Air-drying bin

A technology of silos and ventilation panels, which is applied in the field of air-drying silos, can solve the problems of affecting grain output and quality, increasing the cost of grain air-drying, and many potential safety hazards, achieving the effects of reducing impacts, reducing costs, and solving bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution will be further described below in conjunction with the accompanying drawings.

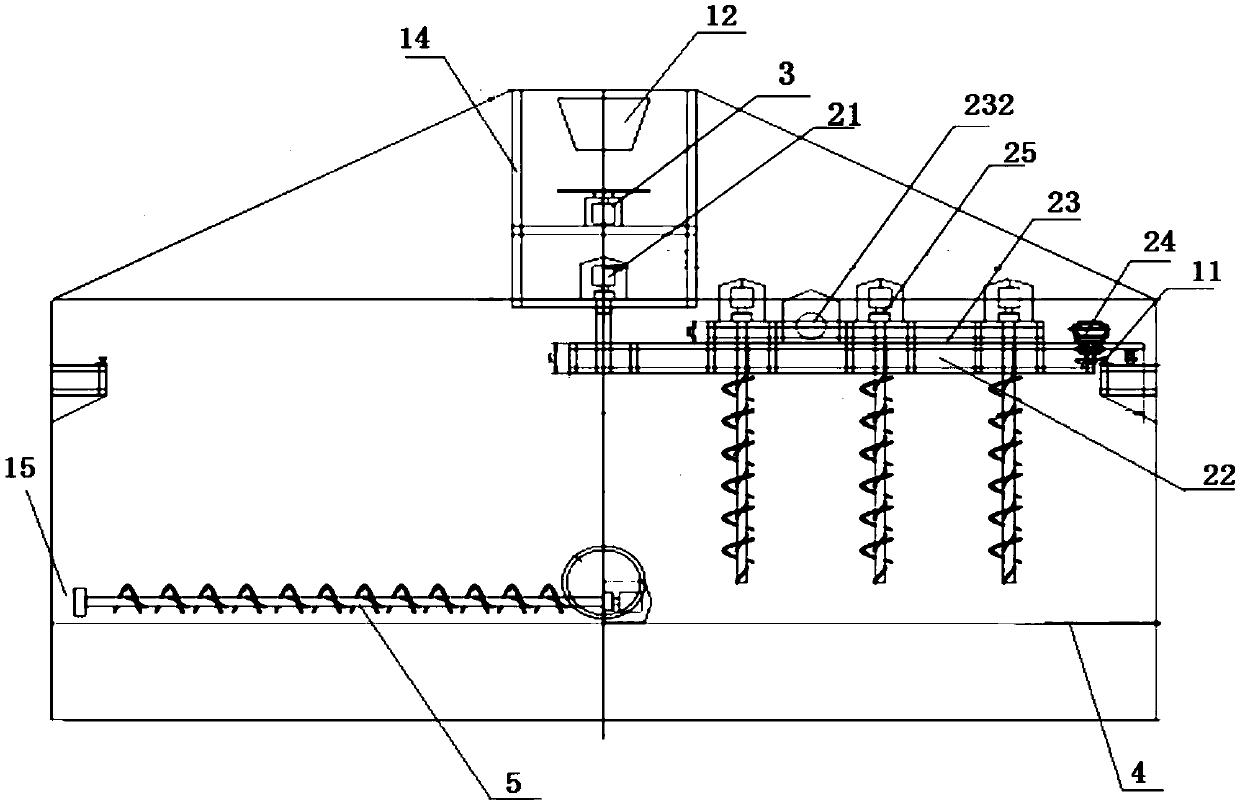

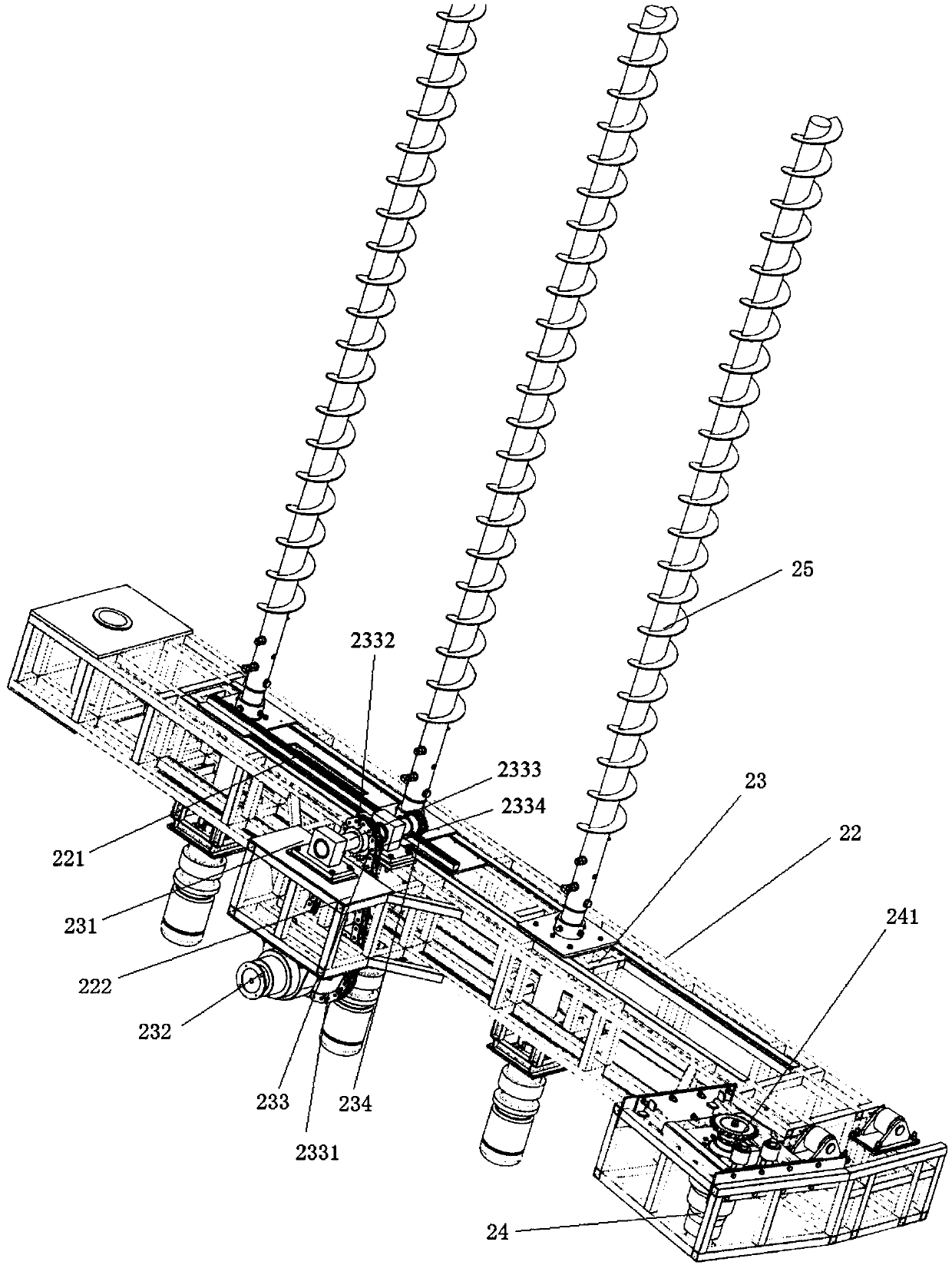

[0024] Such as figure 1 , The air-drying warehouse of this embodiment is mainly composed of a warehouse body 1, a track 11, an auger walking unit 2 connected to the track 11 by transmission, a spinner 3, a ventilation plate 4 and a feeding unit 5. The spinner 3 is arranged below the feeding port 12 of the bin body 1 , and the track 11 is arranged on the inner wall of the bin body 1 . The ventilation plate 4 is arranged at the bottom of the warehouse body and leaves a distance of 1-1.5m from the ground. In this embodiment, the distance is 1.2m. Ventilation plate 4 is provided with ventilation holes 41 distributed perpendicular to the plate surface.

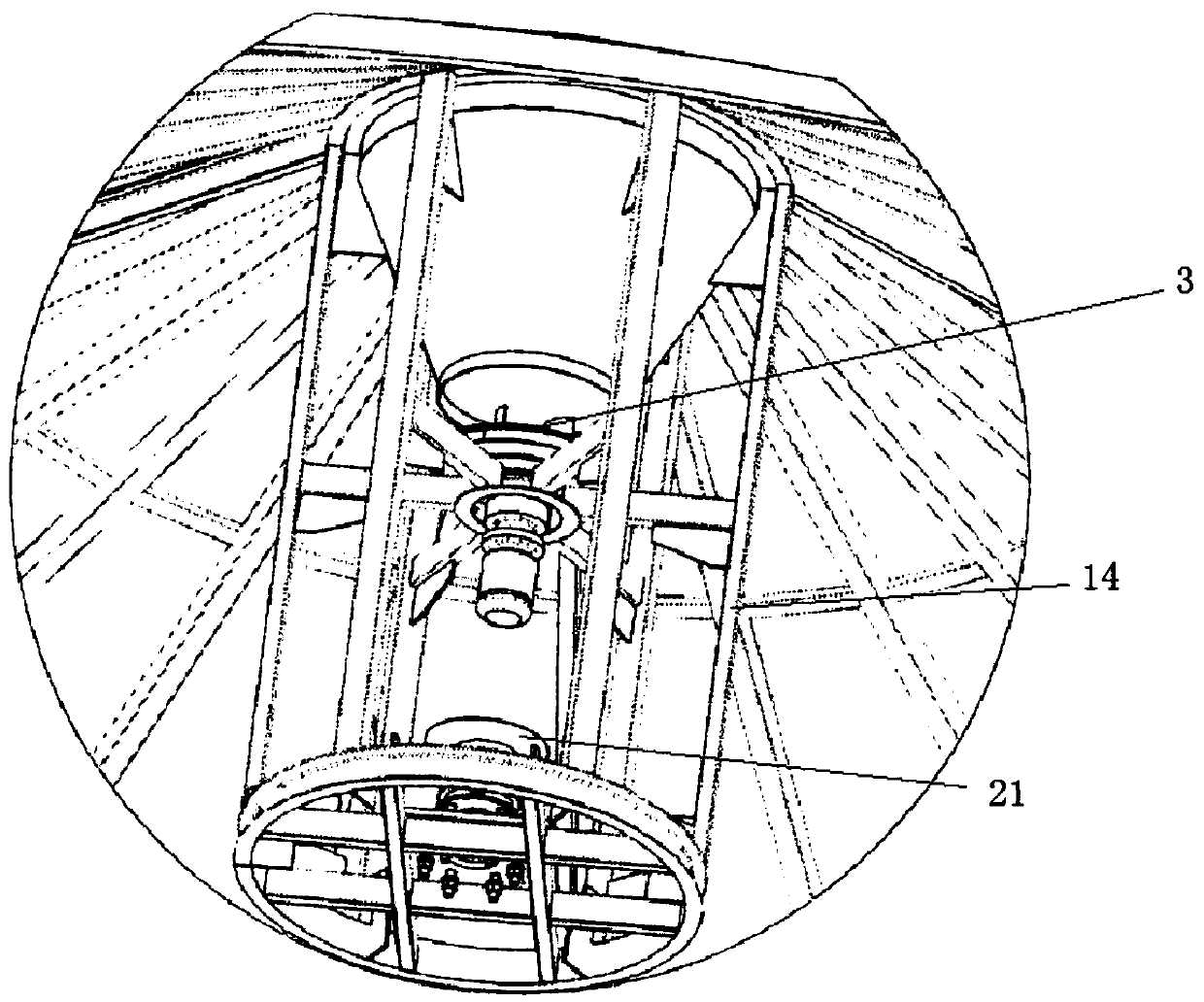

[0025] Further, the upper part of the bin body 1 is a conical bin roof 13 , and the middle part of the bin roof 13 is provided with a feed opening 12 . The bottom of the feed inlet 12 is connected with a suspension bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com