drawings.

[0018] In the figure, it includes an upper mold table (1), a positioning frame (2), a guide post (3), a guide rail (4), a slider (5), a positioning table (6), a turning bearing (7), a turning shaft (8 ), lifting table (9), cylinder rod (10), rack connecting rod (11), rack (12), rack rack (13), overturning oil cylinder (14), gear (15), tee (16 ), bearing seat (17), positioning frame screw (18), flip lever (19), gate (20), lifting cylinder (21), rack pulley (22), upper moving mold template (23), upper moving Die gravity casting machine (24) and so on.

[0019] As shown in the figure, this application is a simple turning equipment for a gravity casting machine, including a positioning mechanism, a lifting mechanism, a turning mechanism, and a control mechanism;

[0020] Described positioning mechanism comprises upper die platform (1), p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com