Patents

Literature

62results about How to "Realize the clamping action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

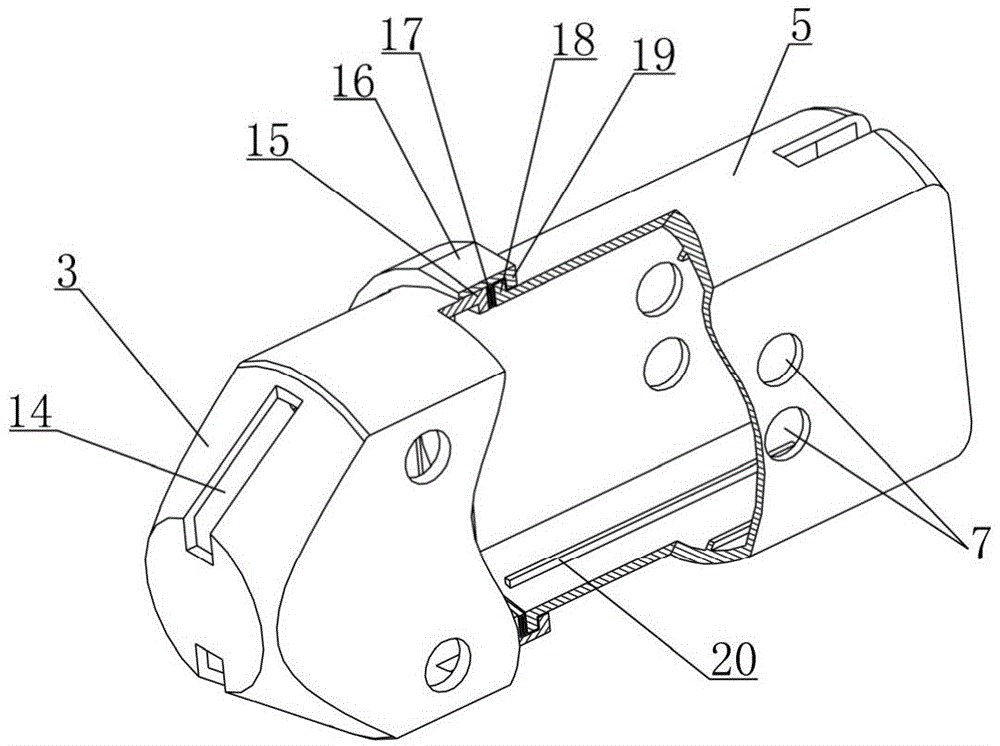

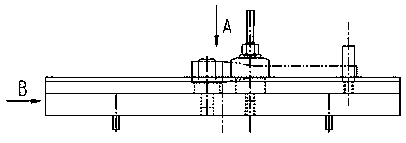

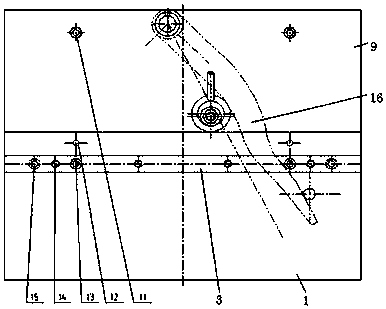

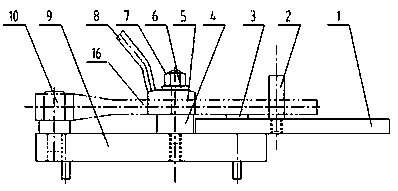

Clamping mechanism

ActiveCN101637909ARealize the clamping actionSimple structureDrilling rodsGripping headsBilateral symmetryPiston rod

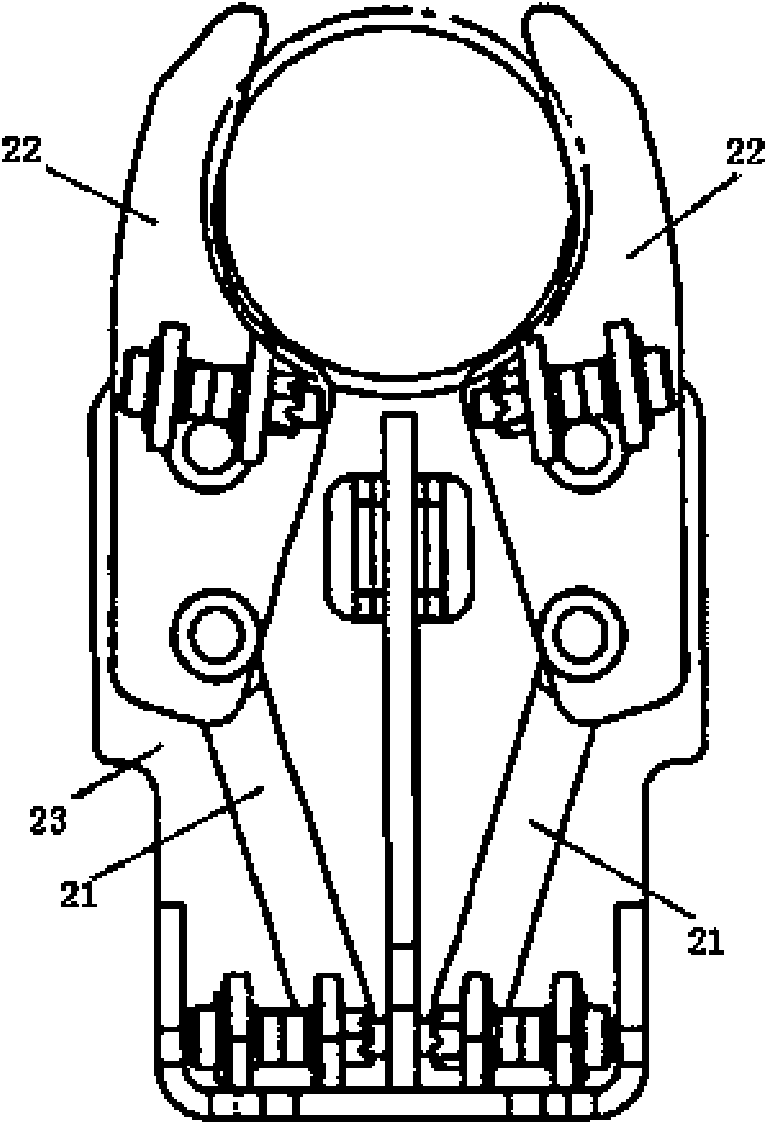

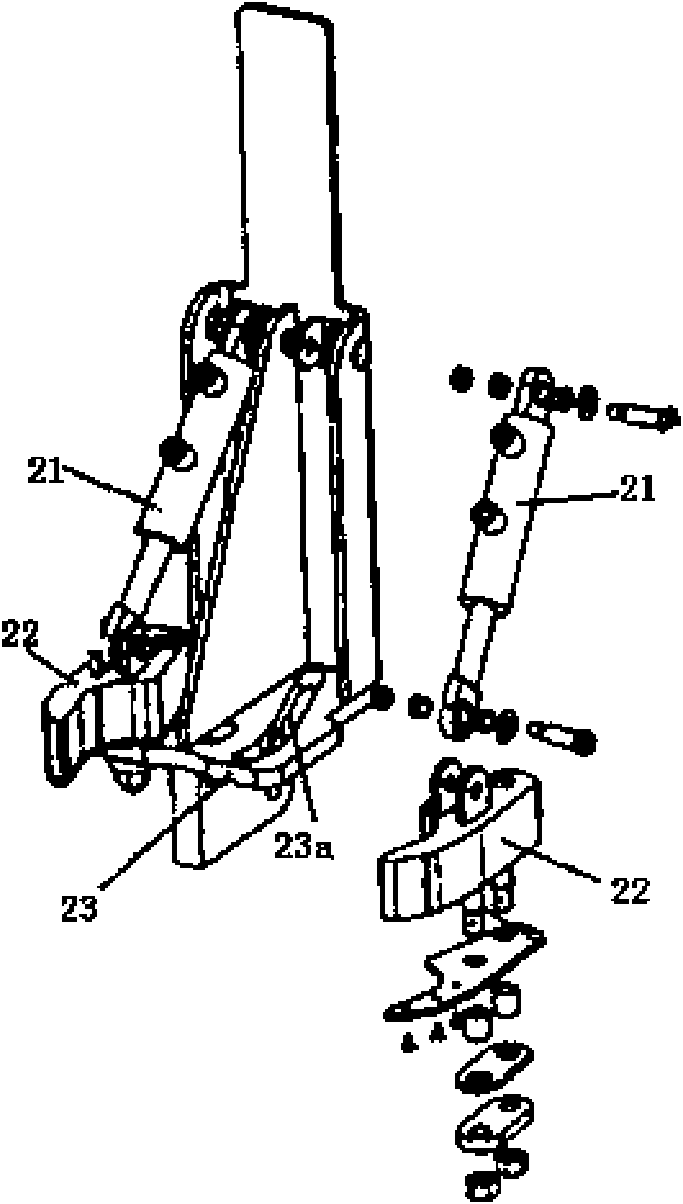

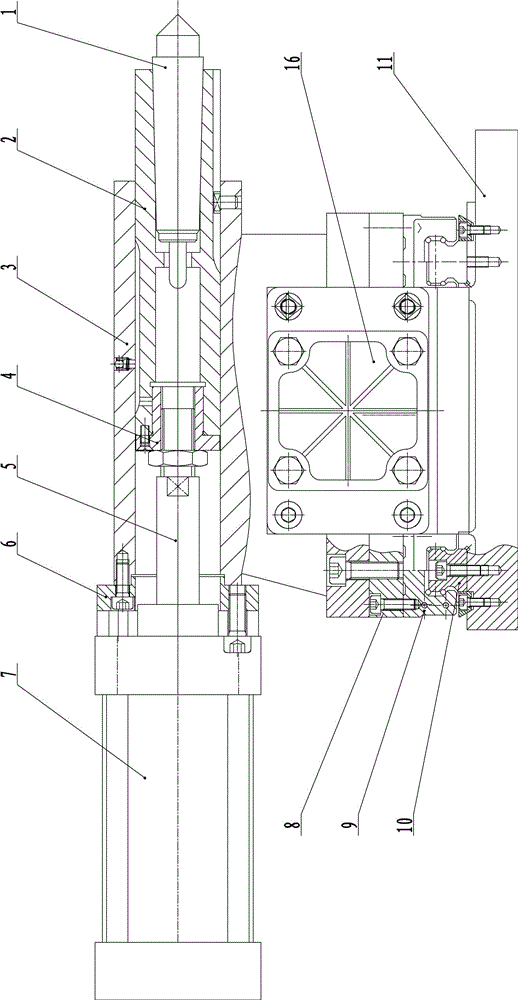

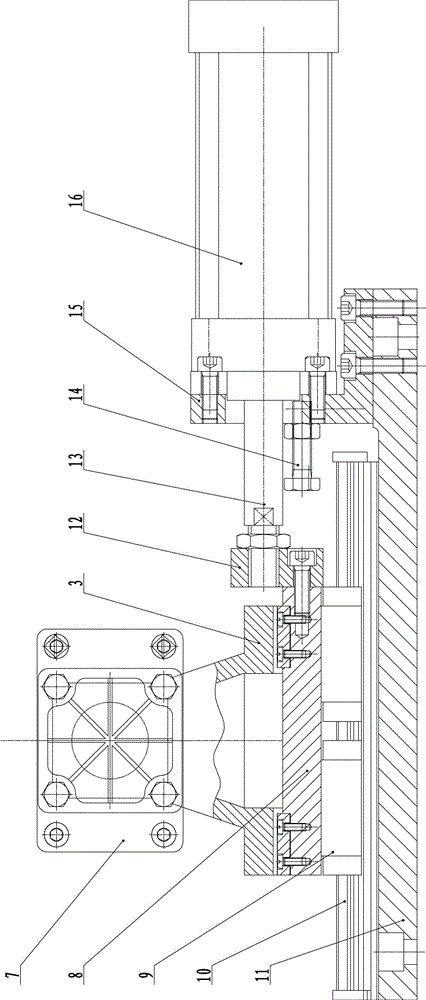

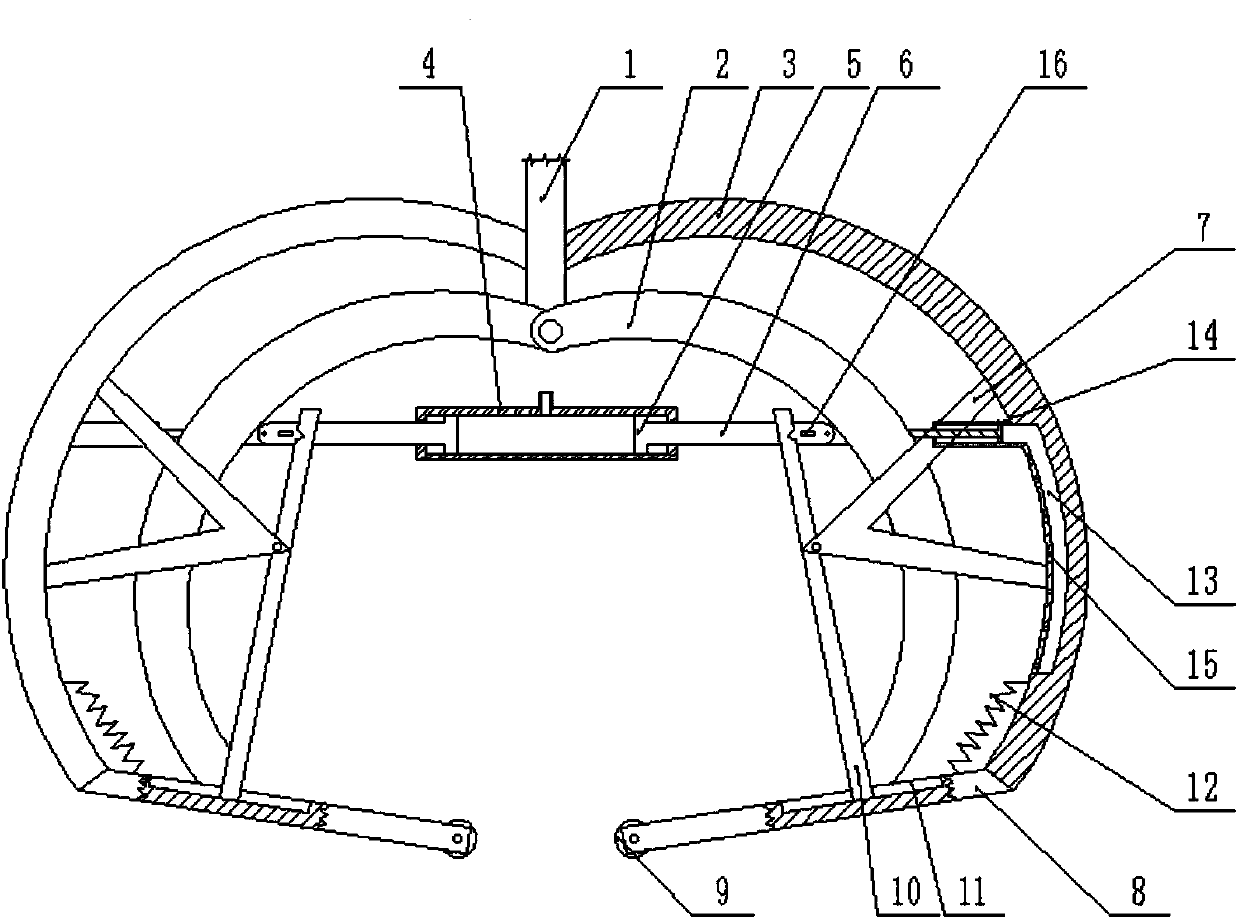

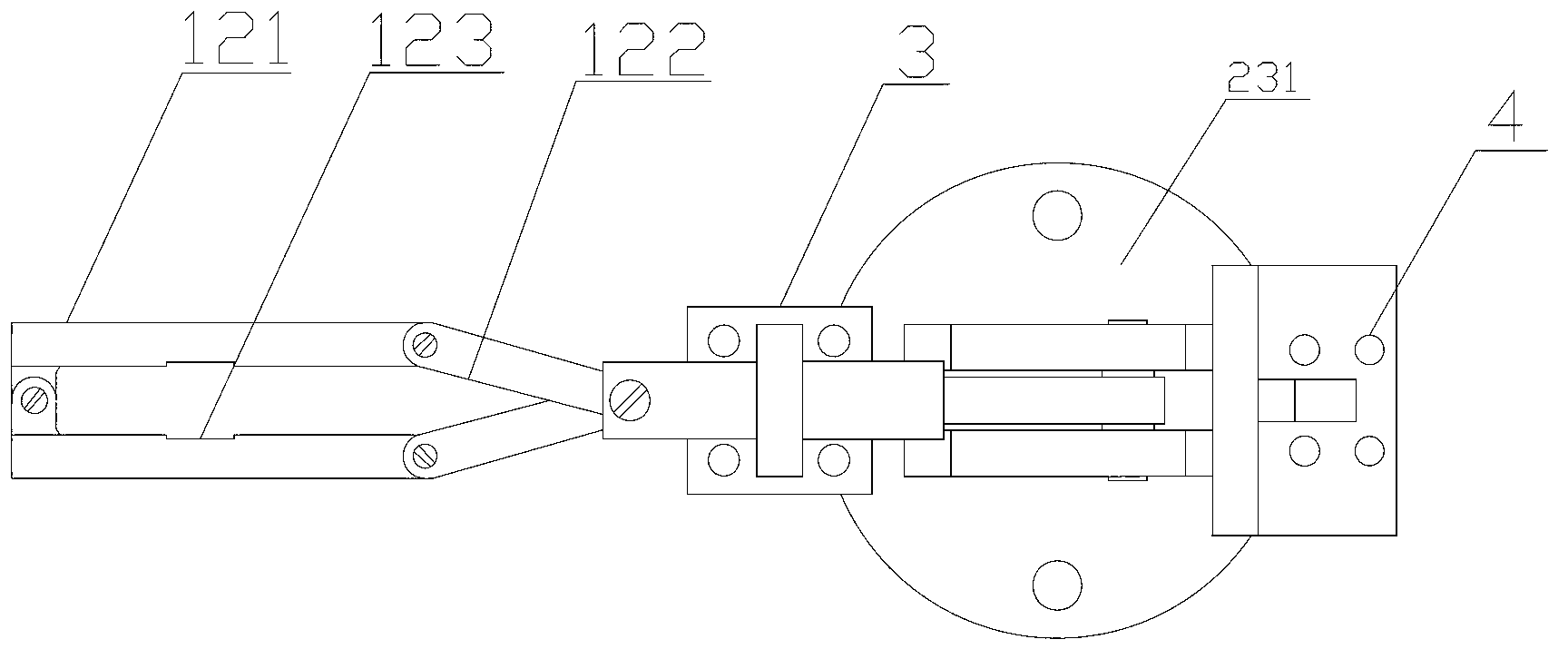

The invention discloses a clamping mechanism which comprises a shell and an oil cylinder installed in the shell, wherein clamping blocks are distributed in the front part of the shell in bilateral symmetry; and the inner side surfaces of the front half parts of the clamping blocks are inner concave surfaces. The clamping mechanism is characterized in that a cylinder barrel of the oil cylinder is centered at the rear part of the shell; the front end of a piston rod of the oil cylinder is articulated with a connecting plate; the left part and the right part of the connecting plate are respectively articulated with the rear ends of the clamping blocks; the front part of at least one cover plate of the shell is symmetrically provided with guide grooves left and right; guide pins are arranged in the middle parts of the two clamping blocks and inserted into the guide grooves; fixed blocks are clamped and fixed in the middle parts of the front ends of the two cover plates, and the normal lineof the surfaces of the front parts of the inner concave surfaces of the two clamping blocks are inclined to the directions of the fixed blocks. The invention has simple structure, high strength and large clamping force and can be suitable for different pipe columns with the external diameter range of 3.5-9.75 inches without replacing the clamping mechanism, and the clamping mechanism can not interfere with the adjacent pipe column during working.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

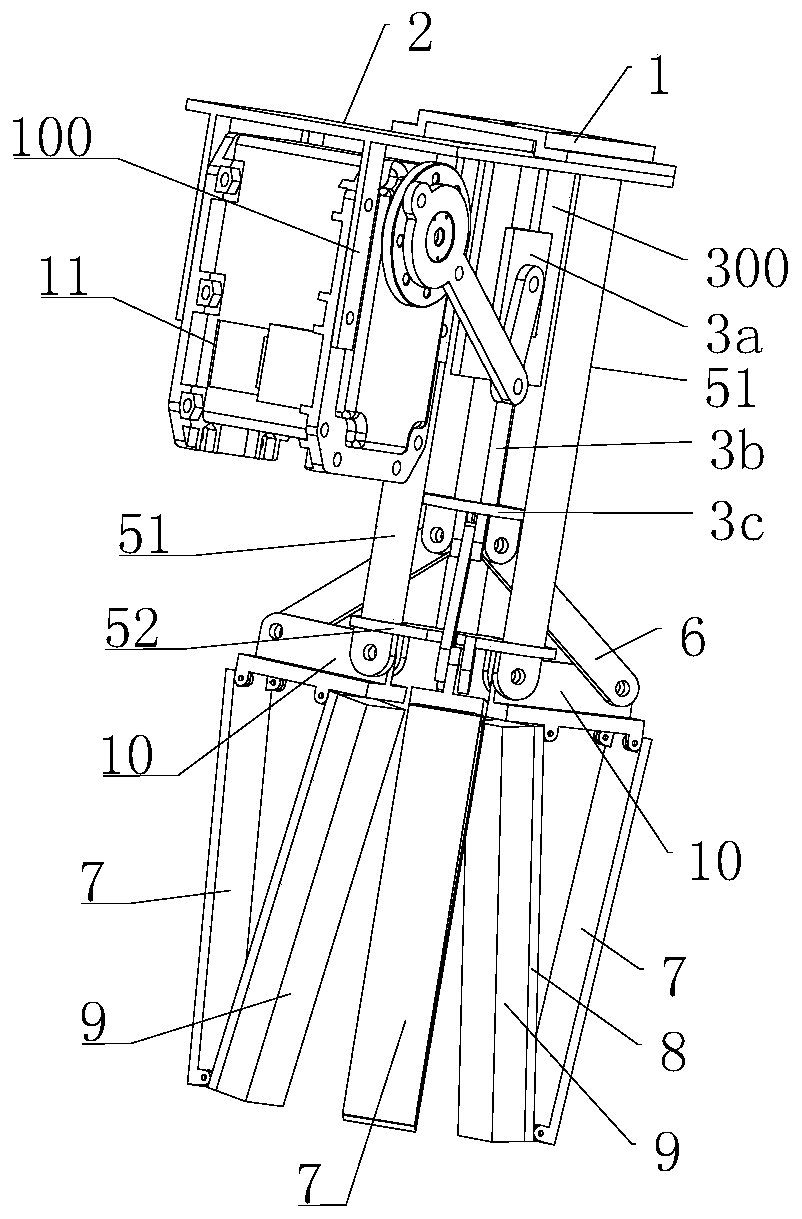

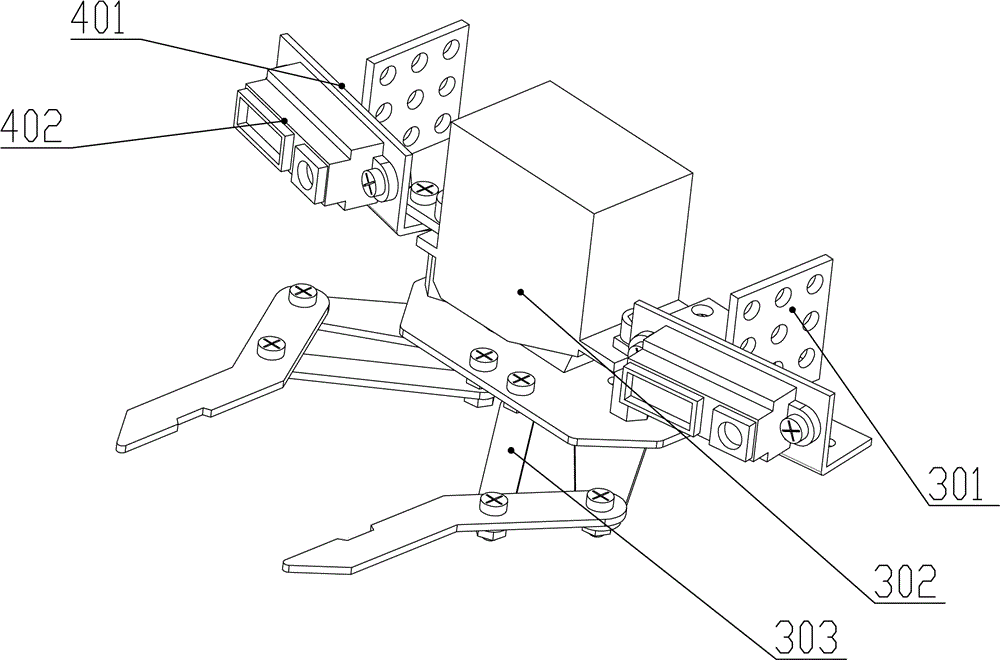

Under-actuated spatial manipulator end effector

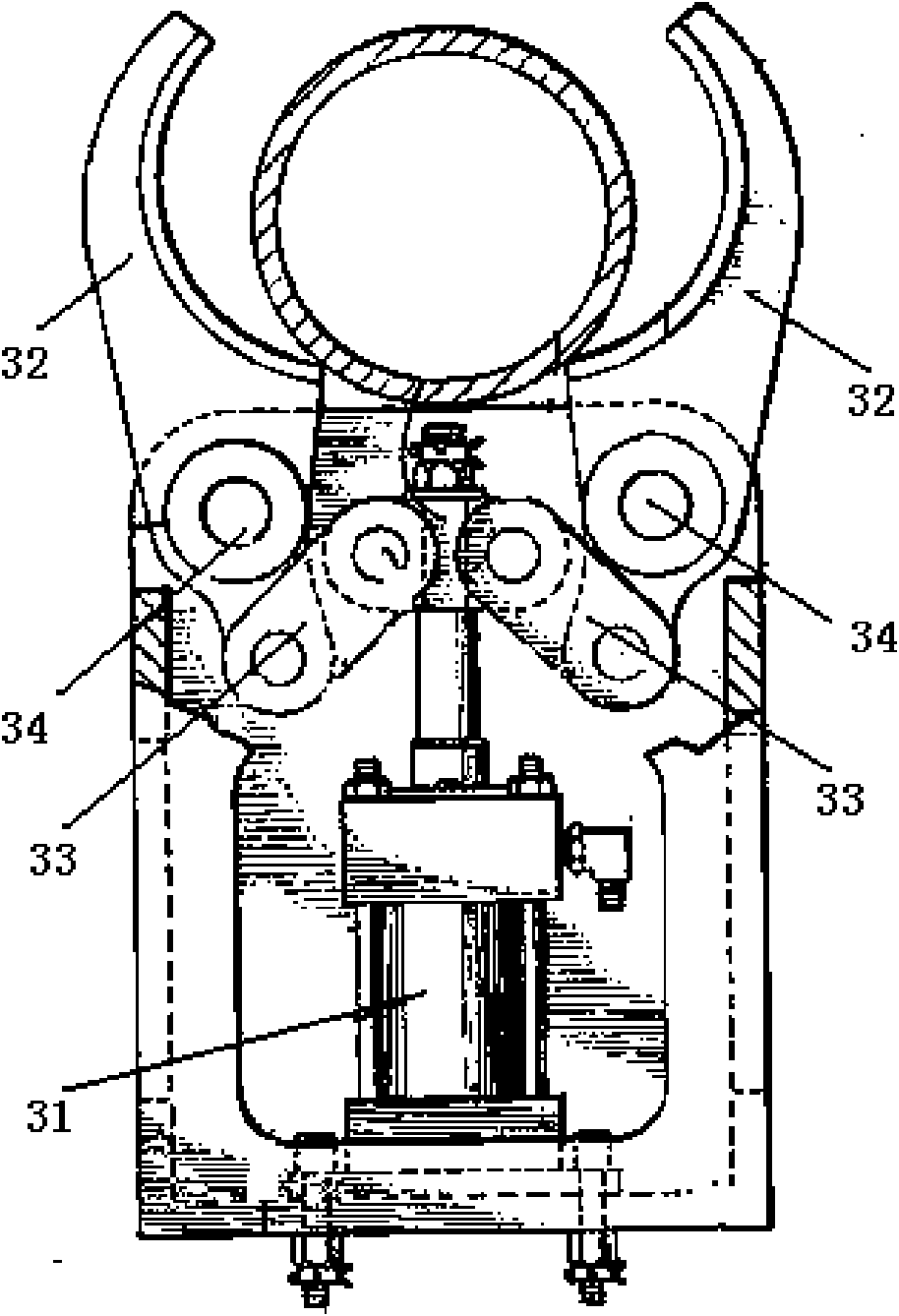

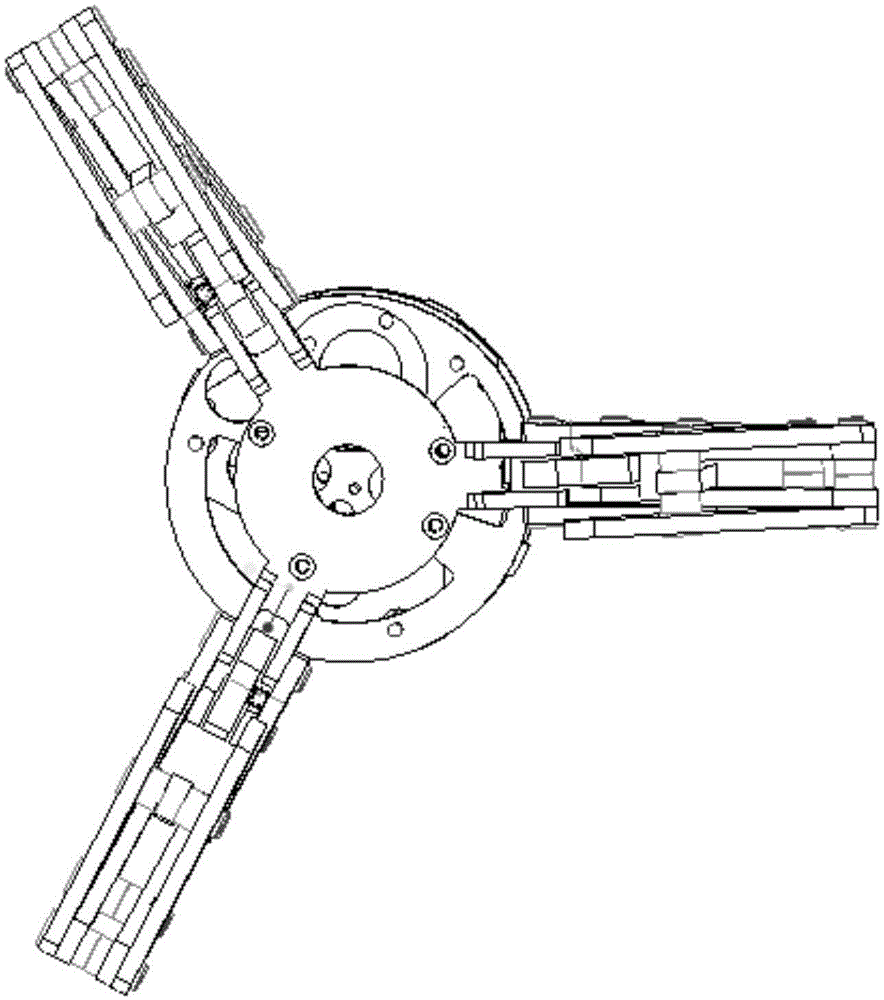

Disclosed is an under-actuated spatial manipulator end effector. A single-sleeve screw nut drives a finger drive platform to drive three mechanical fingers synchronously, and the structural synchronization is improved. By means of parallel-connection transmission arrangement, in other words, a drive motor is arranged on the screw on the same side obliquely through spur gear transmission, the axial length of the end effector is decreased greatly, the entire weight is reduced, and the strength and moving flexibility of the manipulator system are improved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

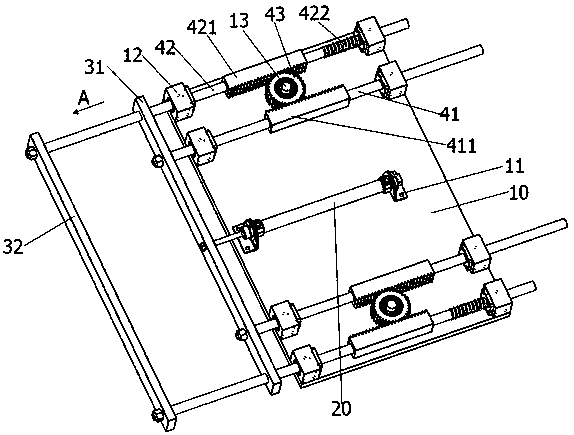

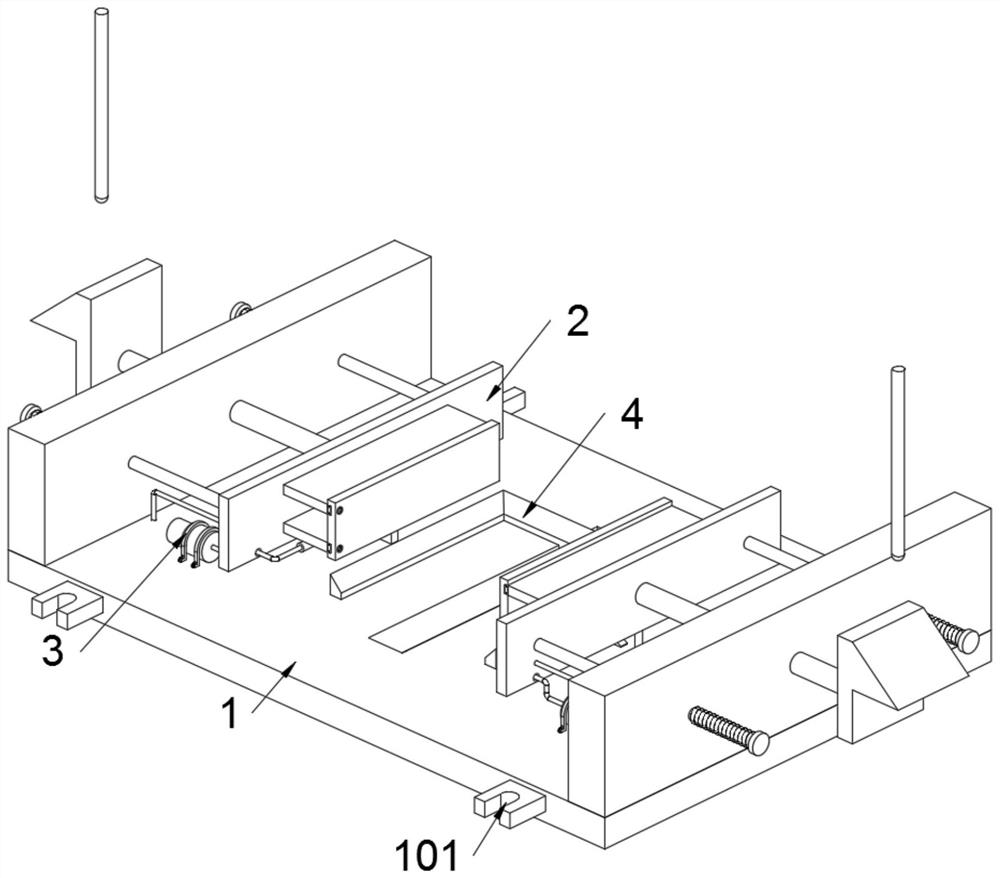

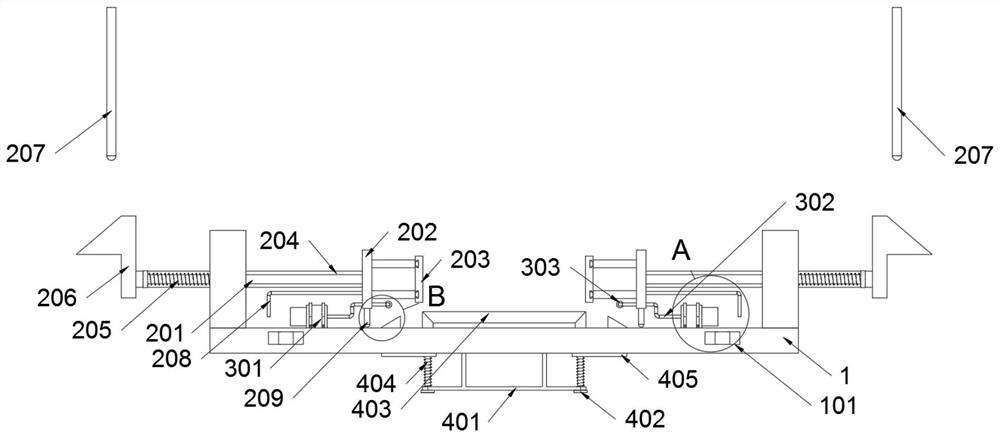

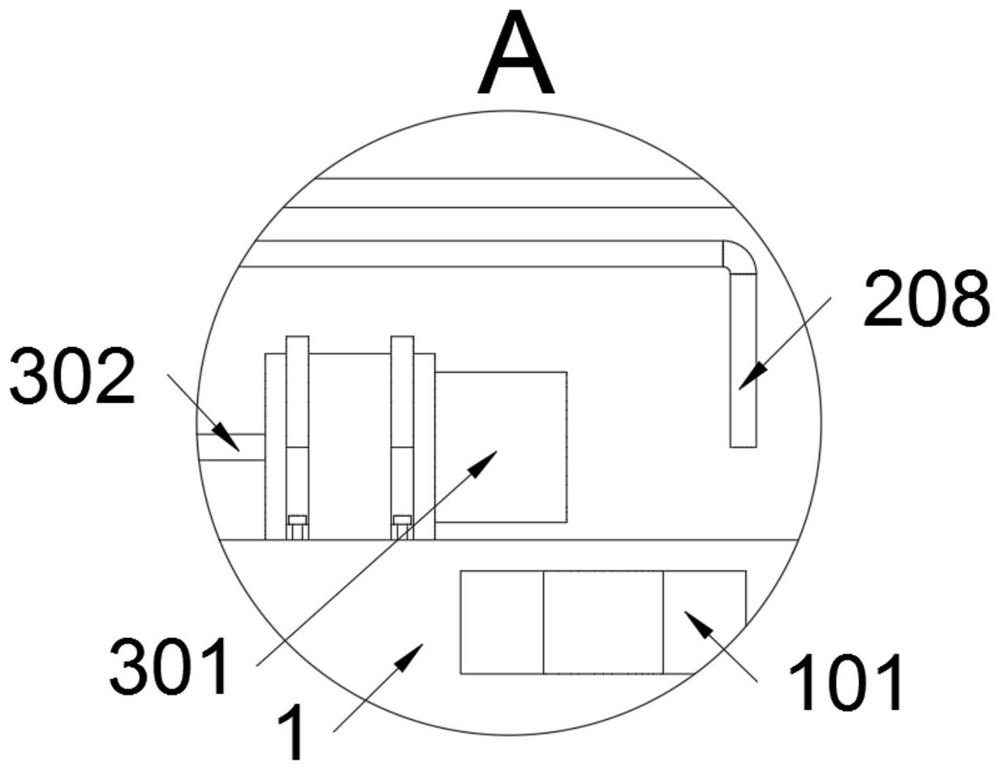

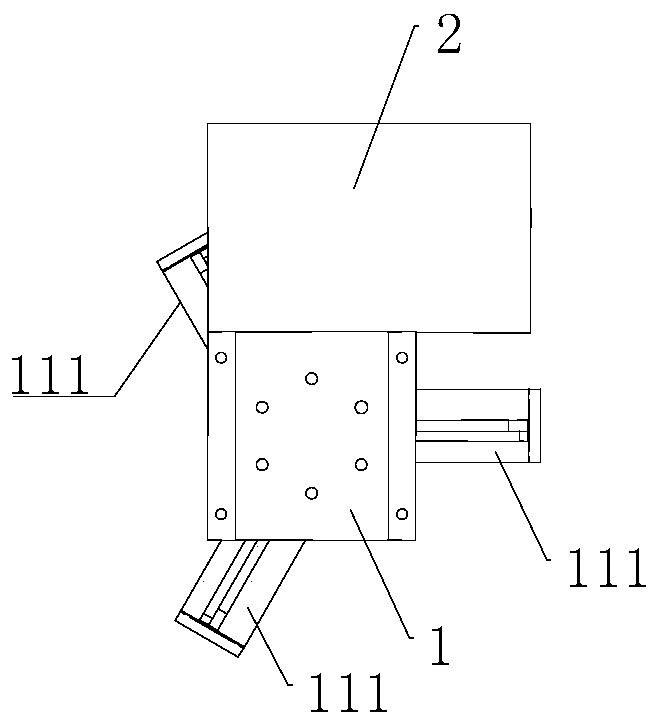

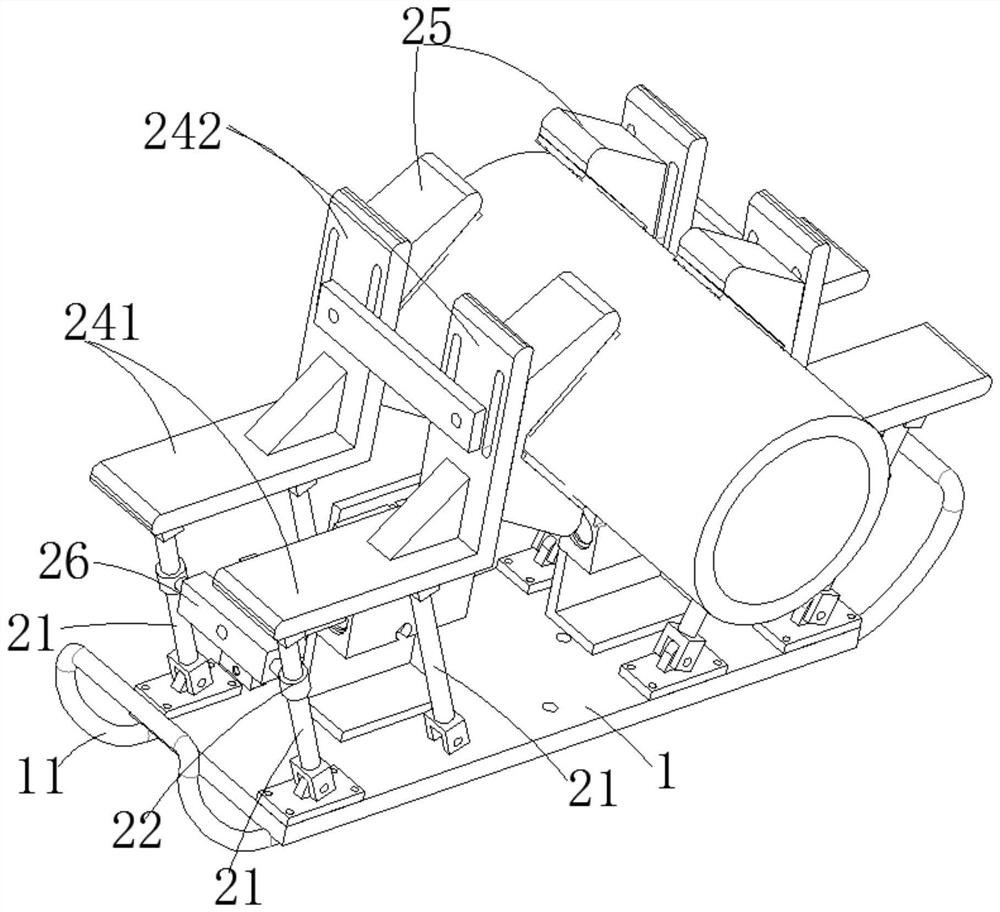

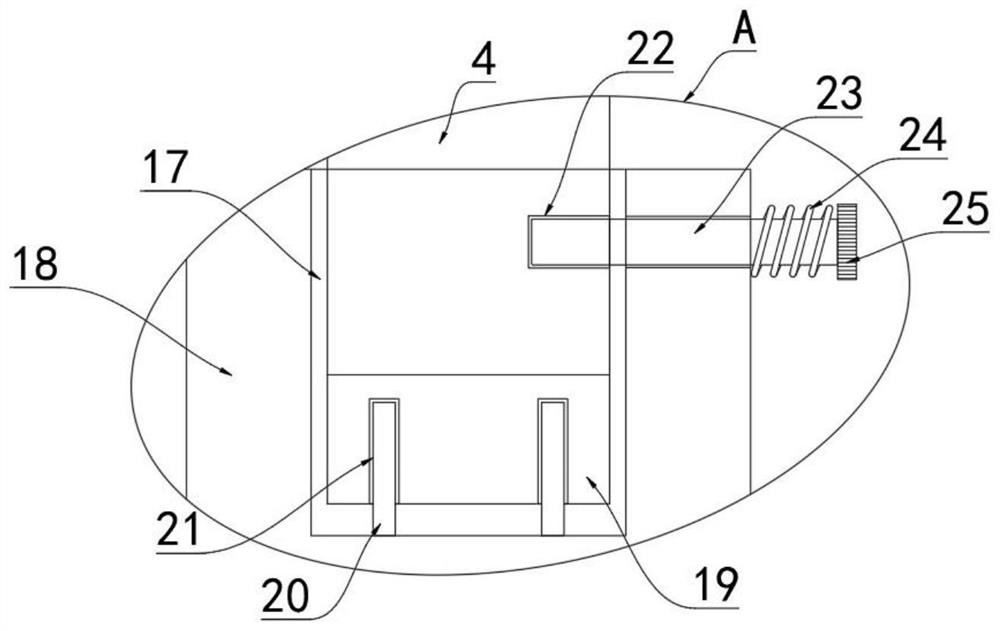

Long shaft part center adjustable quick clamping and machining device and operation method thereof

PendingCN109848735AGood supportReduce processing size and shape errorsChucksPositioning apparatusDrive motorCam

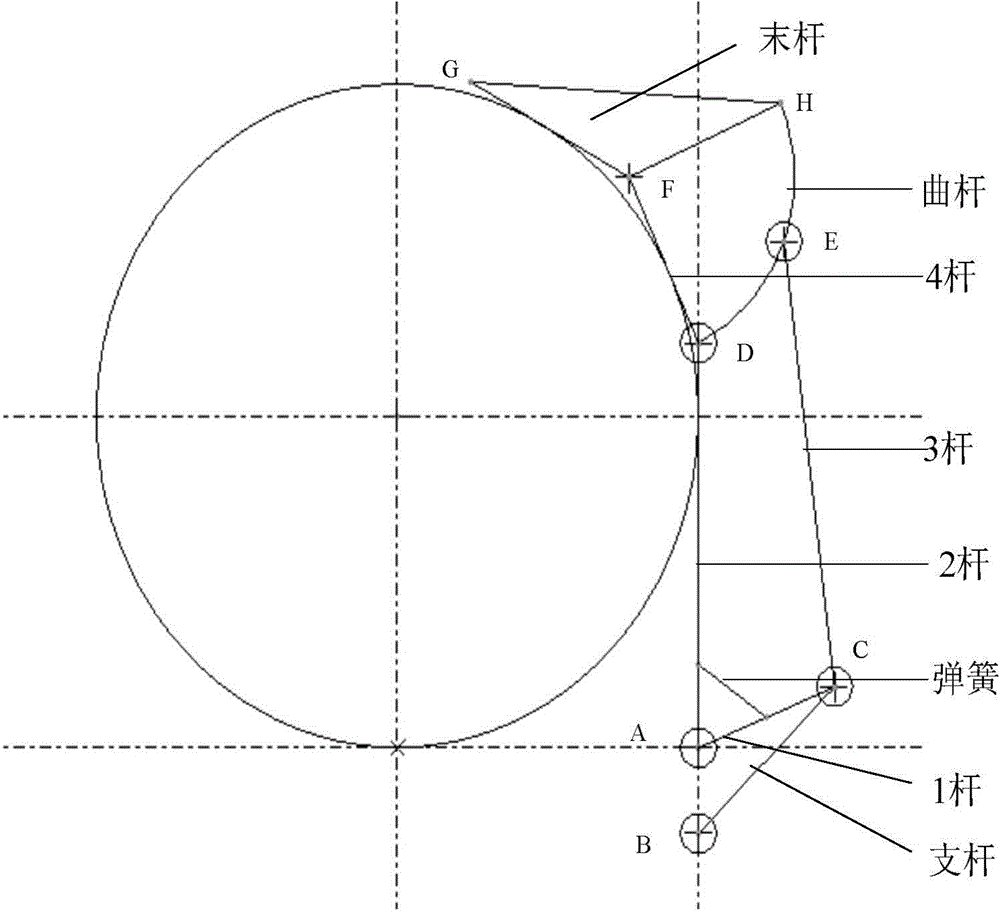

The invention provides a long shaft part center adjustable quick clamping and machining device and an operation method thereof. The device comprises a chuck, a fixture and a force applying device. Thechuck is used for fixing one end of a shaft part. The fixture comprises two V-shaped rods used for clamping the other end of the shaft part. The V-shaped rods are fixedly connected through a spring.The tail ends of the V-shaped rods are provided with rolling wheels. The force applying device comprises a cam, a bevel push block and a driving motor. The two bevels of the bevel push block are arranged in an inverted-V shape. The upper end of the bevel push block is arranged in the space formed by connecting the spring and the V-shaped rods. The lower end of the bevel push block is connected with one side of the cam. The driving motor is arranged on the other side of the cam. The long shaft part center adjustable quick clamping and machining device provided by the invention can implement quick clamping and dynamic clamping and machining on different diameters of shaft parts, is fast and convenient to operate, firm in clamping, integrates the functions of centers and follow-rest devices during traditional shaft part machining, saves the cost and optimizes the machining process.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

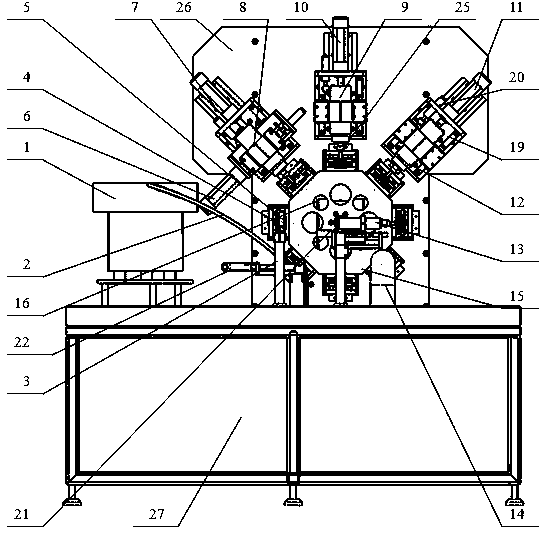

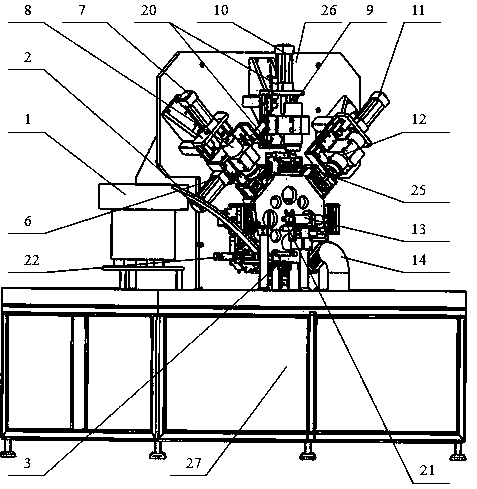

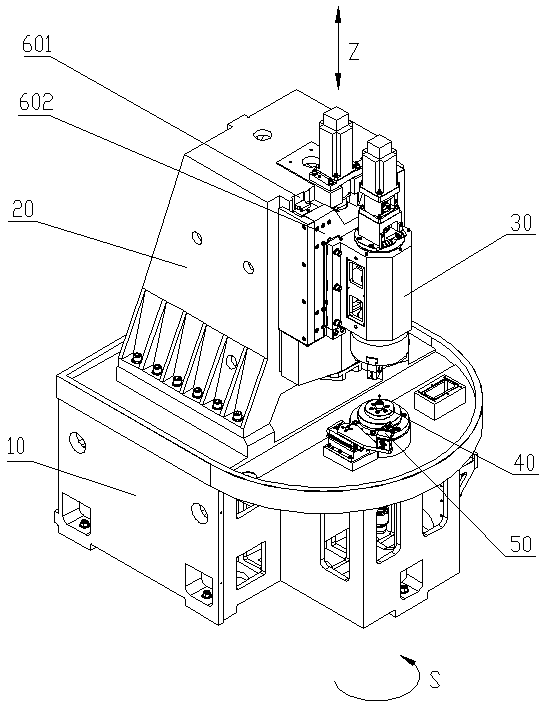

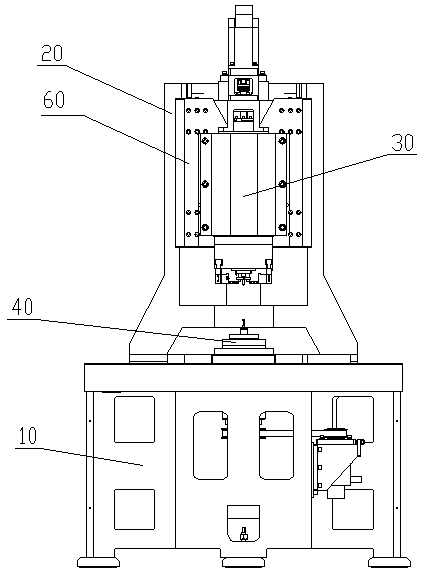

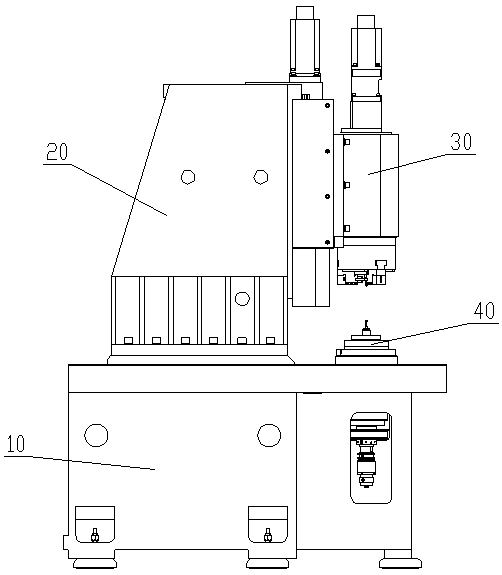

Automatic drilling and milling machine for chain connecting pin shaft

InactiveCN103921121AAchieving installation design complex issuesSolve the labor-intensiveOther manufacturing equipments/toolsMetal working apparatusEngineeringCam

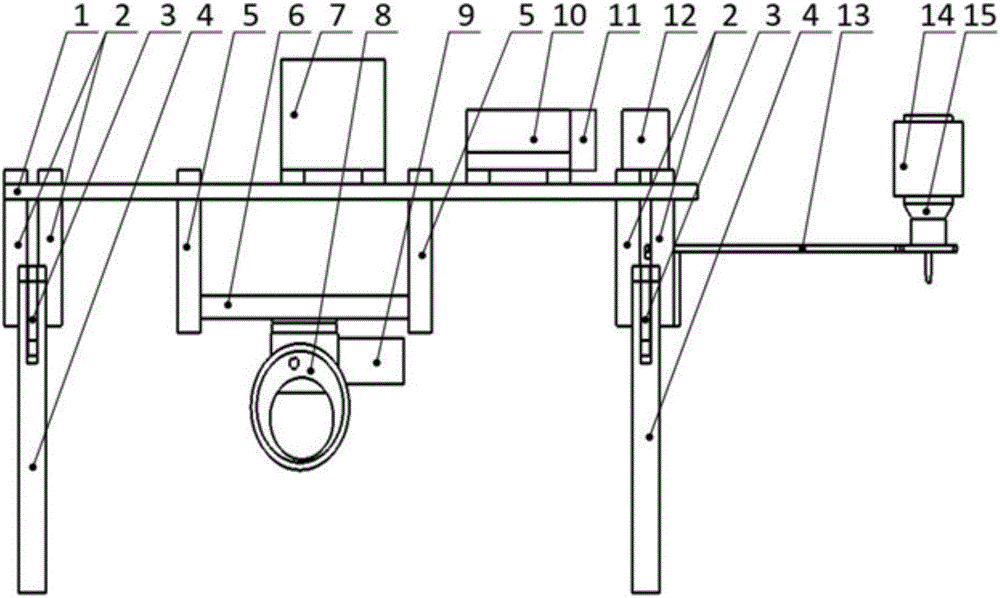

An automatic drilling and milling machine for a chain connecting pin shaft is mounted on a rack table face, the automatic drilling and milling machine comprises a vibration disc, a feeding guide rail, an air cylinder, clamping jigs, a flat table milling mechanism, a central hole drilling mechanism, a small hole drilling mechanism, a chamfering mechanism, an octagonal eight-station rotating disc, a precise cam indexer, an electric motor and an automatic drilling and milling machine body support. The octagonal eight-station rotating disc is arranged on the front side of the automatic drilling and milling machine body support, the precise cam indexer is arranged behind the octagonal eight-station rotating disc, the electric motor is arranged on the rear side of the automatic drilling and milling machine body support, the electric motor is provided with a compressed air flow divider, the vibration disc is arranged on one side of the octagonal eight-station rotating disc, the eight clamping jigs are mounted on the octagonal eight-station rotating disc, the flat table milling mechanism, the central hole drilling mechanism and the small hole drilling mechanism are arranged on the upper side of the octagonal eight-station rotating disc, and the chamfering mechanism is mounted on the front side of the octagonal eight-station rotating disc. According to the technology, the full-automatic production process of part machining is achieved, and production efficiency and product quality are improved greatly.

Owner:肖闯

Pneumatic clamping device

InactiveCN111015316AImplementation driveRealize the clamping actionWork clamping meansPositioning apparatusPhysicsEngineering

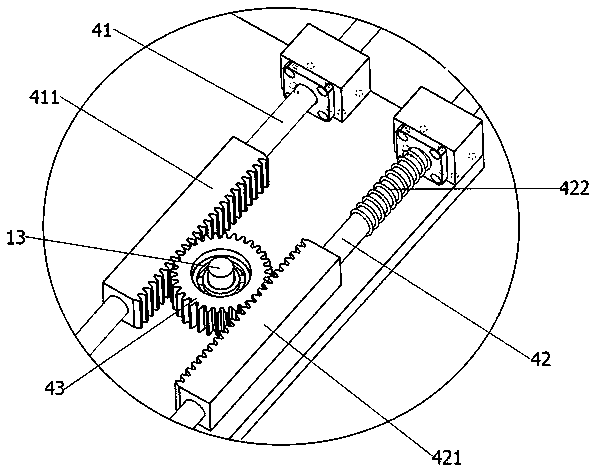

The invention provides a pneumatic clamping device. The pneumatic clamping device comprises a fixing plate, an air cylinder, transmission assemblies and a clamping assembly; the clamping assembly comprises a first clamping plate and a second clamping plate, the first clamping plate is fixedly connected with the output end of the air cylinder, the air cylinder drives the first clamping plate to move in the first direction, and the transmission assemblies are arranged on the two sides of the air cylinder; each transmission assembly comprises a first sliding rod, a second sliding rod and a transmission gear, the ends of the first sliding rods are fixedly connected with the first clamping plate, and the ends of the second sliding rods are fixedly connected with the second clamping plate; and the transmission gears are rotatably connected with rotation shafts fixedly arranged on the fixing plate and mesh with first racks and second racks. The first racks move to drive the transmission gearsto rotate around the rotation shafts to drive the second racks to move in the direction opposite to that of the first racks, then driving on the first clamping plate and driving on the second clamping plate are synchronously achieved, and clamping action on workpieces in the same degree-of-freedom direction is achieved.

Owner:张海旦

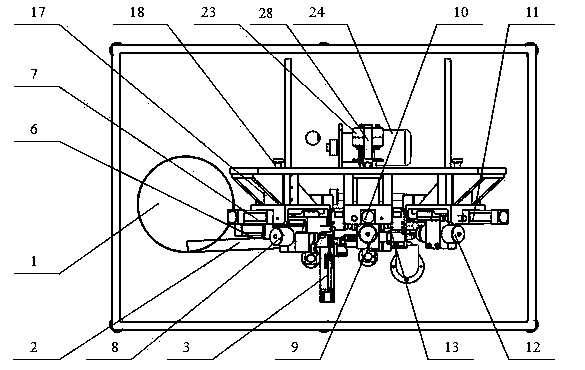

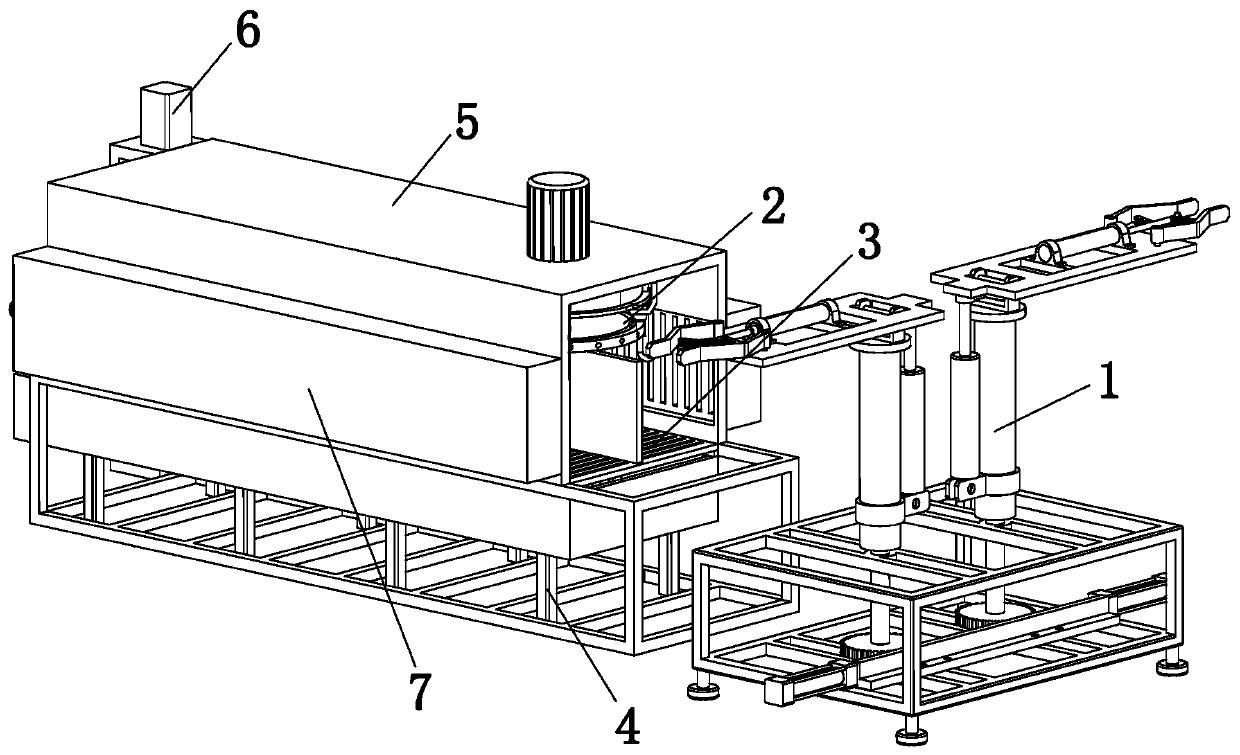

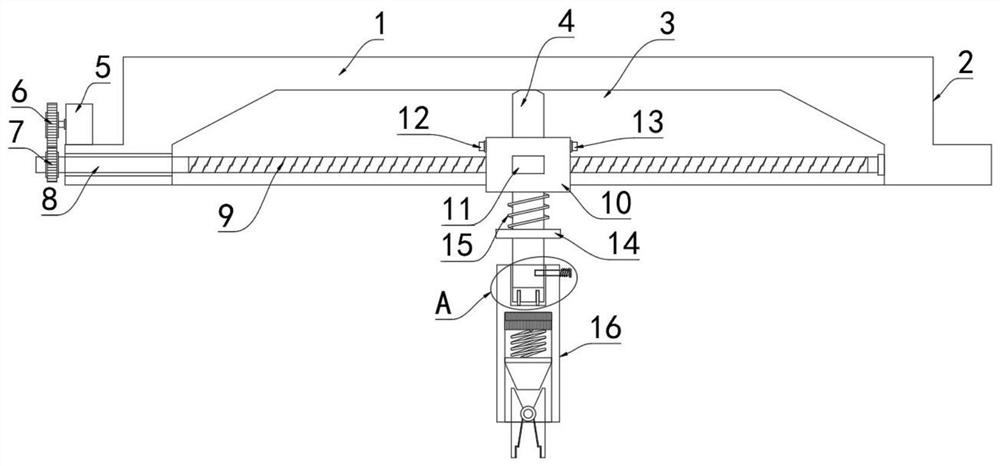

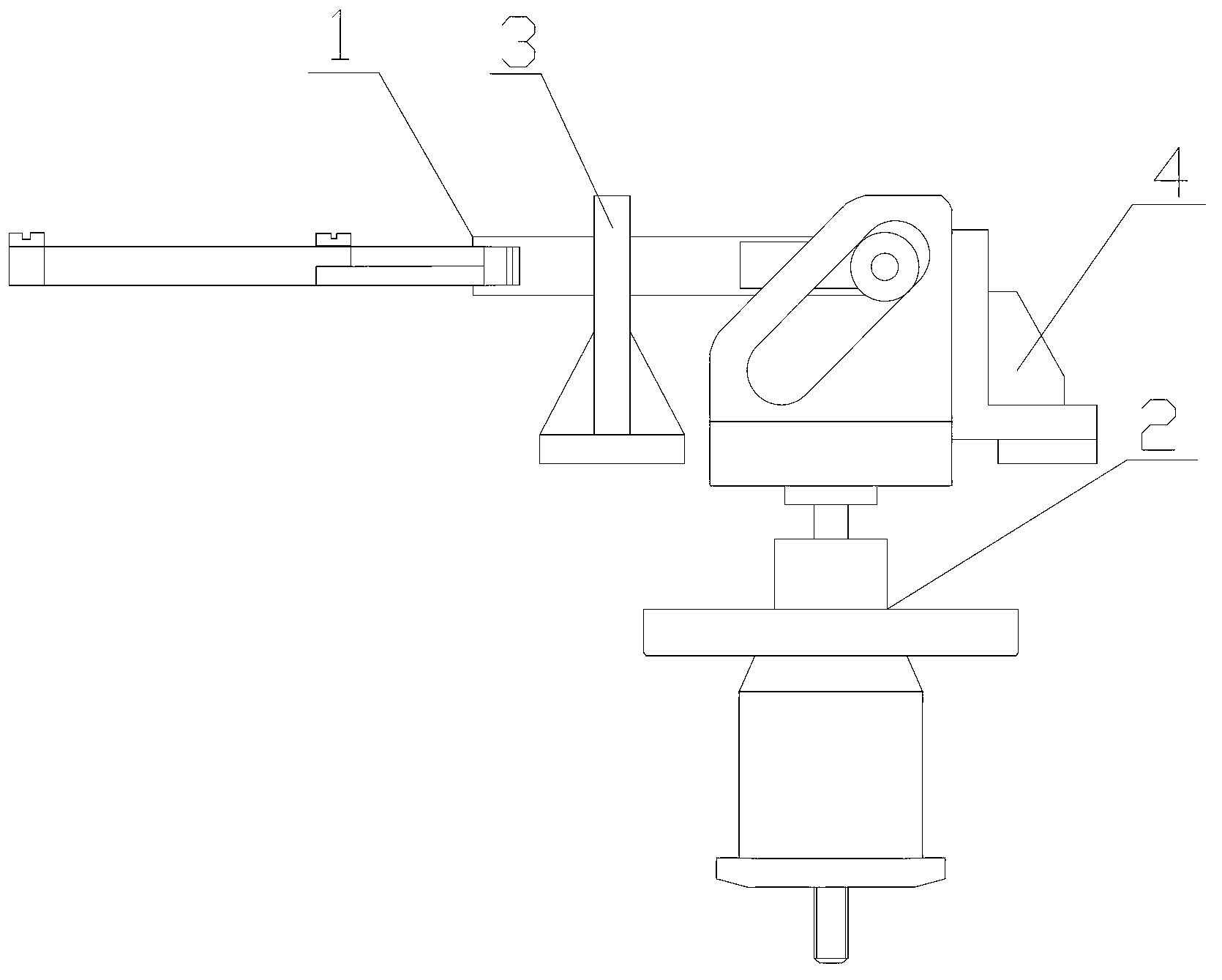

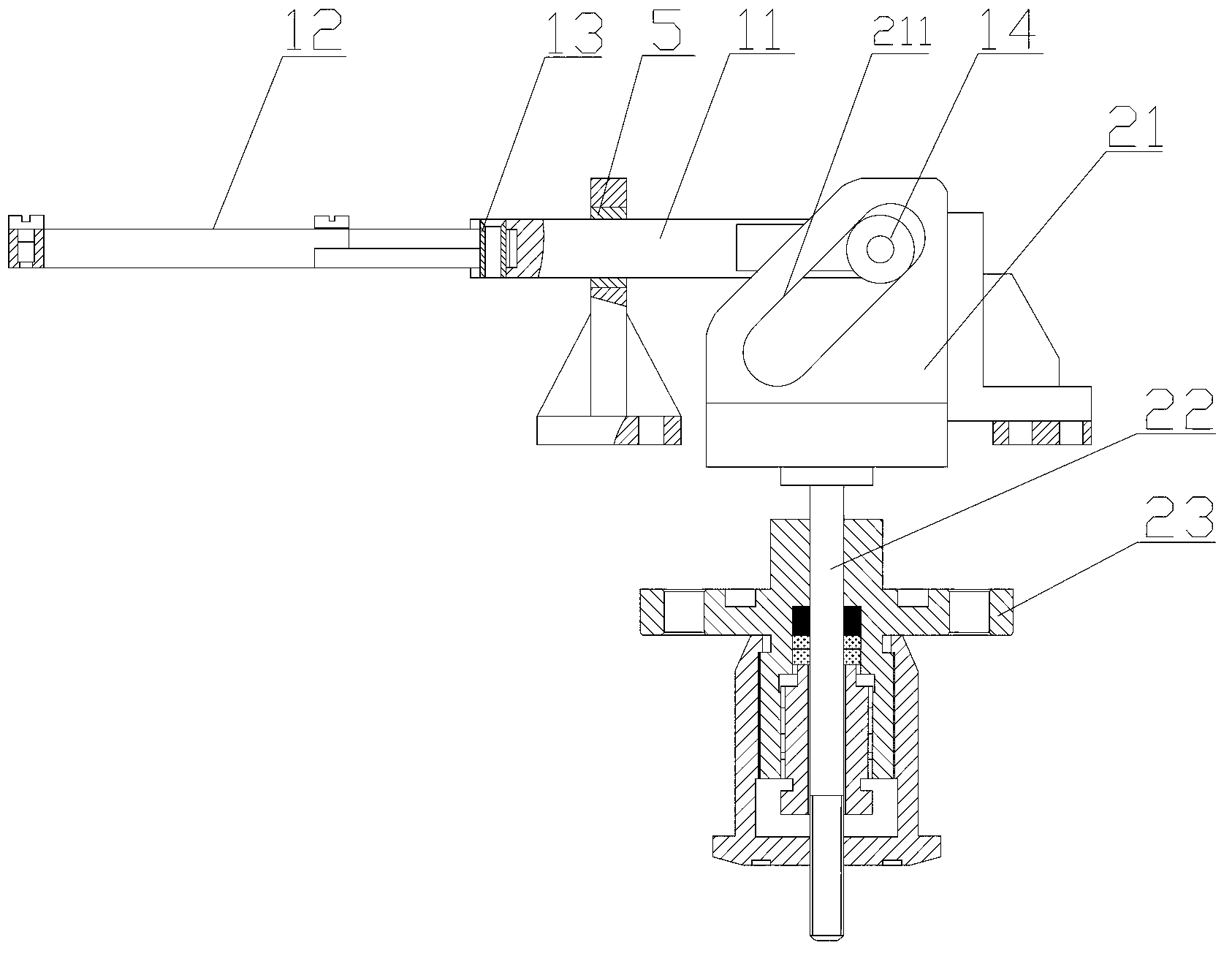

Liquor bottle clamping, placing and discharging device for visible foreign matter detector

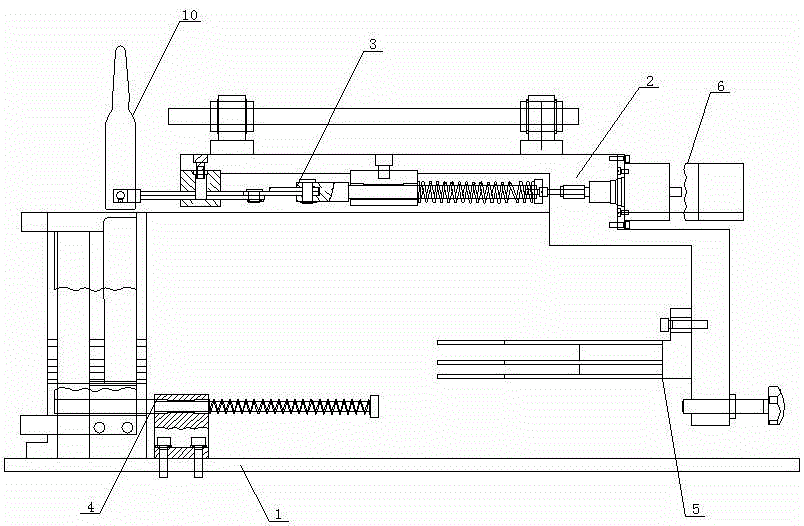

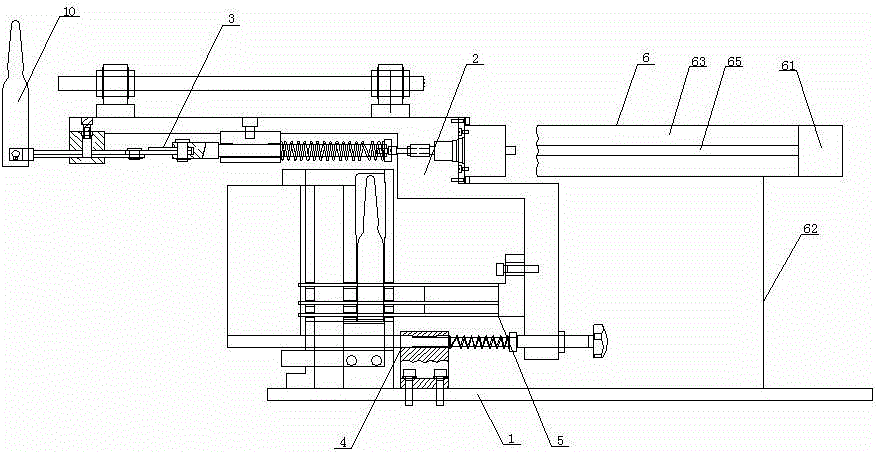

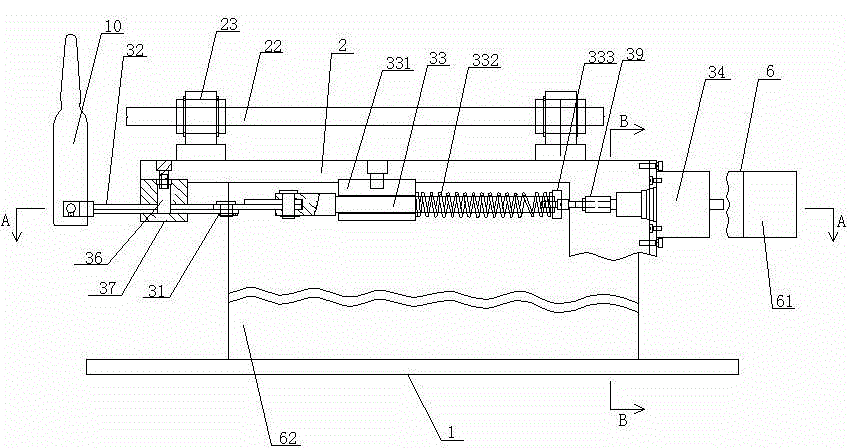

ActiveCN103063680AZoom freelyGuaranteed horizontal movementOptically investigating flaws/contaminationForeign matterAutomatic control

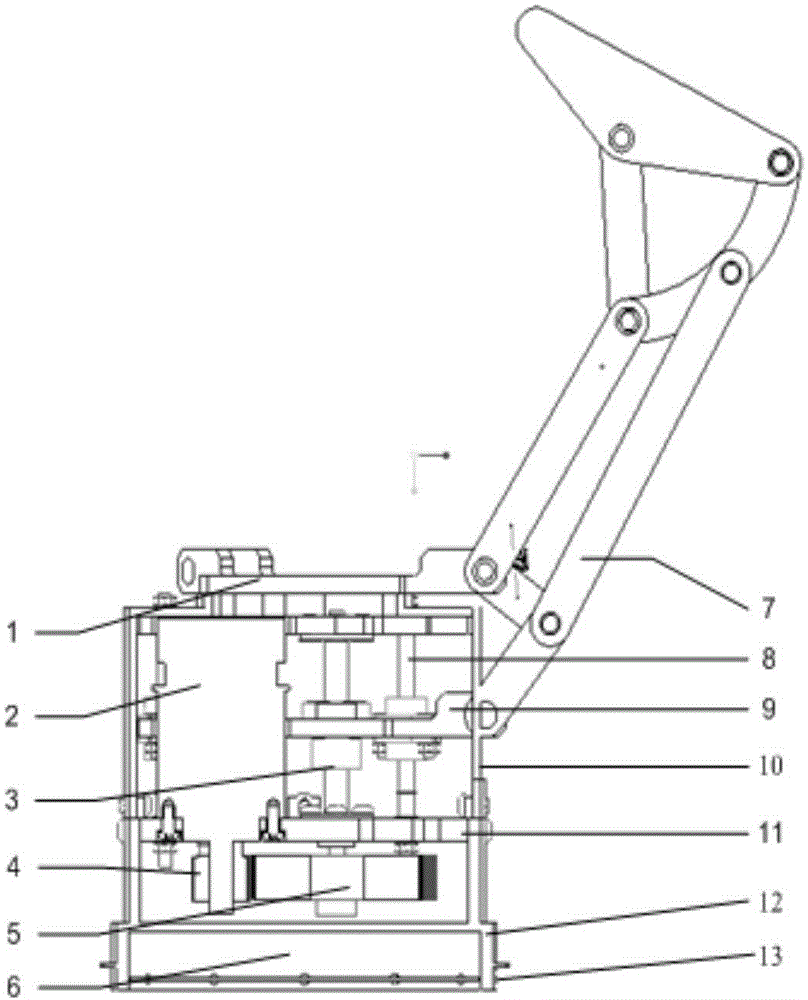

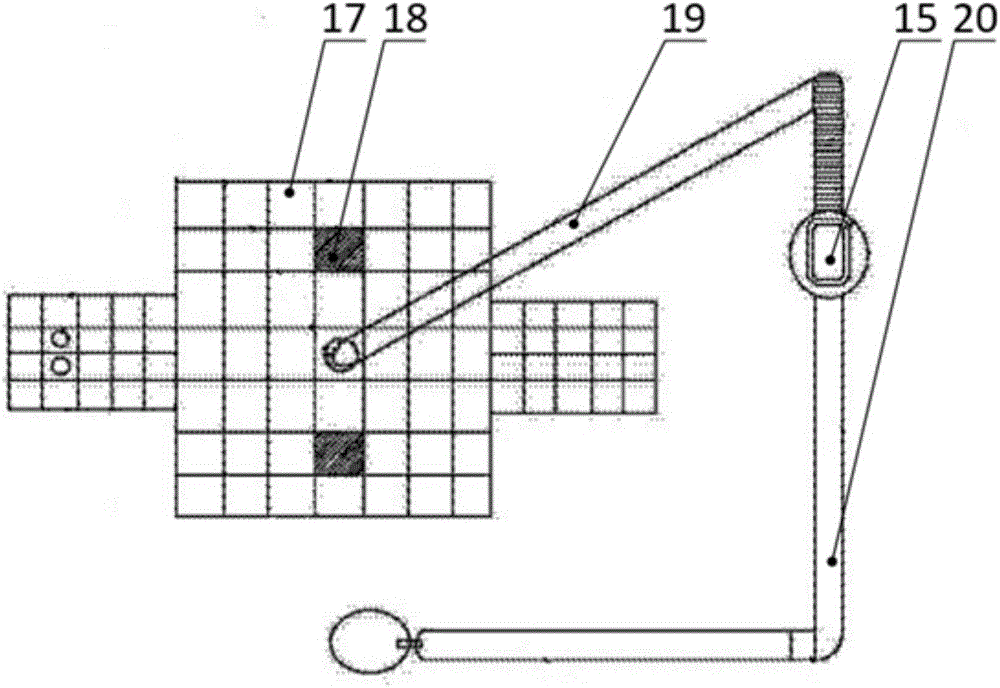

The invention relates to an automatic bottle clamping, placing and discharging device for a visible foreign matter detector. The device comprises a base, a mounting seat, a mechanical arm, a door opening and closing device, a bottle discharging device and a translation device, wherein the mounting seat is fixed with the translation device; the translation device is fixed on the base; and the mechanical arm, the door opening and closing device and the bottle discharging device are connected with the mounting seat. The device is reasonable in structural design, the mechanical arm can automatically translate, clamp and place a liquor bottle, and the liquor bottle is reliably and stably clamped and loosened; the door opening and closing device automatically opens or closes the door of a bottle falling groove and is matched with the bottle discharging device to push the liquor bottle in a bottle discharging box from the bottle falling groove; and the mechanical arm, the door opening and closing device and the bottle discharging device are synchronously controlled to translate by the translation device in the whole process, bottle taking, falling and discharging are integrated, and full-automatic control is realized.

Owner:宋磊

Stable high-precision workpiece fixing tool for stamping die

PendingCN112642942ARealize the clamping actionAchieve hiddenShaping toolsMetal-working feeding devicesEngineeringStamping process

The invention provides a stable high-precision workpiece fixing tool for a stamping die, relates to the technical field of workpiece fixing, and solves the problem that parts cannot be automatically clamped in the stamping process through structural improvement, and cleaning of residues cannot be achieved through linkage in the stamping process through structural improvement are solved. The stable high-precision workpiece fixing tool for the stamping die comprises a base. Two clamp structures are mounted on the base. The poke rod C is welded on the bottom end surface of a clamp plate, and the poke rod C is aligned with the top end surface of a stress seat B. The top end surface of the stress seat B is of an inclined structure, the poke rod C forms an extrusion poke structure of the stress seat B, and therefore when the poke rod C moves along with the clamp plate to achieve part clamping, hiding of a positioning base can be synchronously achieved, and then the cleaning effect is improved.

Owner:刘晓杰

Coupling manipulator capable of grabbing object adaptively

The invention discloses a coupling manipulator capable of grabbing an object adaptively. The manipulator comprises a base, a driving device, a bracket, a transmission module and a finger module, wherein the finger module comprises a rigid element, a first flexible element, a second flexible element, a software element, a displacement sensor, a pressure sensor and a micro camera; the displacement sensor is embedded in the software element; the pressure sensor is attached to the surface of the second flexible element; and the micro camera is attached to the center of the bracket seat for adjusting the posture of the manipulator in real time. The coupling manipulator provided by the invention can realize flexible grabbing of the object and avoid damaging the surface of the object; meanwhile,the coupling manipulator provided by the invention is completely driven by a single steering engine, and compared with the manipulator driven by a plurality of steering engines, the structure is simpler and smaller, the control is simpler and more reliable, and the cost is lower.

Owner:ZHEJIANG UNIV

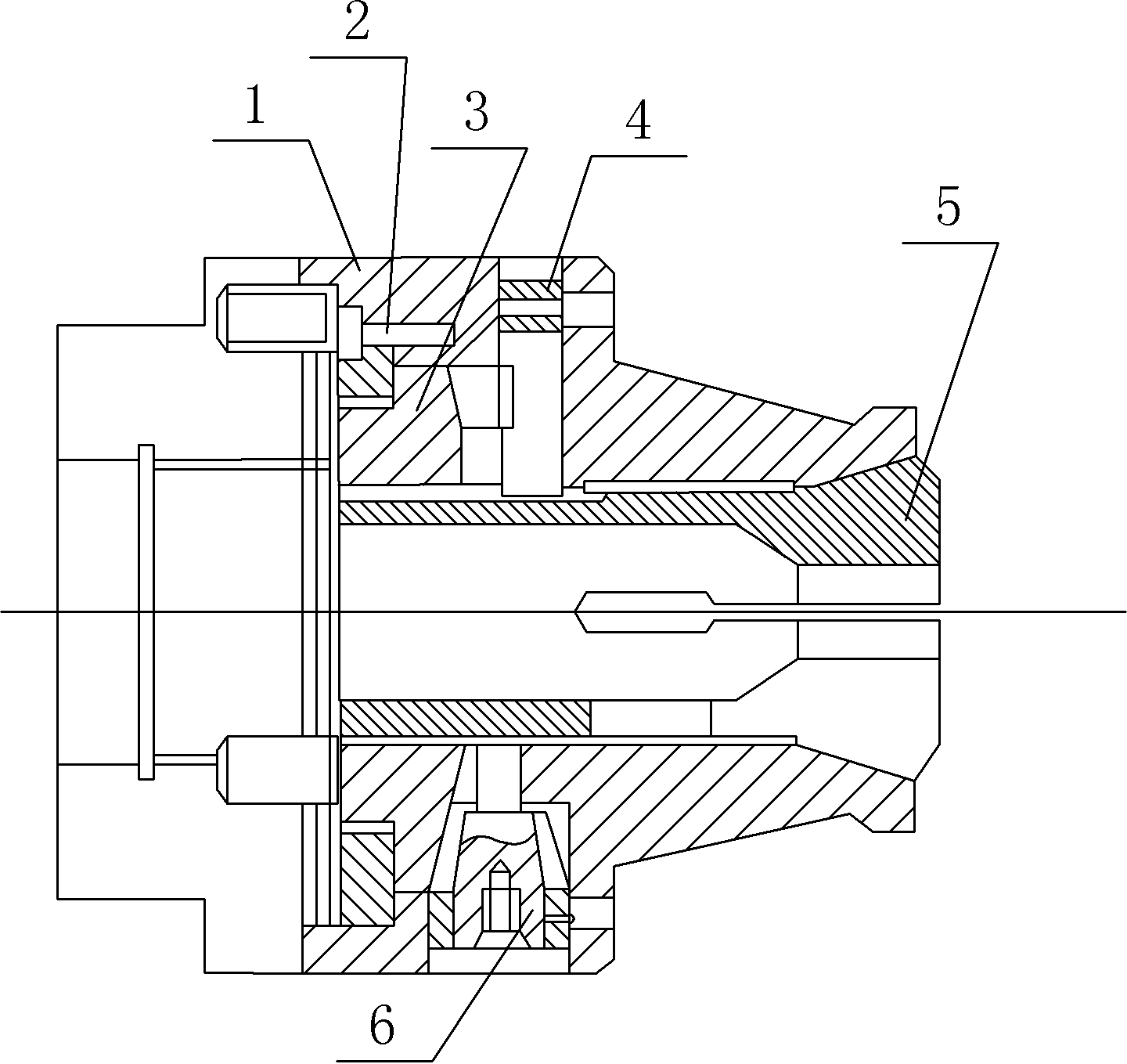

Spring chuck with bevel gears

InactiveCN103639744AAvoid affecting the clamping accuracyRealize the clamping actionTransportation and packagingChucksGear wheelEngineering

The invention discloses a spring chuck with bevel gears. The spring chuck with the bevel gears solves the problem that shaft workpieces in the prior art are inconvenient to clamp and comprises a hollow clamping body and a collet with an open groove, wherein the open groove extends from the head of the collet to the middle of the collet axially, one end of the collet is matched with the cavity of the clamping body, and the other end of the collet extends out of the clamping body. The spring chuck with the bevel gears further comprises a large bevel gear, a small bevel gear and a clamping ring, wherein the large bevel gear is positioned in the cavity of the clamping body, a screw hole is formed in the center of the large bevel gear, the small bevel gear is matched with the large bevel gear, the clamping ring is used for fixing the large bevel gear into the clamping body, one end of the small bevel gear extends out of the clamping body, an inner conical surface matched with the collet is arranged at one end of the clamping body far away from the large bevel gear, one end of the collet is in threaded connection with the screw hole of the large bevel gear, and an elastic rubber layer is filled in the open groove of the collet. The spring chuck with the bevel gears is simple in structure and easy to operate.

Owner:CHONGQING BISHAN AIHUA

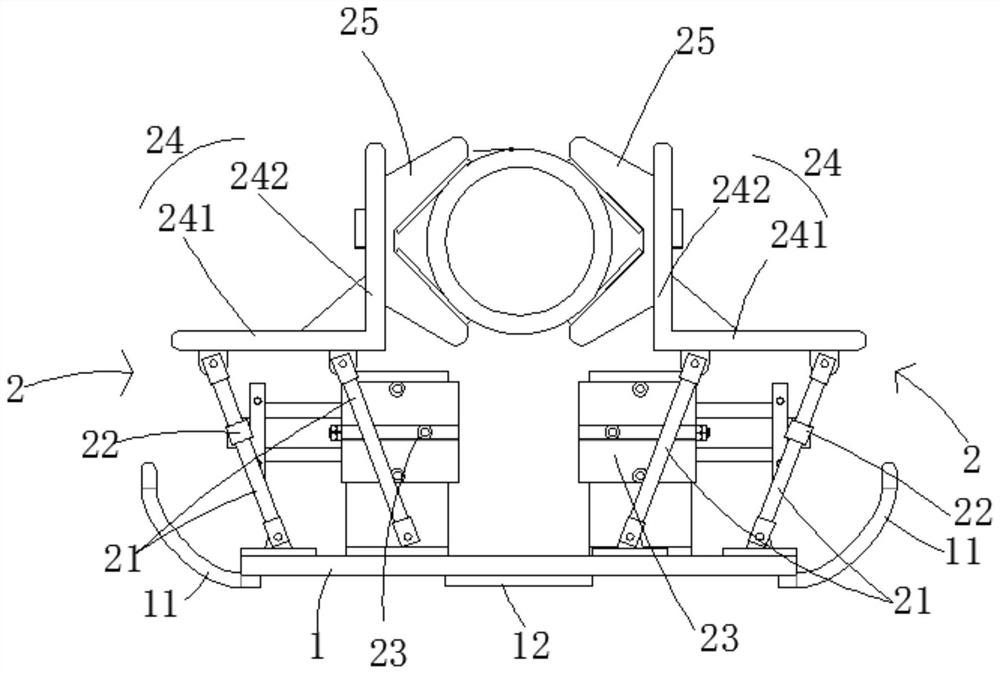

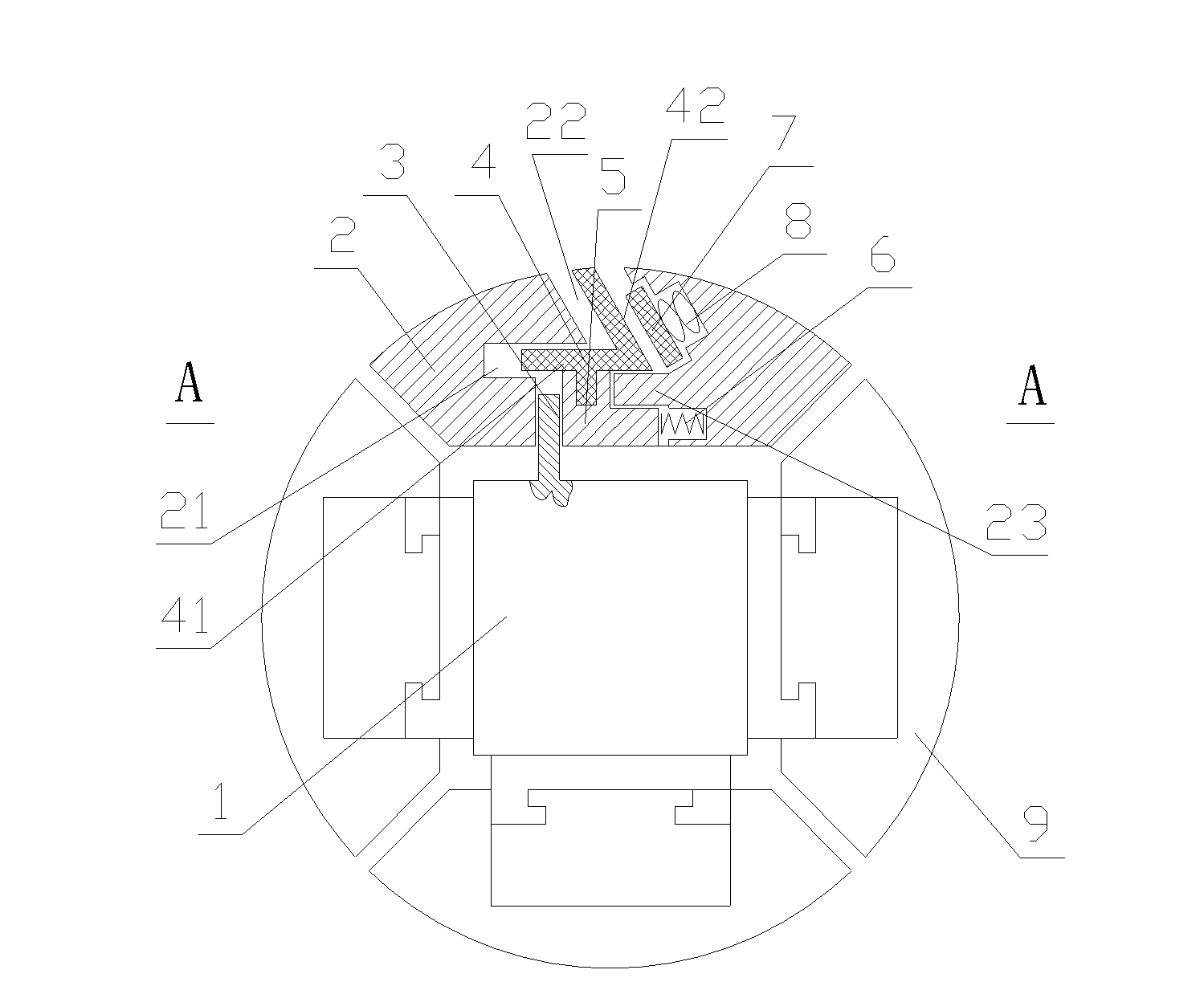

Cylinder clamping device with force sensing capability

The invention provides a cylinder clamping device with force sensing capacity. The problem that in the prior art, cylindrical parts are not easy to grab is solved. A magneto-rheological tactile sensor technology is applied, the clamping force is adjusted and controlled, and grabbing of thin-walled parts prone to deformation is achieved. The cylinder clamping device comprises a base and clamping assemblies installed on the base in pairs, each clamping assembly comprises a swing rod, a sliding sleeve, a linear driving piece, a supporting arm and a tail end clamping piece, one end of each swing rod is hinged to the base, the other end of each swing rod is hinged to the corresponding supporting arm, each sliding sleeve is movably arranged on the corresponding swing rod in a sleeving mode, one end of each linear driving piece is fixed to the base, the other end of each linear driving piece is rotatably connected with the corresponding sliding sleeve, and the relative rotating axis of each linear driving piece and the corresponding sliding sleeve is parallel to the axis of a cylinder. The tail end clamping pieces are of a V-shaped structure, and the tail end clamping pieces of the pair of clamping assemblies are symmetrically arranged to form a butting clamping structure. Clamping of the cylinder can be realized.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

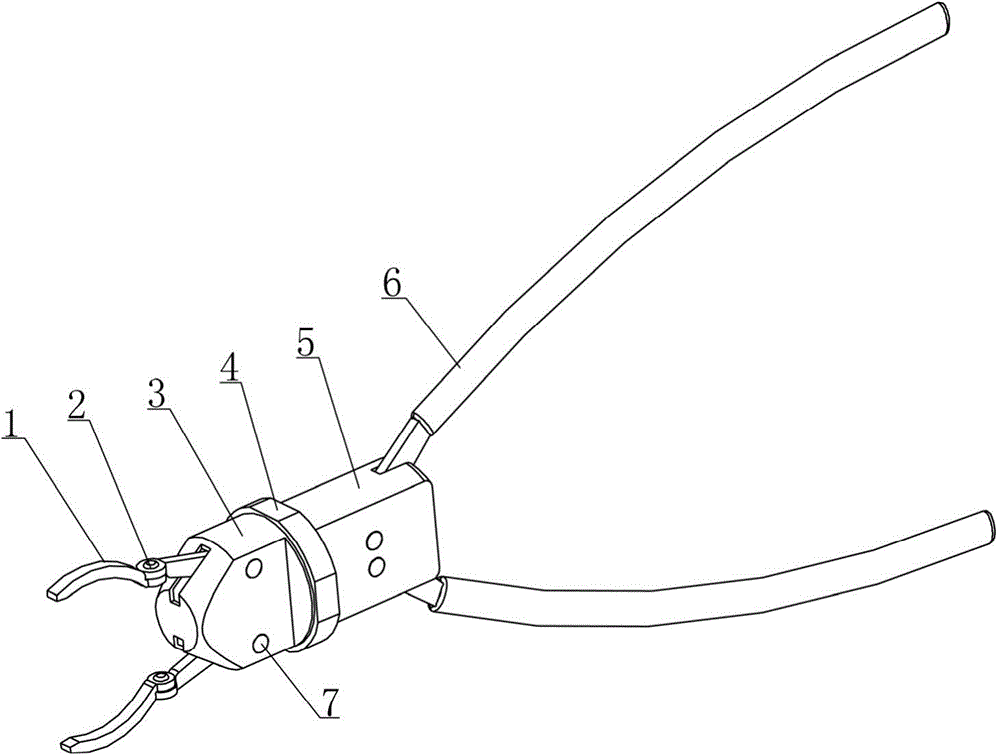

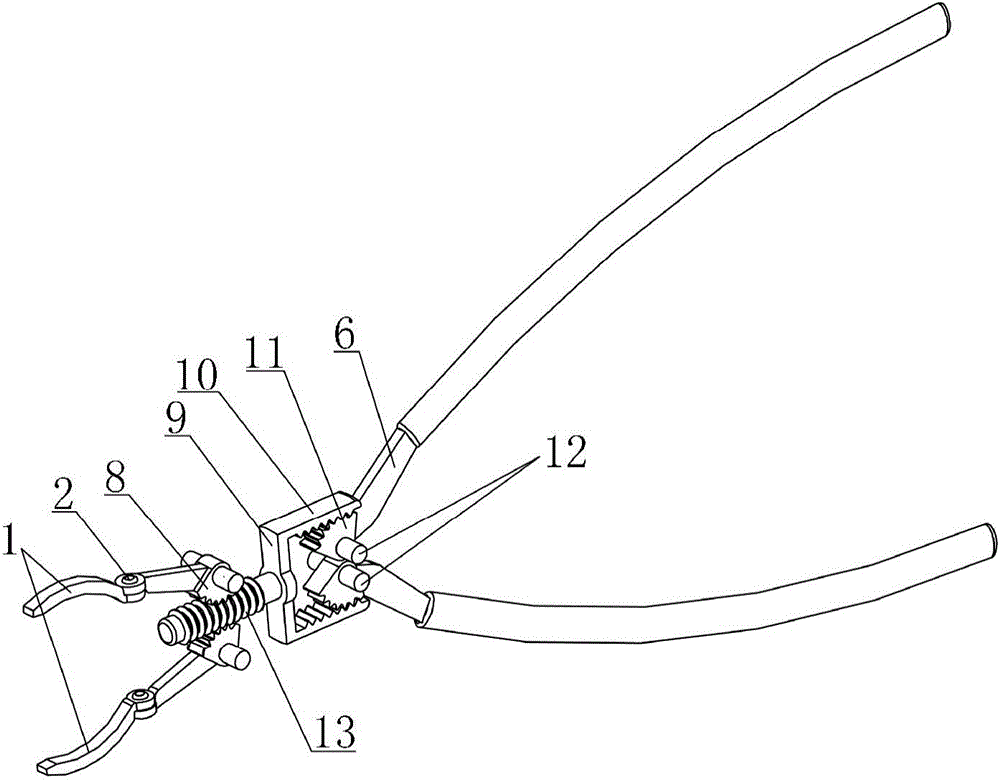

Multipurpose universal medical forceps

InactiveCN104665892AImprove transmission efficiencyFit firmlySurgical forcepsForcepsSacroiliac joint

The invention discloses multipurpose universal medical forceps comprising a forceps handle component, a forceps head component, a housing and a transmission component. The forceps handle component is used for holding and is composed of two parts, and each part is composed of a forceps handle and a drive gear; the forceps head component is used of clamping an item or tissue and is composed of two parts, each part is composed of a forceps head and a driven gear, and the forceps head is composed of two connected rotating joints; the housing is used for supporting other components and is composed of a front housing unit and a rear housing unit connected through a rotating mechanism; the transmission component is used for transmitting the power to the forceps heads and is composed of two parallel racks, a cross beam fixed to the front ends of the racks and a rack post which is fixed to the front of the cross beam and which is parallel to the racks. The forceps are reasonable in design, easy to implement and reasonable in cost; the position of the forceps head can be adjusted in a universal manner in the certain range, and the adjustment is facilitated.

Owner:杜春燕

Automatic-jacking tailstock capable of rapidly moving

InactiveCN102909398AEasy loading and unloading of workpiecesShorten the timeTailstocks/centresEngineeringTailstock

The invention discloses an automatic-jacking tailstock capable of rapidly moving, which has the advantages that the use is convenient and the working efficiency is greatly improved. The automatic-jacking tailstock comprise a bottom plate, wherein a linear slide rail is fixedly connected to the bottom plate; a moving cylinder is fixedly connected to one end of the bottom plate and is provided with a moving cylinder piston rod; the central line of the moving cylinder piston rod is parallel to the walking direction of the linear slide rail; a tailstock backing plate is fixedly connected to the free end of the moving cylinder piston rod; a slide block is fixedly connected below the tailstock backing plate; the slide block is connected with the linear slide rail in a sliding manner; a tailstock body is fixedly connected to the tailstock backing plate; the tailstock body is hollow; a tailstock sleeve is connected in the tailstock body in a sliding manner; a jacking cylinder is fixedly connected to the rear end of the tailstock body and is provided with a jacking cylinder piston rod; the free end of the jacking cylinder piston rod is fixedly connected with the rear end of the tailstock sleeve; a tip is sleeved at the front end of the tailstock sleeve; and the contact surface of the tip and the tailstock sleeve is conical. The free end of the moving cylinder piston rod is connected with the tailstock backing plate via a connecting block.

Owner:SHANDONG LUNAN MACHINE TOOL

Machine tool for sliding shoe closing

ActiveCN110695224ASmooth movementGood stabilityMetal-working feeding devicesStripping-off devicesEngineeringMachine tool

The invention discloses a machine tool for sliding shoe closing, and belongs to the technical field of assembly of plunger assemblies. The machine tool includes a tool body and is characterized in that an upright post and a workpiece spindle for clamping a sliding shoe are fixedly connected to the tool body, a sliding-moving mechanism is fixedly connected to the upright post, and a spinning mechanism for spinning the sliding shoe is connected to the sliding-moving mechanism; the spinning mechanism is directly above the workpiece spindle, and the spinning mechanism comprises a chuck, a roller assembly and a pushing assembly for pushing a plunger ball head; the roller assembly is installed on a base jaw of the chuck, the pushing assembly is installed at the center of the chuck, a mechanicalarm is installed on the tool body, and the mechanical arm is located on one side of the workpiece spindle; and the rotation axis of the spinning mechanism is coaxial with the rotation axis of the workpiece spindle. By controlling the spinning mechanism, the roller assembly mounted on the base jaw of the chuck rolls the sliding shoe, and the machine tool has the characteristics of good stability ofscrewing-closing accuracy and high yield.

Owner:四川普什宁江机床有限公司

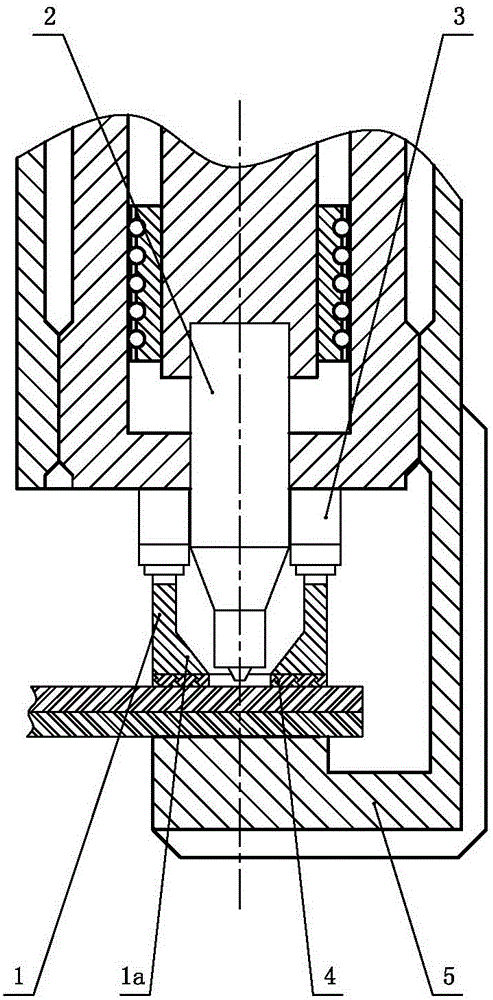

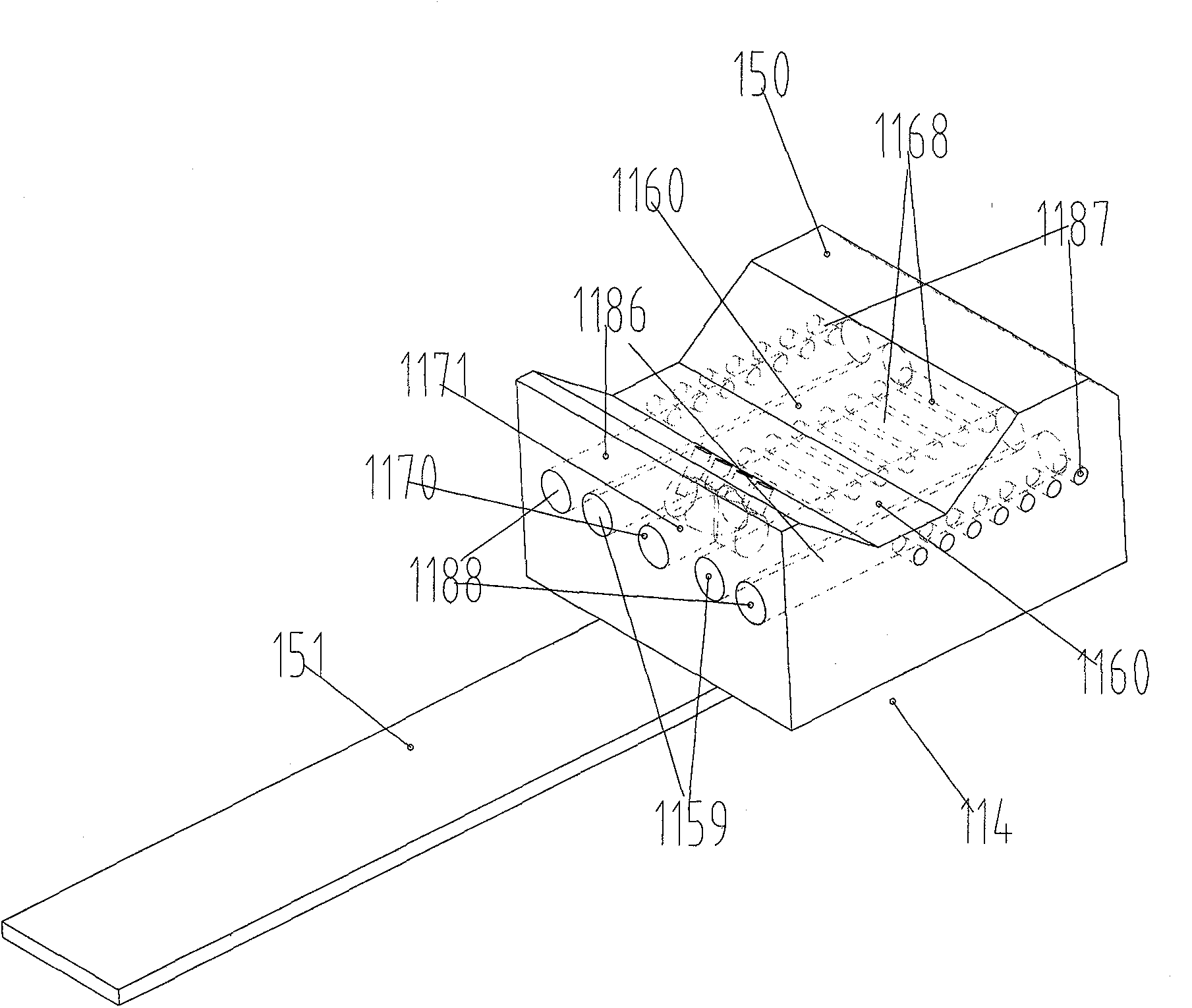

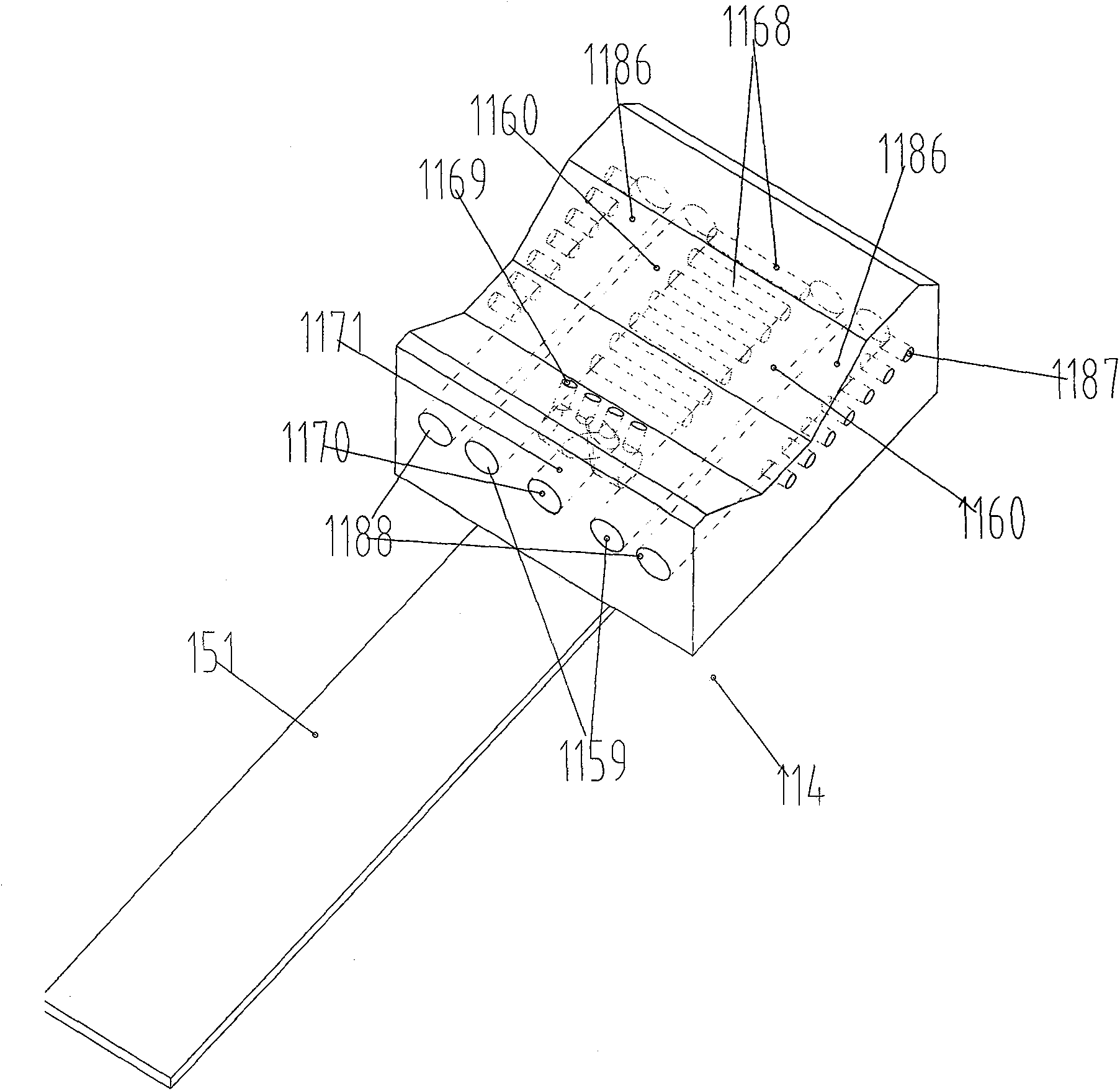

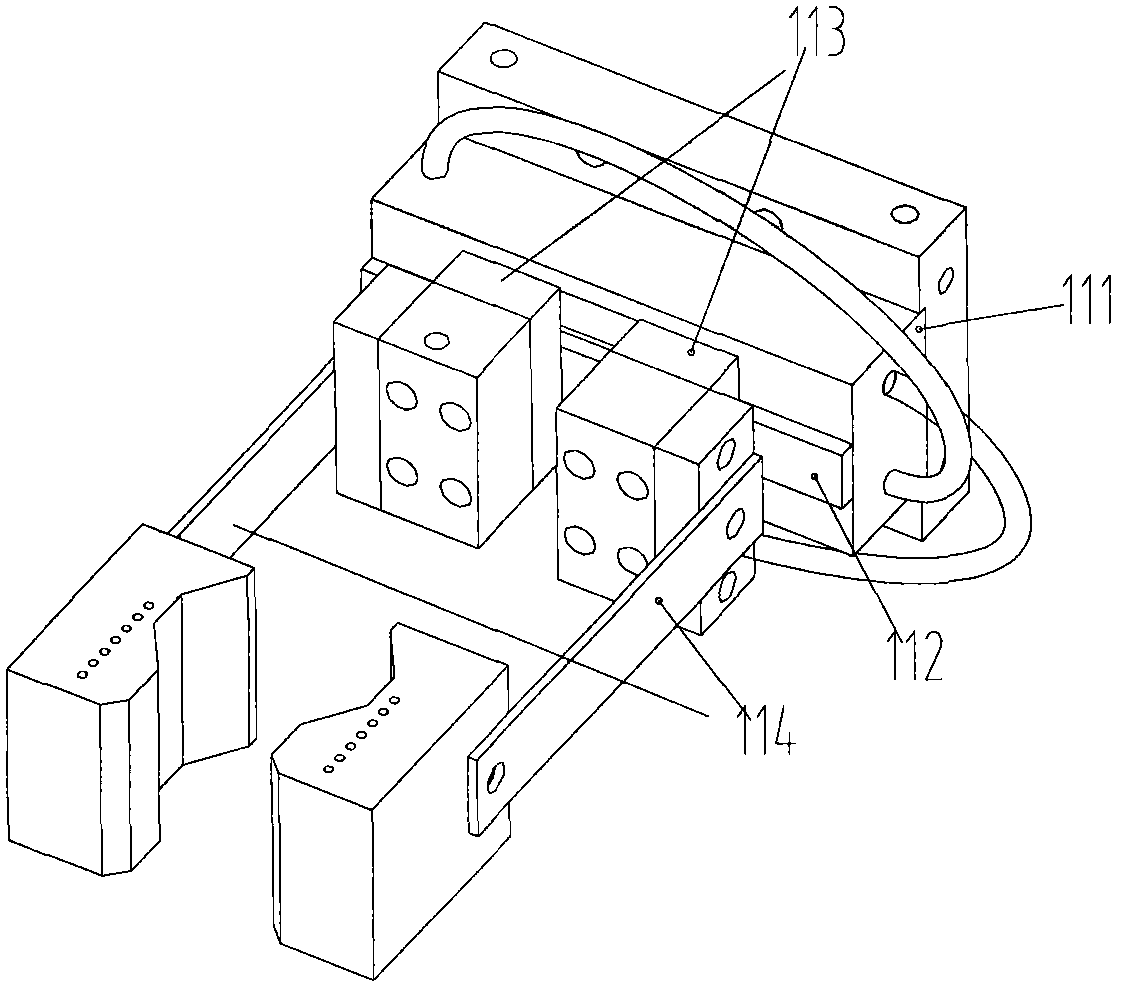

Friction stir spot welding equipment with automatic clamping device

InactiveCN105108315ARealize the clamping actionRealize clamping automatic controlNon-electric welding apparatusDevices fixationEngineering

The invention relates to friction stir spot welding (FSSW) equipment with an automatic clamping device. The FSSW equipment comprises an upper computer, a ring-shaped upper clamping plate, a lower clamping plate arranged corresponding to the upper clamping plate and a driving mechanism used for driving the upper clamping plate to move up and down. The driving mechanism is fixedly connected with the FSSW equipment. A stir head of the FSSW equipment penetrates the upper clamping plate and is perpendicular to a weld joint. The upper computer starts the driving mechanism; the upper clamping plate moves downwards to be matched with the lower clamping plate to clamp a workpiece to be welded; the stir head is started; when welding is completed, the stir head begins to Retreat; and simultaneously the upper clamping plate is controlled by the driving mechanism to move upwards, and the workpiece is unclamped. According to the FSSW equipment, the upper clamping plate is matched with the lower clamping plate, so that the workpiece clamping action is achieved, and the phenomenon of the flexure on the periphery of a welding spot of the workpiece in the welding process of the workpiece is avoided.

Owner:昆山斯格威电子科技有限公司

Positioning drilling tool of pressure adjusting valve

InactiveCN108526538ARealize location positioningSimple structurePositioning apparatusBoring/drilling componentsEngineeringMechanical engineering

Owner:湖北昊昌汽车零部件制造有限公司

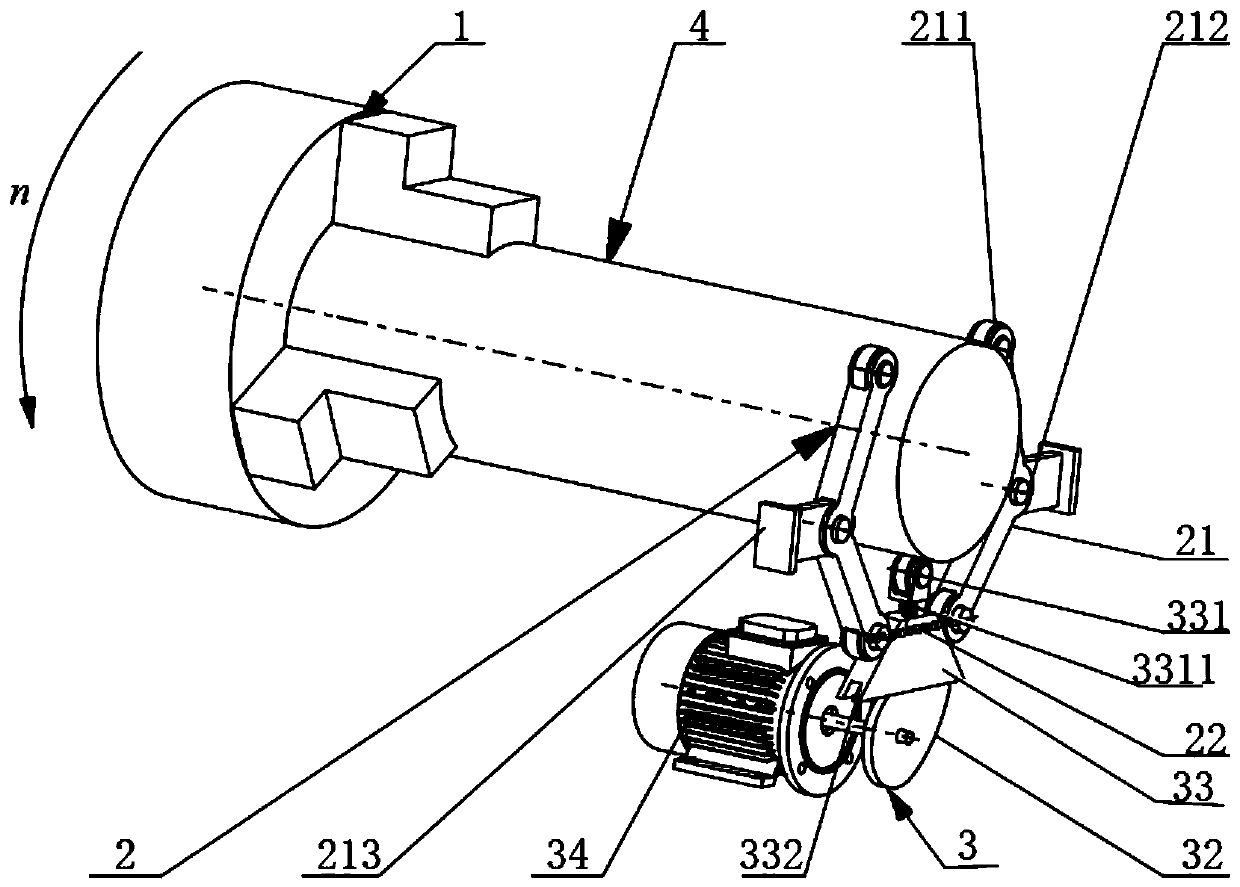

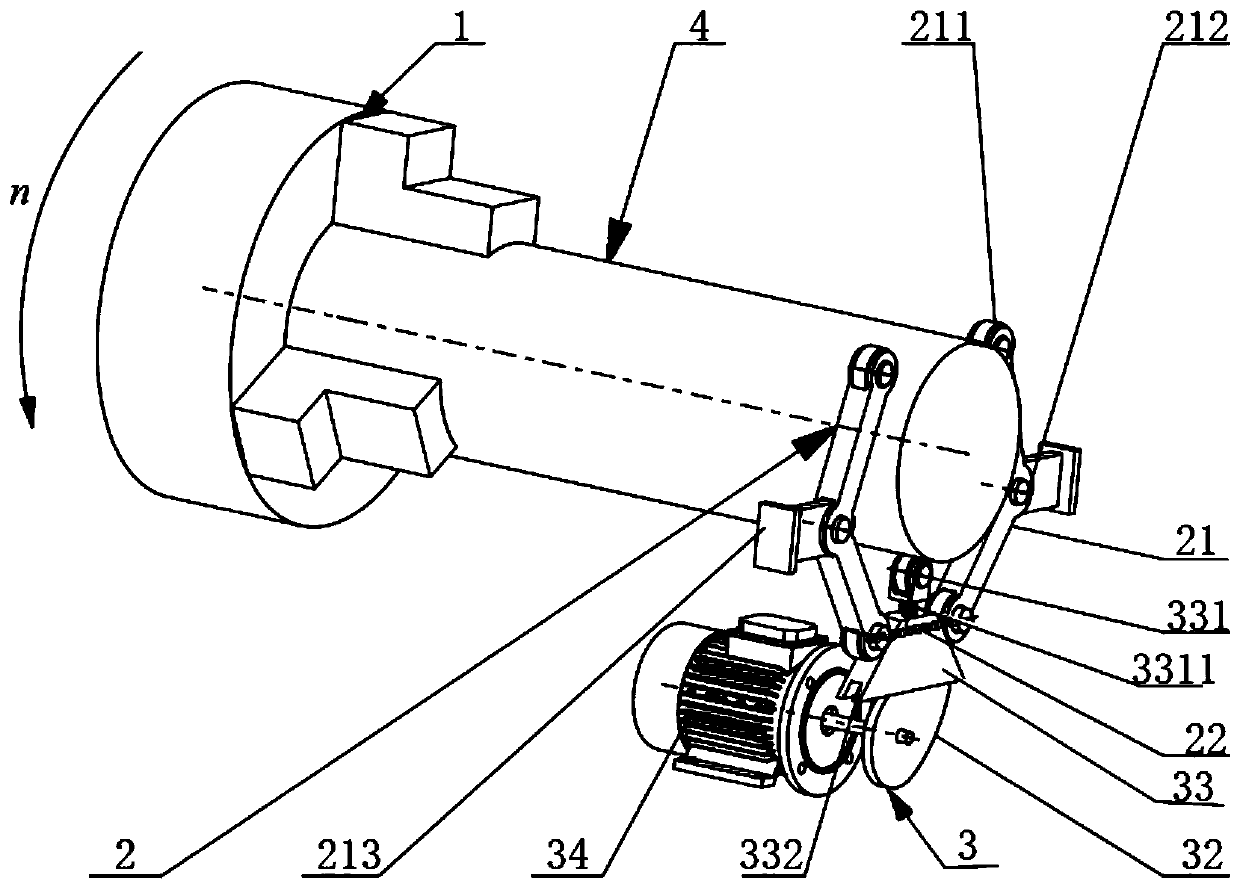

Compound forging manipulator

ActiveCN103878285AIncrease temperatureReduce the temperatureProgramme-controlled manipulatorForging/hammering/pressing machinesForging manipulatorRoom temperature

The invention relates to industrial automation device, in particular to an automation manipulator. The compound forging manipulator comprises a gripper and a finger. The gripper comprises a finger body, a guide rail, pistons, a plunger pin and sliders. The finger is fixedly connected to the sliders and comprises a finger tip and a bridge, one end of the bridge is fixedly connected to the sliders while the other end of the same is fixedly connected with the finger, and a clamping face is arranged on the finger. When a workpiece is impacted or bumped, affections of impact on the gripper can be avoided or reduced due to an elastic function of the finger. Graphite can be sprayed to a die while the workpiece is gripped simultaneously, so that production efficiency is improved; liquid fed into an inlet flows out of an outlet via a channel, heat accumulated through the fingers is taken away by the flowing liquid, temperature of the fingers can be greatly reduced, and the finger can be kept at constant temperature under working conditions; meanwhile, the high-temperature workpiece is subjected to quenching treatment.

Owner:ZHEJIANG WEILI METALFORMING MACHINERY

Spraying device for new energy vehicle parts

ActiveCN111359806AAchieve rotationRealize the clamping actionPretreated surfacesCoatingsMotor vehicle partNew energy

The invention relates to the field of automobile part processing equipment, and discloses a spraying device for new energy vehicle parts. The spraying device comprises a transfer mechanism, a conveying mechanism and a bearing mechanism, wherein a support frame is arranged beside the transfer mechanism, a U-shaped cover plate is arranged on the top of the support frame, the conveying mechanism is installed on the inner top of the U-shaped cover plate, the bearing mechanism is installed on the top of the support frame and located on the top of the U-shaped cover plate, a coating mechanism is arranged at one end, away from the transport mechanism, of the U-shaped cover plate, and a spraying mechanism and a hot air group mechanism are arranged on the two sides of the U-shaped cover plate respectively. The spraying device can achieve automatic transfer, feeding and discharging and automatic paint spraying of the vehicle parts, manual labor intensity is reduced, the production efficiency isimproved, the production cost is reduced, practicability of the device is improved, and painting quality of the special-shaped vehicle parts can be ensured.

Owner:福建龙岩飞腾科技有限公司

Lifting appliance for crane maintenance

ActiveCN108046118AReduce distanceRealize the clamping actionLoad-engaging elementsMechanical engineering

Owner:徐州天骋智能科技有限公司

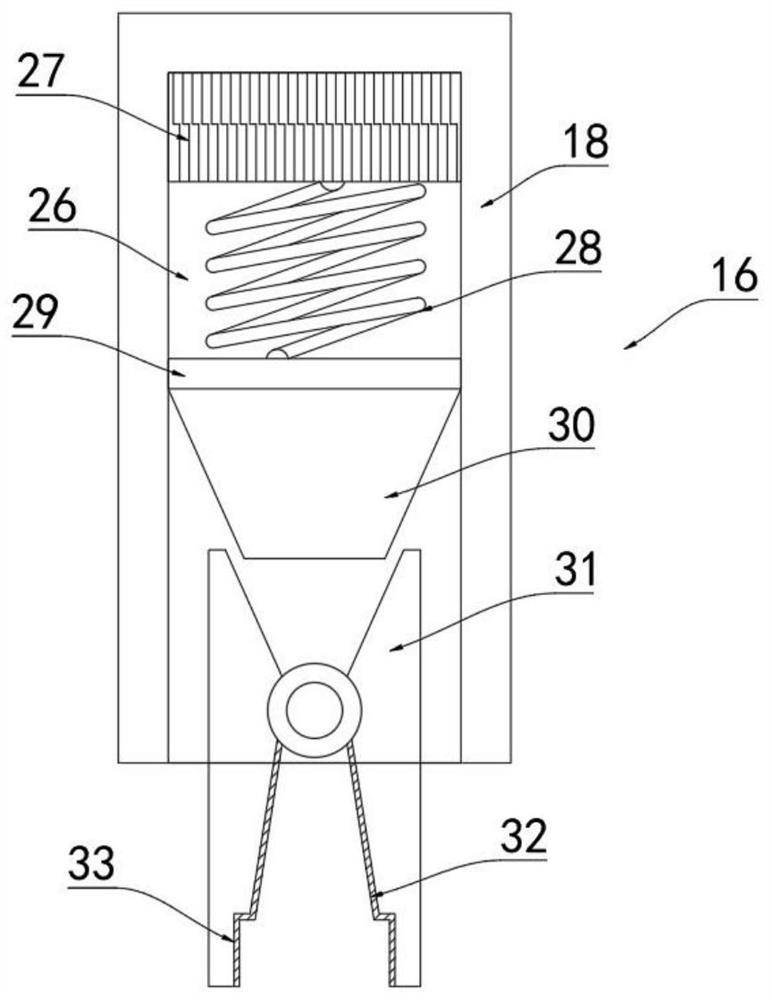

Live lead clip

PendingCN110829060ASimple structureLow costCoupling device detailsElectric connection basesScrew threadElectrical and Electronics engineering

The invention provides a live lead clip which includes a main body, a wire clamping slider, a first nut, a second nut, and a driving bolt. The main body is composed of a wire clamping part which is used for clamping a wire and wedge-shaped in the whole when used, and a drainage wire connecting part which is arranged on the lower side of the wire clamping part, integrally connected with the wire clamping part and connected with a drainage wire when in use, wherein the wire clamping part and the drainage wire connecting part are integrated. The wire clamping slider is a structural member which is in sliding fit with the wire clamping part of the main body and wedge-shaped in the whole. The first nut is fixed on the wire clamping slider. The second nut is fixed on the wire clamping part of the main body. The driving bolt is screwed with the first nut and the second nut. When the live lead clip is used, the driving bolt is screwed by an arranging tool, and the wire clamping slider can slide in the wire clamping part of the main body to clamp the wire of a power transmission line. The lead clip provided by the invention has the advantages of simple structure, low cost, convenient installation and operation during use, has the advantages of the existing similar devices, and overcomes the disadvantages of the existing similar devices.

Owner:JIANGSU ELECTRIC POWER CO +1

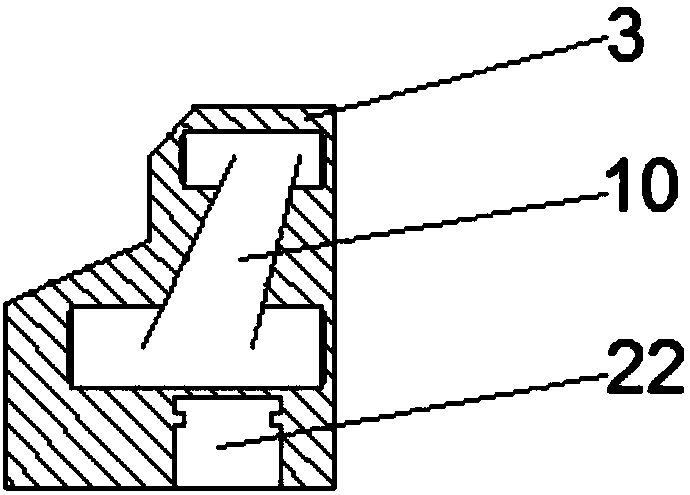

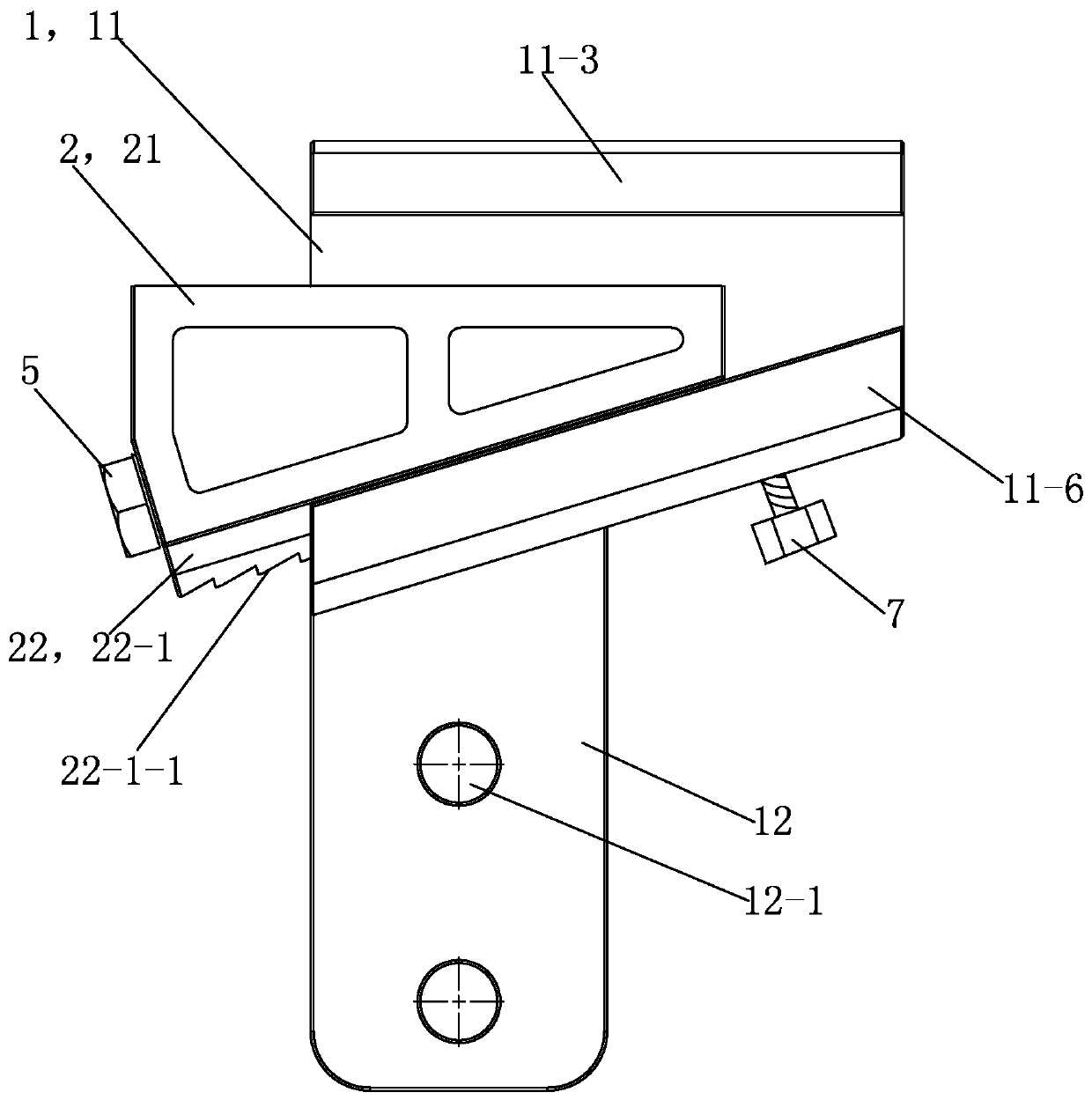

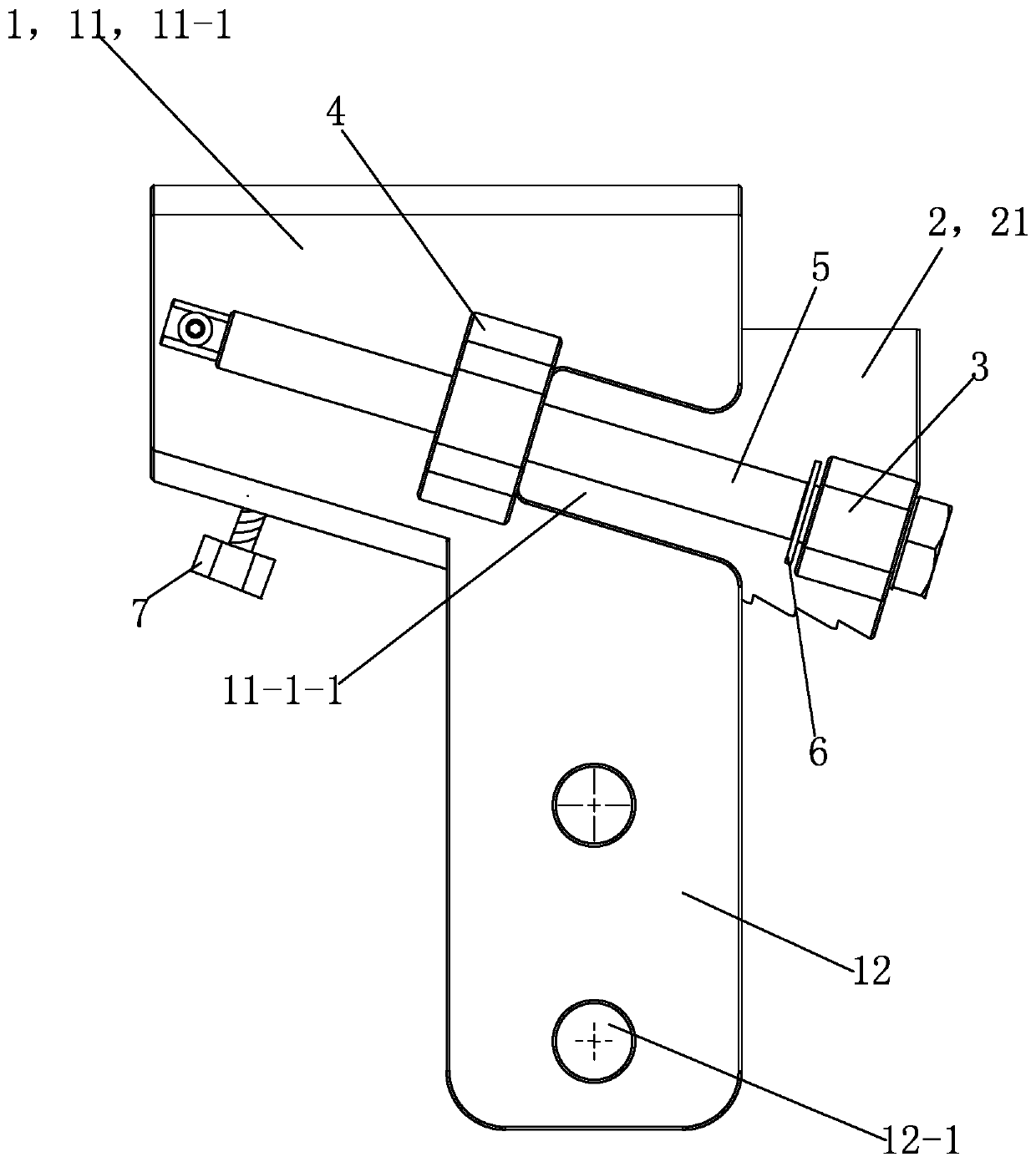

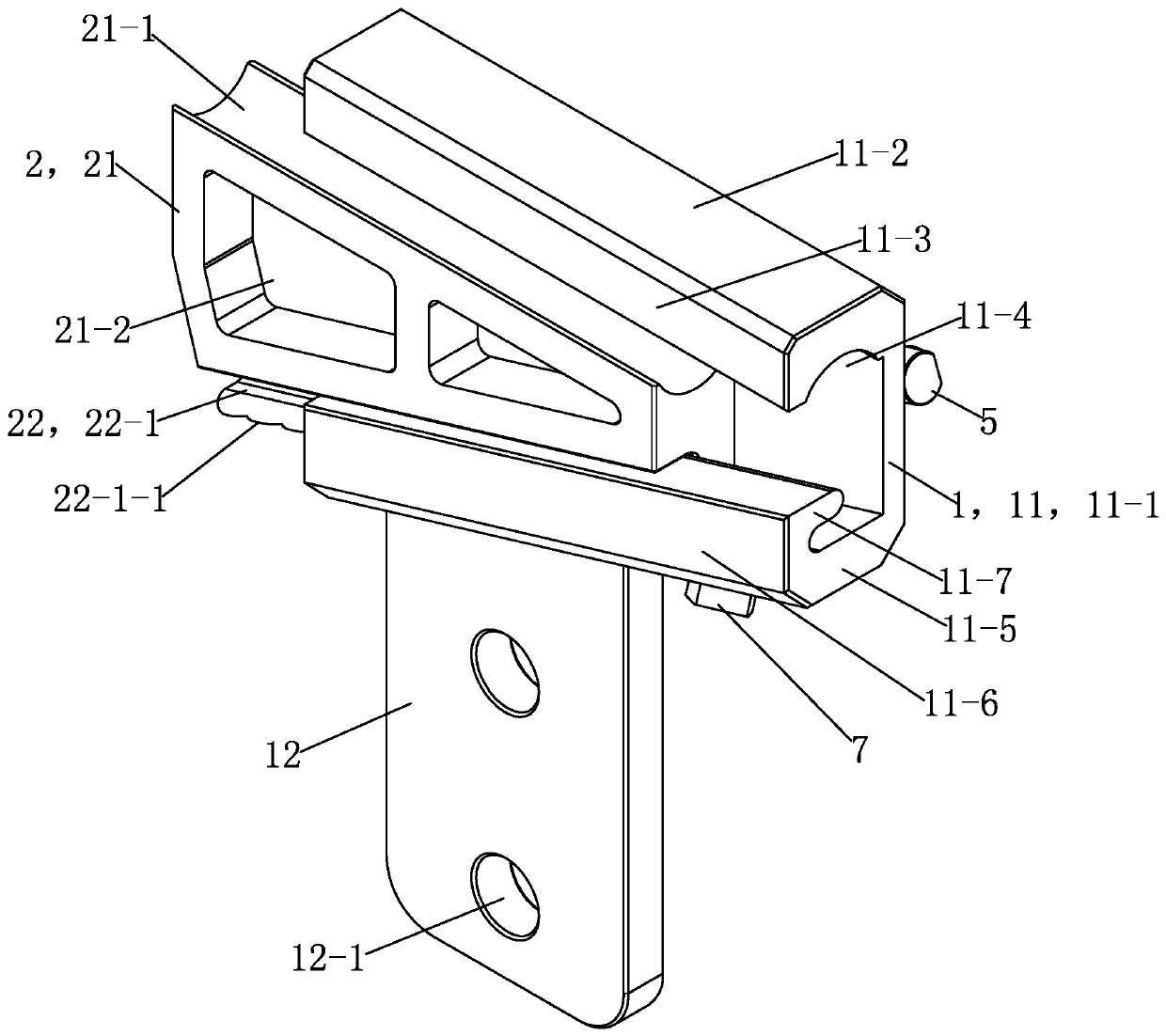

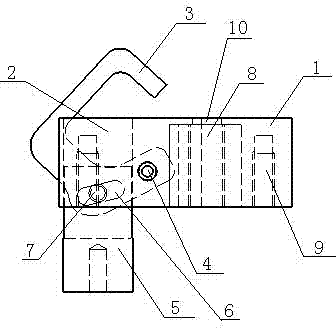

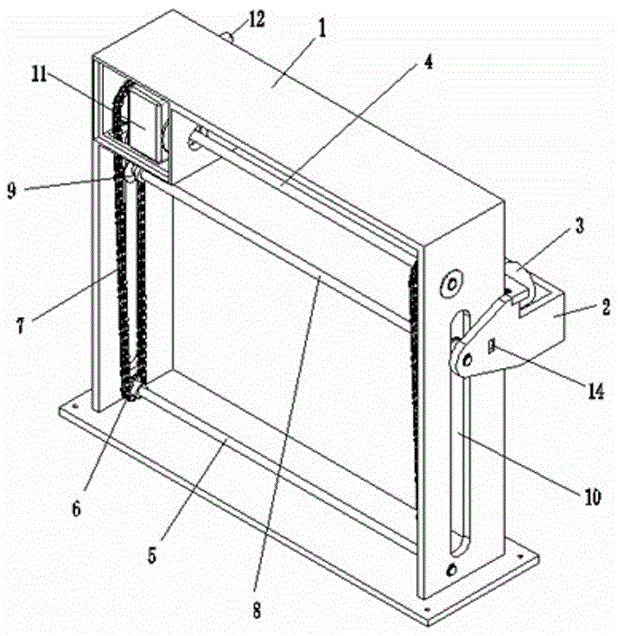

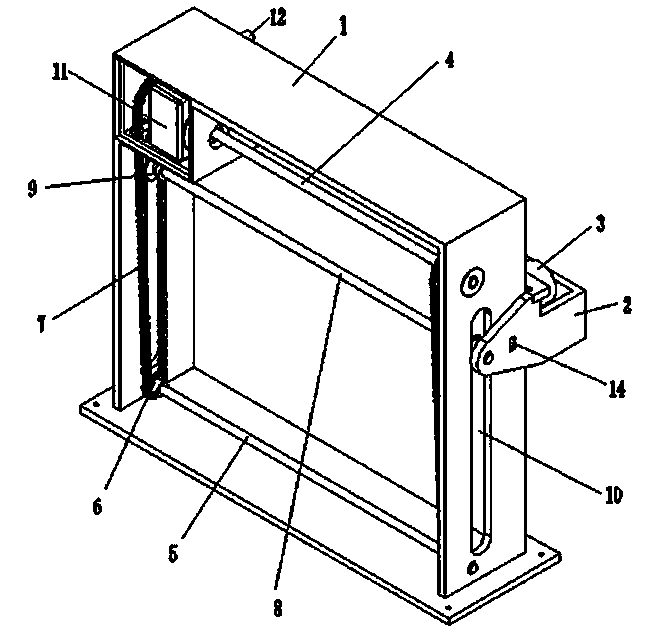

Hook type clamping mechanism

The invention provides a hook type clamping mechanism. The hook type clamping mechanism comprises a base seat, wherein a through hole is formed in the base seat, a hook is arranged in the through hole, a rotation shaft is arranged on the base seat, one end of the hook is fixedly connected onto the rotation shaft, a drive shaft is arranged right below the hook, the hook is connected with the drive shaft, a waist-shaped hole is formed in a matching position of the hook and the drive shaft, a positioning block is arranged on the hook, the positioning block is installed in the waist-shaped hole, and the lower end of the drive shaft is connected with a drive air cylinder. The hook type clamping mechanism translates linear motion of the drive shaft into circular motion of the hook by using the hook, the rotation shaft and the drive shaft in combination, can achieve clamping motion in the vertical direction, can avoid interference possibly generated on the side face, and furthermore is compact in structure, small in occupied space, and suitable for various work environments small in space.

Owner:WUHU MOTIONTEC AUTOMOTIVE

Manipulator for electronic component production

ActiveCN113977616ALow input costRealize the clamping effectFinal product manufactureGripping headsElectric machineryStructural engineering

The invention discloses a manipulator for electronic component production. The manipulator comprises a connecting plate, wherein mounting grooves are arranged on upper ends of two ends of the connecting plate; a trapezoidal groove arranged at the bottom of the connecting plate; a rotating rod is rotationally connected to an inner wall of the trapezoidal groove; the other end of the rotating rod penetrates through the connecting plate and is rotationally connected with the connecting plate; a driving mechanism is arranged between the rotating rod and the mounting grooves; the middle section of the rotating rod is a reciprocating screw rod; the reciprocating screw rod is sleeved with a moving block which is in threaded connection with the reciprocating screw rod; a vertical rod is arranged on the moving block in an up-down penetrating mode; a reset mechanism is arranged between the vertical rod and the moving block; and the bottom of the vertical rod is connected with a manipulator assembly. According to the invention, a motor can be matched with an electromagnet to clamp electronic components, and the clamped electronic components can be conveyed and placed, so that participation of more power equipment is not needed, and the production cost is reduced; and meanwhile, the manipulator is convenient to replace, and clamping of different electronic components is achieved.

Owner:JIUJIANG UNIVERSITY

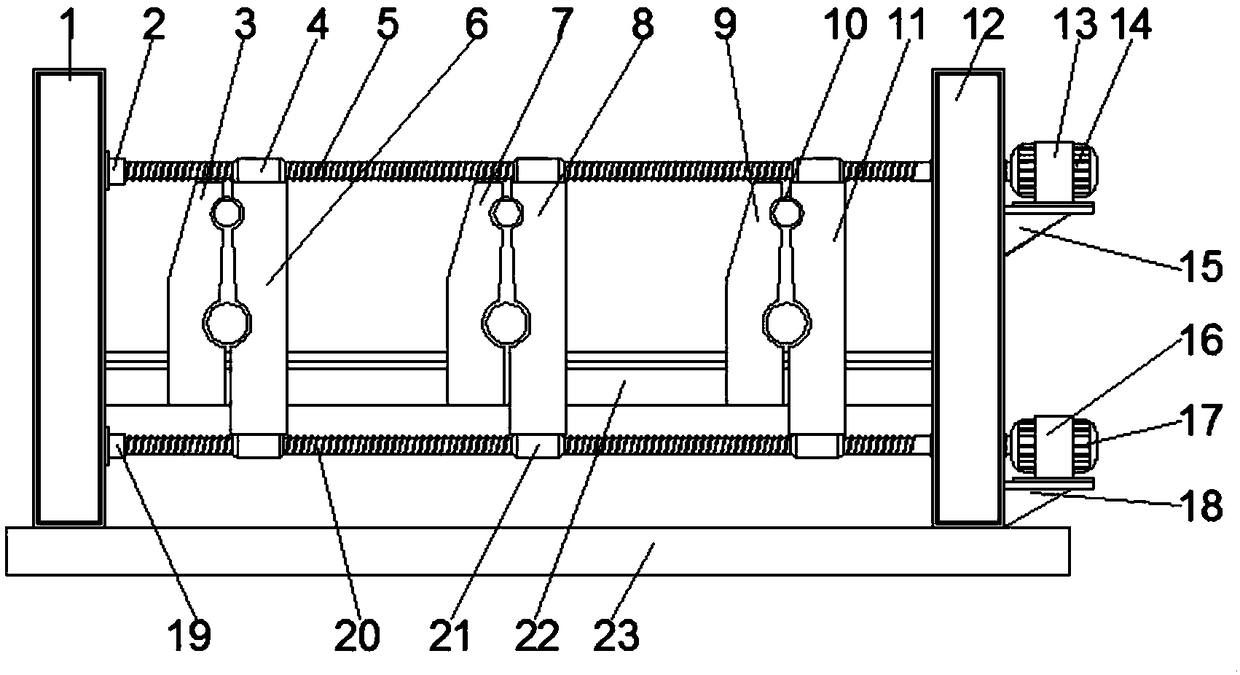

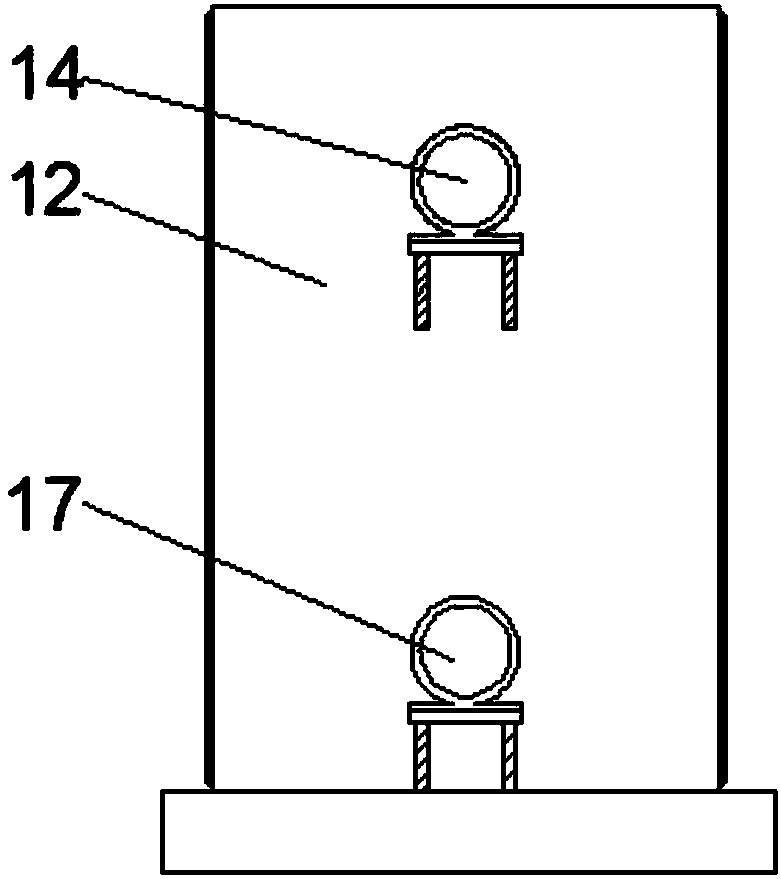

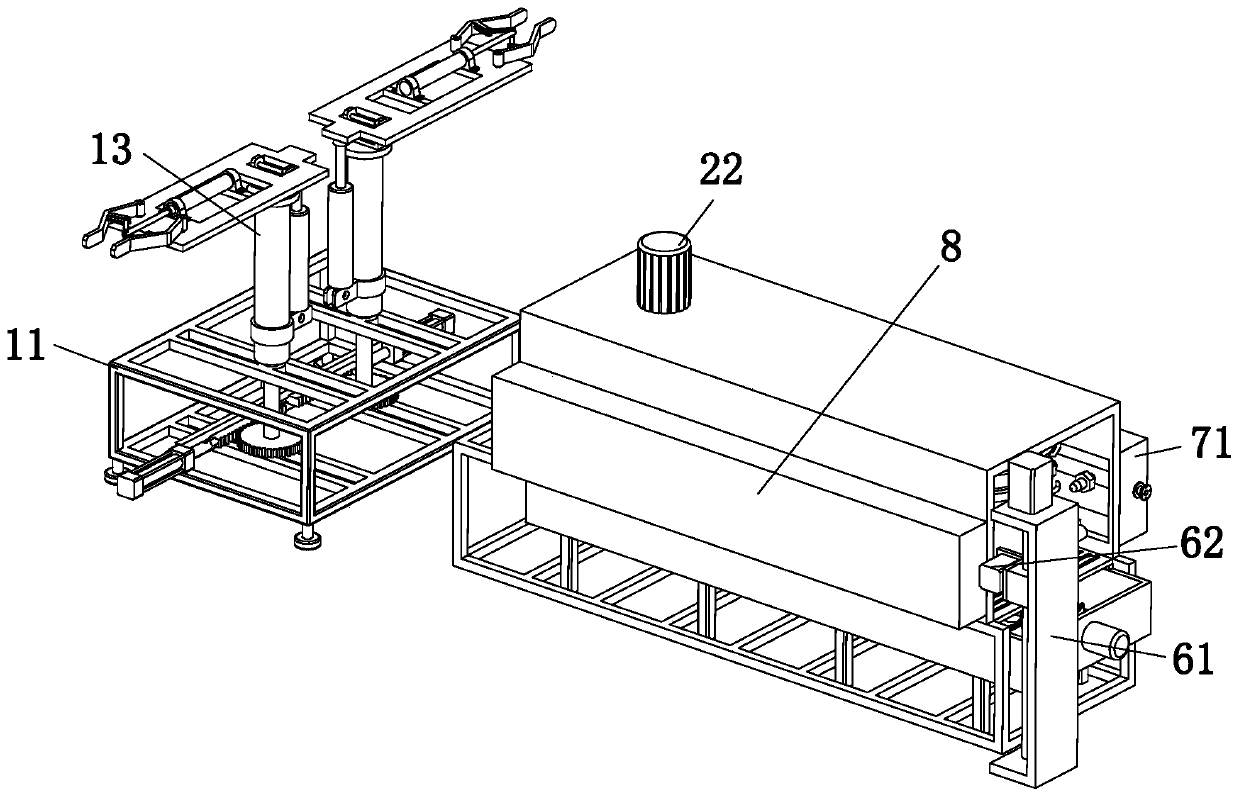

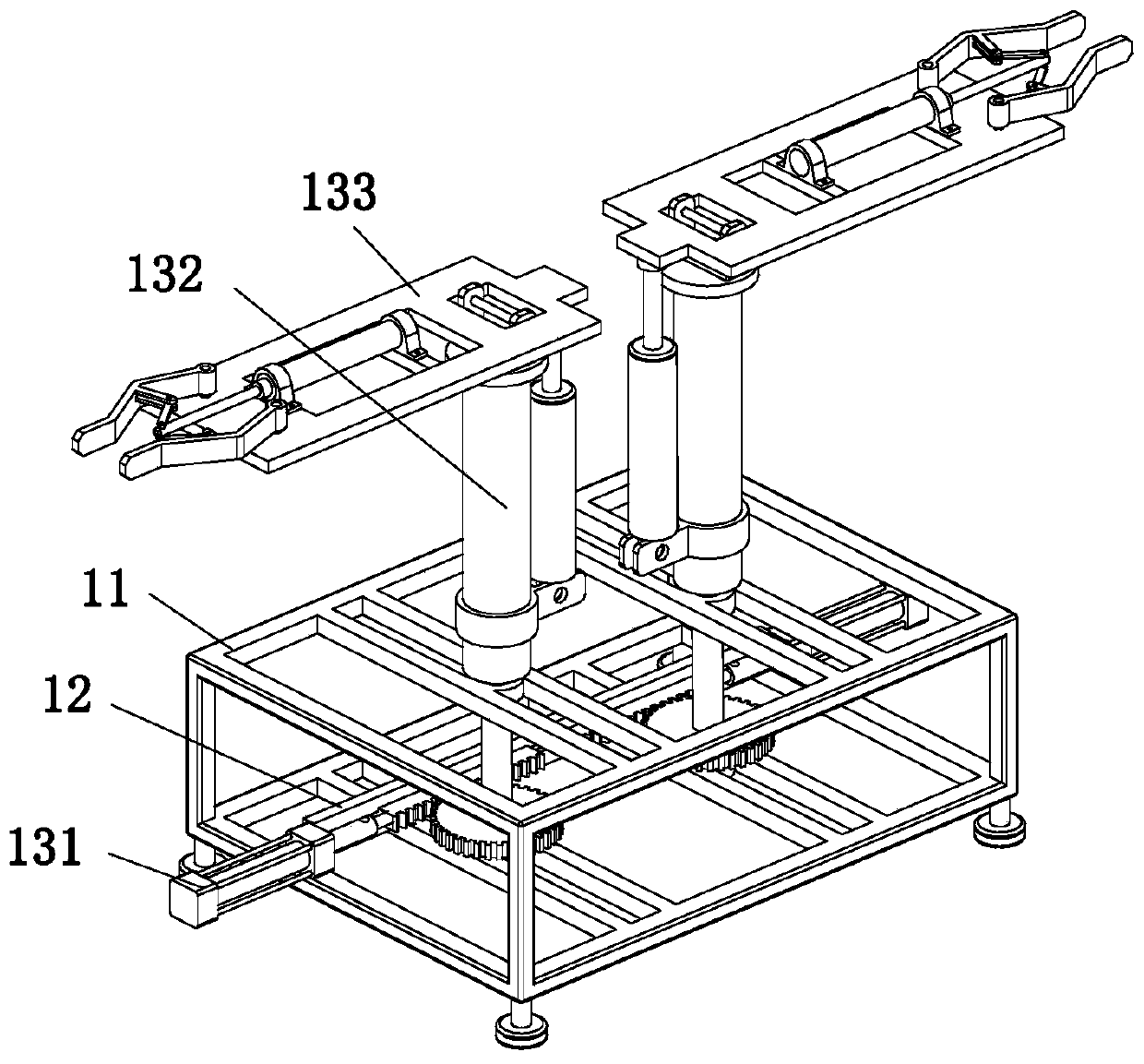

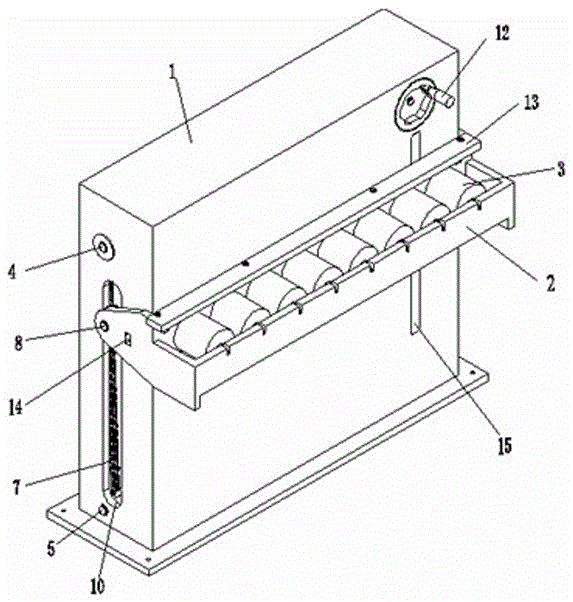

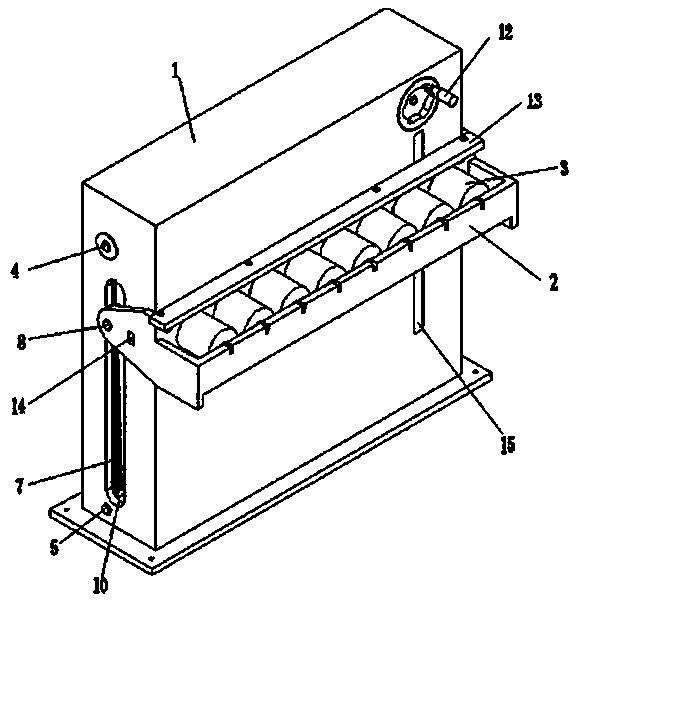

Auxiliary loading device for vertical continuous plating lines

ActiveCN103572355BRealize the clamping actionSave human effortElectrolysis componentsEngineeringUltimate tensile strength

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Auxiliary material-loading device for vertical continuous plating line

ActiveCN103572355ARealize the clamping actionSave human effortElectrolysis componentsEngineeringUltimate tensile strength

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

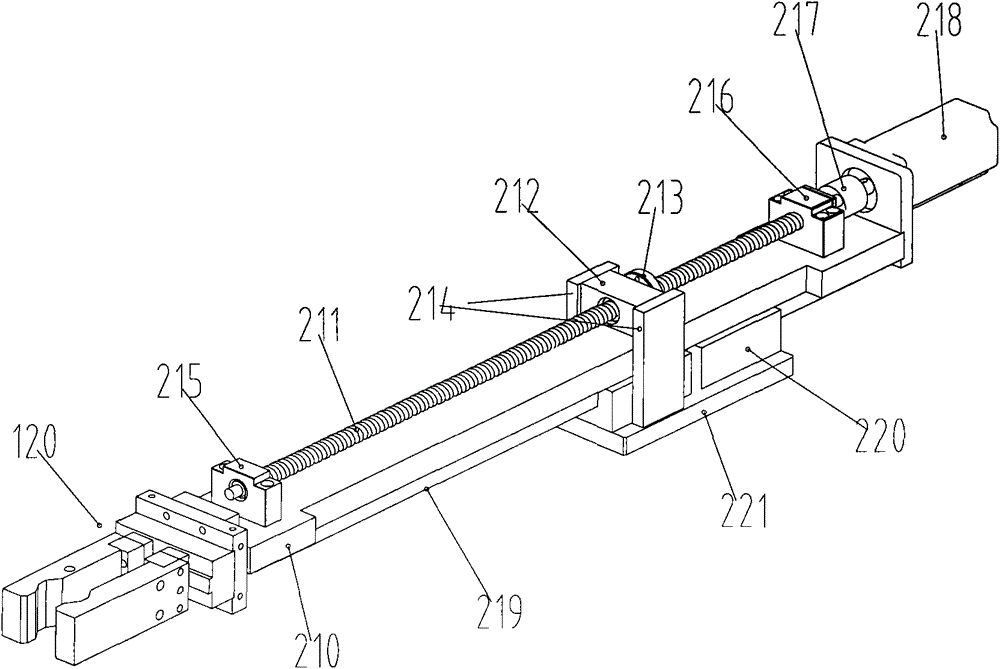

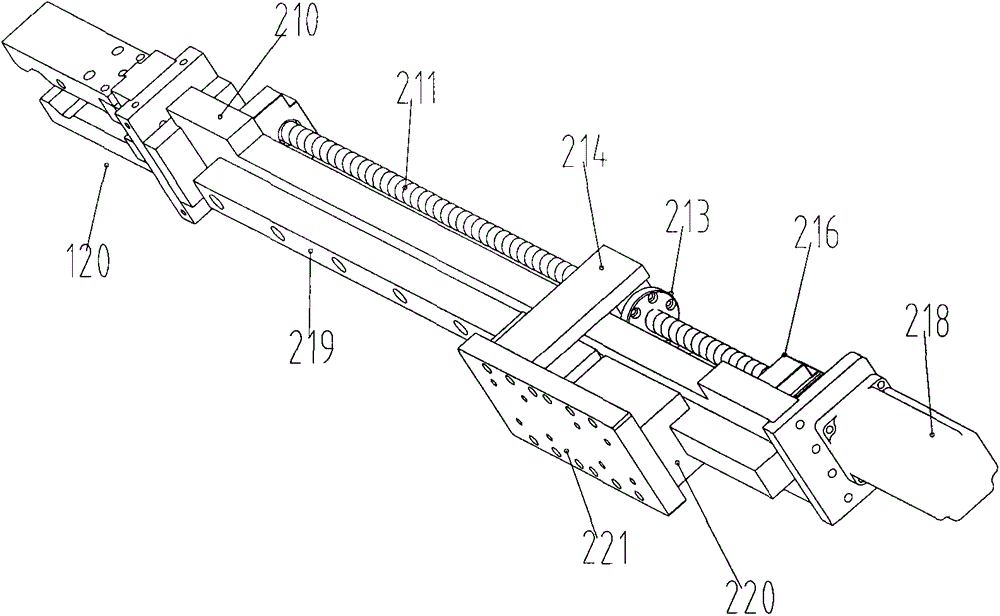

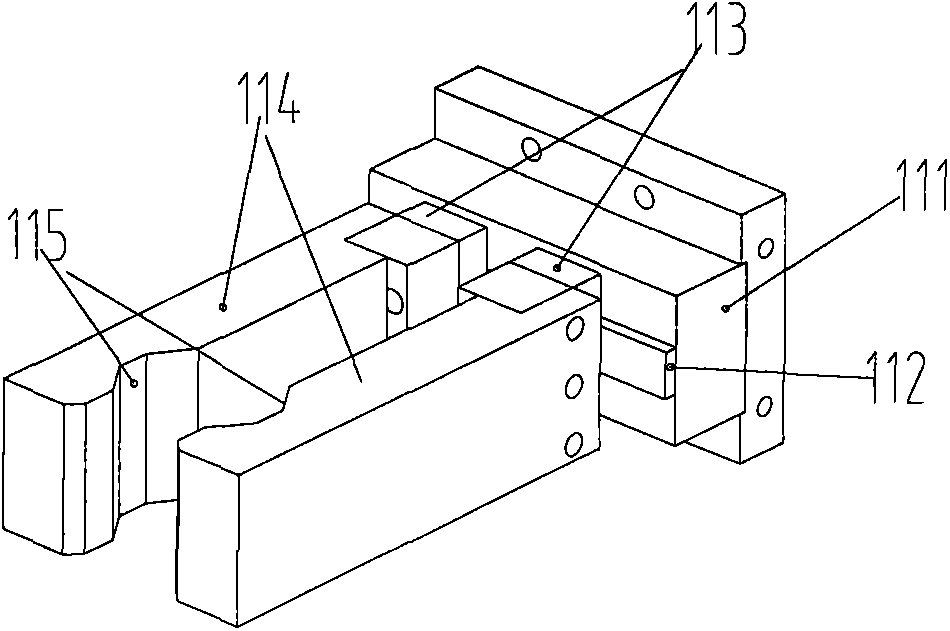

Straight-line motion manipulator

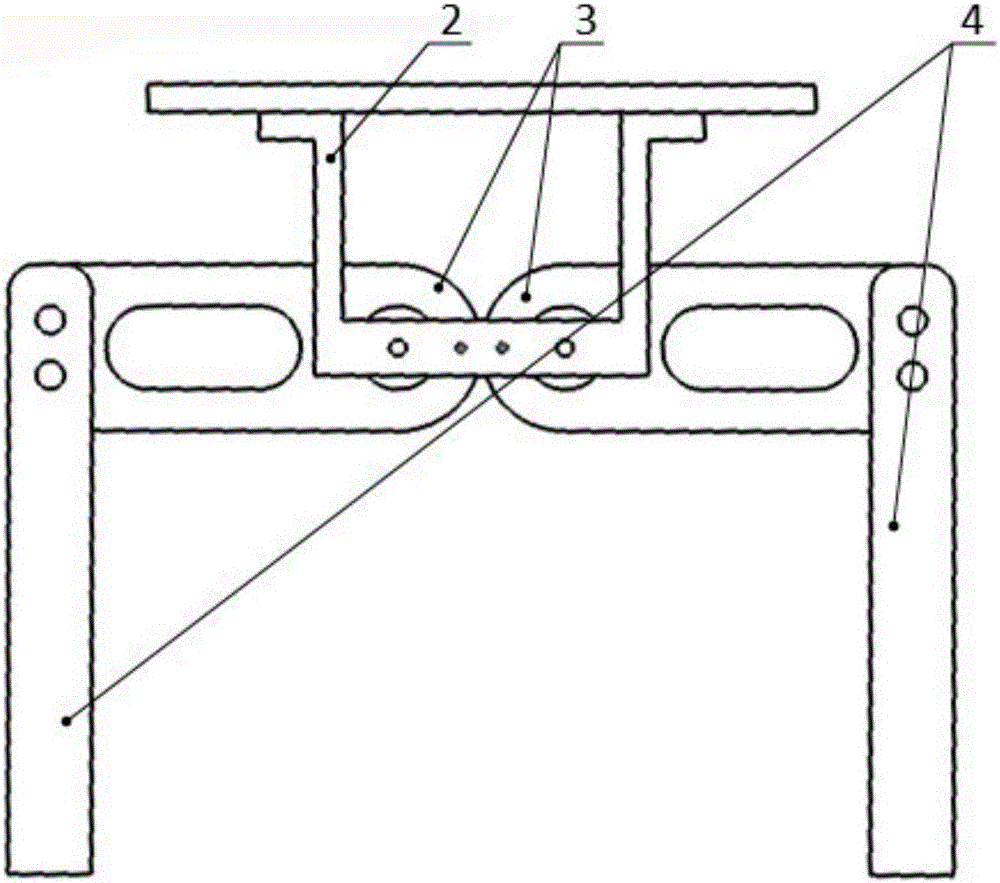

InactiveCN104526679AReduce frictional resistanceRun smoothlyProgramme-controlled manipulatorGripping headsPistonManipulator

The invention relates to industrial automation devices, in particular to an automated manipulator. A straight-line motion manipulator comprises an arm and a paw; the paw is fixedly connected to one end of the arm; the arm comprises a bottom plate, a lead screw, a long guide rail, a square slider, a nut, a servo motor and a coupling; one end of the lead screw is movably connected with a lead screw fixing seat, and the other end of the lead screw is movably connected with a lead screw supporting seat; the lead screw fixing seat and the lead screw supporting seat are fixedly connected to the bottom plate; the lead screw is parallel to the long guide rail; the paw comprises a slider module and fingers; the fingers are fixedly connected to sliders; the slider module comprises a finger body, a guide rail, pistons, a plunger pin and the sliders. The guide rail type manipulator is applicable to a machine manufacturing process, and is small in frictional resistance, stable in operation, high in precision and long in operating life, and carrying and transferring of materials are realized.

Owner:WENZHOU POLYTECHNIC

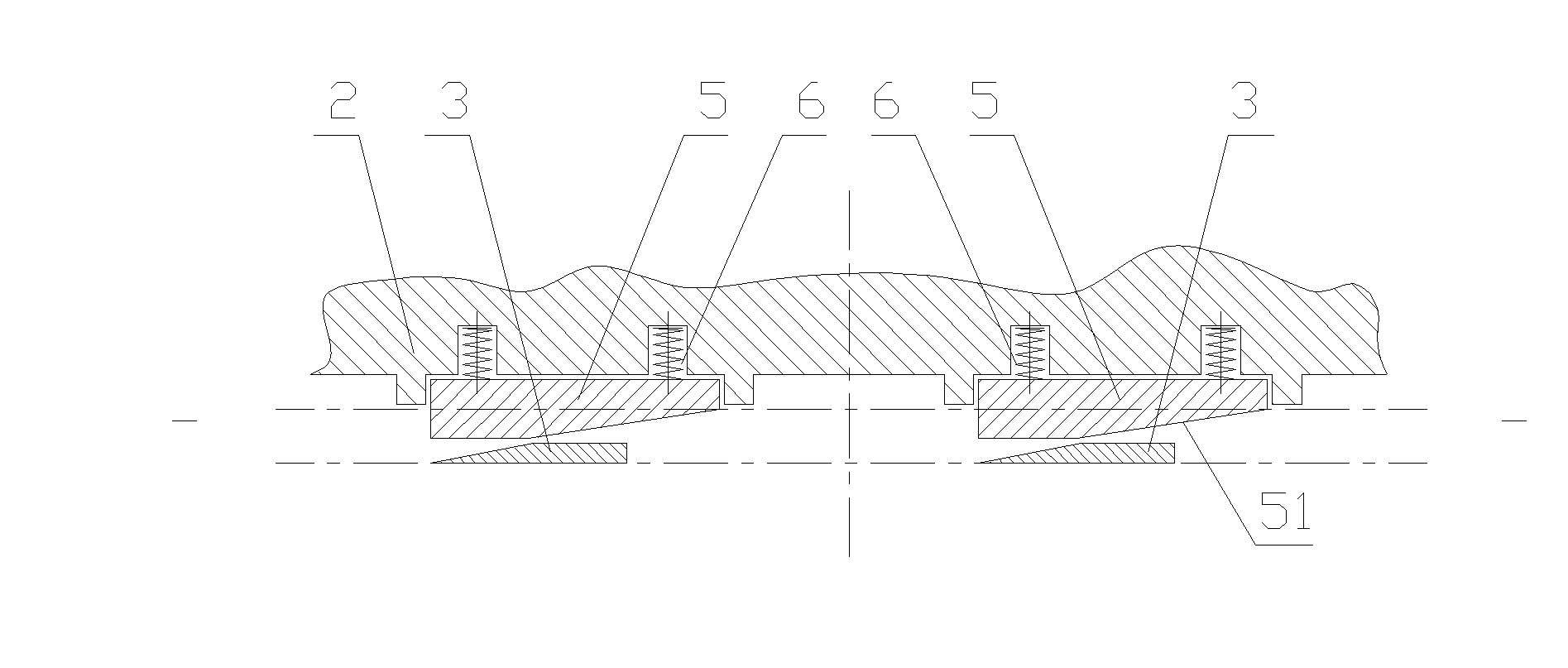

Vertical swing-rod holding device applicable to low-frequency internal-friction measurements

ActiveCN103233952AReduce manufacturing costRealize the clamping actionFriction grip releasable fasteningsBall bearingEngineering

The invention discloses a vertical swing-rod holding device applicable to low-frequency internal-friction measurements. The vertical swing-rod holding device mainly comprises a holding mechanism and an adjusting mechanism, wherein the holding mechanism is used for maintaining the horizontal direction, the adjusting mechanism is used for producing vertical displacement, the holding mechanism is connected with the adjusting mechanism in such a way that a bearing is matched with a bevel wheel groove, the deep groove ball bearing is arranged at the tail end of the holding mechanism, a wheel groove frame is arranged at the upper end of the adjusting mechanism, and the bevel wheel groove is arranged on the wheel groove frame. According to the method, the vertical swing-rod holding device applicable to low-frequency internal-friction measurements is skillful in design, simple in structure and low in manufacturing cost. The bevel wheel groove is matched with the bearing, so that the displacement of the adjusting mechanism in the vertical direction can be converted into position changes of the holding mechanism in the horizontal direction, and a clamping structure is pulled to achieve clamping of a vertical swing rod by a holding rod.

Owner:SUZHOU VOCATIONAL UNIV

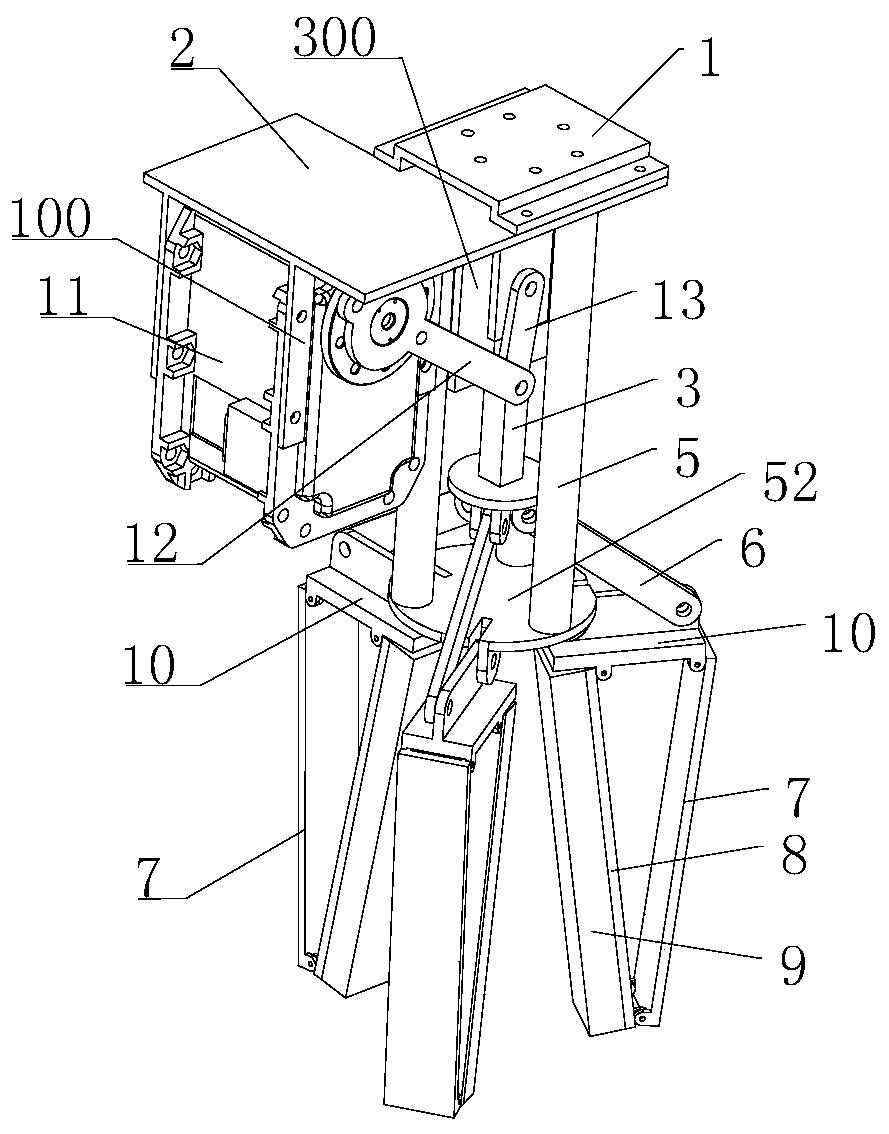

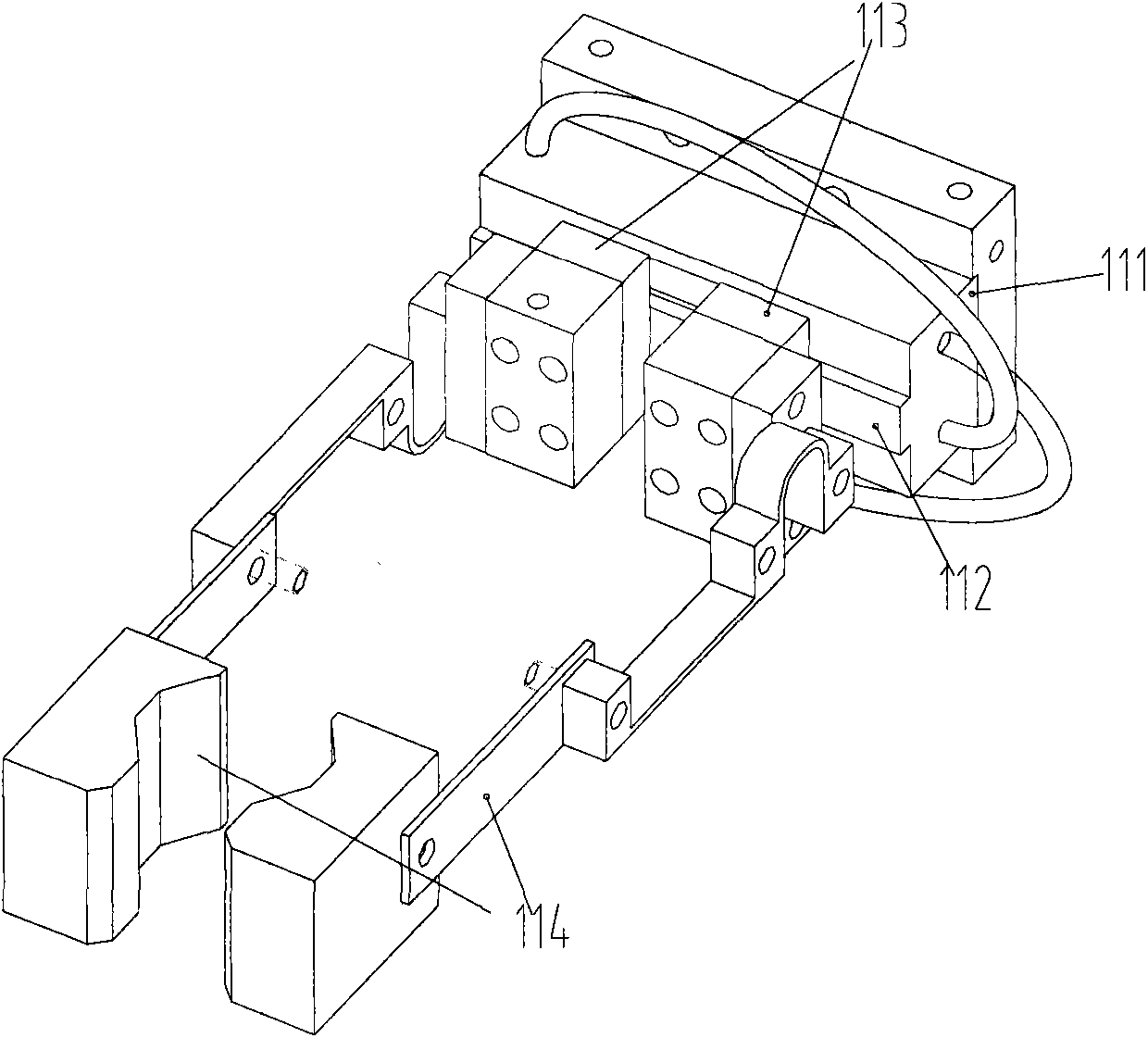

Bionic artificial insemination machine for livestock

InactiveCN107174372AEnhance sexual stimulationHigh degree of mechanizationAnimal reproductionLitterSexual stimuli

The invention discloses a bionic artificial insemination machine for livestock, which comprises a main beam, a leg structure, a back pressing structure, a semen injection structure, an electrical system and a bionic shell; the leg structure, the back pressing structure and the electrical system are respectively connected by bolts It is fixed on the main beam, the semen injection structure is hung on the main beam through hole matching, and the bionic shell and the main beam are fixed by matching clamps. The bionic artificial insemination machine for livestock of the present invention can simulate the physiological behavior of male animals, strengthen the sexual stimulation to female animals, induce more ovulation and actively accept semen in female animals, so as to achieve the purpose of increasing conception rate and litter size.

Owner:北京清博华创测控技术有限公司

Manipulator with three-dimensional elastic clamping paw

The invention relates to industrial automatic equipment, in particular to an automatic manipulator. The manipulator with a three-dimensional elastic clamping paw comprises a paw body and fingers; the paw body comprises a finger body, a guide rail, a piston, a plunger pin and sliding blocks; the fingers are fixedly connected to the sliding blocks; the fingers comprise finger heads and bridges; one ends of the bridges are fixedly connected to the sliding blocks and the other ends of the bridges are fixedly connected to the finger heads; the finger heads are provided with clamping surfaces. Practice proves that in the application fields such as free forging, the mechanical paw with three-dimensional elastic deformation capacity can completely prevent vibration generated when an air hammer strikes a workpiece from being transferred to a body of the manipulator.

Owner:东莞智得电子制品有限公司

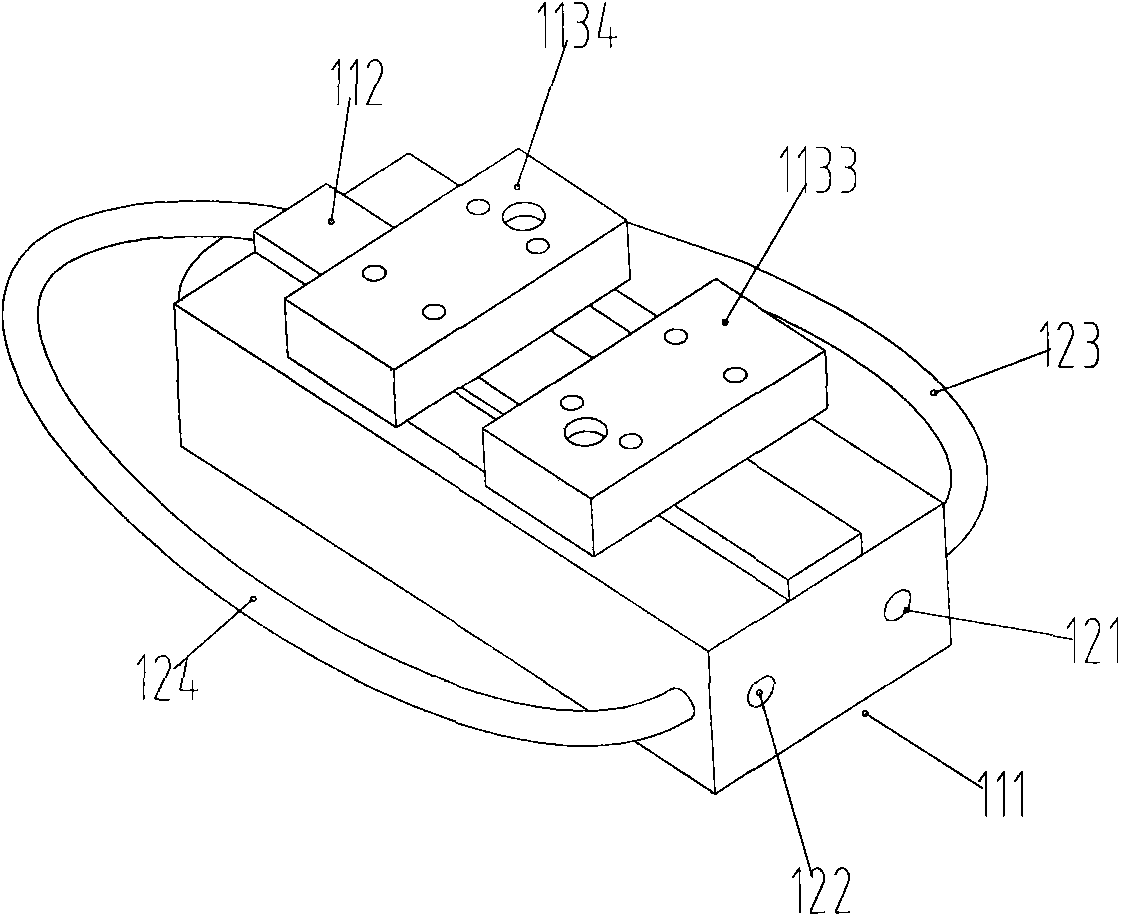

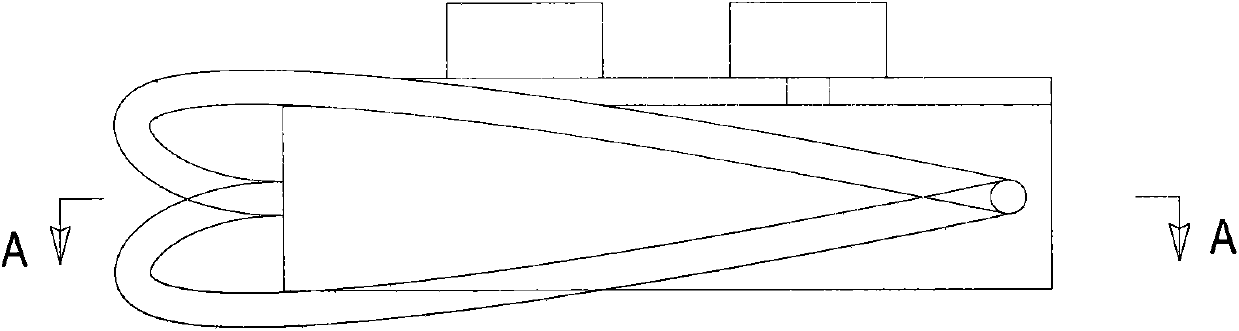

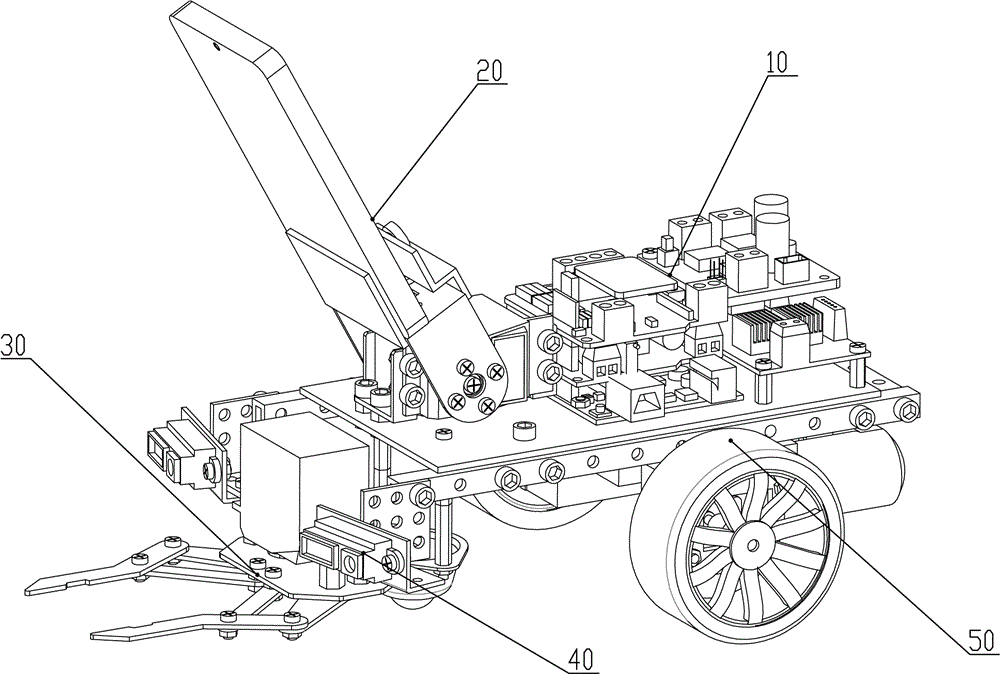

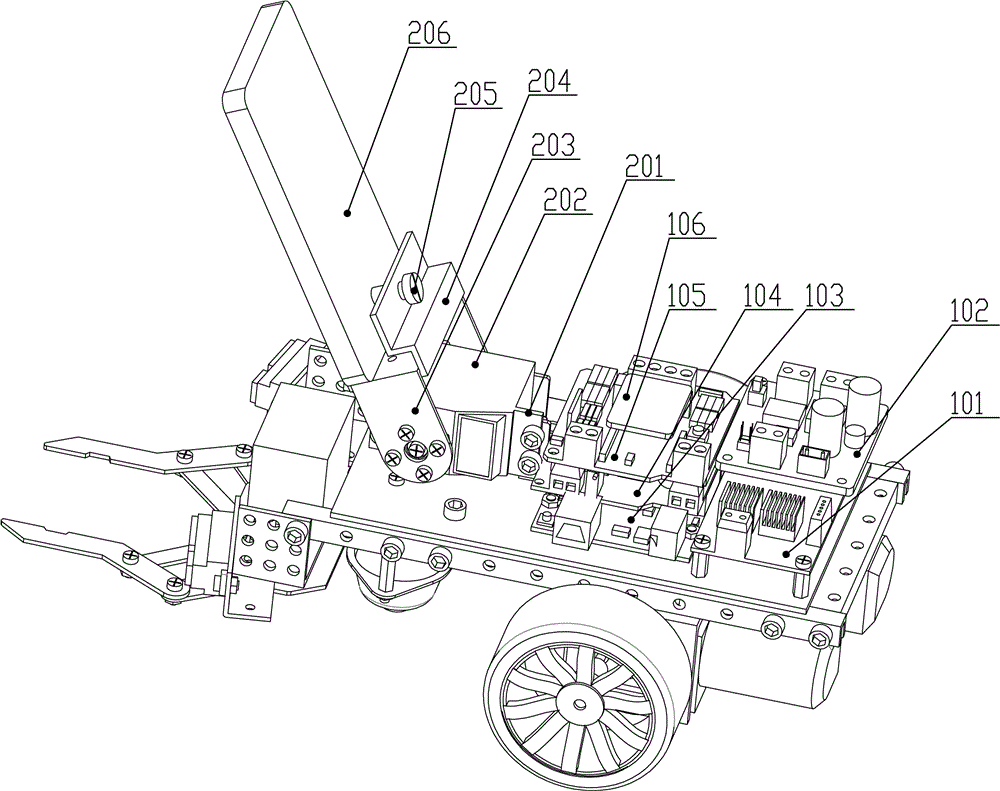

Smartphone-based wheeled soccer robot and its operating method

ActiveCN105108757BIntelligent entertainmentStrong sense of technologyManipulatorSoccer robotControl system

The invention relates to a wheeled soccer robot based on a smartphone, and an operation method thereof. The wheeled soccer robot comprises a robot chassis device. The head of the robot chassis device is provided with a ball holding mechanism. The ball holding mechanism is provided with an evadible system. A master control system is installed on the upper surface of the robot chassis device, close to the tail part. A camera following system is installed on the upper surface of the robot chassis device, close to the head part. The master control system can receive and process image signals transmitted by the camera following system, and position signals detected by the evadible system, so as to control action of the robot chassis device and the ball holding mechanism. The wheeled soccer robot combines with a smartphone, and brings brand new and intelligentized entertainment experience for people.

Owner:MENGYIN JINHUA MACHINERY CO LTD

Coiler jaw

The invention discloses a coiler jaw. The coiler jaw comprises sector blocks, a four-edge mandril, a jaw sector block, a movable jaw and a fixed jaw, wherein the jaw sector block and the sector blocks are pieced together to form a cylinder; the four-edge mandril is arranged in the center of the cylinder; the movable jaw and the fixed jaw are arranged in the jaw sector block; the four-edge mandrilis driven by a driving mechanism to axially move along the center of the cylinder; and a wedge mechanism which converts axial movement of the four-edge mandril to radial movement of the movable jaw is arranged between the four-edge mandril and the movable jaw. The coiler jaw has the following beneficial effects: as the jaw horizontal movement wedge which can drive the jaw to horizontally move is adopted and is connected with the four-edge mandril as a whole, the pyramid coiler realizes expansion and shrinkage of the coiling block and clamping and loosening of the jaw by only using an expanding and shrinking cylinder used for pushing the four-edge mandril, thus greatly reducing the complexity of the coiling block and ensuring the coiling block to act sensitively and accurately.

Owner:ZHEJIANG CHANGXING COPPER

Milling fixture for automobile torsion bar moment arm thread end surface

PendingCN111318906ASolve the problem of placement at different anglesRealize the clamping actionPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention discloses a milling fixture for an automobile torsion bar moment arm thread end surface. The milling fixture comprises an upper bottom plate, a lower bottom plate and a supporting plate,the upper bottom plate is fixedly connected with the lower bottom plate, the lower bottom plate and the upper bottom plate are fixed to a working table, the supporting plate is fixedly connected withthe upper bottom plate, a pre-tightening core shaft and a positioning core shaft are arranged on the lower bottom plate, an eccentric wheel is arranged on the pre-tightening core shaft, a handle shank is arranged on the eccentric wheel, the eccentric wheel is in adjustable connection with the pre-tightening core shaft, and a positioning column is arranged on the upper bottom plate. Through the cooperation of the pre-tightening core shaft and the positioning core shaft, the problem of the placement of different angles of a torsion bar moment arm is solved, the clamping action of the torsion bar moment arm with different bending radians is realized through the rotation adjustment of the eccentric wheel, and the stability and precision of the integral machining operation are improved.

Owner:SUQIAN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com