Coiler jaw

A technology of jaws and pliers, which is applied in the field of quadrangular pyramid coiling machines, can solve problems such as complex oil circuit, heavy maintenance workload, and oil leakage of the jaw clamping cylinder, and achieve simple complexity, sensitive and accurate movements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

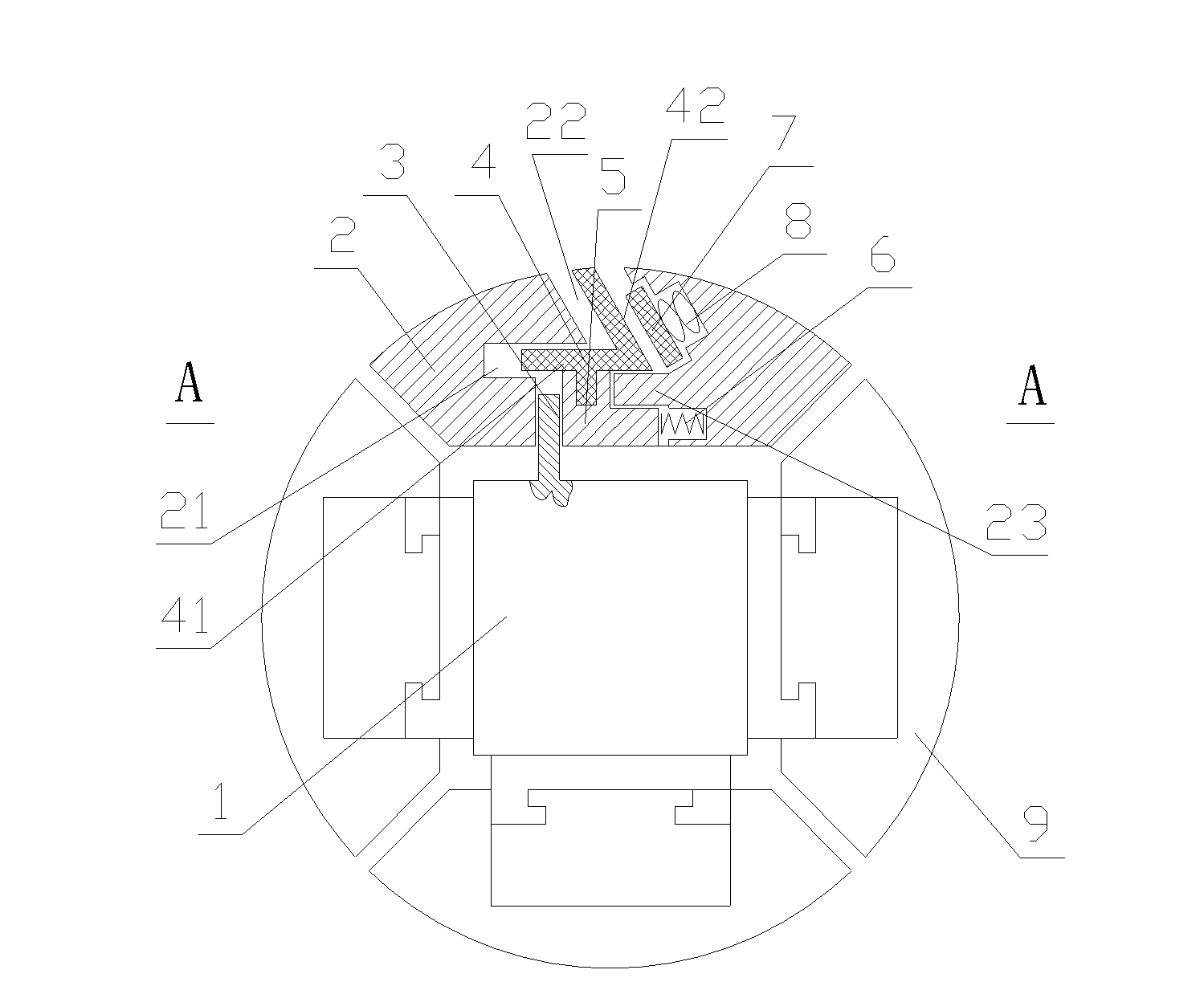

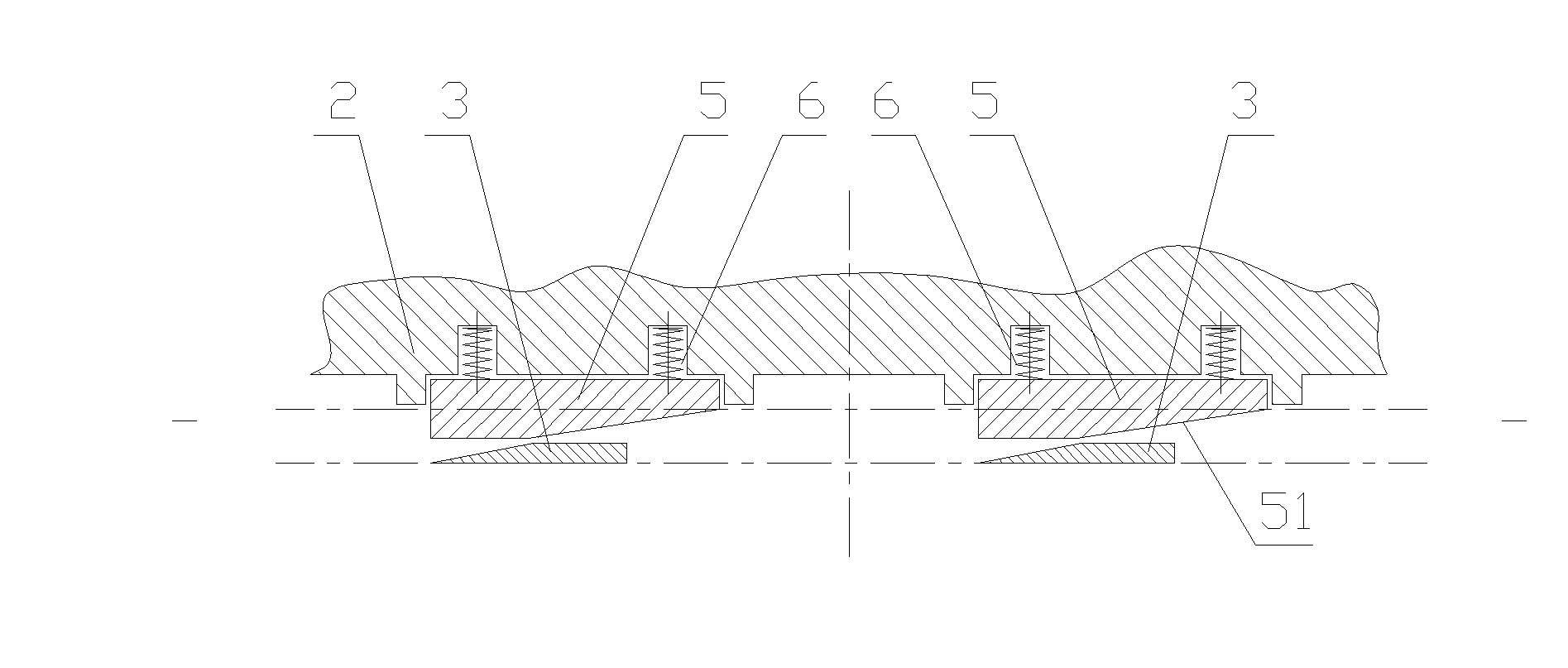

[0014] Such as figure 1 and figure 2 As shown, it is an embodiment of the jaws of the coiler of the present invention, including a sector block 9, a quadrangular mandrel 1, a jaw sector block 2, a moving jaw 4 and a fixed jaw 7, wherein the jaw sector block and the sector block Assembled into a cylinder, the four-sided mandrel is set in the center of the cylinder, the movable jaw and the fixed jaw are set in the jaw sector, and the four-sided mandrel is driven by the driving mechanism along the center of the cylinder. Axial movement, a wedge mechanism for converting the axial movement of the quadrangular mandrel into the radial movement of the movable jaw is provided between the quadrangular mandrel and the movable jaw. The wedge mechanism includes at least one wedge 3 axially arranged along the four-edge mandrel and jaw connecting bodies 5 corresponding to the number of the wedges, the jaw connecting bodies are fixed with the moving jaws, and the jaw connecting bodies are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com