Machine tool for sliding shoe closing

A sliding shoe and machine tool technology, which is applied in the field of plunger assembly assembly, can solve the problems of poor screwing accuracy and stability of the sliding shoe closure, low yield rate, etc., and achieve the effect of smooth movement, good stability, and good spinning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

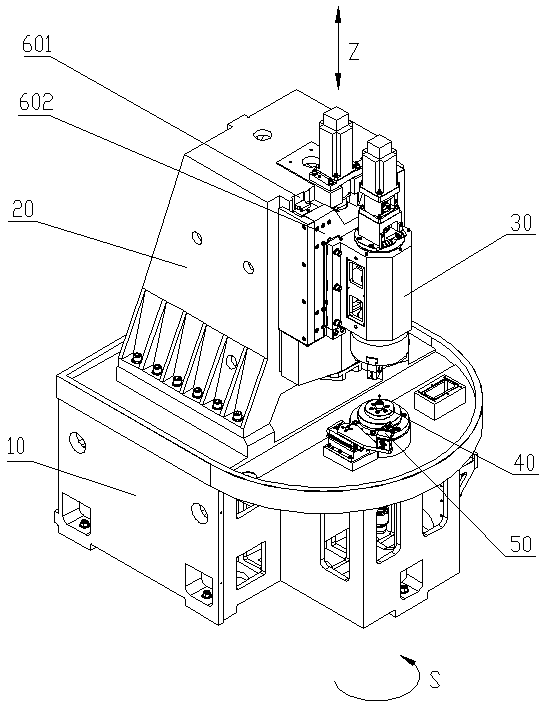

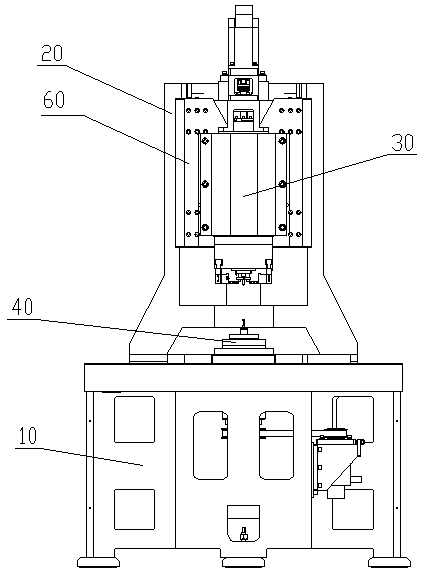

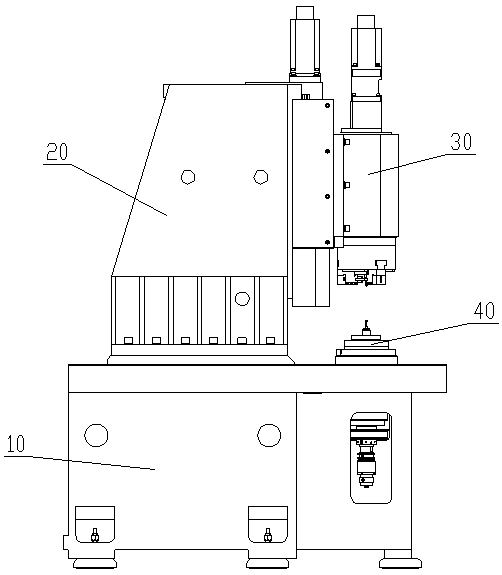

[0036] see figure 1 , figure 2 and Figure 4 , a machine tool for sliding shoe closing, including a bed 10, a column 20 and a workpiece spindle 40 for clamping the shoe are fixedly connected to the bed 10, and a sliding mechanism is fixedly connected to the column 20 60, the sliding mechanism 60 is connected with a spinning mechanism 30 for spinning shoes, the spinning mechanism 30 is located directly above the workpiece spindle 40, and the spinning mechanism 30 includes a chuck 305, a roller assembly 307 and a The top assembly 306 that tightens the plunger ball head, the roller assembly 307 is installed on the base jaw of the chuck 305, the top assembly 306 is installed at the center of the chuck 305, and the bed 10 is equipped with a manipulator 50 , the manipulator 50 is located on one side of the workpiece spindle 40 , and the rotation axis of the spinning mechanism 30 is coaxial with the rotation axis of the workpiece spindle 40 .

[0037] This embodiment is the most ...

Embodiment 2

[0039] see figure 1 , figure 2 , Figure 4 and Figure 5 , a machine tool for sliding shoe closing, including a bed 10, a column 20 and a workpiece spindle 40 for clamping the shoe are fixedly connected to the bed 10, and a sliding mechanism is fixedly connected to the column 20 60, the sliding mechanism 60 is connected with a spinning mechanism 30 for spinning shoes, the spinning mechanism 30 is located directly above the workpiece spindle 40, and the spinning mechanism 30 includes a chuck 305, a roller assembly 307 and a The top assembly 306 that tightens the plunger ball head, the roller assembly 307 is installed on the base jaw of the chuck 305, the top assembly 306 is installed at the center of the chuck 305, and the bed 10 is equipped with a manipulator 50 , the manipulator 50 is located on one side of the workpiece spindle 40 , and the rotation axis of the spinning mechanism 30 is coaxial with the rotation axis of the workpiece spindle 40 .

[0040] The workpiece s...

Embodiment 3

[0043] see figure 1 , figure 2 , Figure 4 and Figure 5 , a machine tool for sliding shoe closing, including a bed 10, a column 20 and a workpiece spindle 40 for clamping the shoe are fixedly connected to the bed 10, and a sliding mechanism is fixedly connected to the column 20 60, the sliding mechanism 60 is connected with a spinning mechanism 30 for spinning shoes, the spinning mechanism 30 is located directly above the workpiece spindle 40, and the spinning mechanism 30 includes a chuck 305, a roller assembly 307 and a The top assembly 306 that tightens the plunger ball head, the roller assembly 307 is installed on the base jaw of the chuck 305, the top assembly 306 is installed at the center of the chuck 305, and the bed 10 is equipped with a manipulator 50 , the manipulator 50 is located on one side of the workpiece spindle 40 , and the rotation axis of the spinning mechanism 30 is coaxial with the rotation axis of the workpiece spindle 40 .

[0044] The workpiece s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com