Gravity casting machine with sunken portion detector

A technology of gravity casting machine and detector, applied in the direction of casting mold, casting mold composition, casting equipment, etc., can solve the problems of safety addiction, labor force, waste of manpower, etc., to save investment, improve income, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners in this application will be further described below in conjunction with the accompanying drawings.

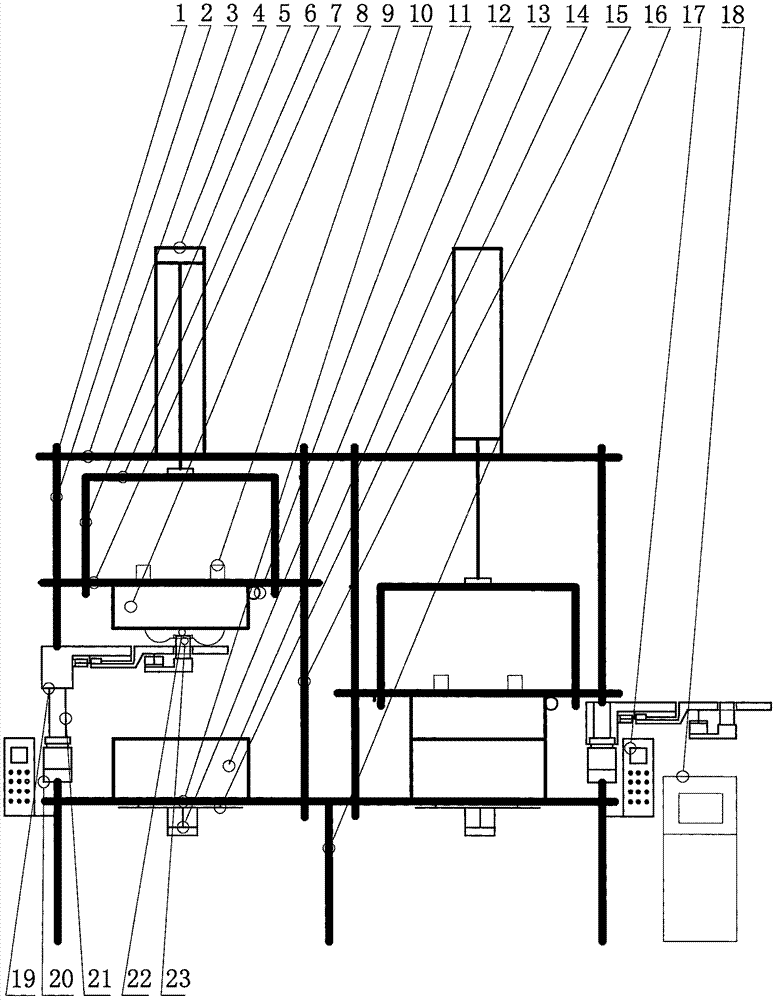

[0022] In the figure, it includes a gravity casting machine 1, a side column 2, an upper plate 3, an oil cylinder 4, a support 5, a top plate 6, an upper formwork 7, an upper formwork 8, a riser groove 9, a lower formwork 10, and an upper demoulding device 11 , lower oil cylinder 12, lower mold 13, lower top template 14, center column 15, machine foot 16, control box 17, hydraulic system 18, mechanical arm 19, rotating cylinder 20, lifting cylinder 21, sag detection part 22, sag detector 23 etc.

[0023] As shown in the figure, this application is a gravity casting machine with a sag detector, including a frame mechanism, an upper movable mold mechanism, a mechanical detection mechanism, and a control mechanism;

[0024] The frame mechanism includes an upper machine plate 3, a lower template 10, a machine foot 16, a side column 2, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com