Patents

Literature

77results about How to "Sensitive and accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

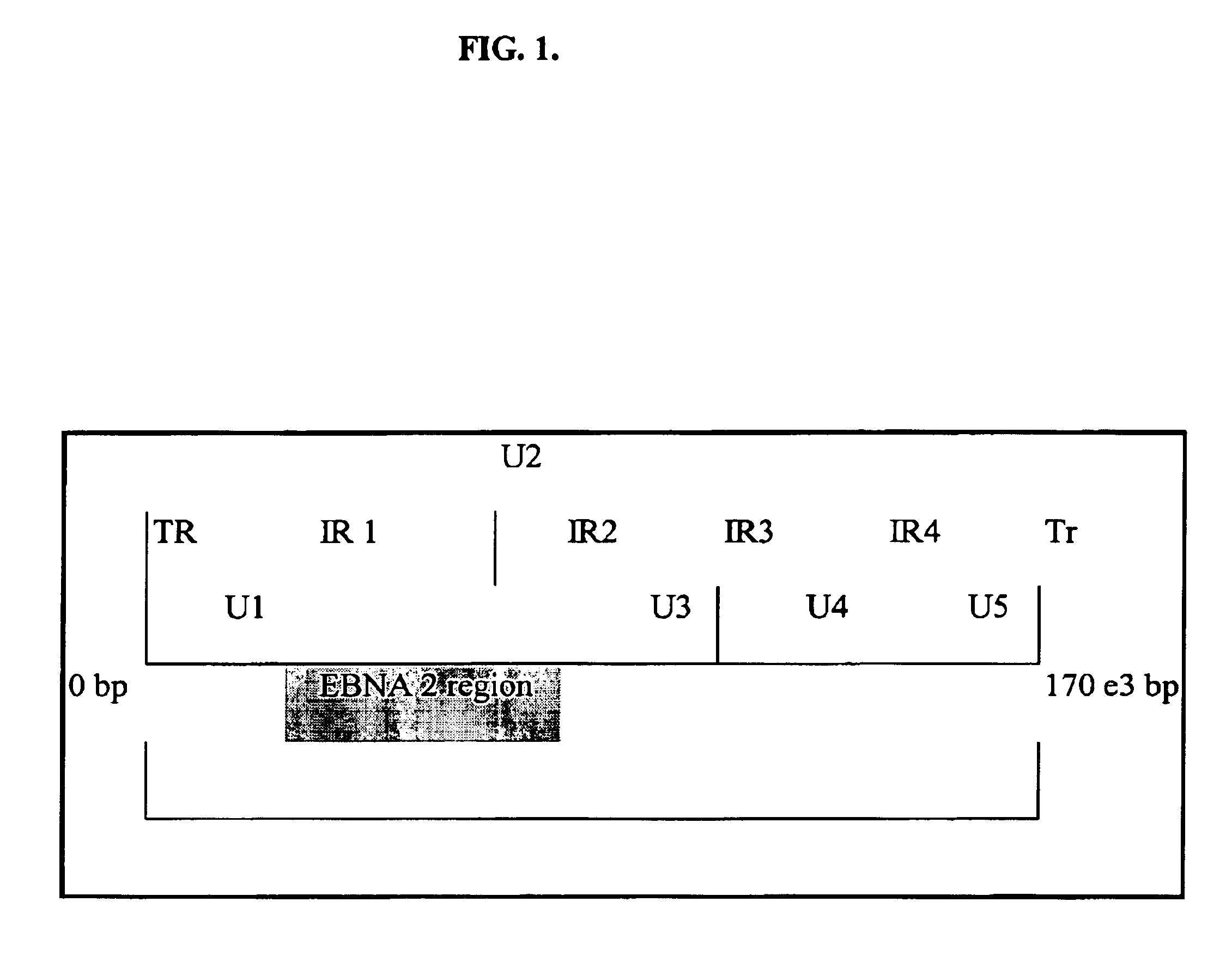

Quantitative epstein barr virus PCR rapid assay

InactiveUS6790952B2Sensitive and accurateSugar derivativesMicrobiological testing/measurementEpstein bar virusNucleotide

The present invention provides novel compositions comprising Epstein-Barr virus-specific oligonucleotides that are useful as primers to amplify particular regions of the genome during enzymatic nucleic acid amplification. The invention also provides a rapid, sensitive and specific method for the detection and quantitation of the virus which may be present in a clinical specimen, using the virus-specific primers and enzymatic nucleic acid amplification; hybridization of amplified target sequences, if present, with one or more Epstein-Barr virus-specific oligonucleotide probes which are labeled with a detectable moiety; and detection of the detectable moiety of labeled oligonucleotide probe hybridized to amplified target sequences of Epstein-Barr virus DNA.

Owner:CHILDRENS HOSPITAL RES FOUND

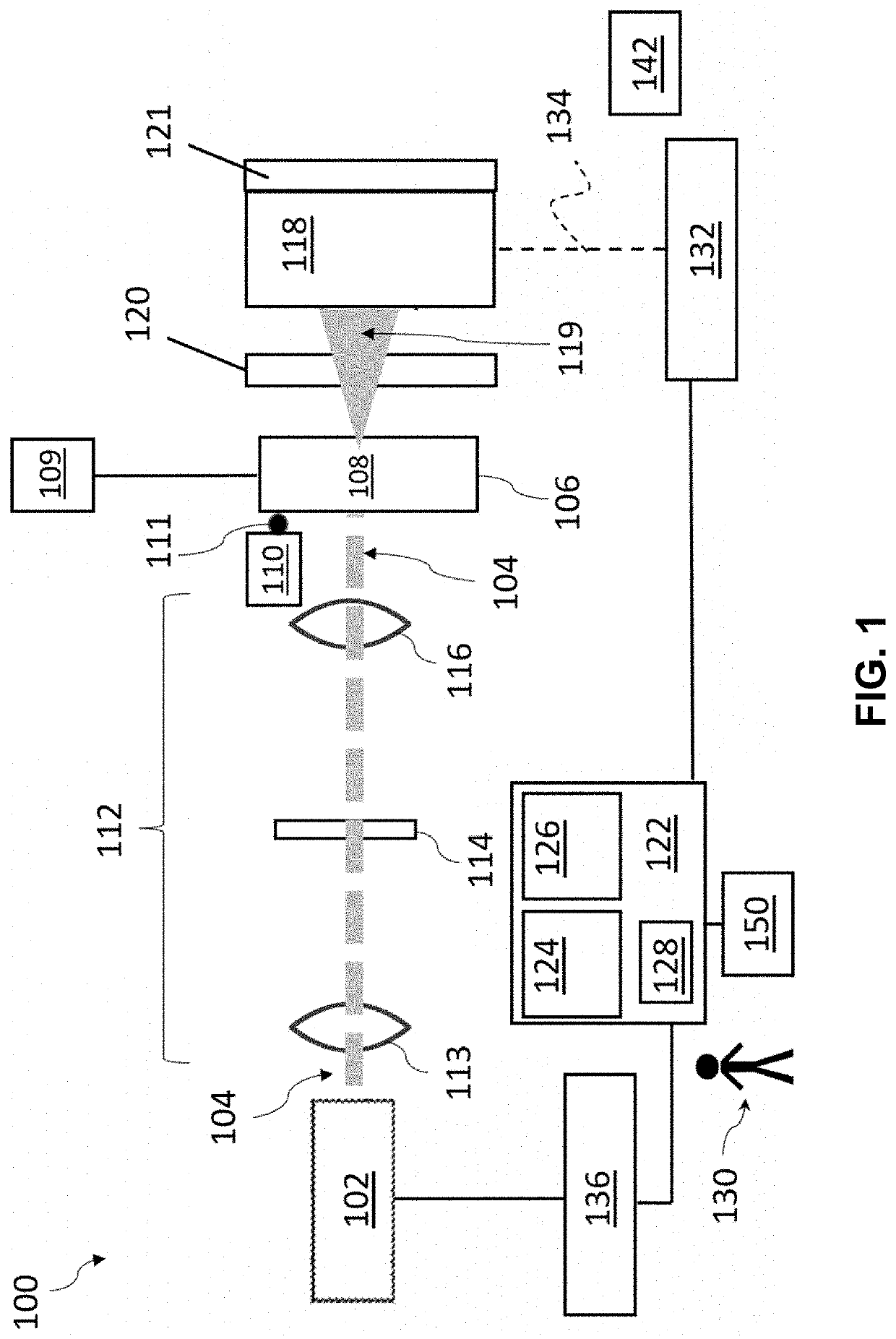

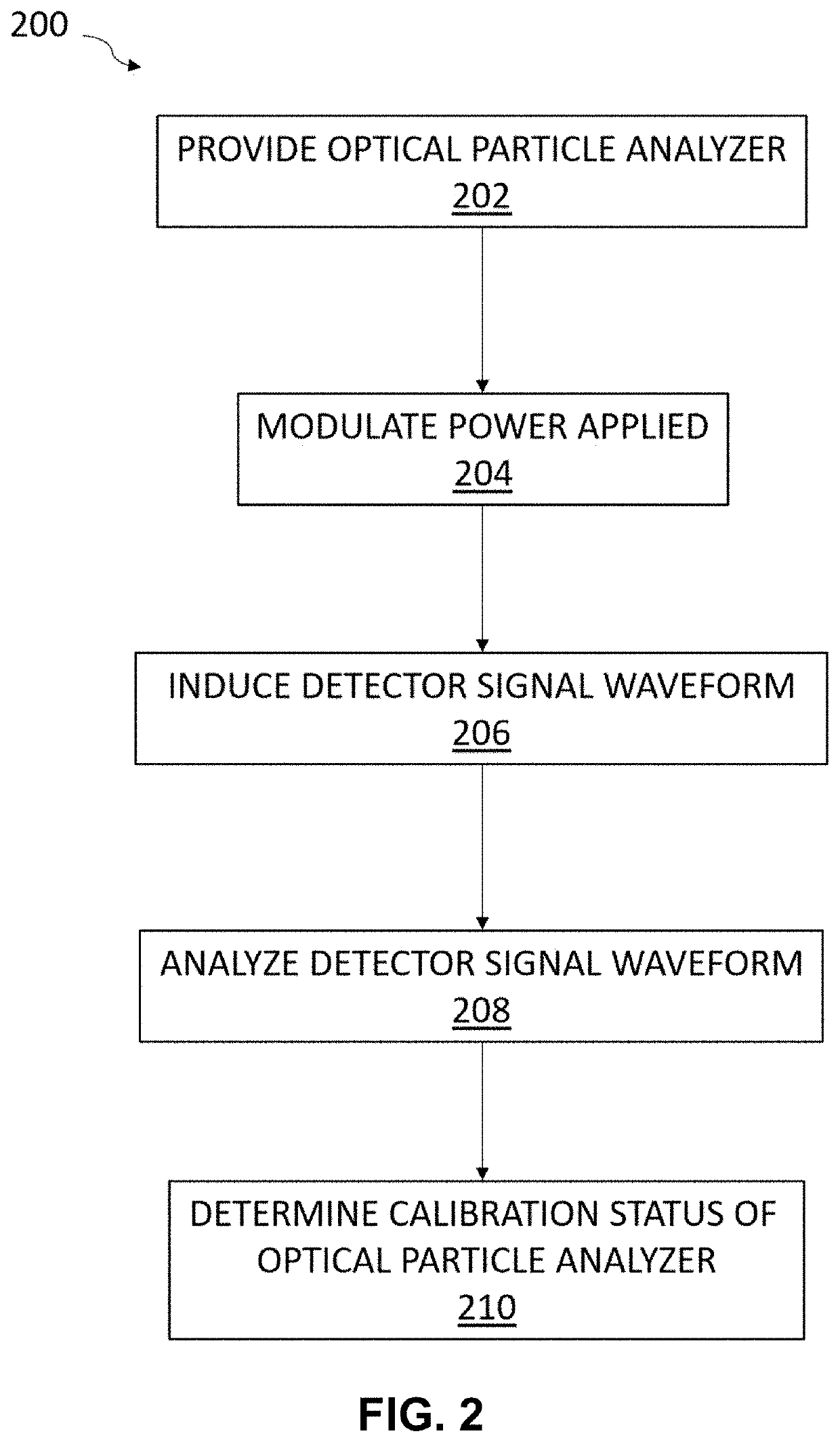

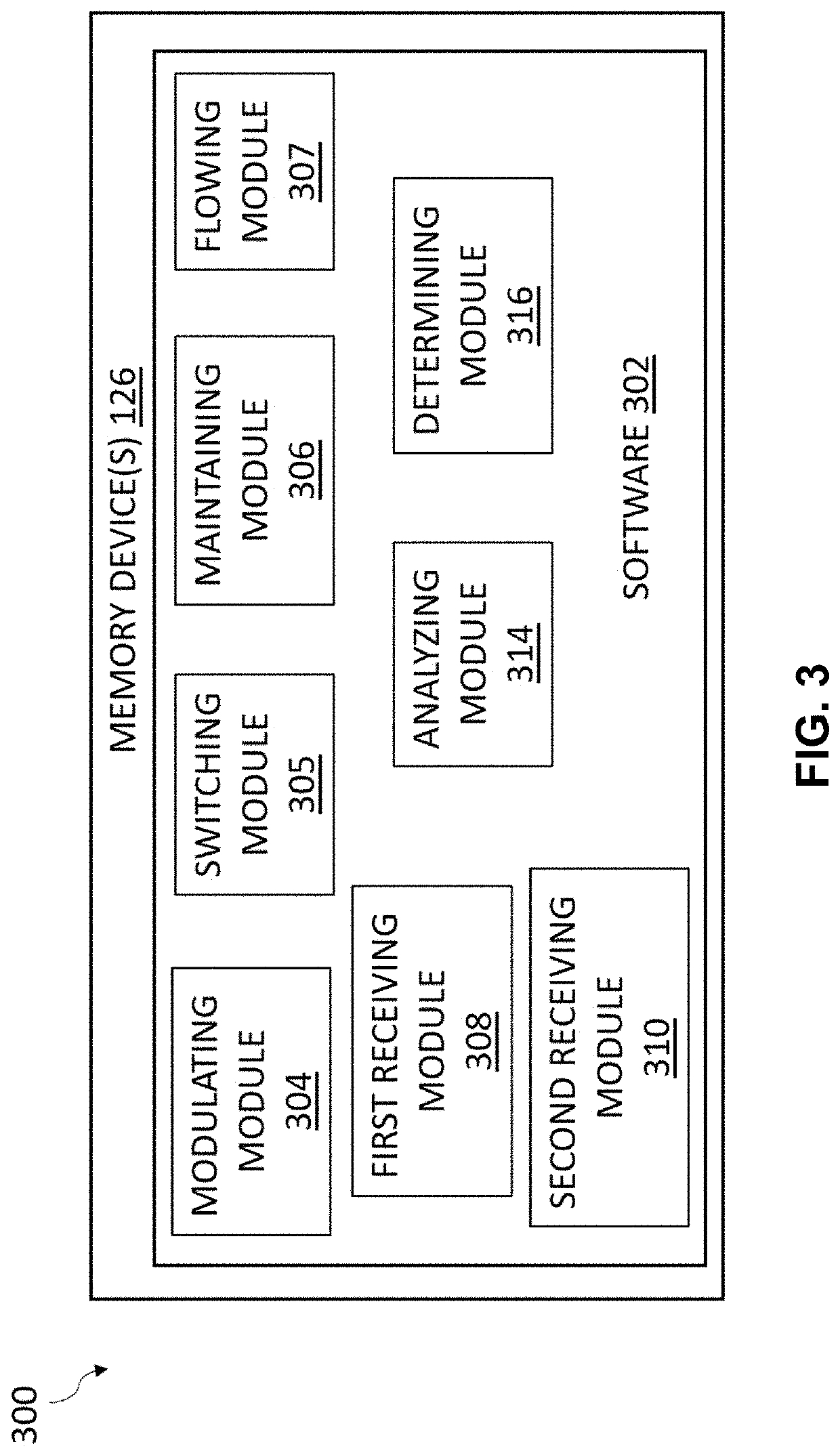

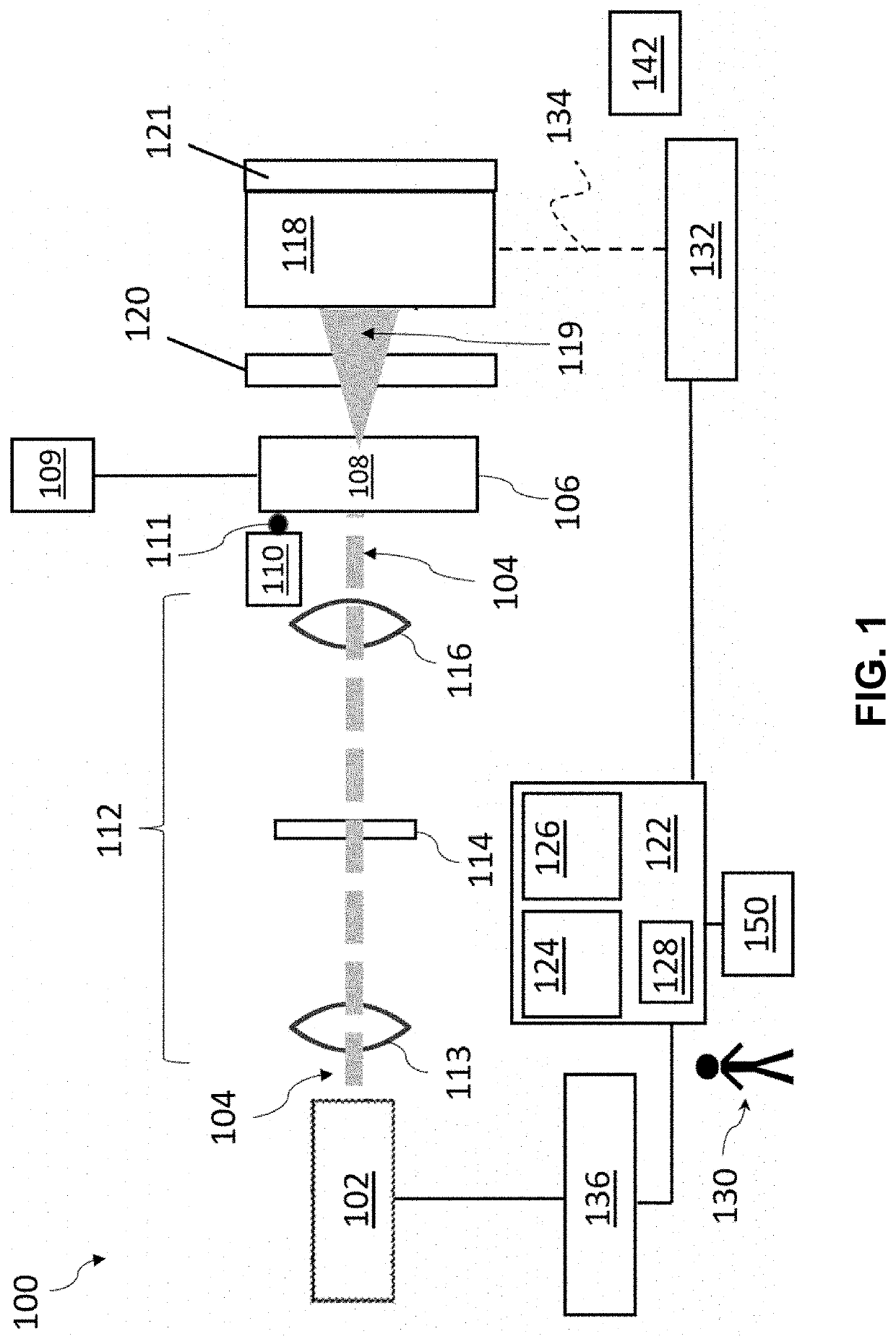

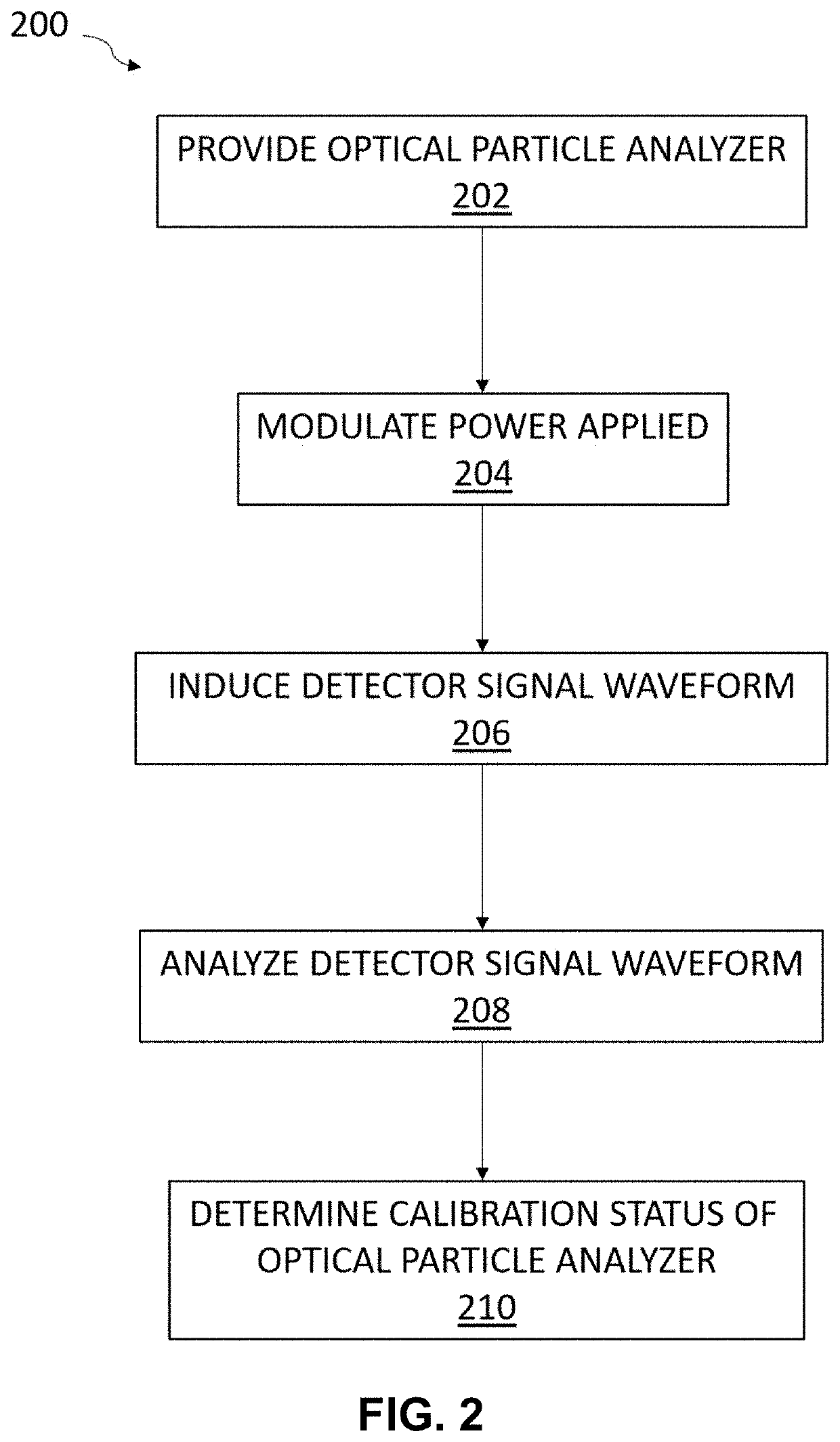

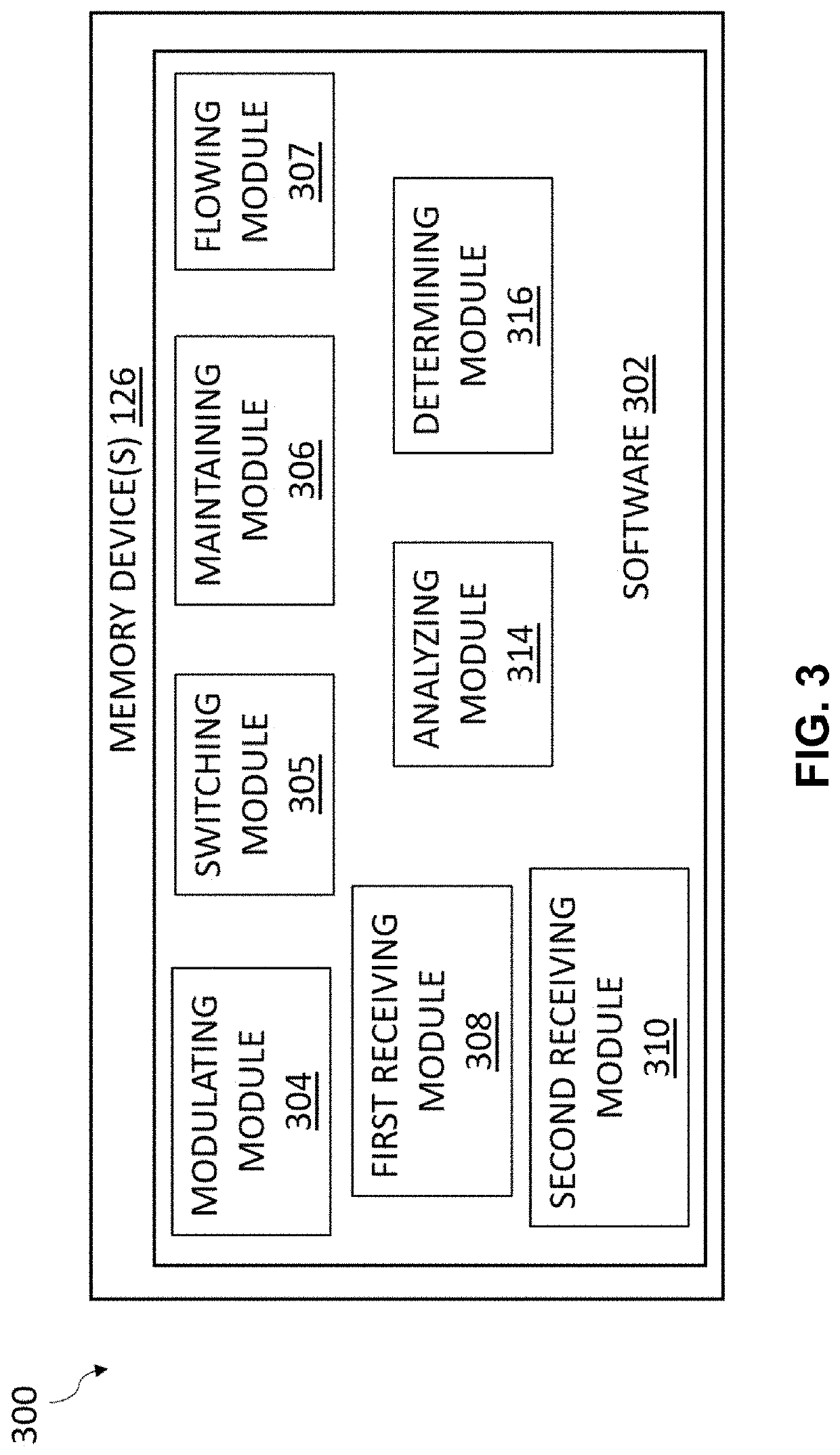

Calibration verification for optical particle analyzers

ActiveUS20200150017A1Increase probabilitySensitive and accurateLaser detailsParticle size analysisSignal waveCollection system

Provided are particle analyzers and related methods for verifying calibration status of the particle analyzer. The method includes the steps of providing an optical particle analyzer and modulating a power applied to a source of EMR. The method includes the steps of, in response to the modulating step, inducing a detector signal waveform and analyzing the detector signal waveform to determine a value of at least one diagnostic parameter associated with one or more of the source of EMR, an optical assembly, a chamber, a detector, and an optical collection system of the optical particle analyzer. The method includes the step of determining a calibration status of the optical particle analyzer based on the one or more determined values of the at least one diagnostic parameter.

Owner:PARTICLE MEASURING SYST

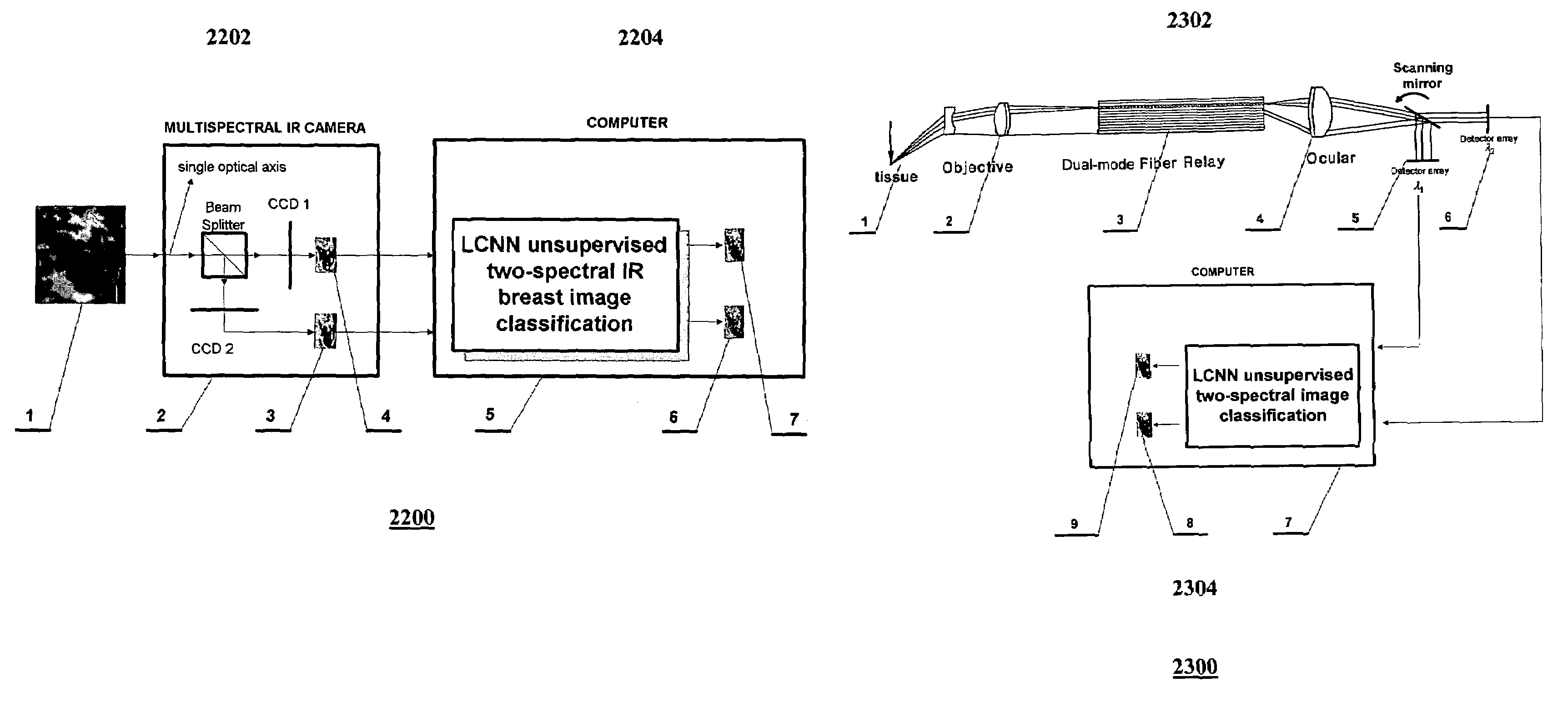

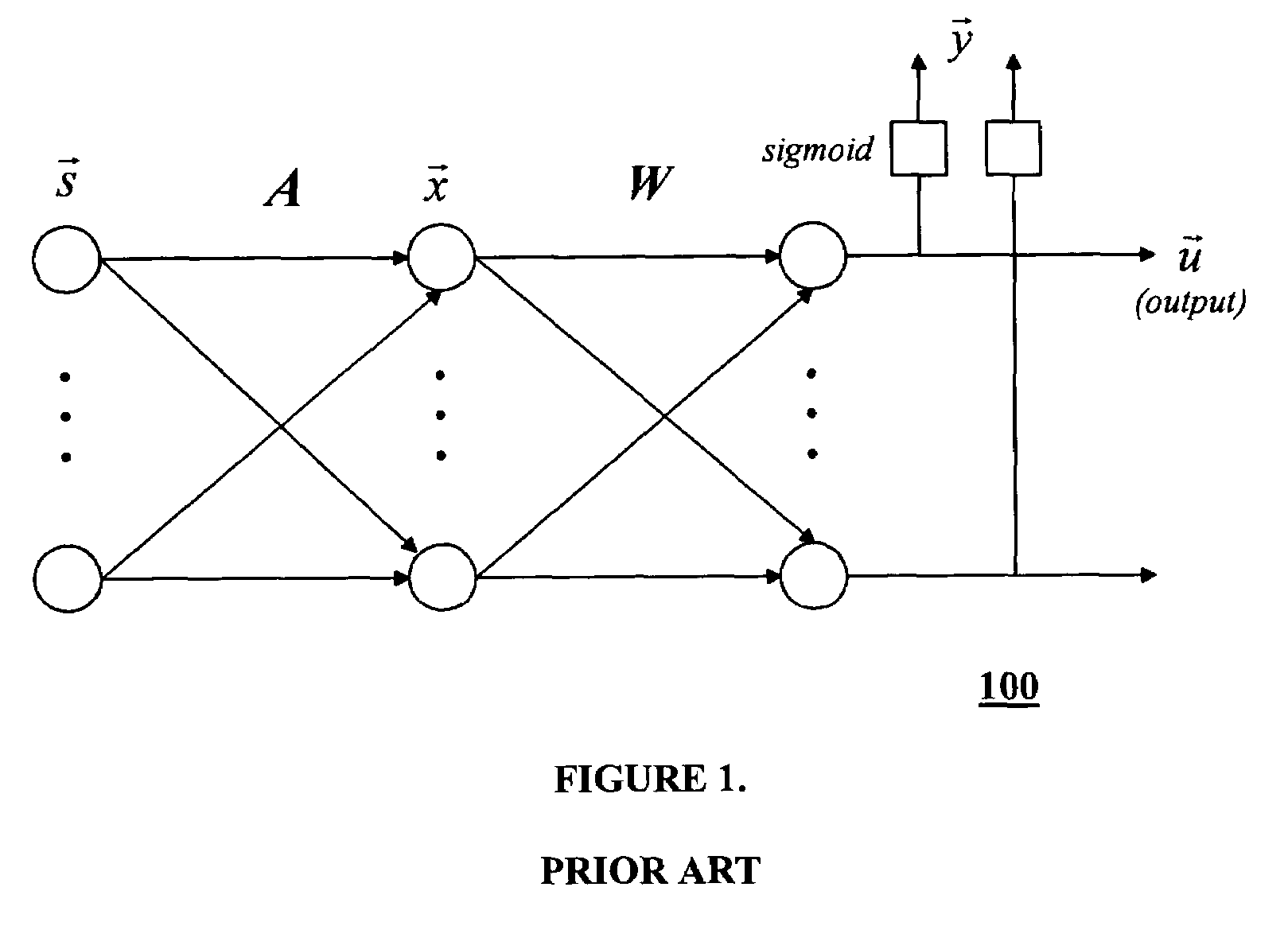

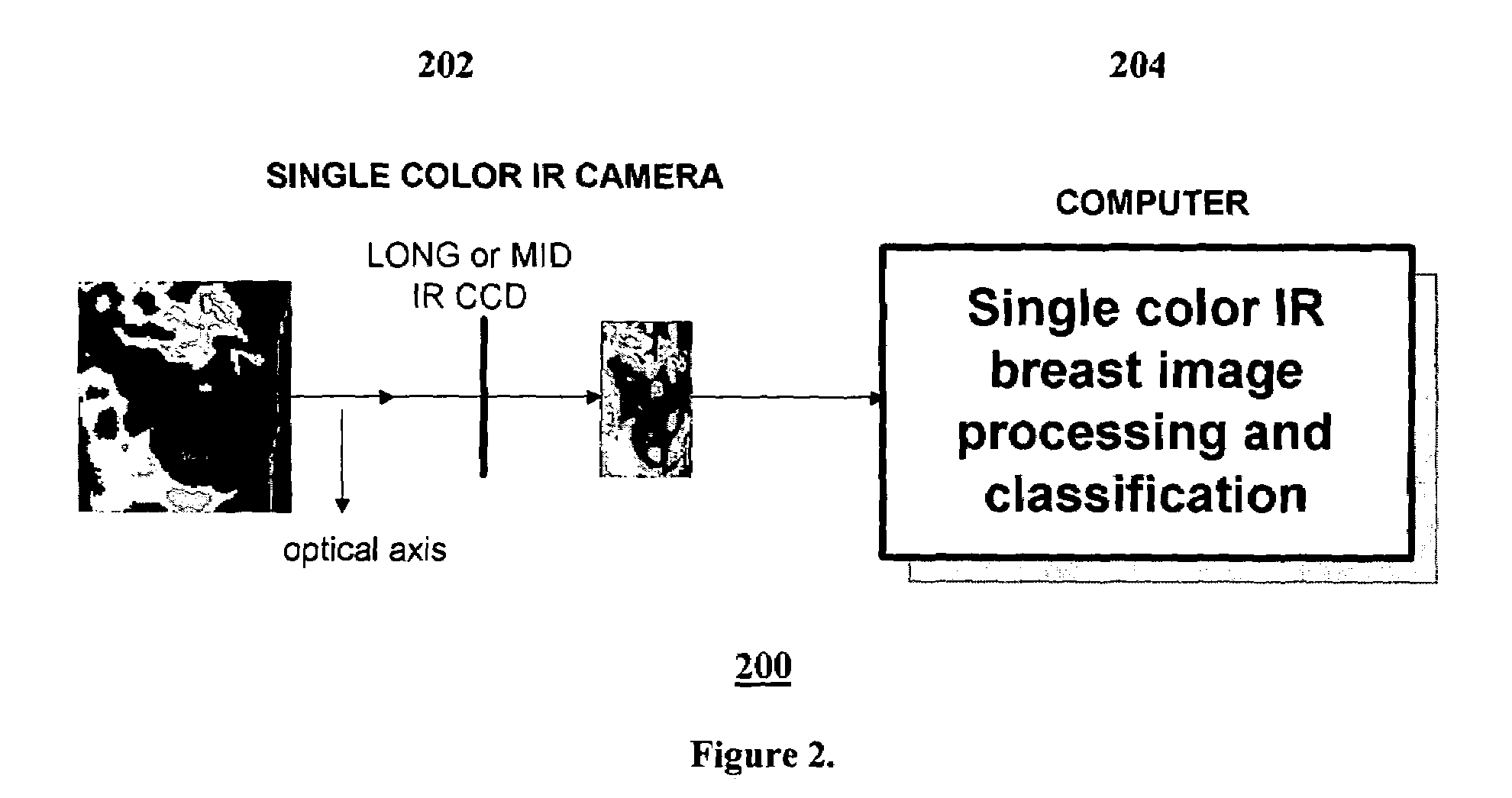

Nonlinear blind demixing of single pixel underlying radiation sources and digital spectrum local thermometer

InactiveUS7366564B2Sensitive and accurateIncrease variabilityMedical data miningImage analysisFrequency spectrumSignal classification

Changes, increase or decrease, in the body fluid flow are passively detected by using a single pixel, non-linear blind de-mixing procedure, which can be extended to general biomedical measurement and diagnoses instruments. More specifically the single pixel, non-linear blind de-mixing procedure is applied on the hot spots of rheumatic arthritis or breast cancer detection problem using passive two-color infrared imaging as well as to passively detect blockages in the body fluid circulatory system that might be of importance for coronary artery bypass surgery, diabetes and deep vein thrombosis. Other applications of the mentioned algorithm include a pair of cameras for video, a pair of antennas for cell phones, and in situ data gathering or imaging using multiple mode fiberoptical sensing as well as selective amplification hearing aids through two-ear binaural processing for de-noise echo cancellation and signal classification.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

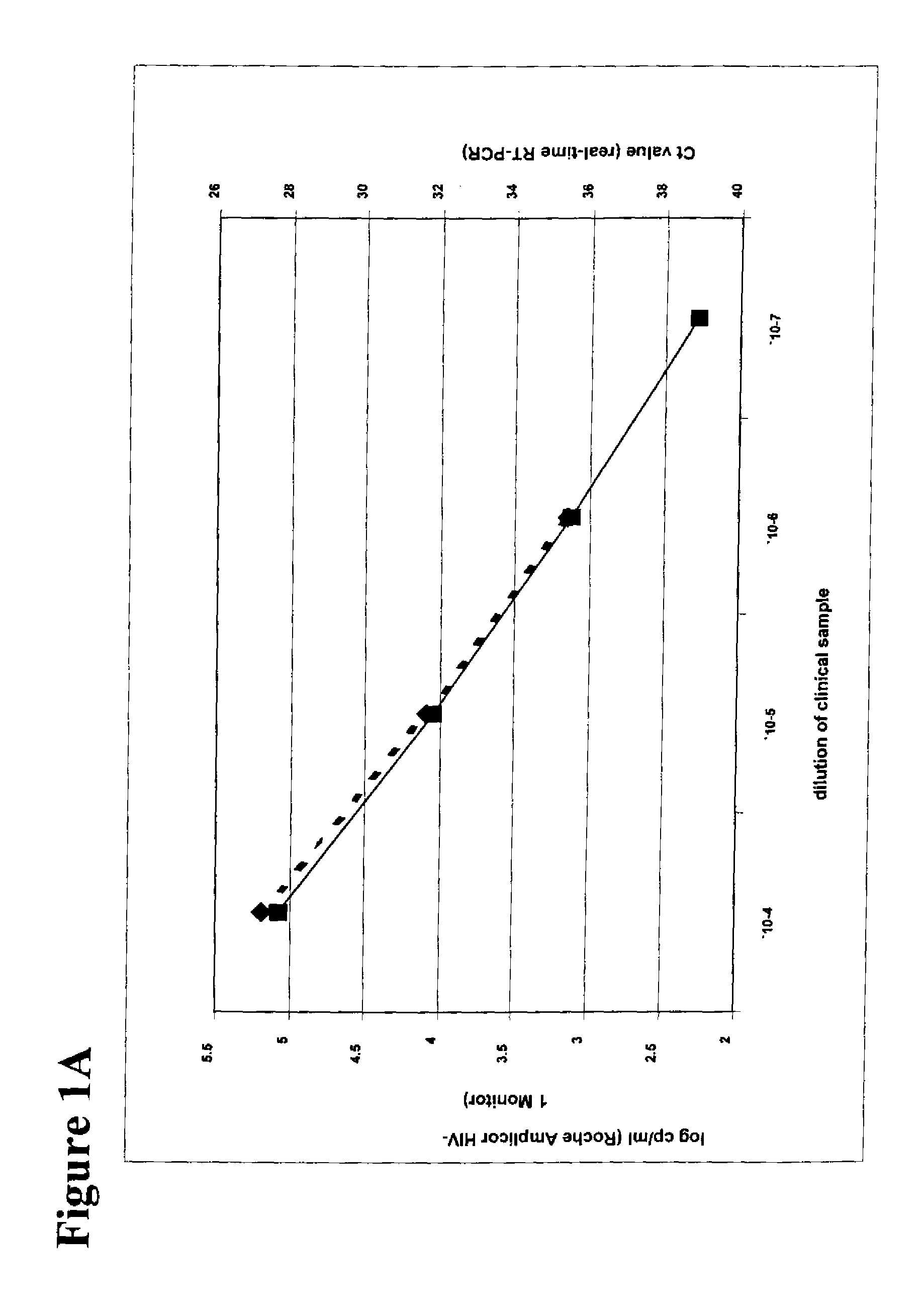

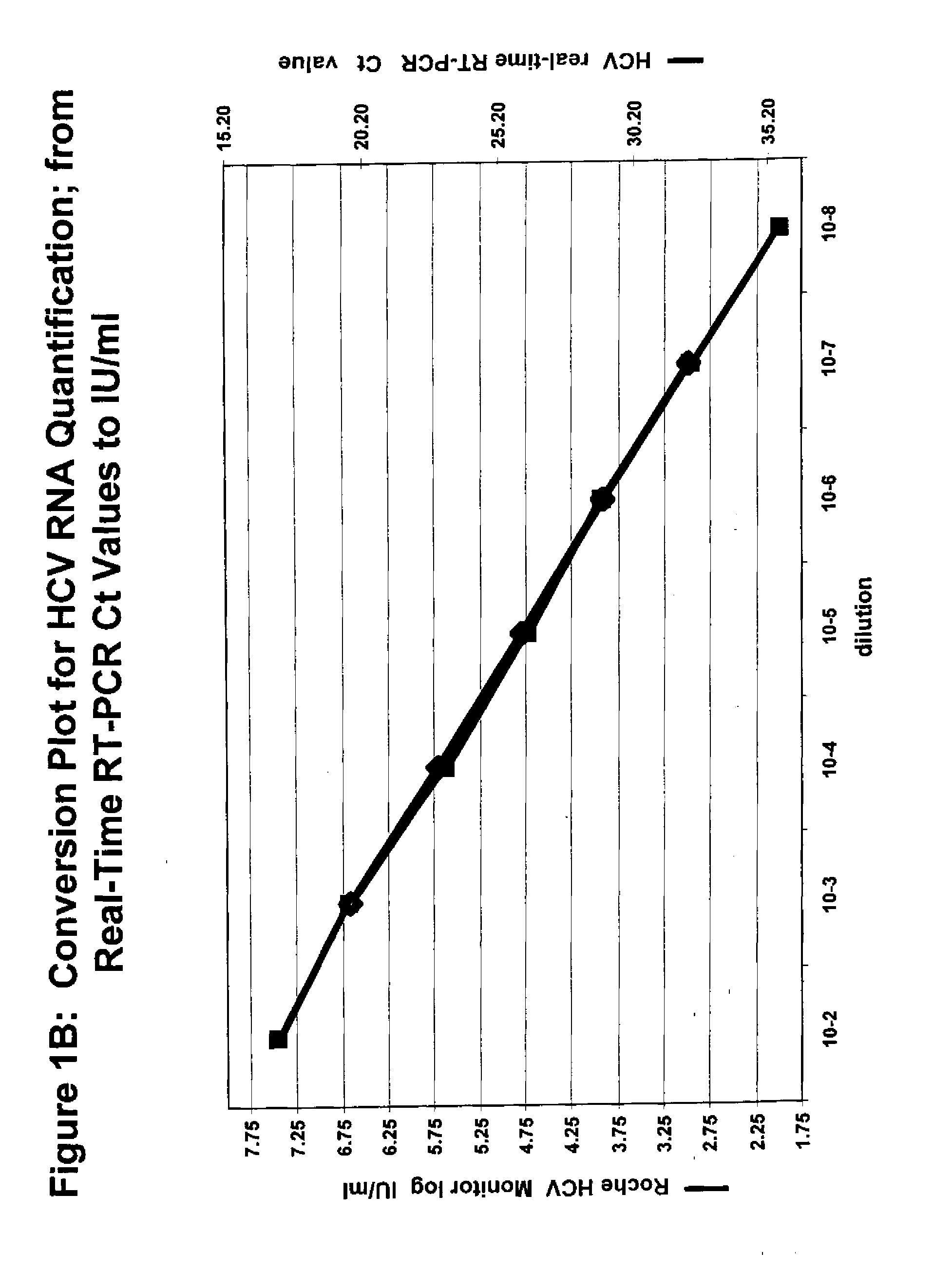

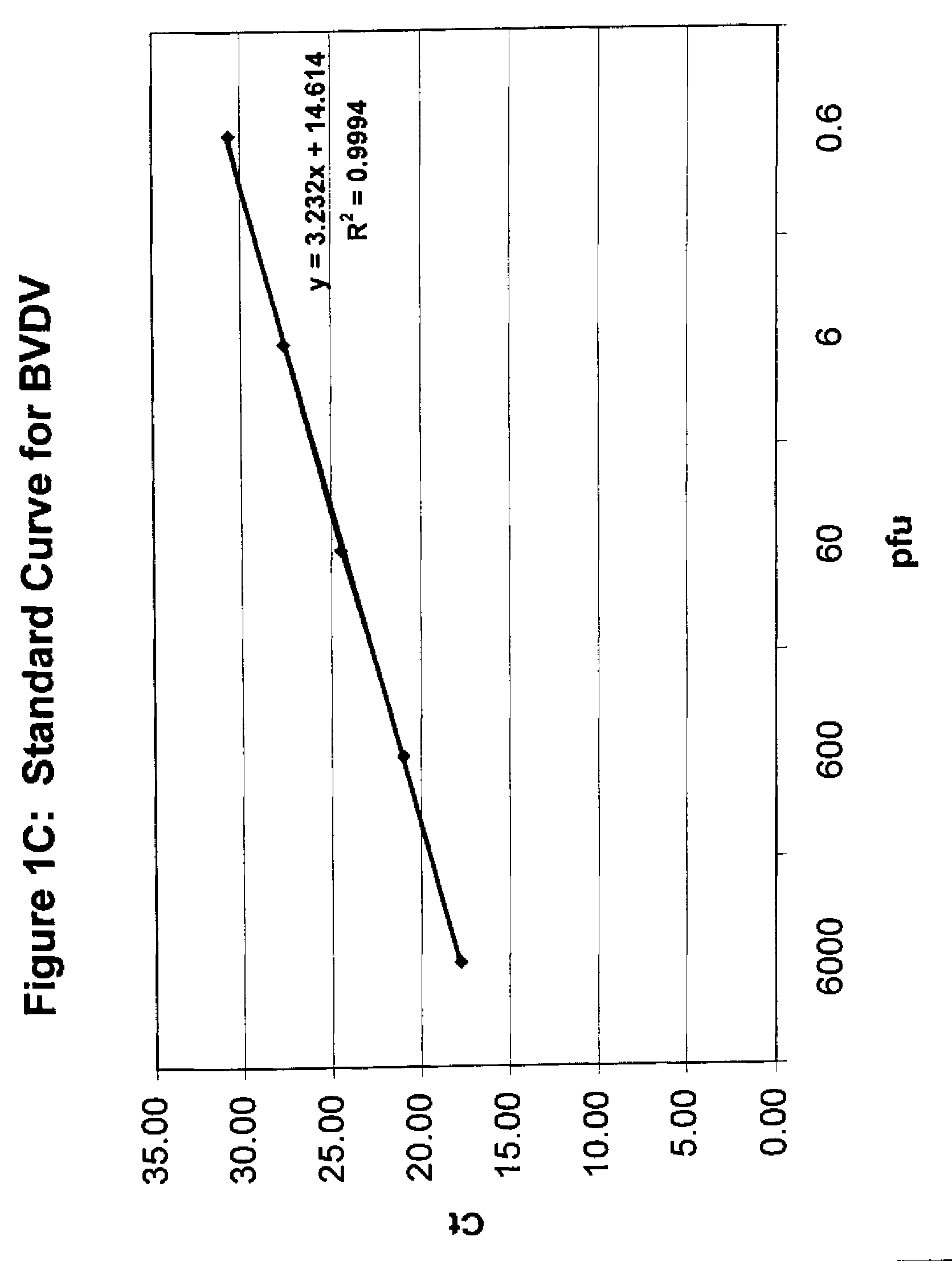

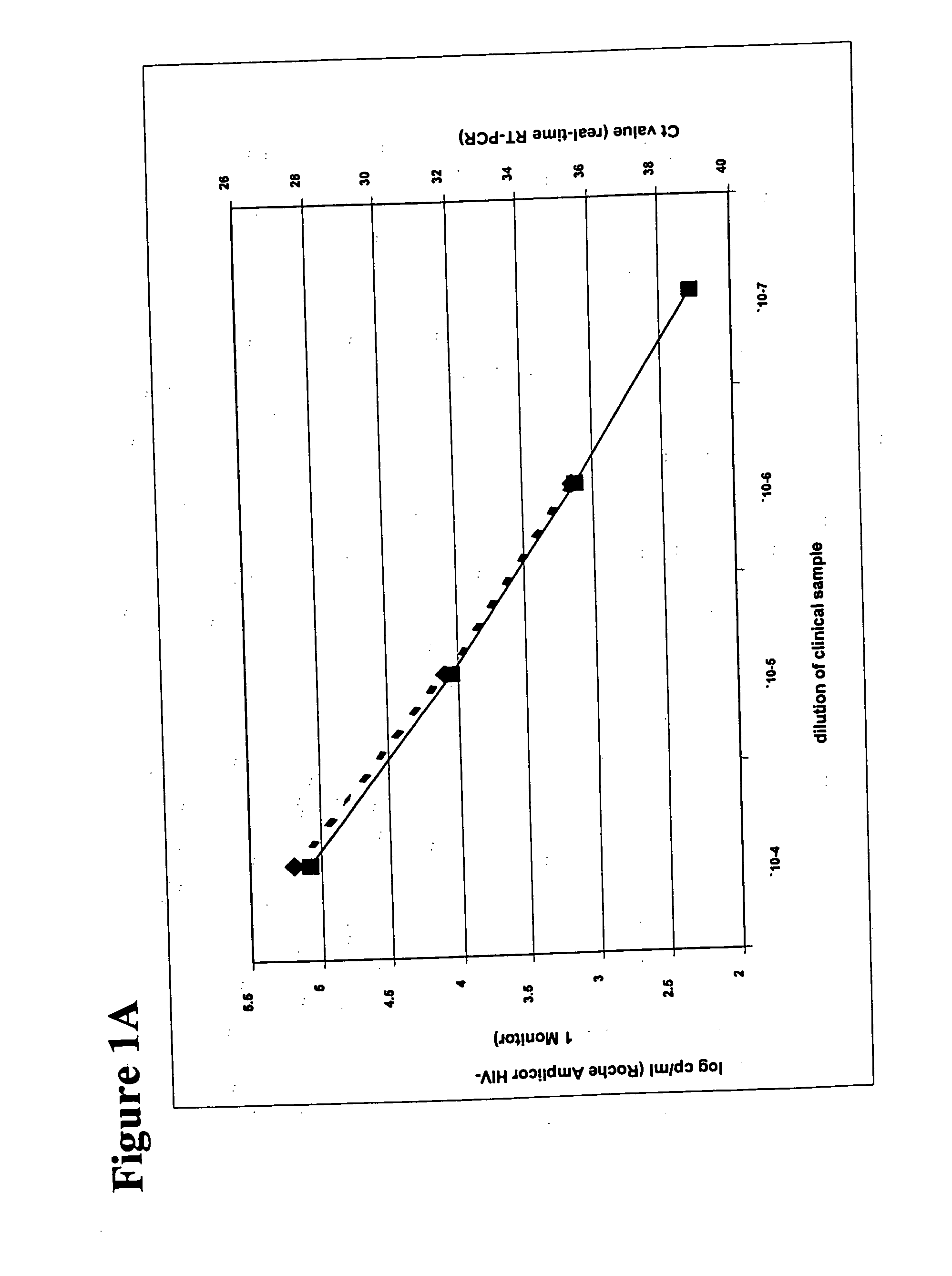

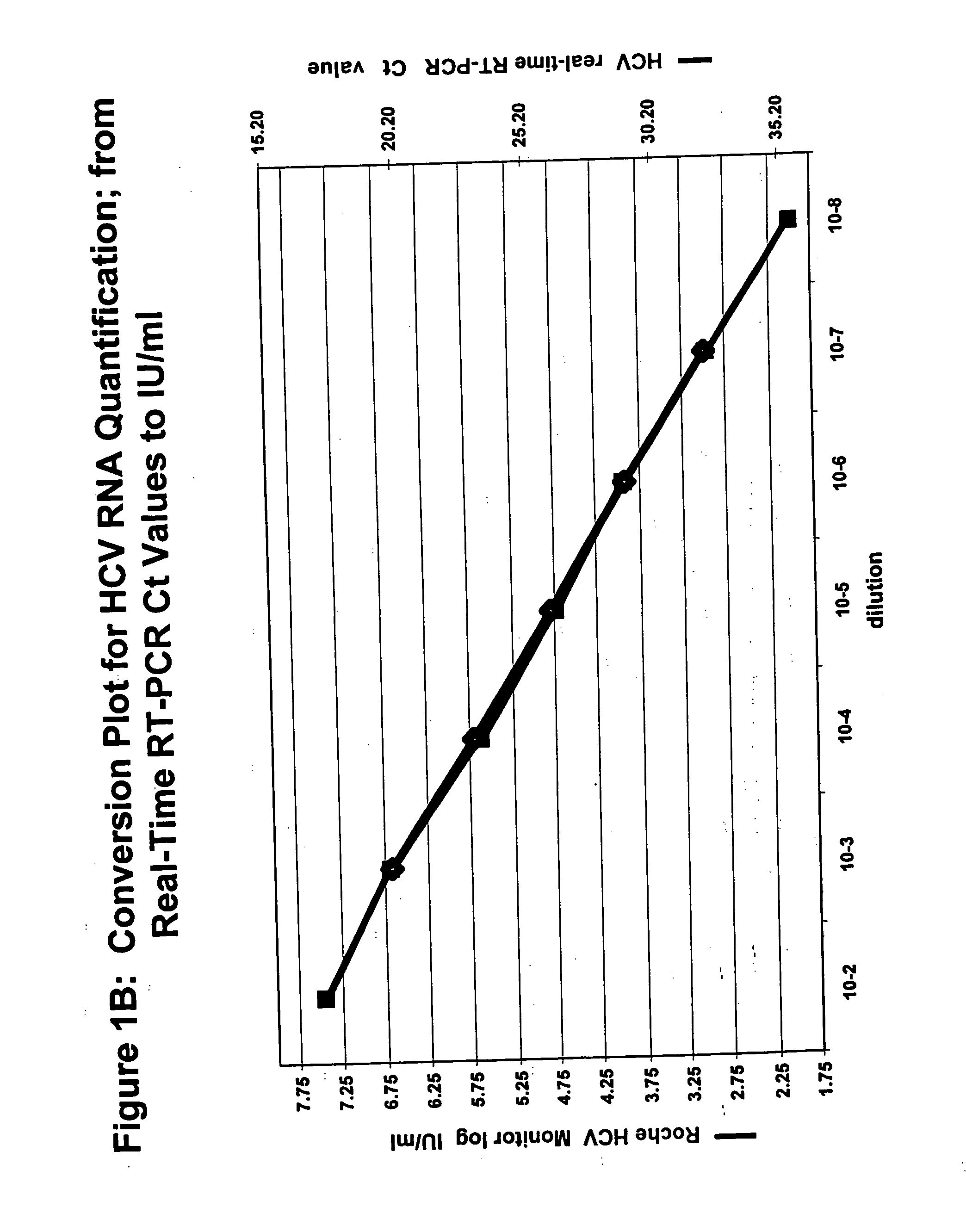

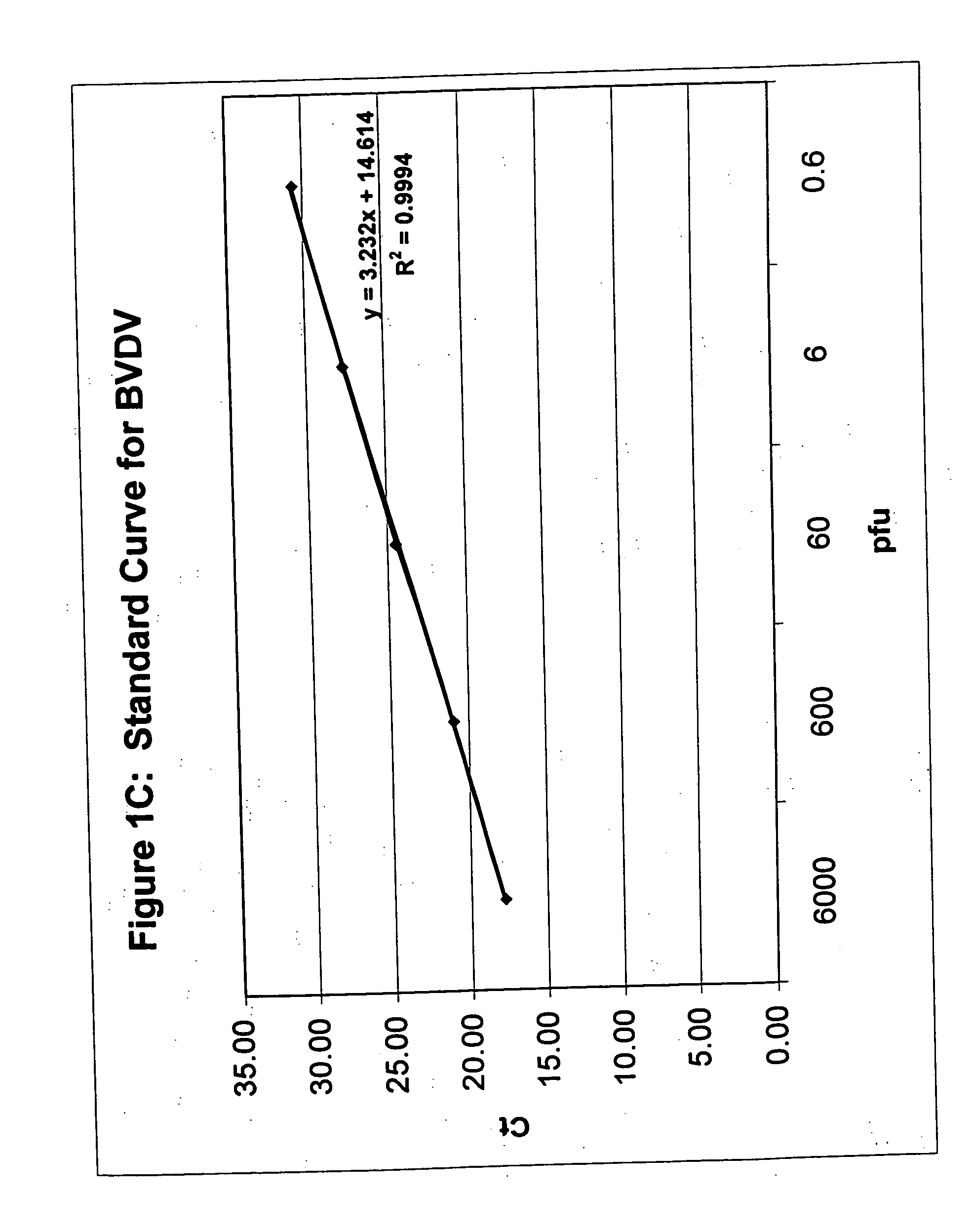

Simultaneous quantification of nucleic acids in diseased cells

InactiveUS20070196824A1Assess potential side-effectsLow variabilitySugar derivativesMicrobiological testing/measurementReal-Time PCRsAntiviral drug

Processes and methods for the simultaneous quantification of nucleic acids in diseased cells that are based on real-time PCR are provided. The real-time PCR protocol is an excellent tool for reliable quantification of in vitro drug screening and evaluation protocols to determine the efficacy of potential anti-viral agents. Quantification using these simultaneous PCR cycle threshold (Ct) detection techniques during one-step real-time RT-PCR (Applied Biosystems, CA) eliminates the variability resulting from quantification of end-point RT-PCR products. In addition, the mitochondrial toxicity assay is an added tool to assess potential side-effects for these chemotherapeutic agents.

Owner:GILEAD PHARMASSET LLC

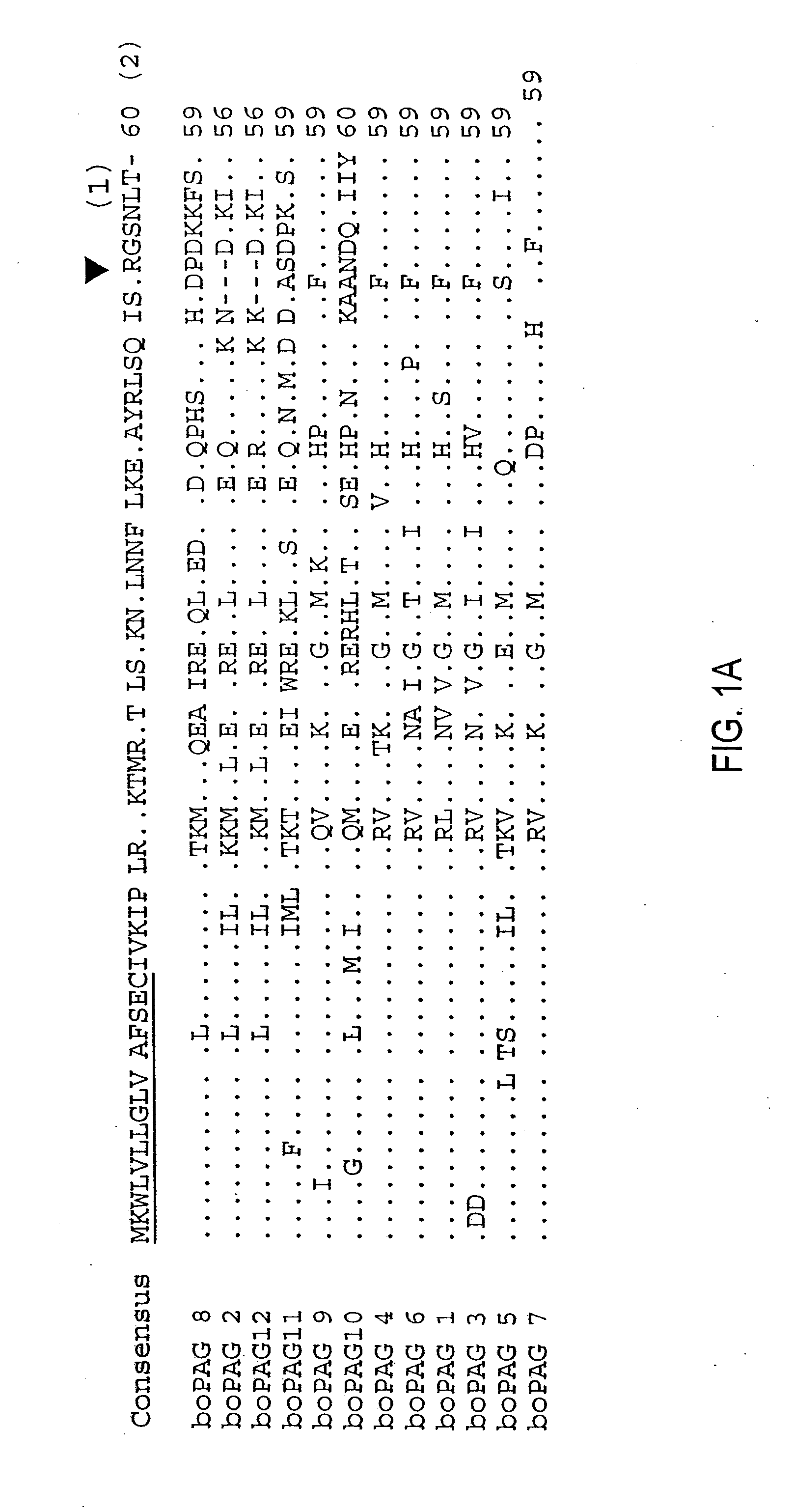

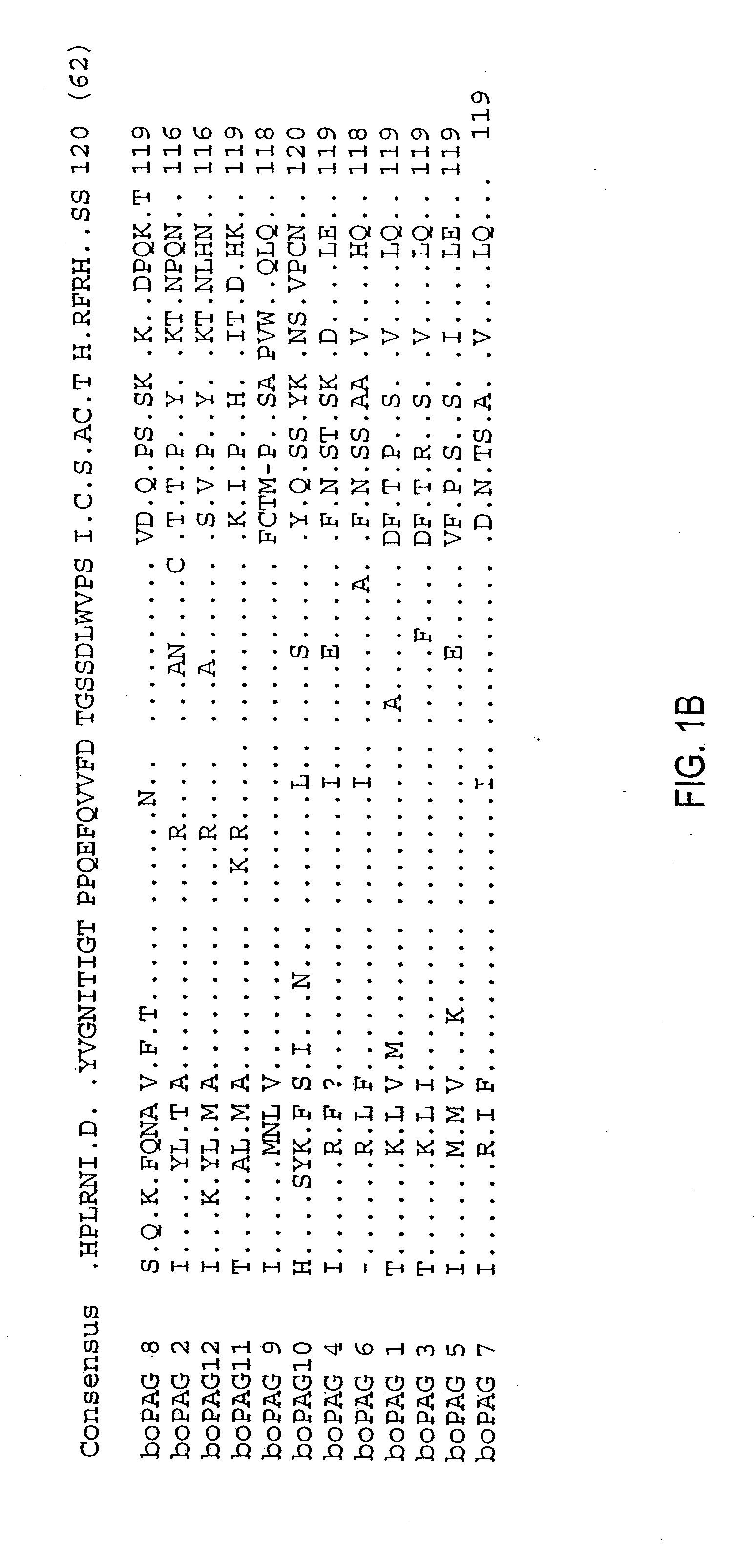

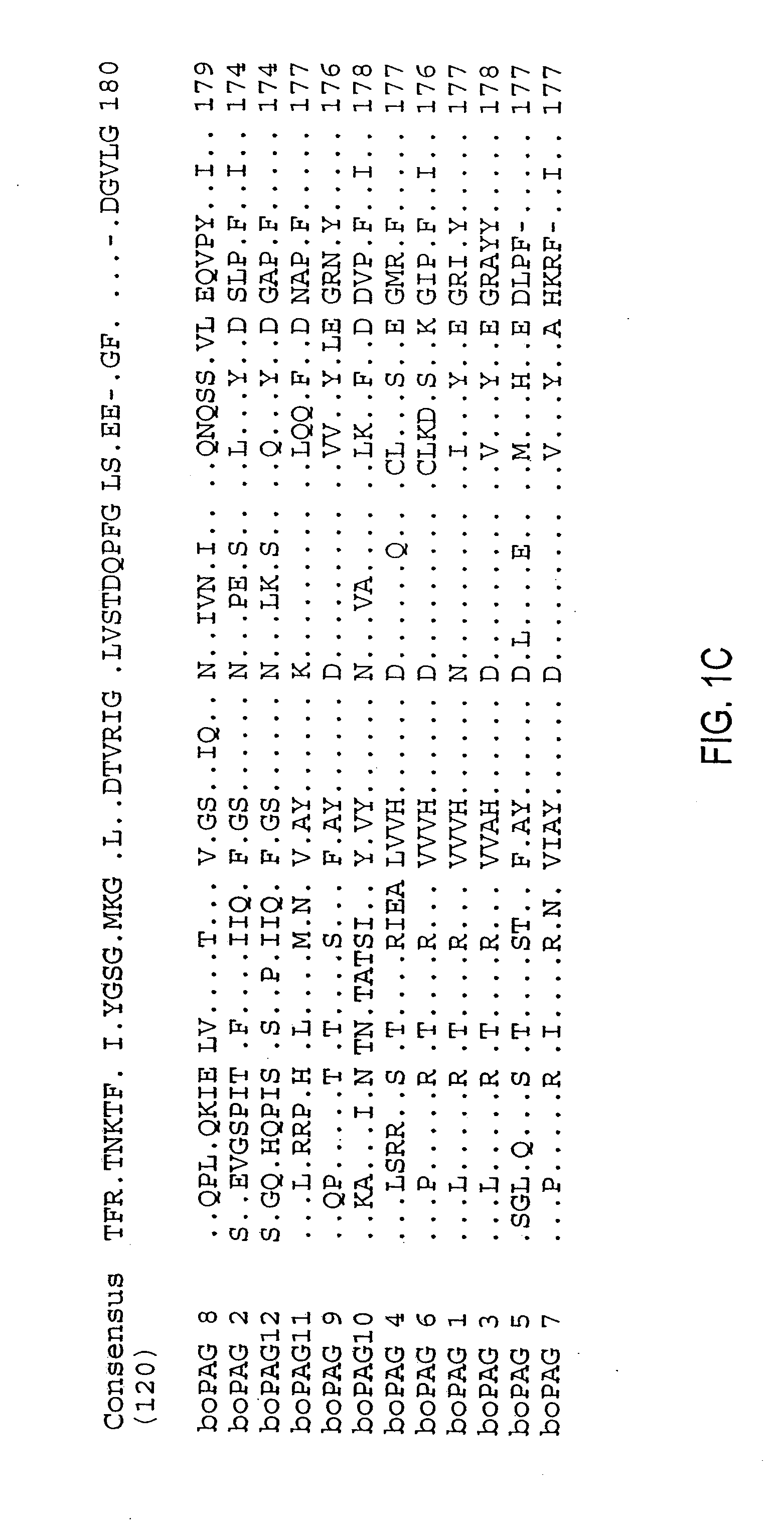

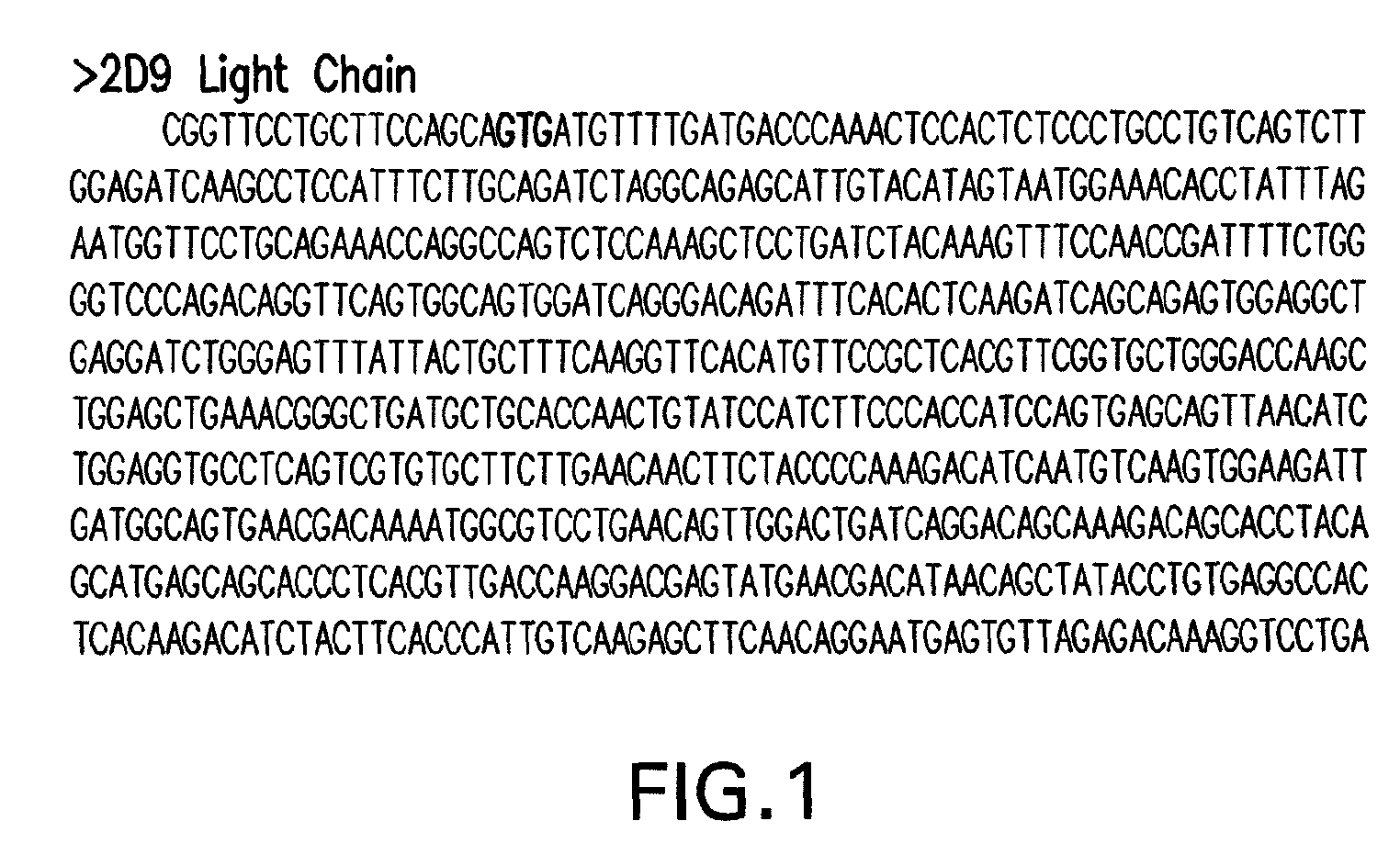

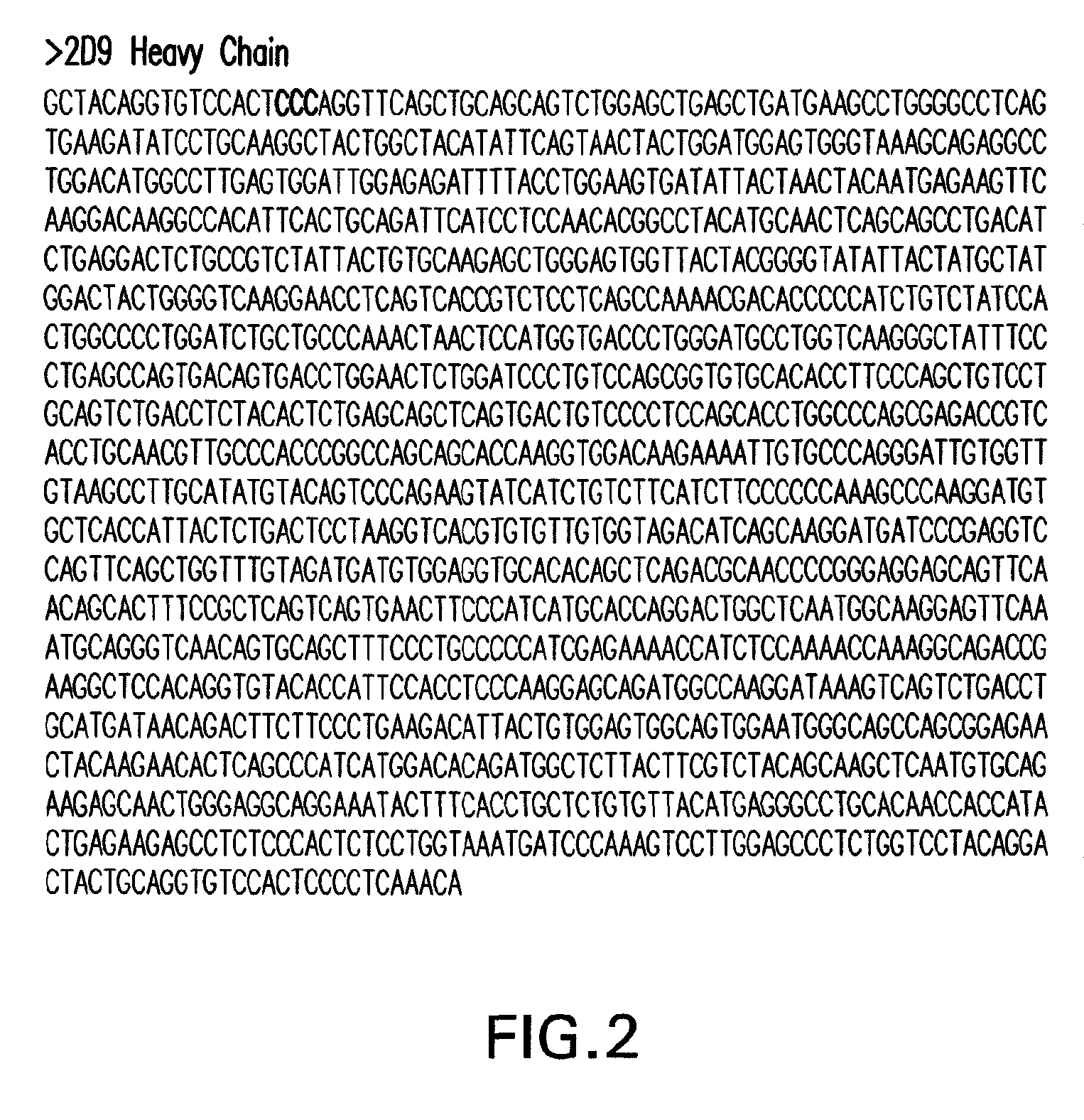

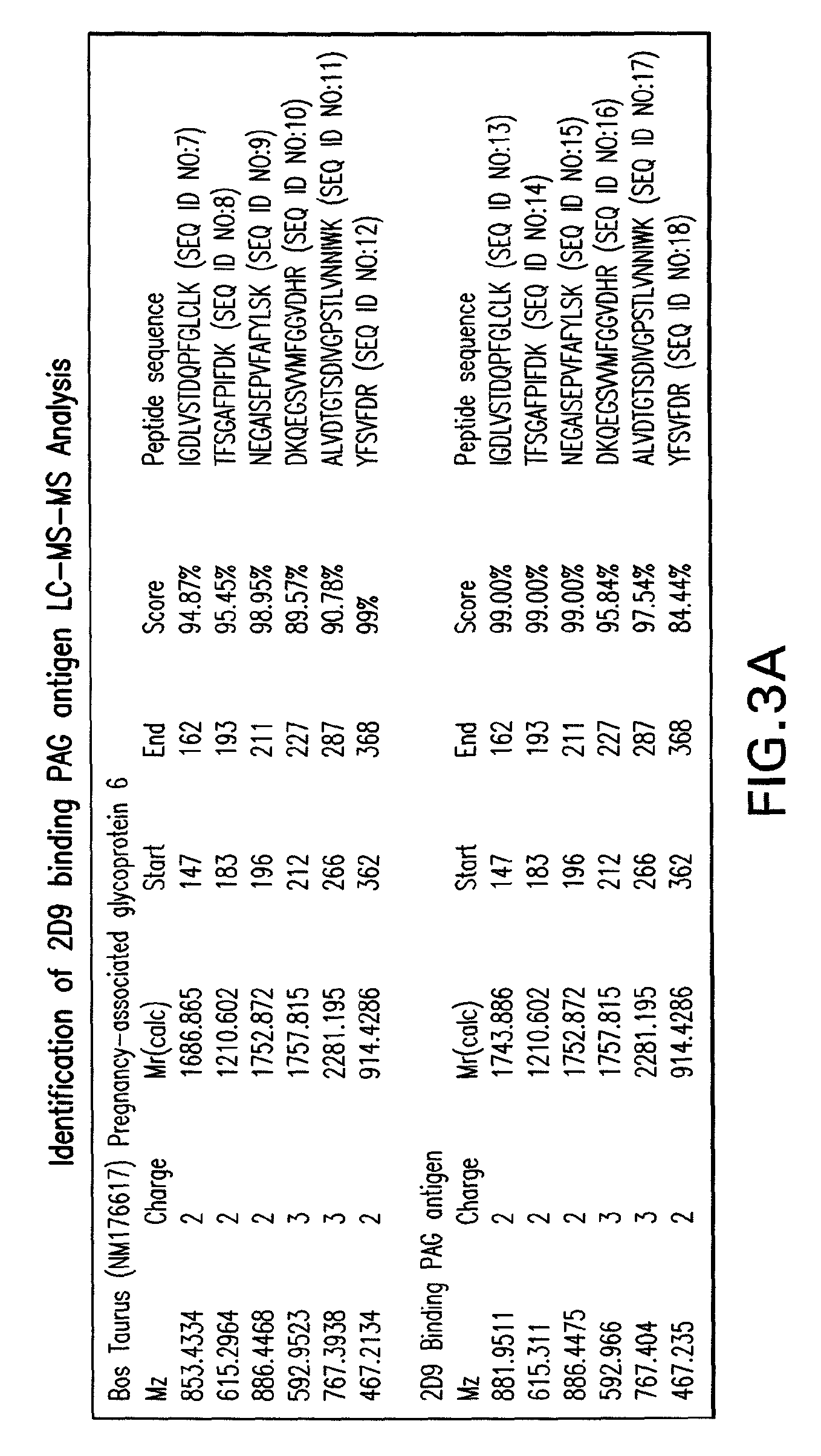

Compositions and methods for early pregnancy diagnosis

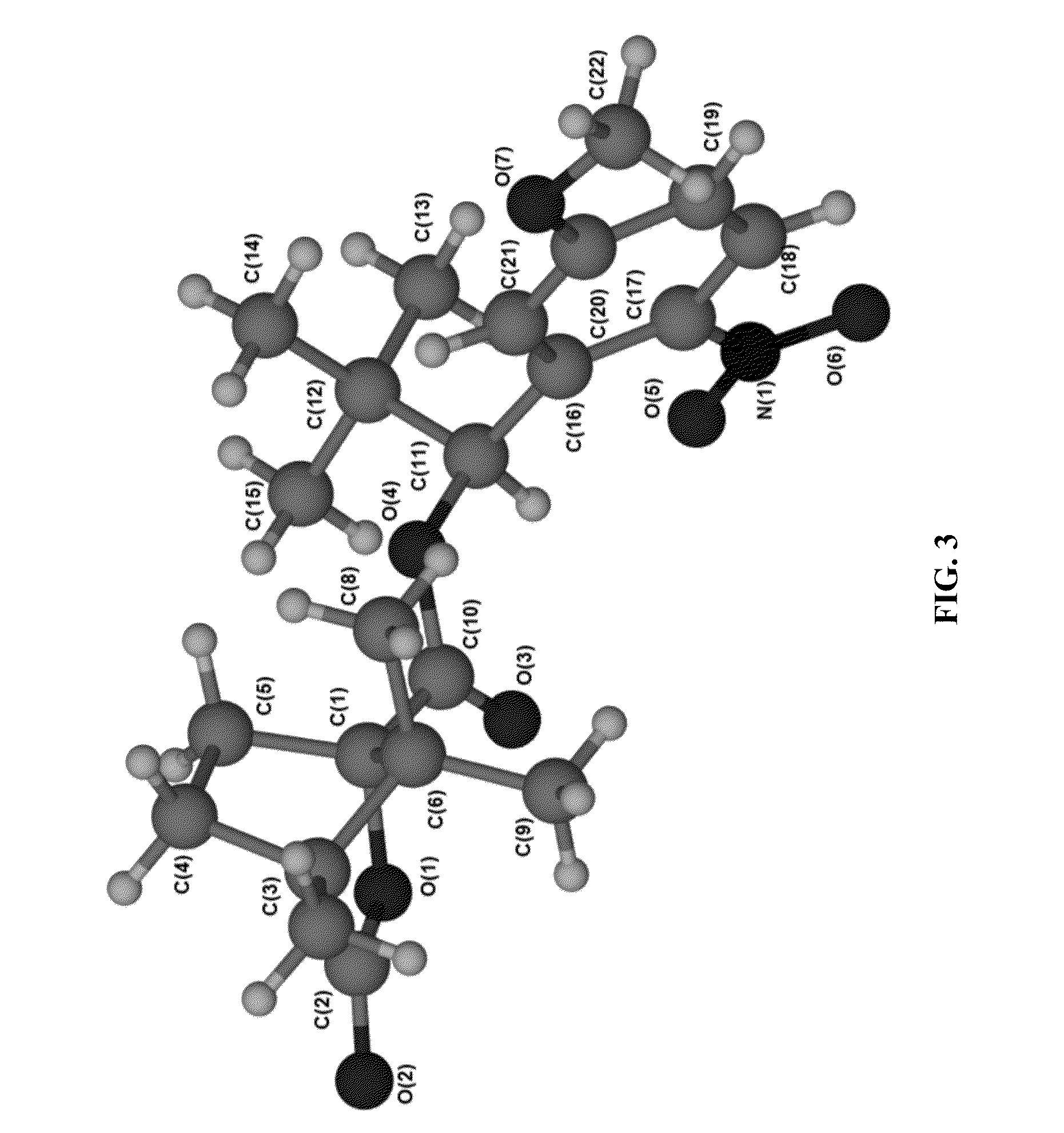

Pregnancy-associated glycoproteins (PAGs) are structurally related to the pepsins, thought to be restricted to the hoofed (ungulate) mammals and characterized by being expressed specifically in the outer epithelial cell layer (chorion / trophectoderm) of the placenta. By cloning expressed genes from ovine and bovine placental cDNA libraries, the inventors estimate that cattle, sheep, and most probably all ruminant Artiodactyla, possess possibly 100 or more PAG genes, many of which are placentally expressed. The PAGs are highly diverse in sequence, with regions of hypervariability confined largely to surface-exposed loops. Selected PAG that are products of the i0nvasive binucleate cells, expressed highly in early pregnancy at the time of trophoblast invasion and expressed weakly, if at all, in late gestation are useful in the early diagnosis of pregnancy. In a preferred embodiment, the invention relates to immunoassays for detecting these PAGs.

Owner:UNIVERSITY OF MISSOURI

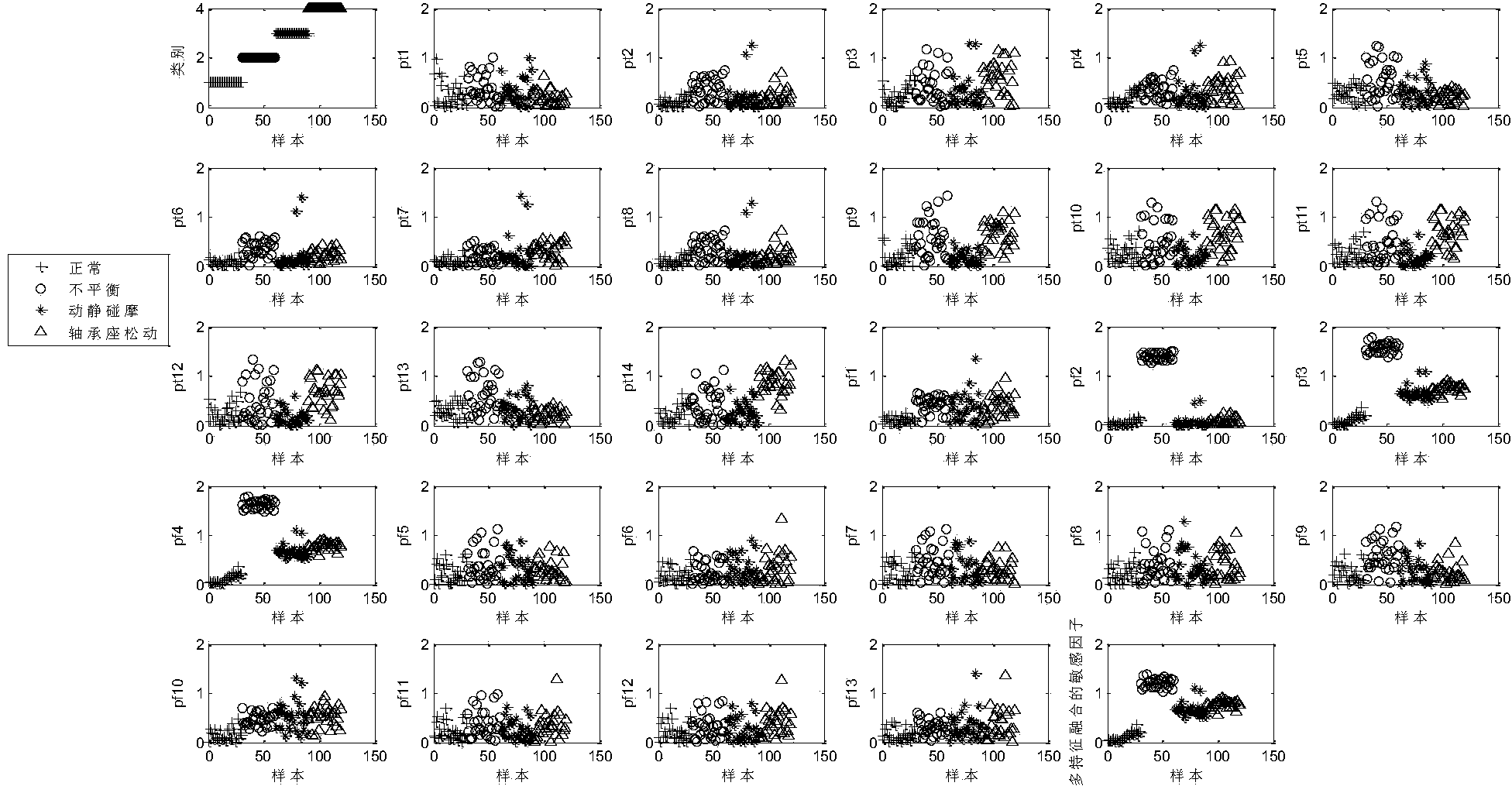

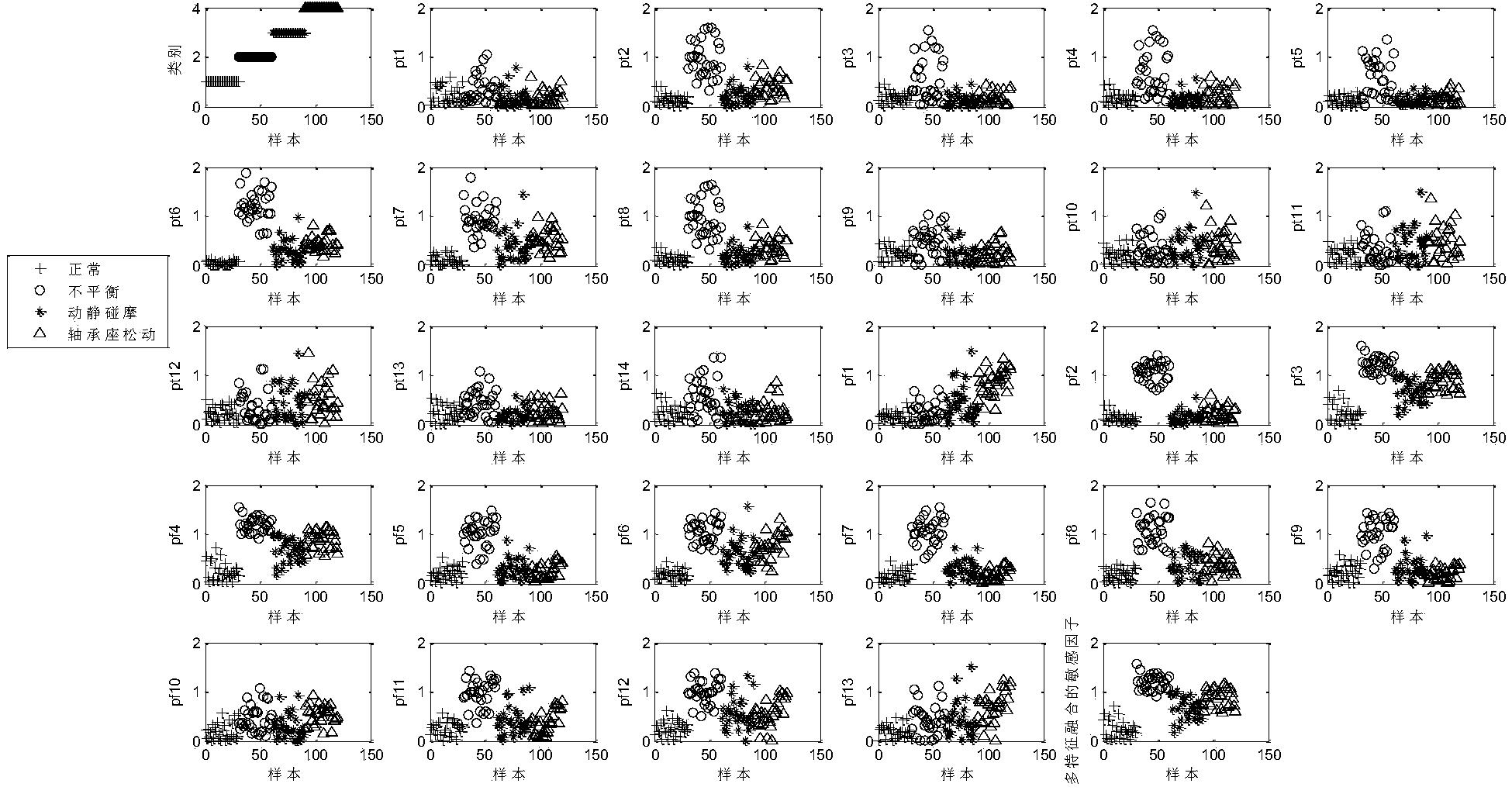

Method for determining sensitivity of each sensor in mechanical equipment vibrating sensor network

InactiveCN104215323AAccurately reflectSensitivity is easy to measureSubsonic/sonic/ultrasonic wave measurementMechanical equipmentComputer science

The invention relates to a method for determining the sensitivity of each sensor in a mechanical equipment vibrating sensor network. A vibrating sensor network node sensitivity evaluation index is provided according to the actual conditions of the vibrating sensor network and by using common complex network importance evaluation indexes and methods as reference. The vibrating sensor network node sensitivity evaluation index is a sensor network sensitivity factor based on multi-feature fusion. The vibrating sensor network sensitivity factor must sensitively and accurately reflect system state change and measure the sensitivity of all sensors to the same state. The calculation thought of the vibrating sensor network sensitivity factor is characterized in that maximization of the distance between an abnormal fault state and a normal state can be achieved by using the normal state as reference; the factor is comparable, and the sensitivity of each sensor to the same fault or abnormal state can be measured. Compared with a single feature, the method has the advantages that the method considers more feature attributes, system state change can be comprehensively and accurately reflected, and the sensitivity of all the sensors to the same state can be well measured. In addition, by the method, the importance of the nodes of the sensor network can be evaluated and sorted, the key nodes can be found, and foundation is laid for sensor network consistency decision fusion.

Owner:AIR FORCE UNIV PLA

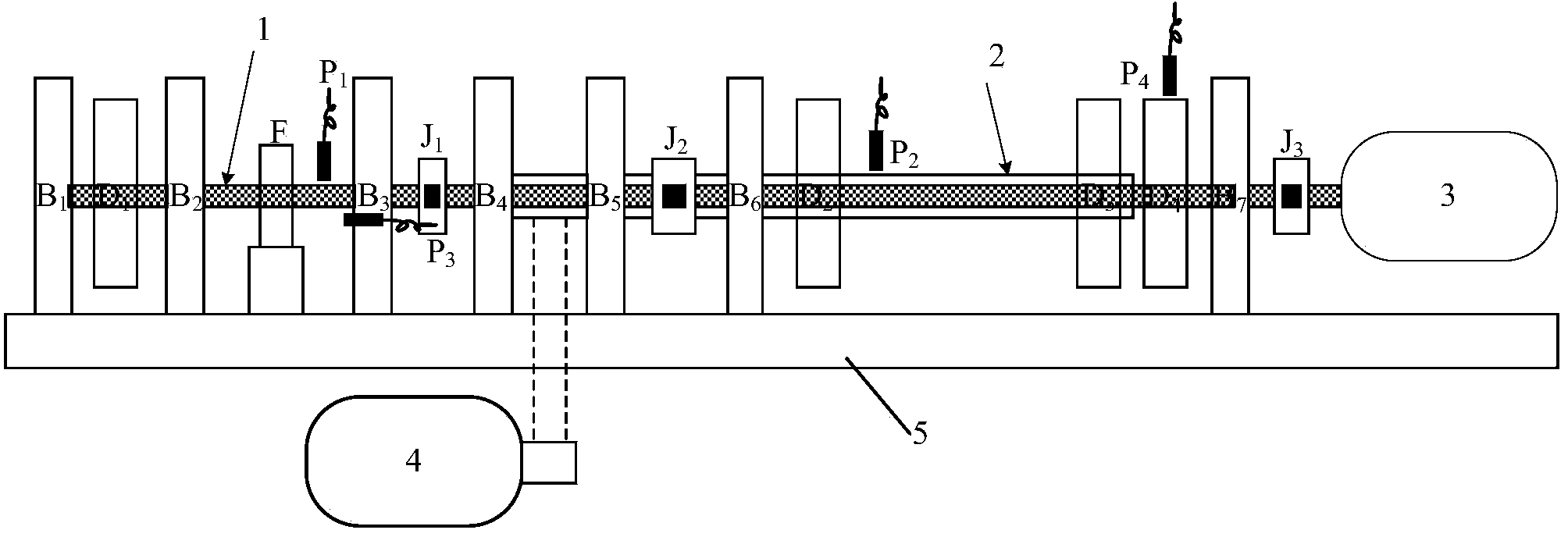

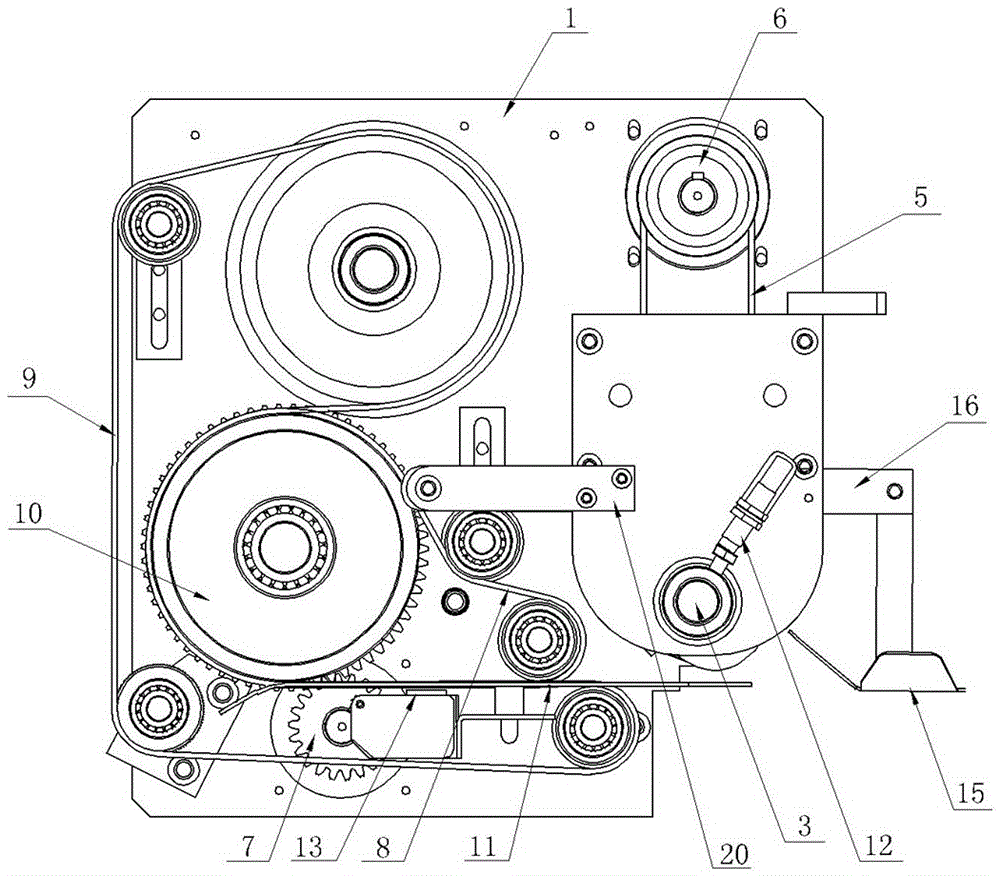

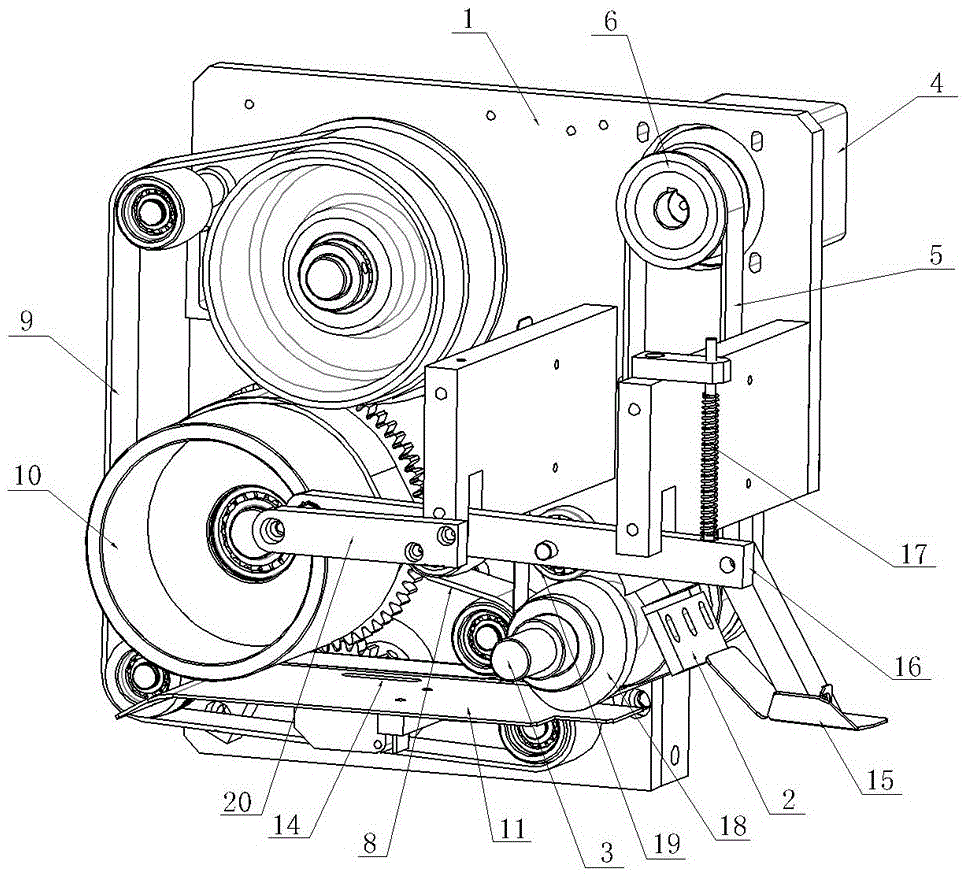

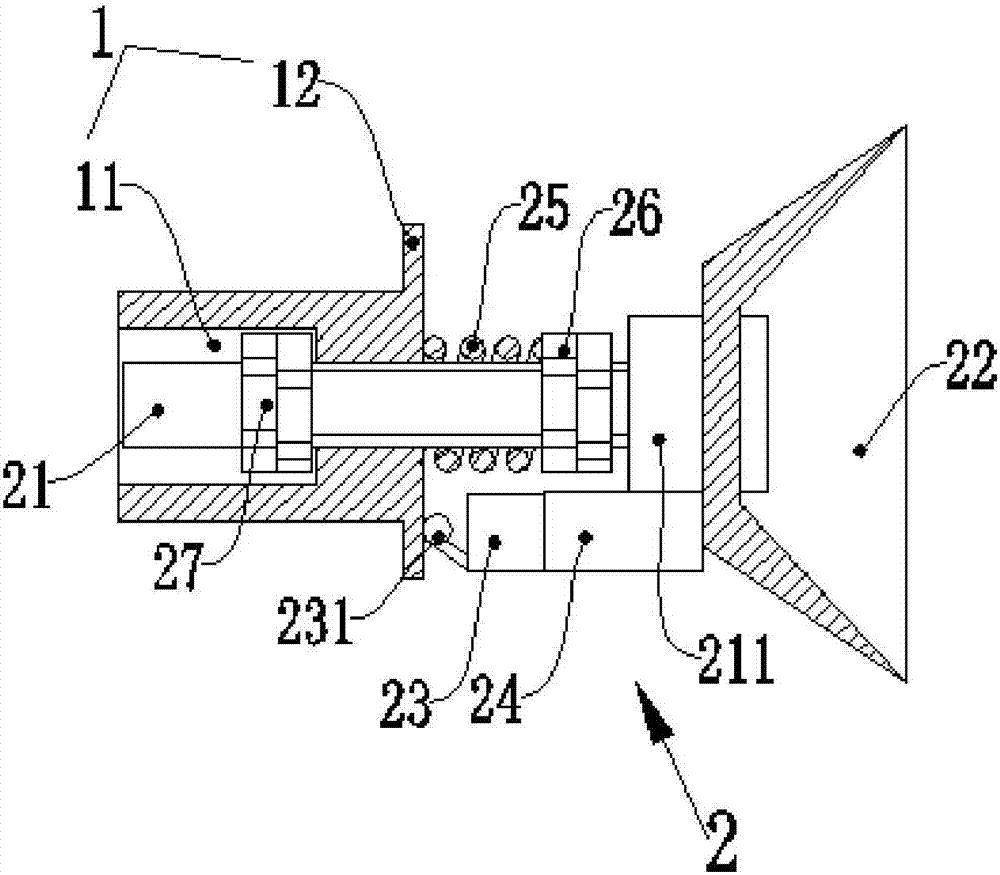

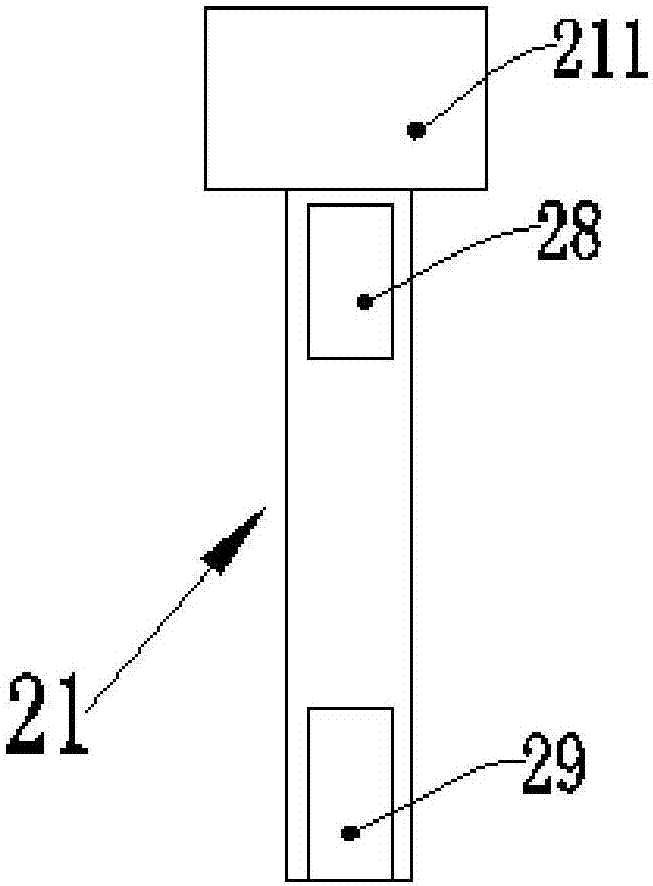

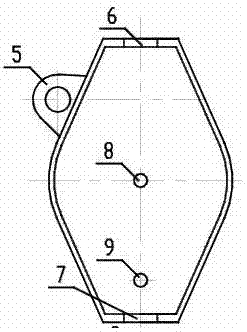

Full-automatic bag making machine handle feeding and cutting device

ActiveCN106607952AEasy to tuneSensitive and accurateBag making operationsPaper-makingEngineeringMechanical engineering

The invention discloses a full-automatic bag making machine handle feeding and cutting device comprising a rack. The full-automatic bag making machine handle feeding and cutting device is characterized in that a handle feeding mechanism and a handle cutting mechanism are arranged on the rack. The handle cutting mechanism comprises a paper cutter. The handle feeding mechanism is connected with a material feeding power source in a transmission way. The paper cutter is connected with a material cutting power source in the transmission way. The handle feeding mechanism and the paper cutter are mutually cooperated to perform material cutting. The handle feeding mechanism stops material feeding in material cutting, and the handle feeding mechanism continues material feeding after completion of material cutting so that the degree of cooperation of the handle feeding mechanism and the handle cutting mechanism can be enhanced. The handle cutting mechanism is connected with the material cutting power source, the handle feeding mechanism is connected with the material feeding power source, and transmission of the handle cutting mechanism and the handle feeding mechanism is performed by the respective power sources so that the handle cutting mechanism and the handle feeding mechanism can be separately controlled, and machine debugging is more convenient.

Owner:WENZHOU ZENBO PRINTING MACHINERY

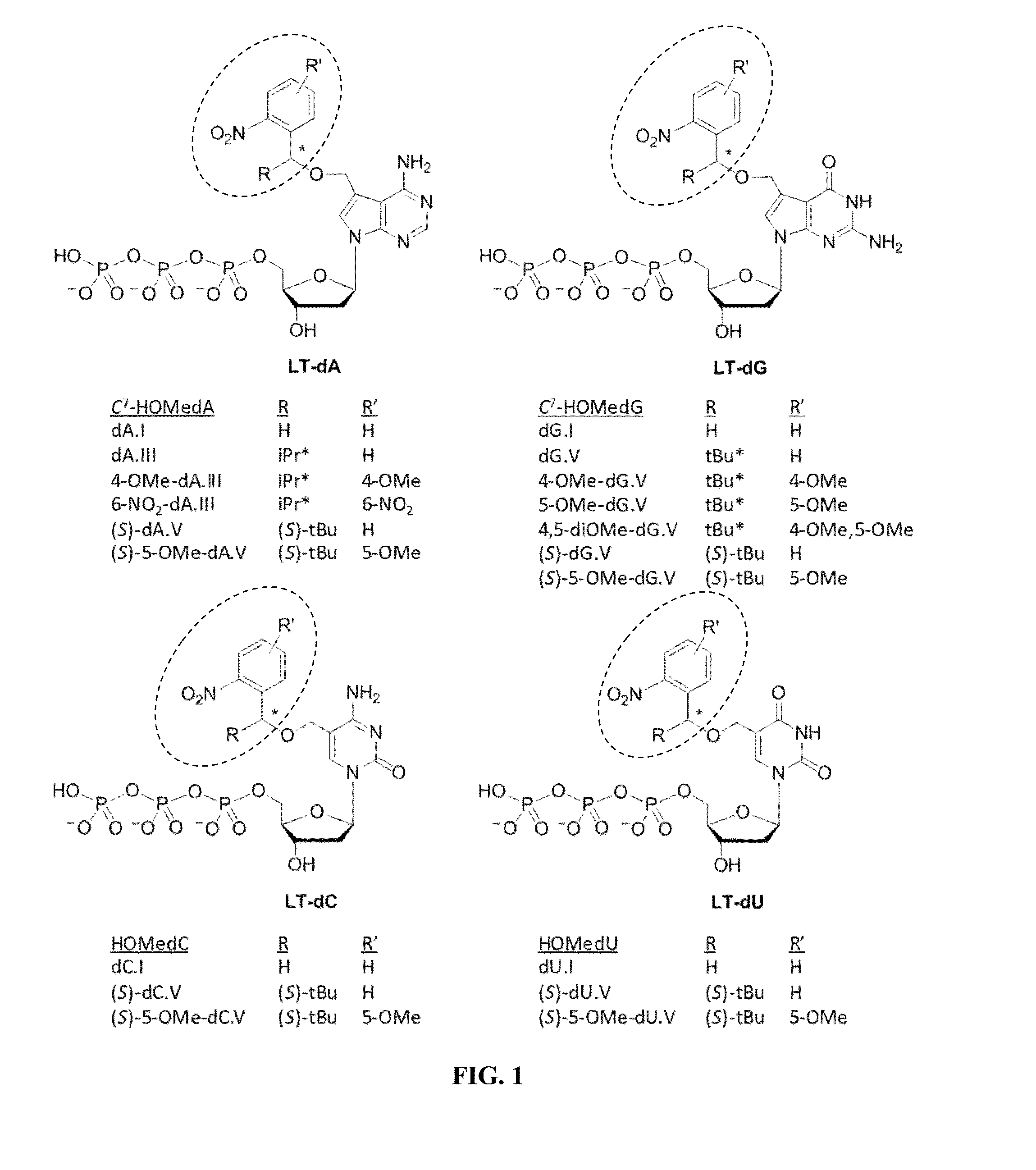

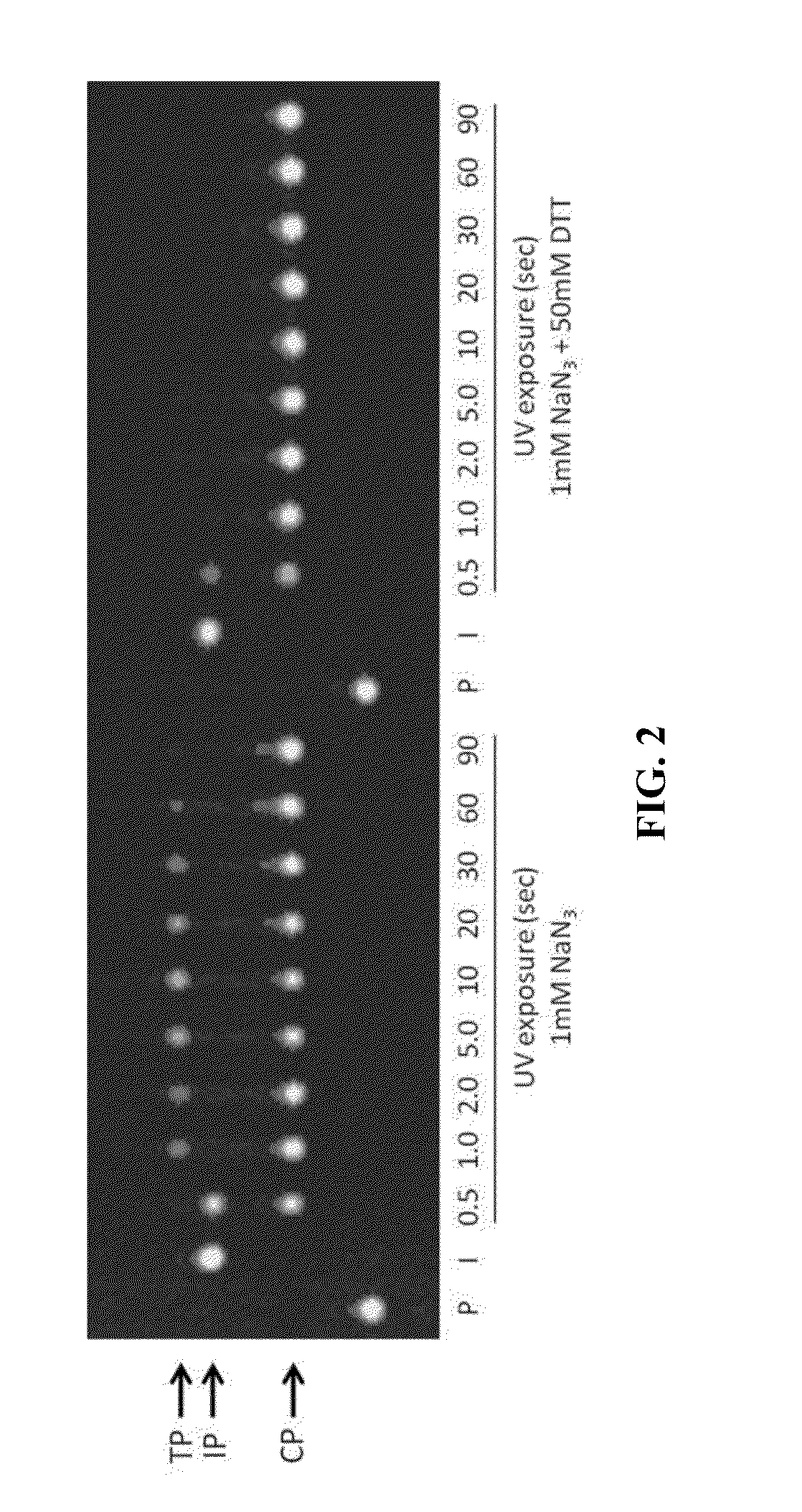

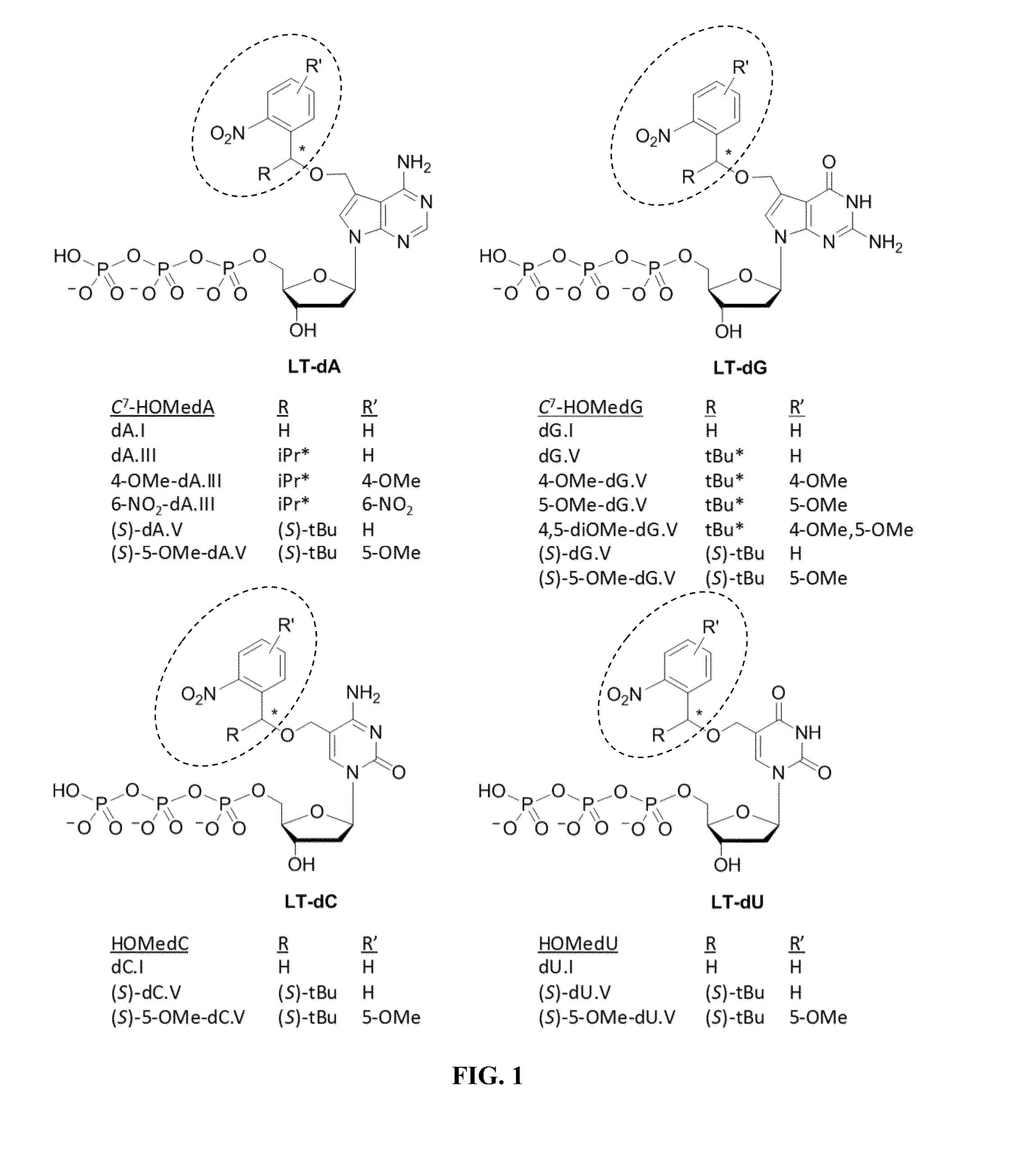

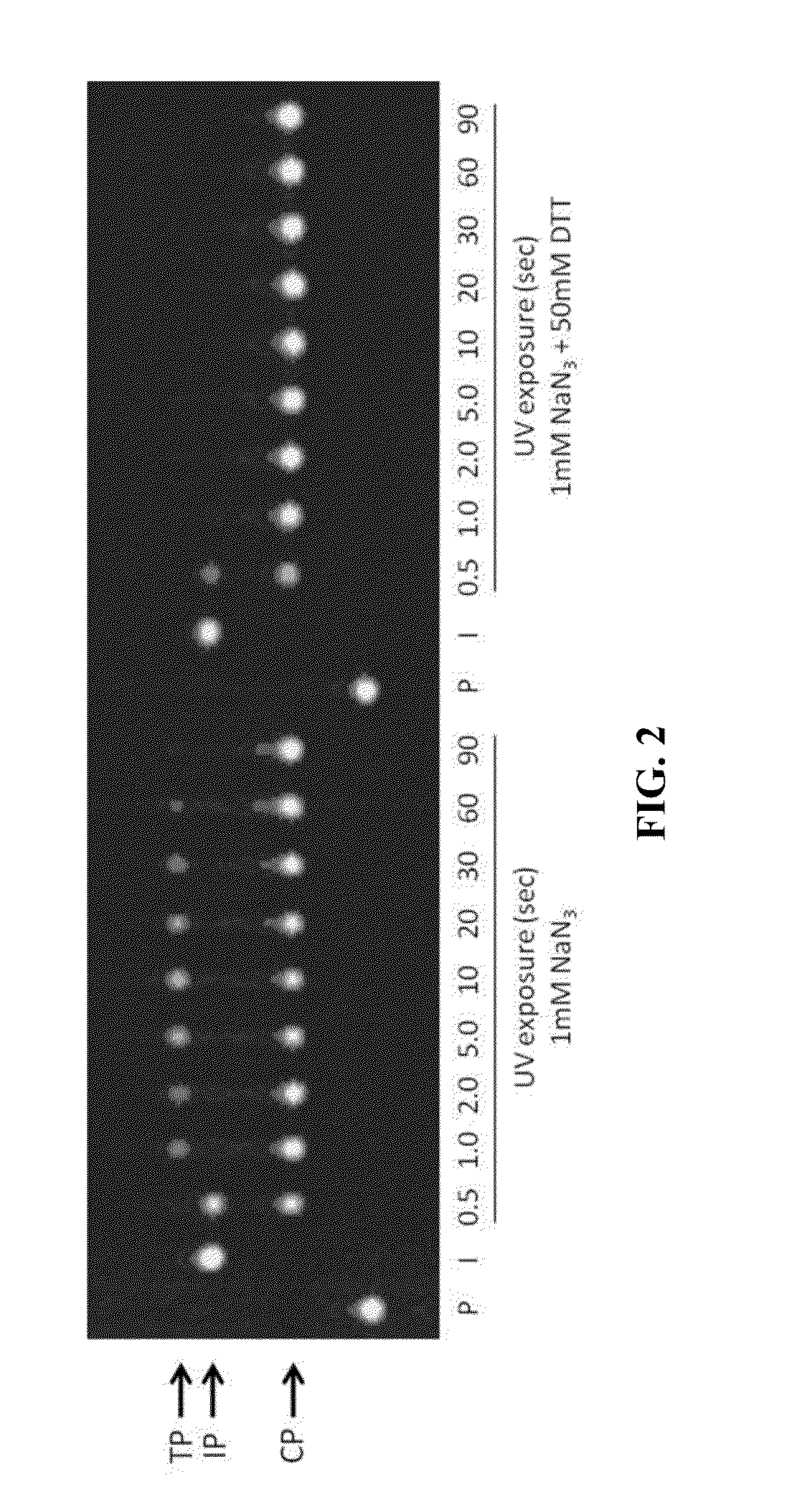

3′-OH unblocked, fast photocleavable terminating nucleotides and methods for nucleic acid sequencing

ActiveUS8889860B2Efficiently and affordably provideEfficient sequencingSugar derivativesMicrobiological testing/measurementNucleic acid sequencingDNA

Owner:AGILENT TECH INC

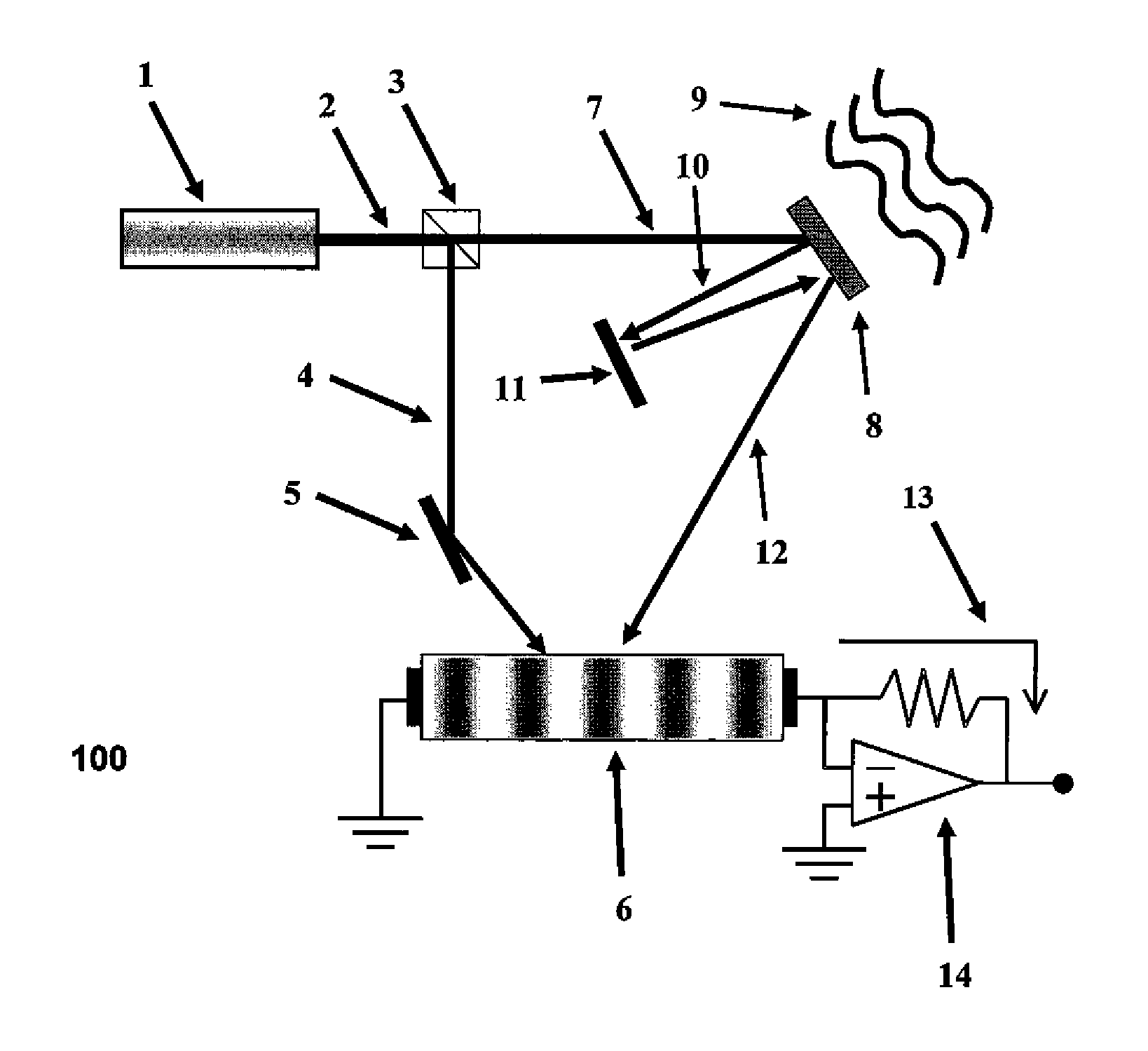

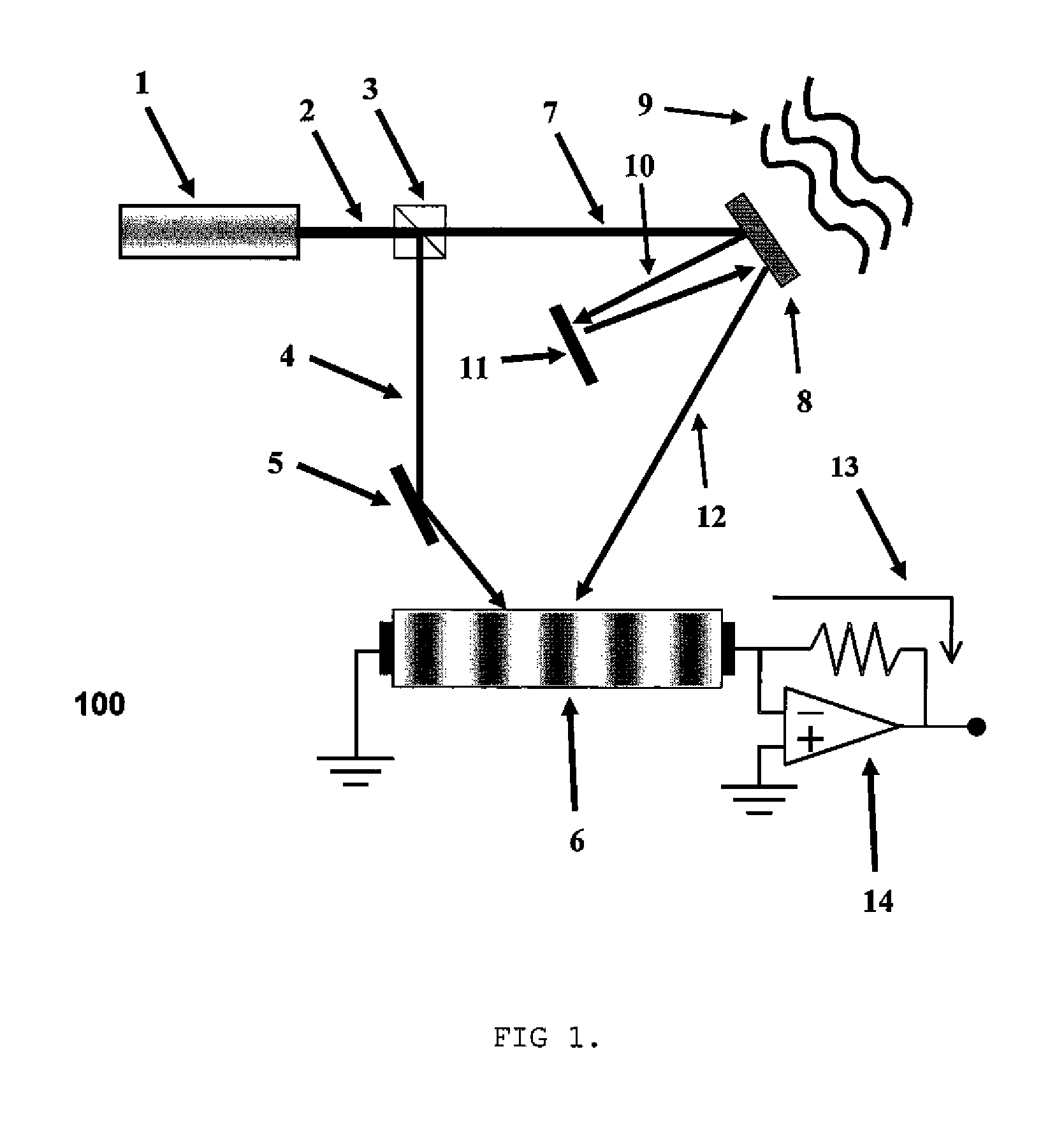

Enhanced sensitivity vibrometer

InactiveUS8072609B1Increase signal strengthHigh detection sensitivitySubsonic/sonic/ultrasonic wave measurementUsing optical meansPressure senseLight beam

An enhanced sensitivity laser vibrometer with increased output signal strength and more sensitive surface vibration detection, is provided by using a reflective mirror assembly to repeatedly bounce the sensing laser beam against the acoustic pressure-sensing diaphragm to magnify the acoustic incident pressure wave being detected. The enhancement in signal strength, in terms of power spectral density, is a function of the number of bounces squared and the detection of surface vibrations with a displacement of smaller than 4 picometers is demonstrated experimentally.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Simultaneous quantification of nucleic acids in diseased cells

InactiveUS20070031824A1Assess potential side-effectsLow variabilitySugar derivativesMicrobiological testing/measurementMitochondrial toxicityHost mitochondria

A process for assessing mitochondrial toxicity of a compound that includes contacting nucleic acids from a host with an amplification reaction mixture that contains at least two primers that provide detectable signals, wherein: a first primer provides a first detectable signal upon amplification of a host mitochondrial nucleic acid; a second primer provides a second detectable signal upon amplification of a host nuclear nucleic acid; and comparing the first and second detectable signals.

Owner:PHARMASSET

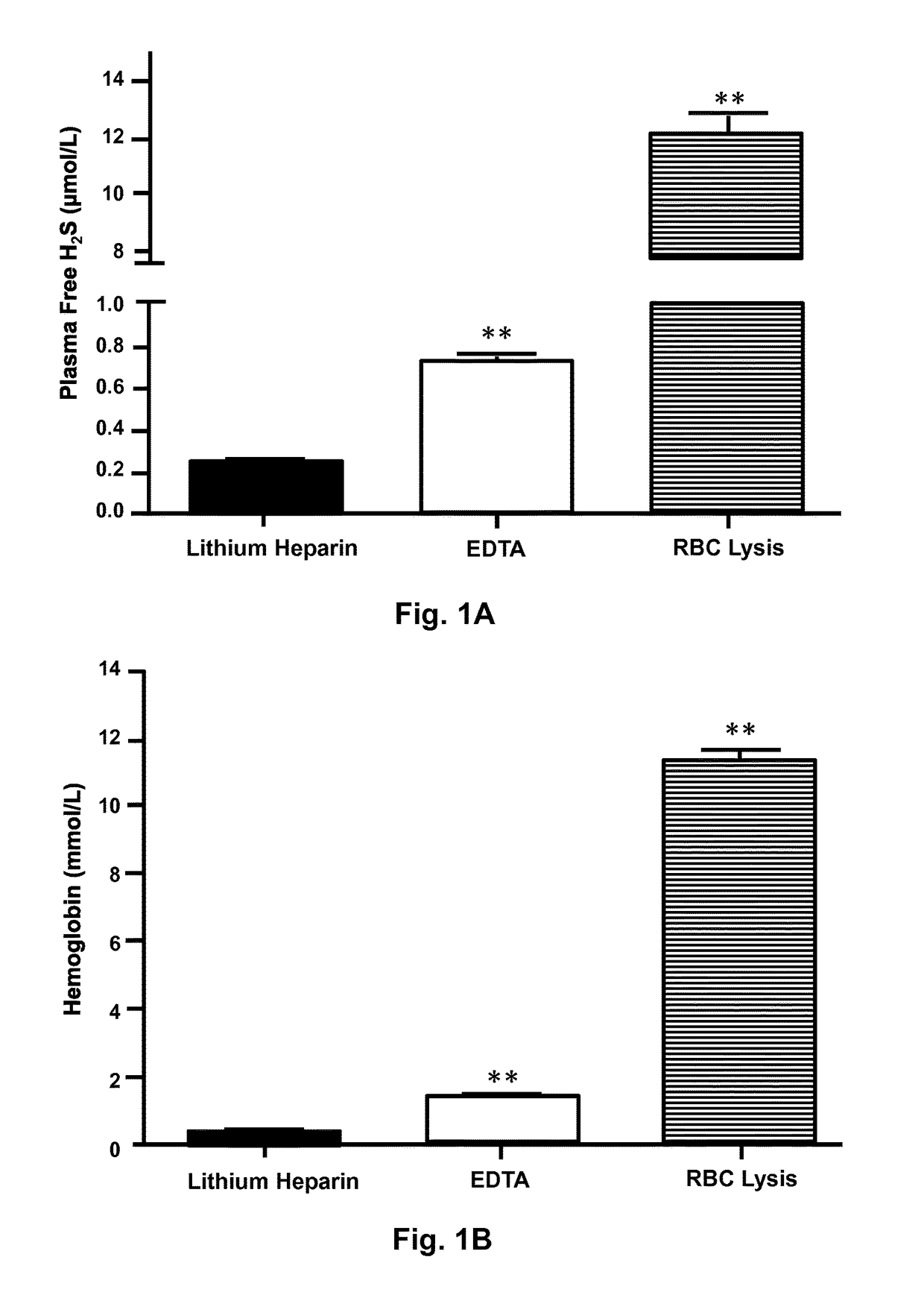

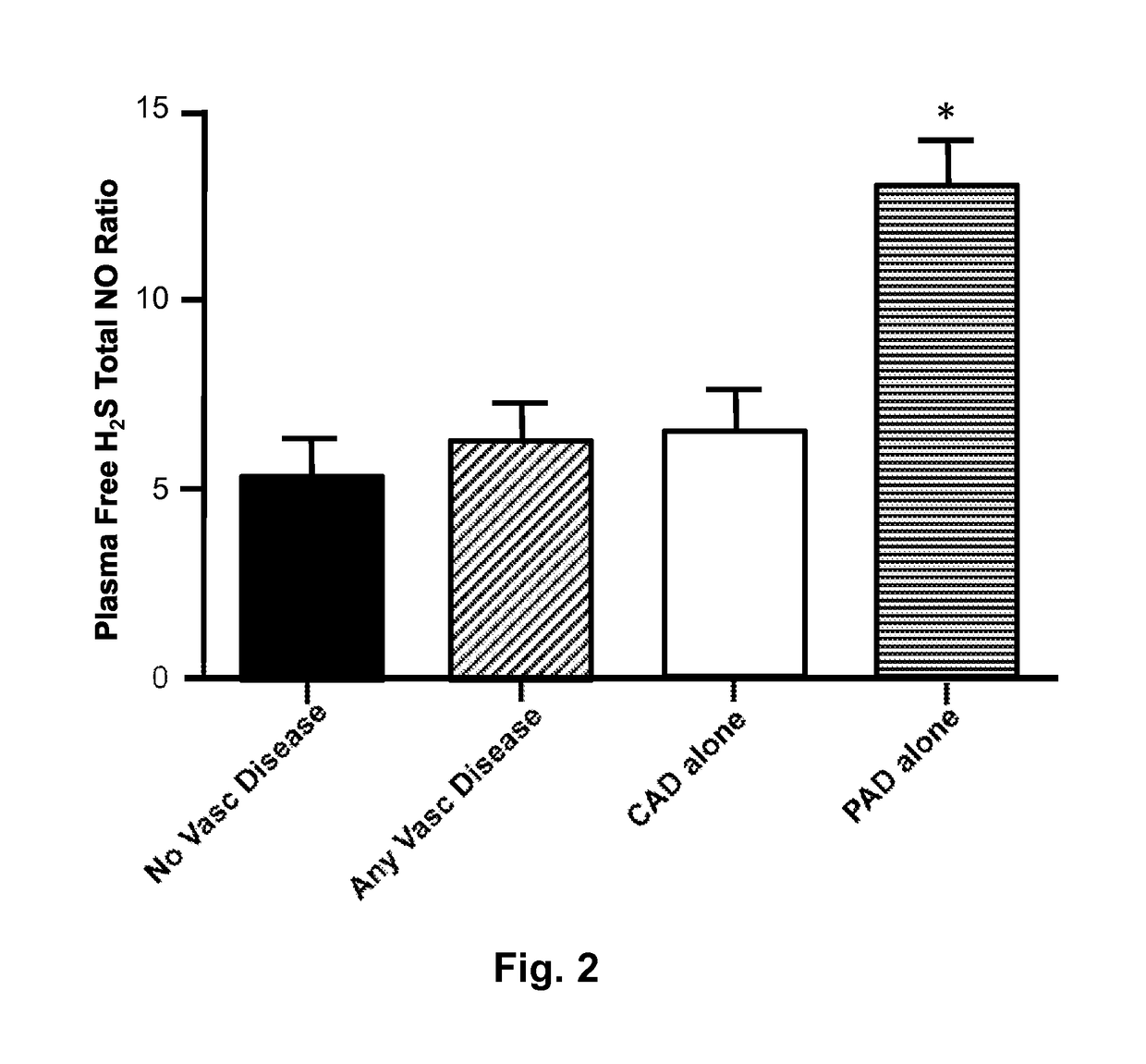

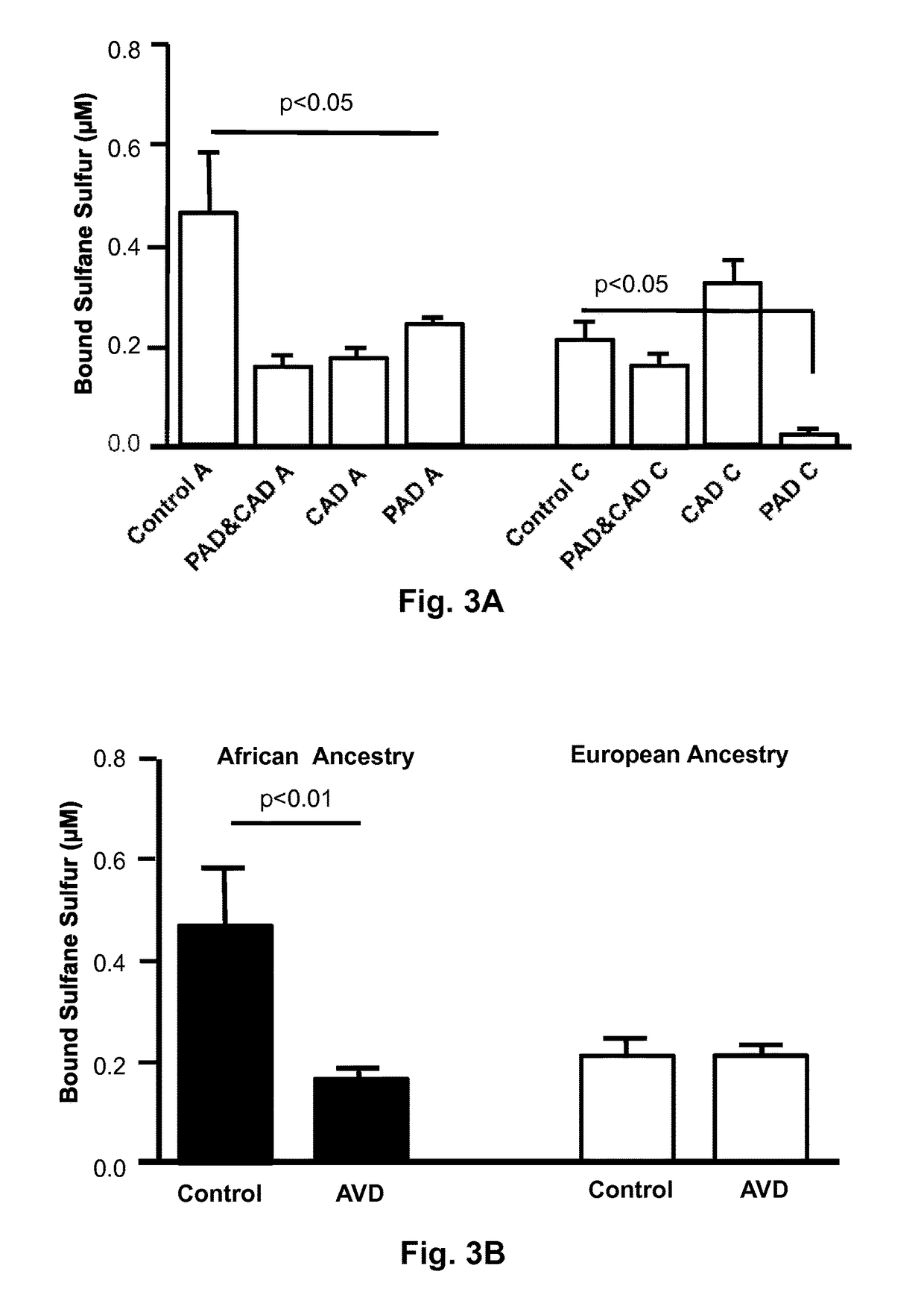

Plasma H2S levels as biomarkers for vascular disease

ActiveUS9599602B2Minimal risk of harmSensitive and accurateBiocideDisease diagnosisBlood plasmaBiomarker (petroleum)

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

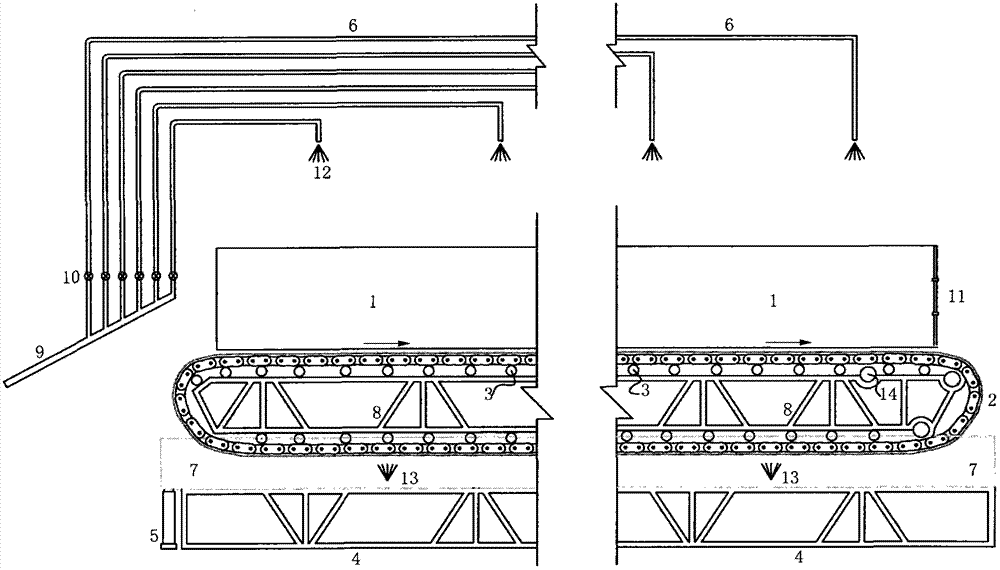

Leaching device for processing heavy metal in house refuse and sludge by using citric acid

InactiveCN102728608ANo damageExtended service lifeContaminated soil reclamationContinuous/uninterruptedSludge

The invention provides a leaching device for processing heavy metal in house refuse and sludge by using citric acid, comprising a pedestal (4), a leacheate collecting tank (7), and a frame (8), wherein the periphery of the frame is provided with straight form support rotating rods (3), the axial two end portions of the straight form support rotating rods support a transmission chain, a crawler type filter screen conveyer belt (2) is fixed on the chain, a stainless steel sludge reserve tank (1) is fixed above the crawler type filter screen conveyer belt, an atomization spray system (6) is arranged above the stainless steel sludge reserve tank, and a set of filter screen cleaning devices (13) are arranged below the crawler type filter screen conveyer belt and above the leacheate collecting tank. The leaching device disclosed herein can continuously work, has large handling capacity, convenient maintenance, and low maintenance cost. The leaching device adopts bilayer rollers to drive and has no damage to the crawler type filter screen conveyer belt, thus multi-protection is realized, and the service life of the crawler type filter screen conveyer belt is prolonged.

Owner:GUANGXI LAIBIN TIANREN BIOLOGICAL ORGANIC FERTILIZER

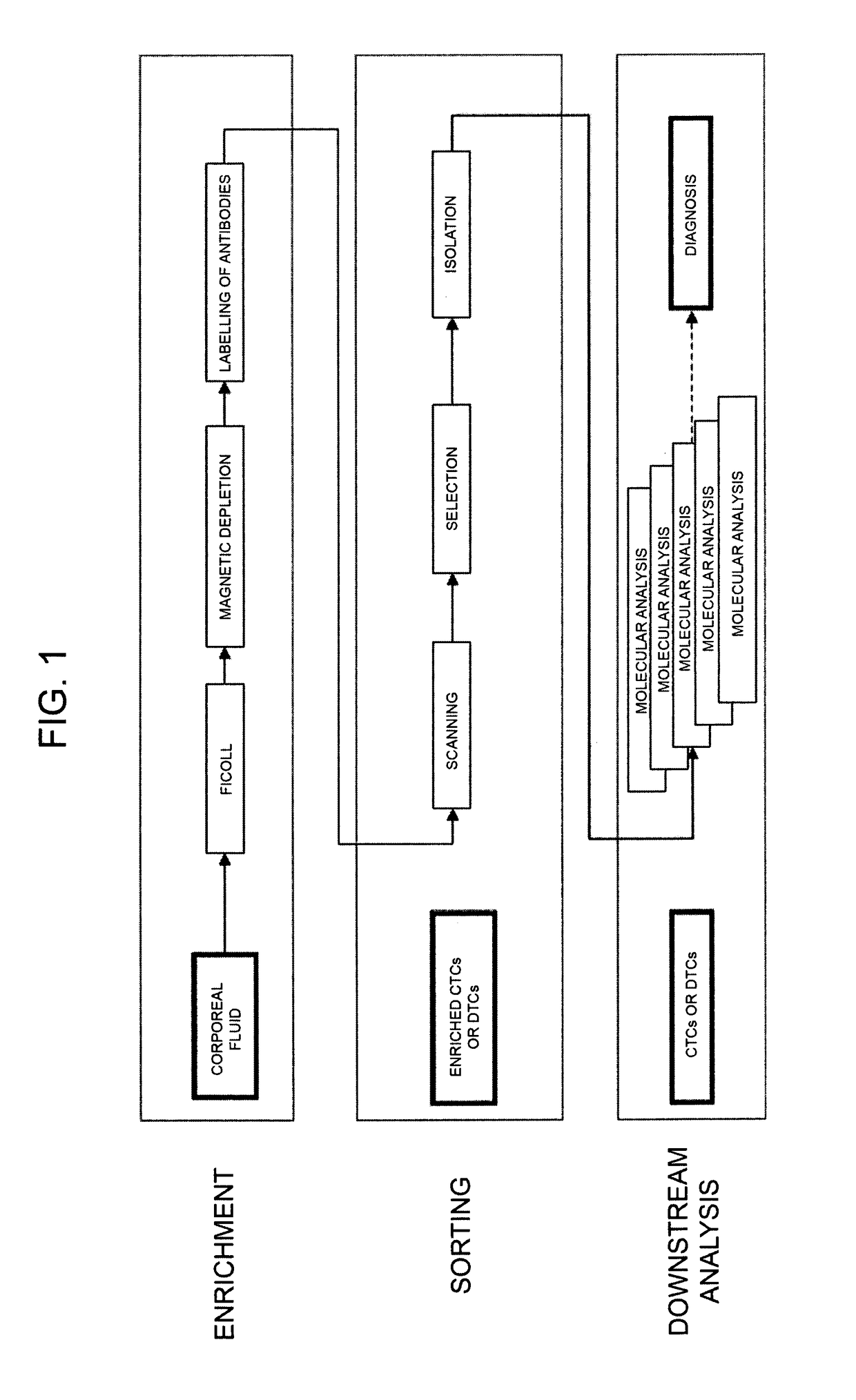

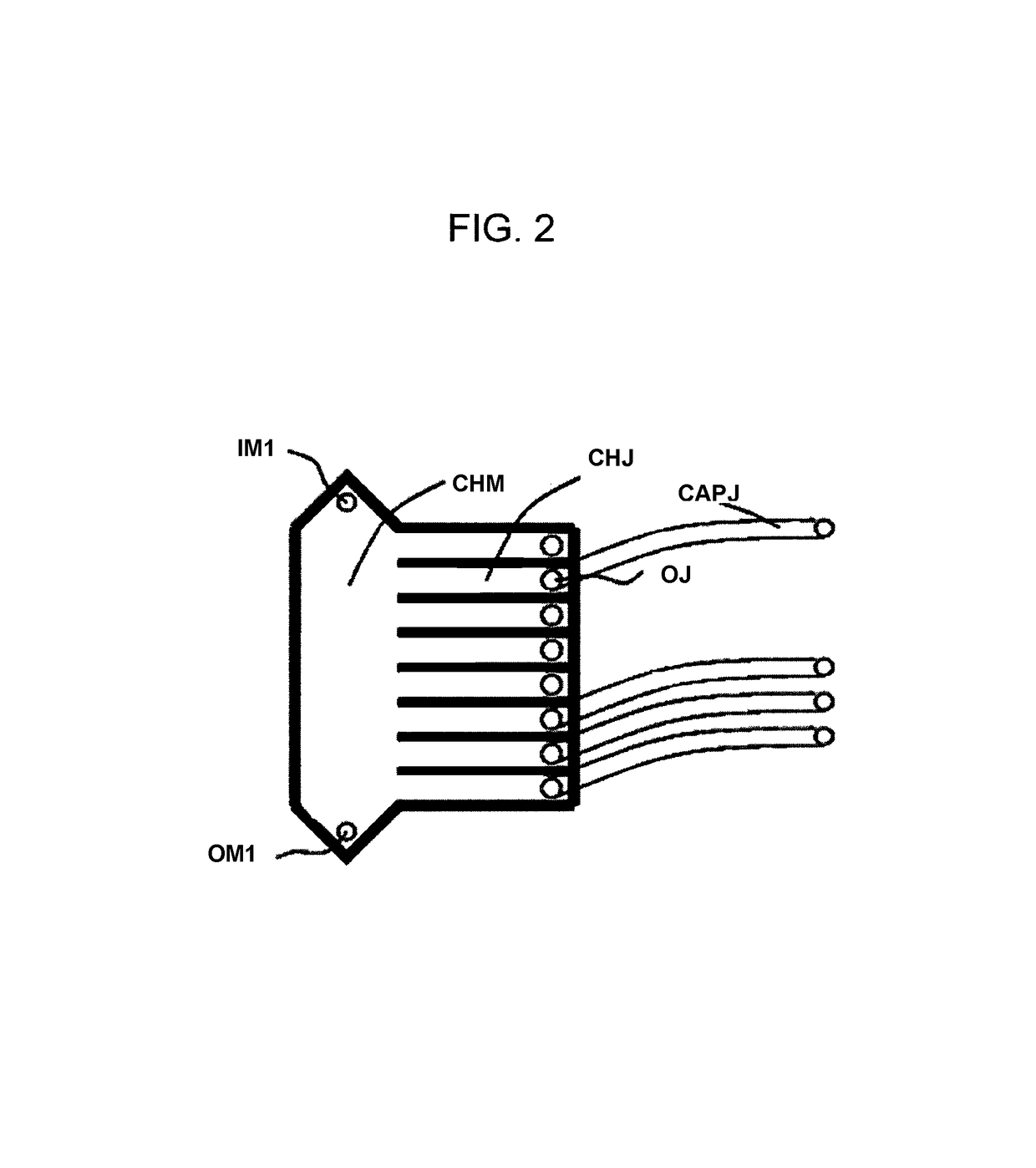

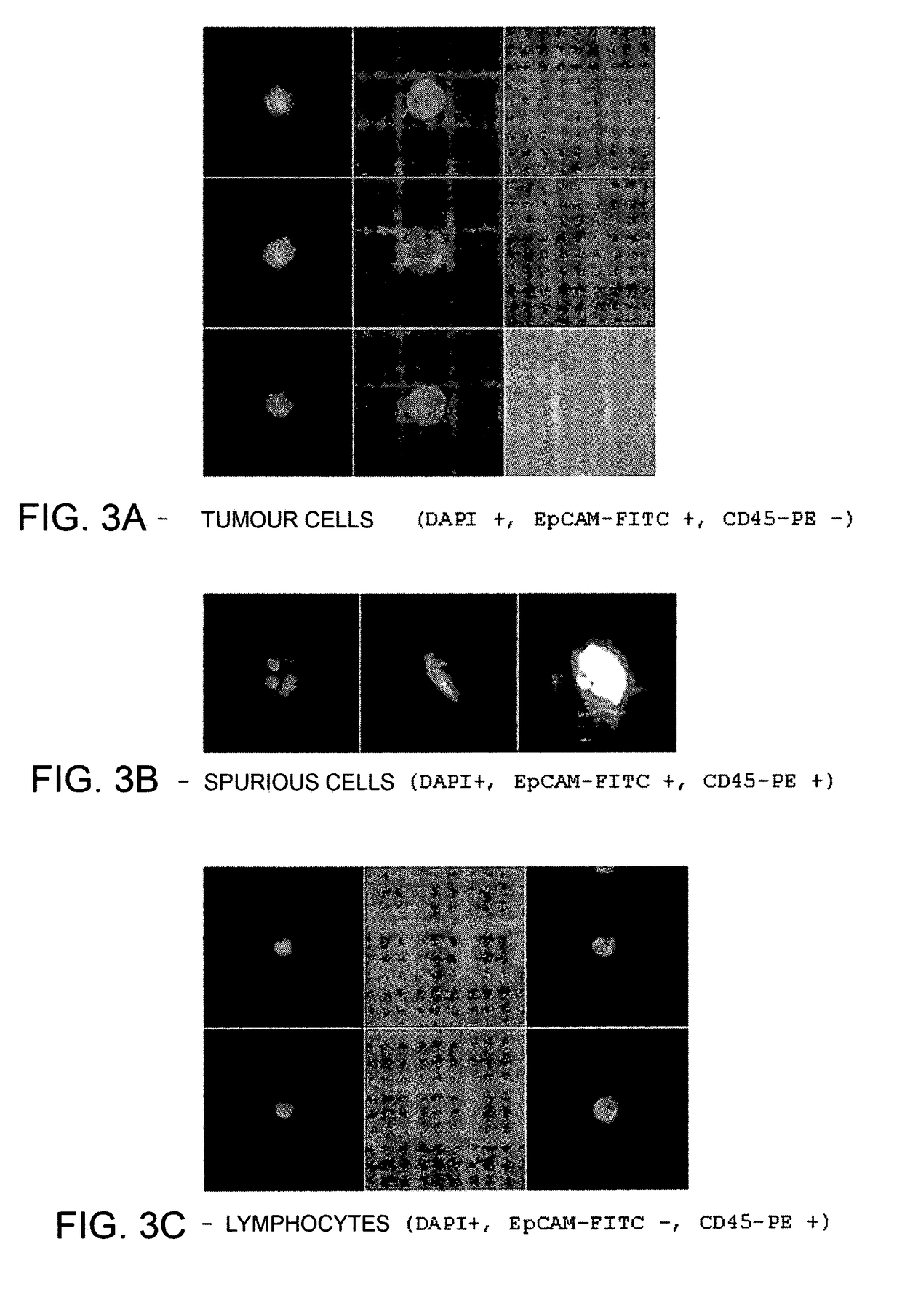

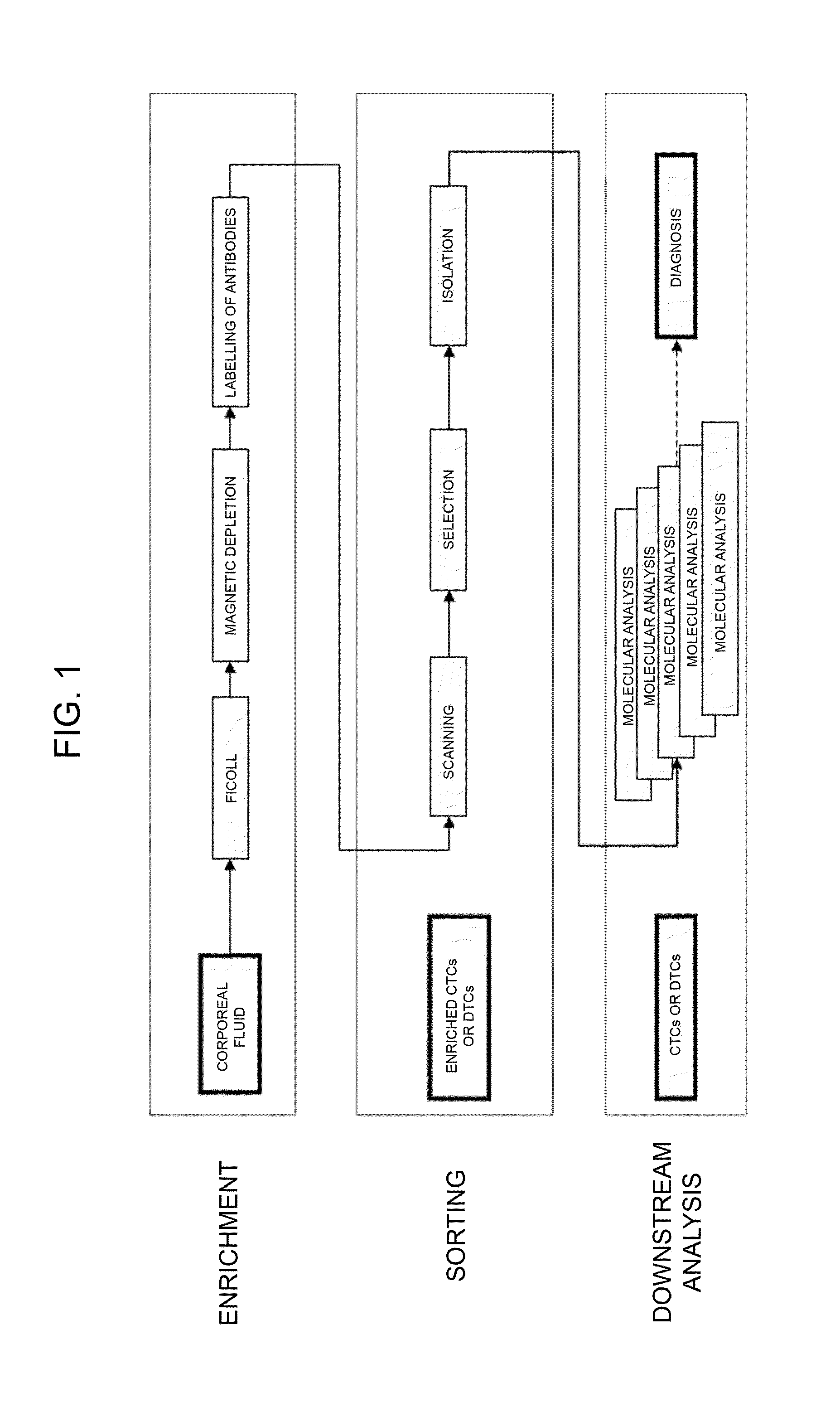

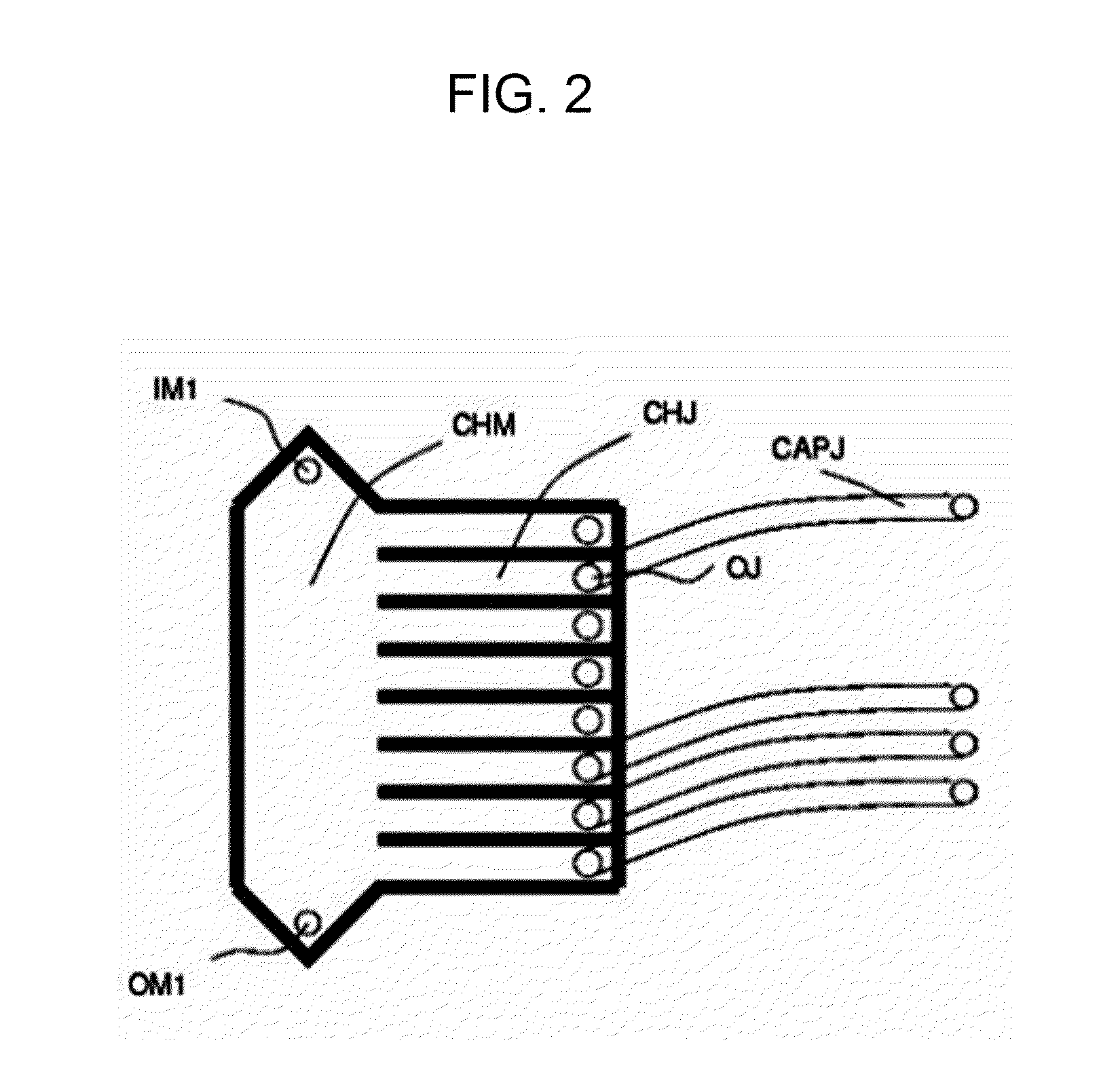

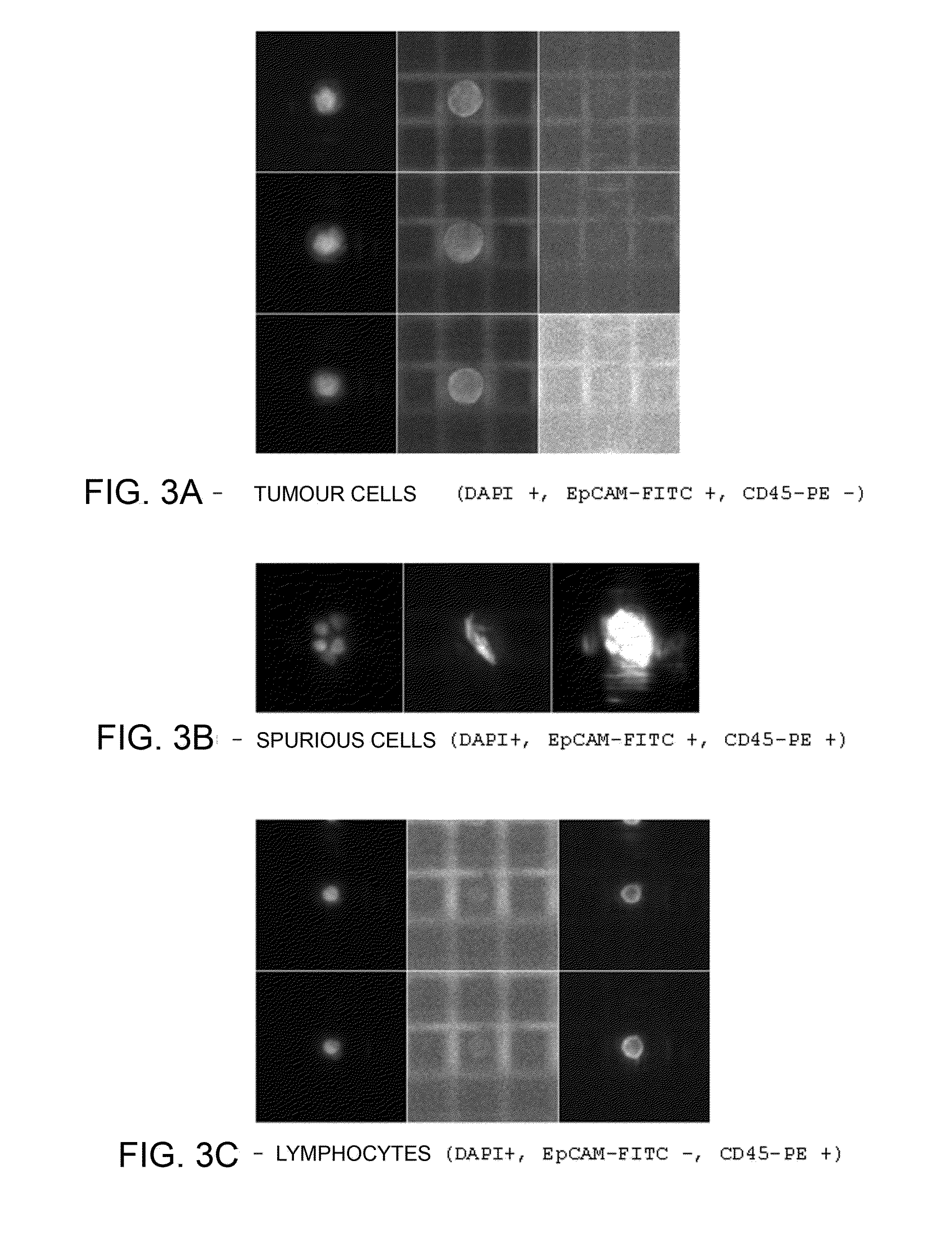

Method for identification, selection and analysis of tumour cells

ActiveUS10234447B2Overcomes drawbackHigh purityDielectrophoresisMicrobiological testing/measurementMolecular analysisDiagnostic specimens

The present invention relates to a method for the diagnosis of tumoural conditions and / or of the corresponding state of advance, wherein a specimen of an organic fluid taken from the patient and having a high probability of containing at least one circulating tumor cell (CTC) or a disseminated tumor cell (CTD) is enriched in a population of CTCs or CTDs. According to the invention, at least one type of CTCs or CTDs is isolated by selecting individually single cells in a microfluidic device so to constitute a diagnostic specimen having a purity of at least 90%. On the specimen thus obtained there is subsequently performed a molecular analysis such as to highlight a characteristic thereof suited to enabling diagnosis.

Owner:MENARINI SILICON BIOSYSTEMS SPA

Method for Identification, Selection and Analysis of Tumour Cells

ActiveUS20150126396A1High purityImprove automationMicrobiological testing/measurementLibrary screeningMolecular analysisBiochemistry

The present invention relates to a method for the diagnosis of tumoural conditions and / or of the corresponding state of advance, wherein a sample from a patient comprising at least one tumour cell is obtained. According to the invention, a purified specimen of the at least one tumour cell is obtained by individually selecting and isolating single cells in a microfluidic device the purified specimen having a purity of at least 90%. On the purified specimen thus obtained there is subsequently performed a molecular analysis such as to highlight a characteristic thereof suited to enabling diagnosis.

Owner:MENARINI SILICON BIOSYSTEMS SPA

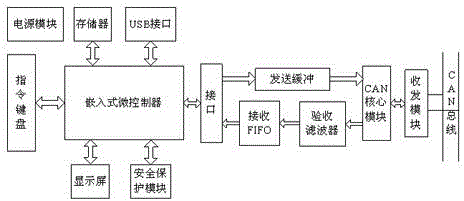

Demonstrator key reaction sensitivity optimization method

InactiveCN104626165AStrong targetingStrong timelinessProgramme-controlled manipulatorKey pressingComputer module

The invention discloses a demonstrator key reaction sensitivity optimization method which includes the steps that an array type keyboard is adopted as a demonstrator keyboard in a demonstrator system, an independent keyboard scanning management chip is selected to reduce keyboard refresh frequency, an I2C bus mode is adopted in the keyboard scanning management chip, and meanwhile, in order to quickly respond to key pressing events in time and automatically eliminate jitters, an interrupt mode is selected to serve as a work mode of the keyboard; a central processor in the demonstrator system is responsible for coordination and management between modules of the system and detection of external interrupt and interrupt processing, and finishes communication tasks with a controller, a CAN bus structure with high anti-interference performance is adopted between the modules, multi-node efficient control is achieved by means of rich message structures, and multi-point real-time communication is achieved through programs in the system. The method is easy, convenient and quick to operate, movement of robots is flexible and accurate, and timeliness is high.

Owner:NANJING PANDA ELECTRONICS +2

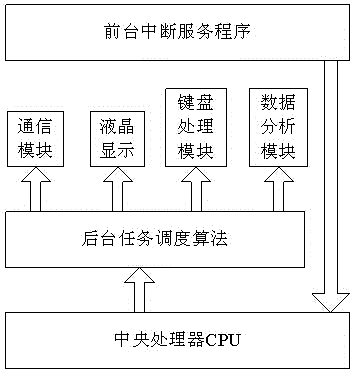

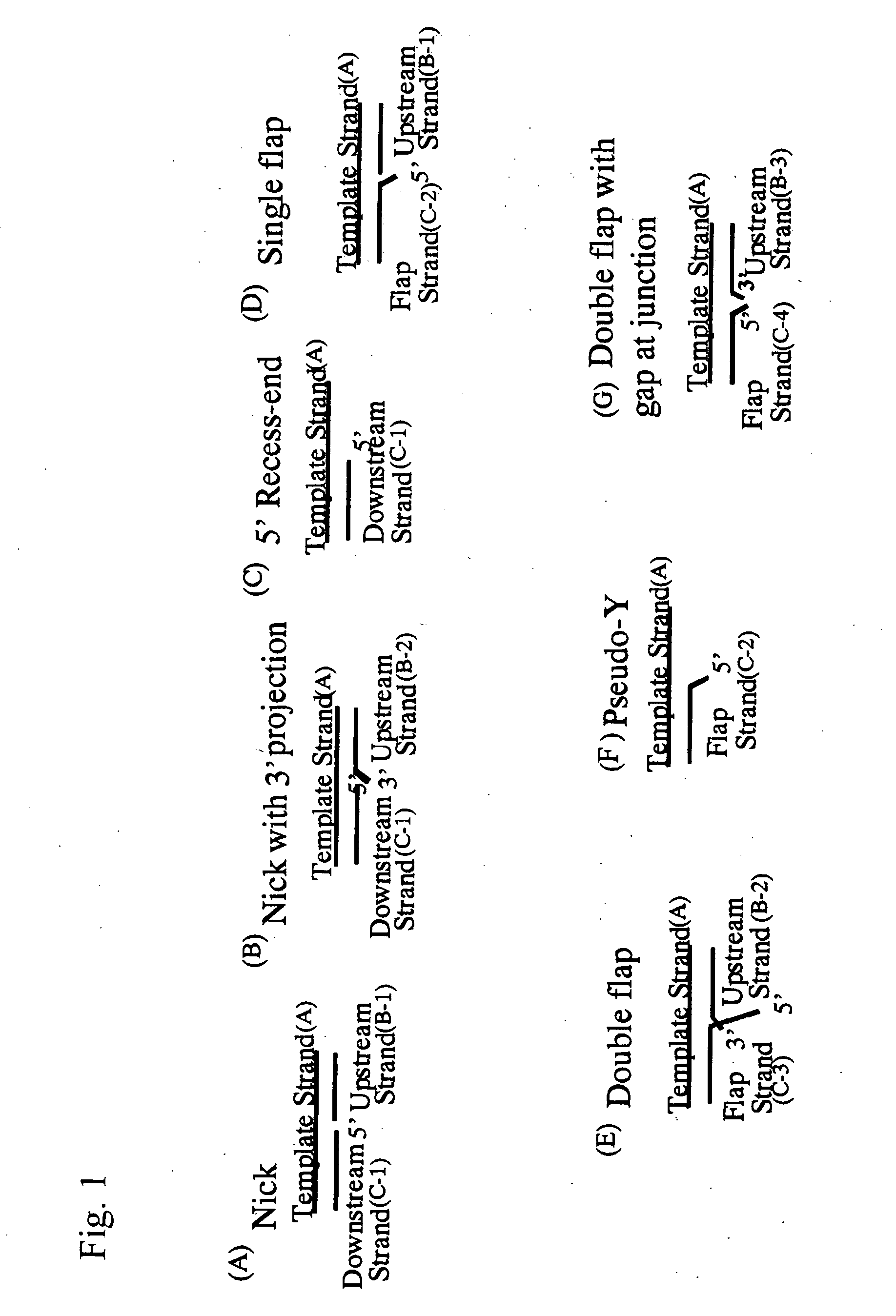

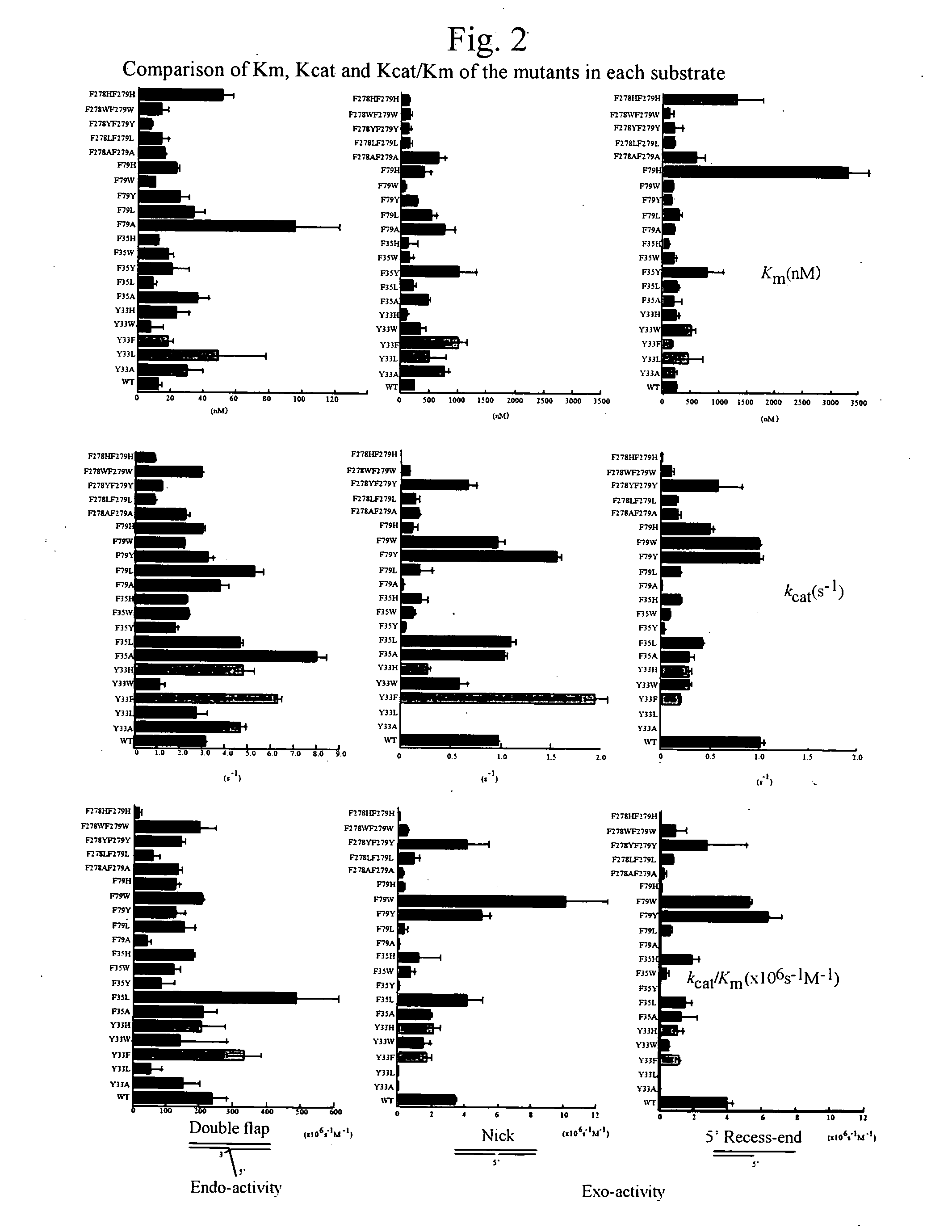

Flap Endonuclease Mutants

InactiveUS20080118922A1Sensitive and accurateBacteriaSugar derivativesBinding siteSubstrate Specificities

A mutation is introduced into the substrate-binding site of flap endonuclease to prepare a mutant with modified substrate specificity. Using the mutant as a reagent for the analysis of genetic polymorphism, the analysis of genetic polymorphism can be performed more accurately, easily and sensitively as compared with conventional methods.

Owner:NAT INST OF ADVANCED IND SCI & TECH

3'-oh unblocked, fast photocleavable terminating nucleotides and methods for nucleic acid sequencing

ActiveUS20130122489A1Efficiently and affordably provideEfficient sequencingSugar derivativesMicrobiological testing/measurementNucleotideNucleic acid sequencing

The present invention relates generally to 3′-OH unblocked nucleotides and nucleosides labeled and unlabeled with 5-methoxy-substituted nitrobenzyl-based photocleavable terminating groups for use in methods and systems related to DNA and RNA sequencing and analysis. These compounds may be used as reversible terminators as they exhibit fast nucleotide incorporation kinetics, single-base termination, high nucleotide selectivity, and rapid terminating group cleavage that results in a naturally occurring nucleotide.

Owner:AGILENT TECH INC

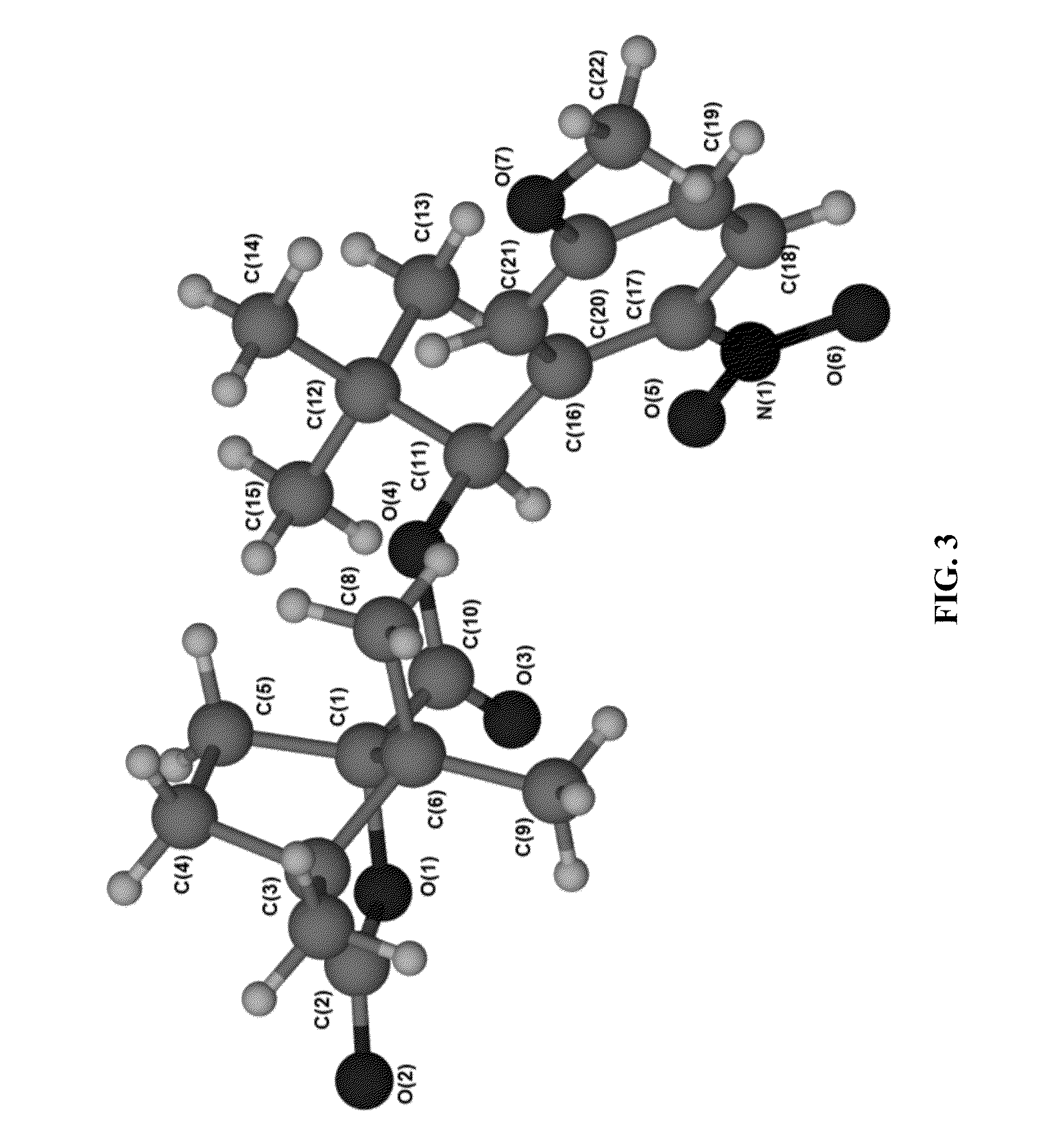

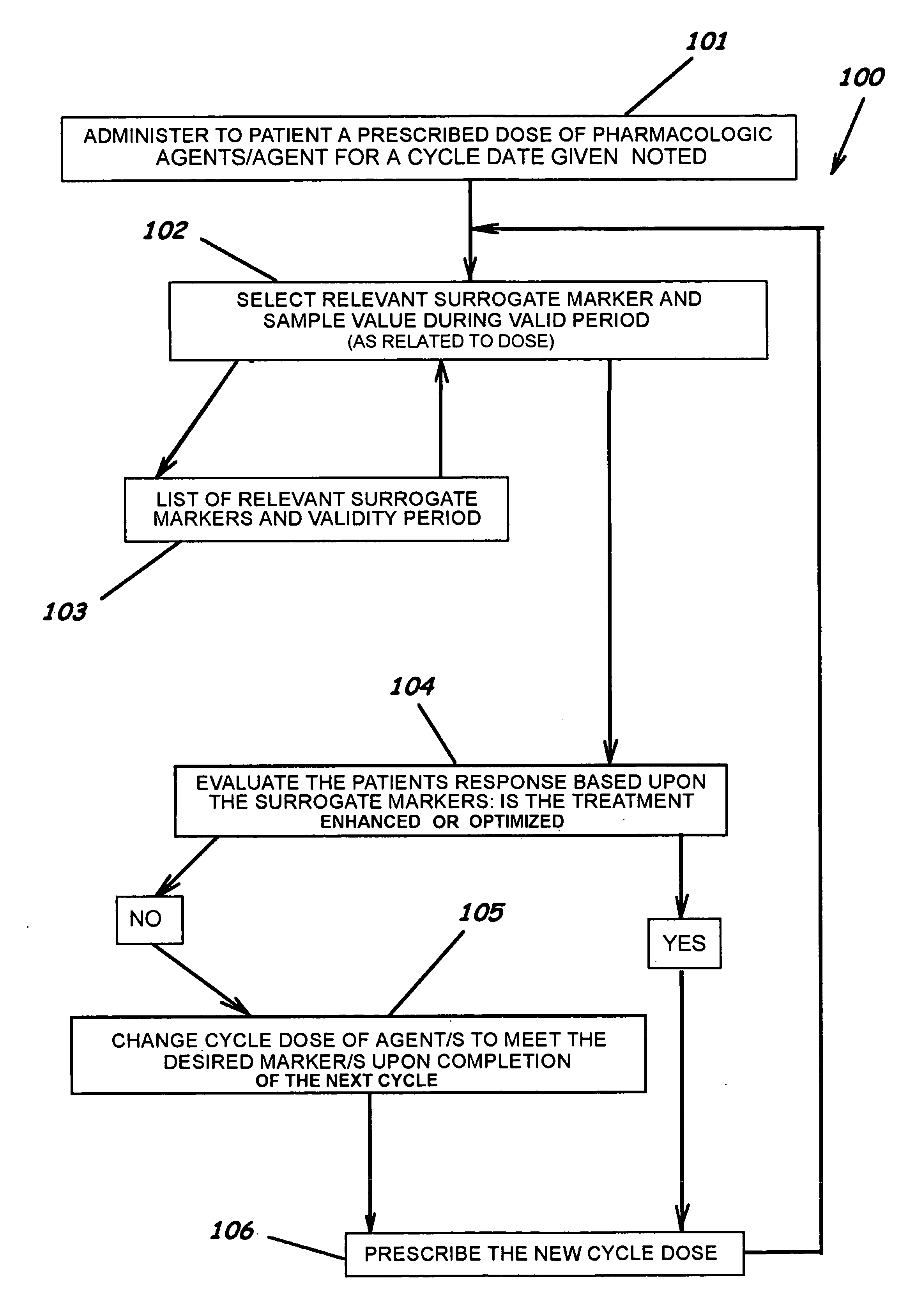

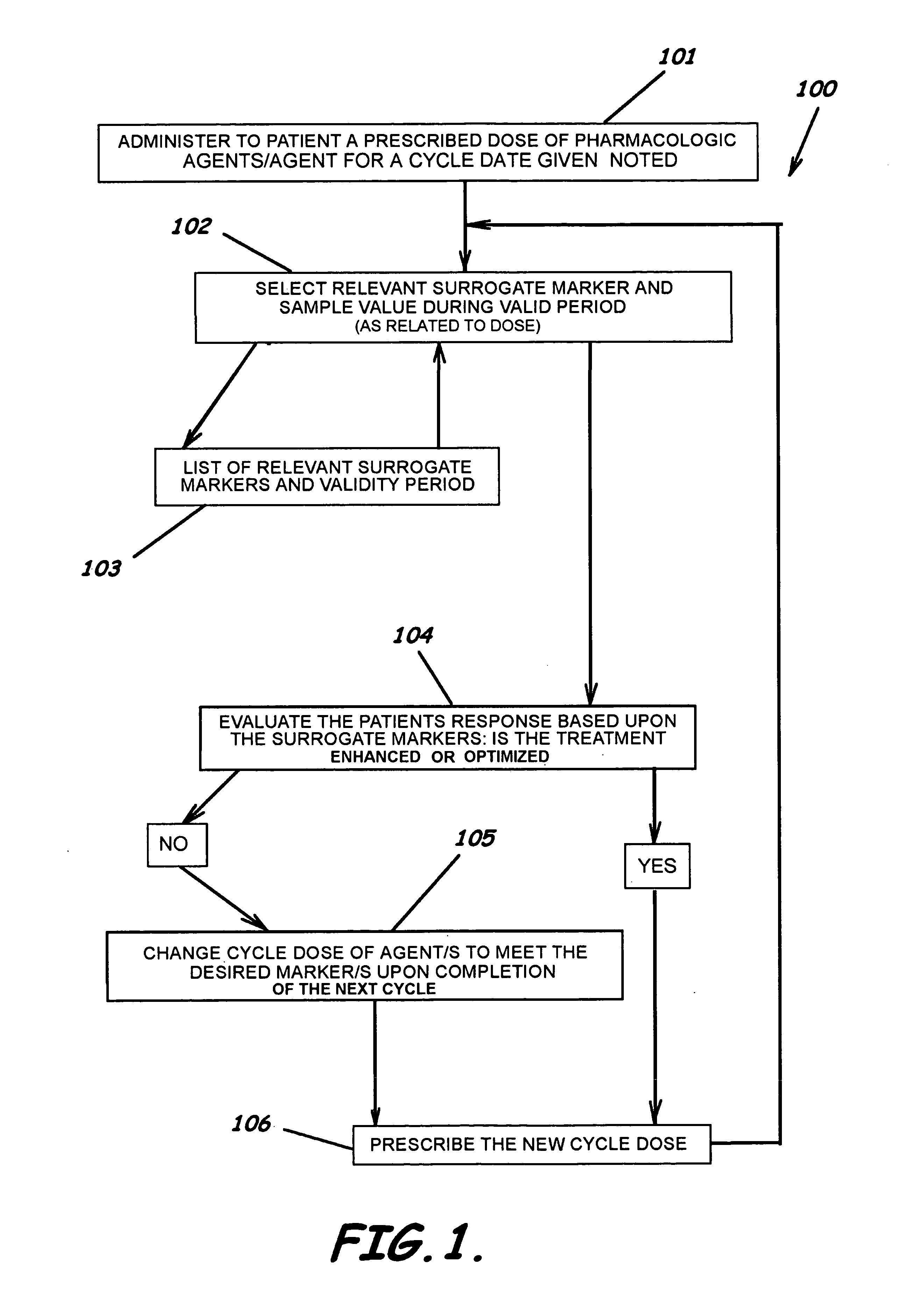

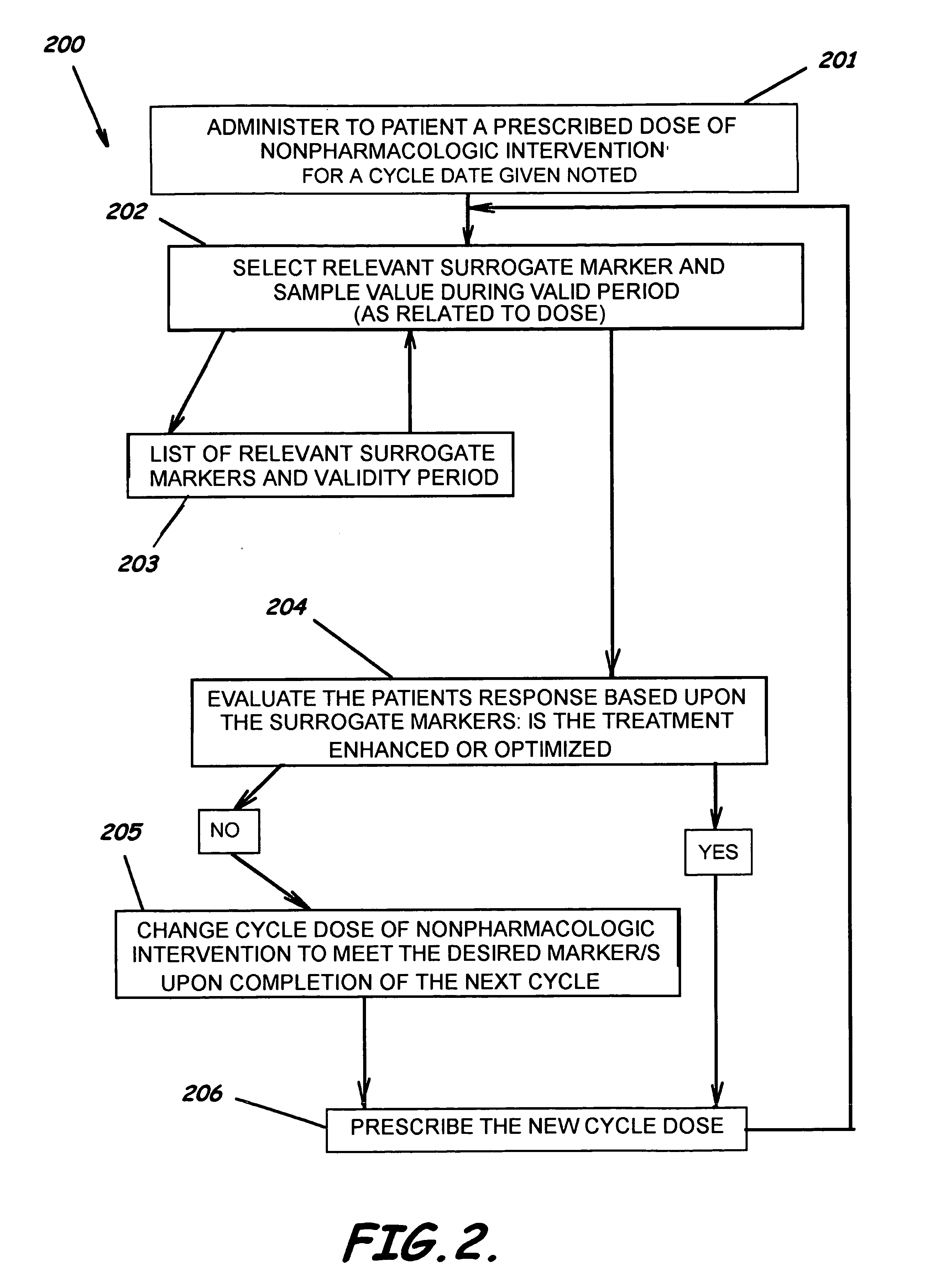

Methods, program products, and systems for single and multi-agent dosing and other related methods

InactiveUS20050154537A1Accurate and appropriate and effectiveGood treatment effectCompounds screening/testingBiocidePsychiatry

Methods, program product, and systems for single and multi-agent dosing are provided. An embodiment of a method for revising a cycle dose of at least one agent for a patient receiving a single or multi-agent therapy includes accepting as a first input the patient's cycle dose(s) of the at least one agent, accepting as a second input determination of the relevancy of at least one surrogate marker indicating a pharmacologic response of the patient and determining a revised dose of the at least one agent. Embodiments of systems and program products are also provided for use in calculating revised dose of at least one agent.

Owner:KUTZKO JOHN D +1

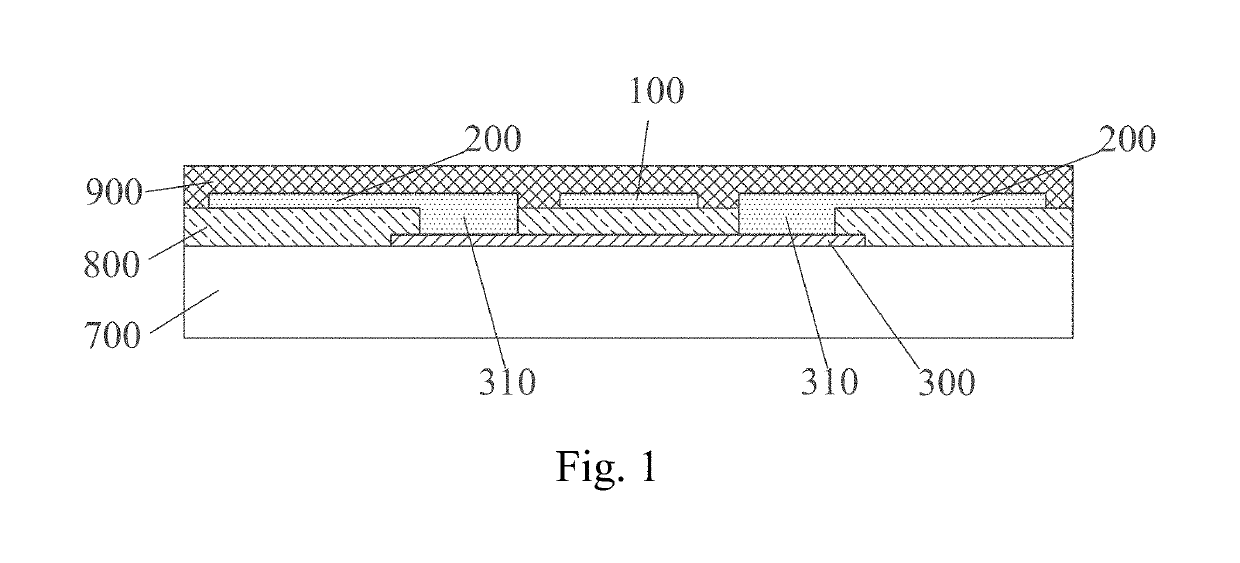

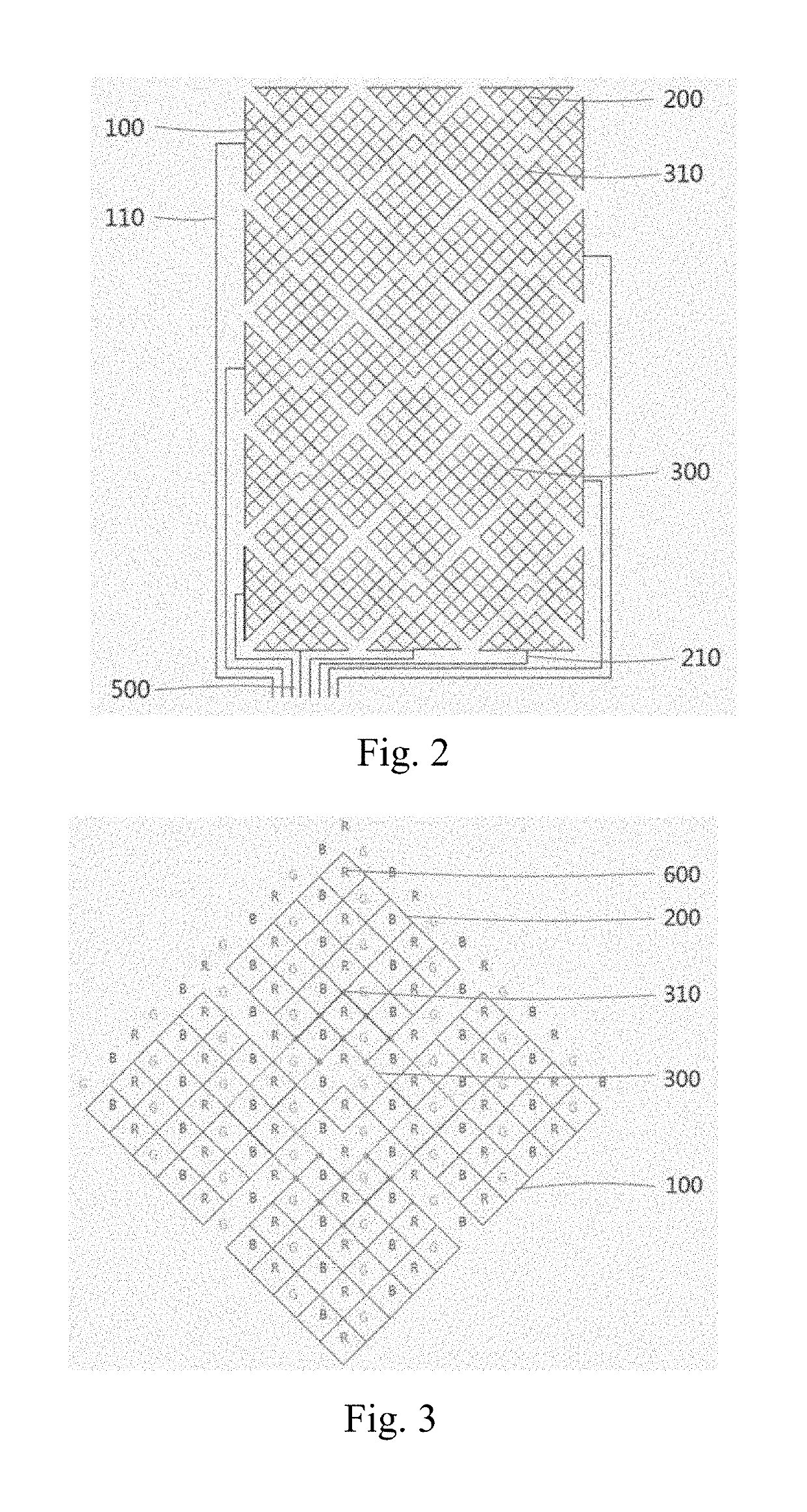

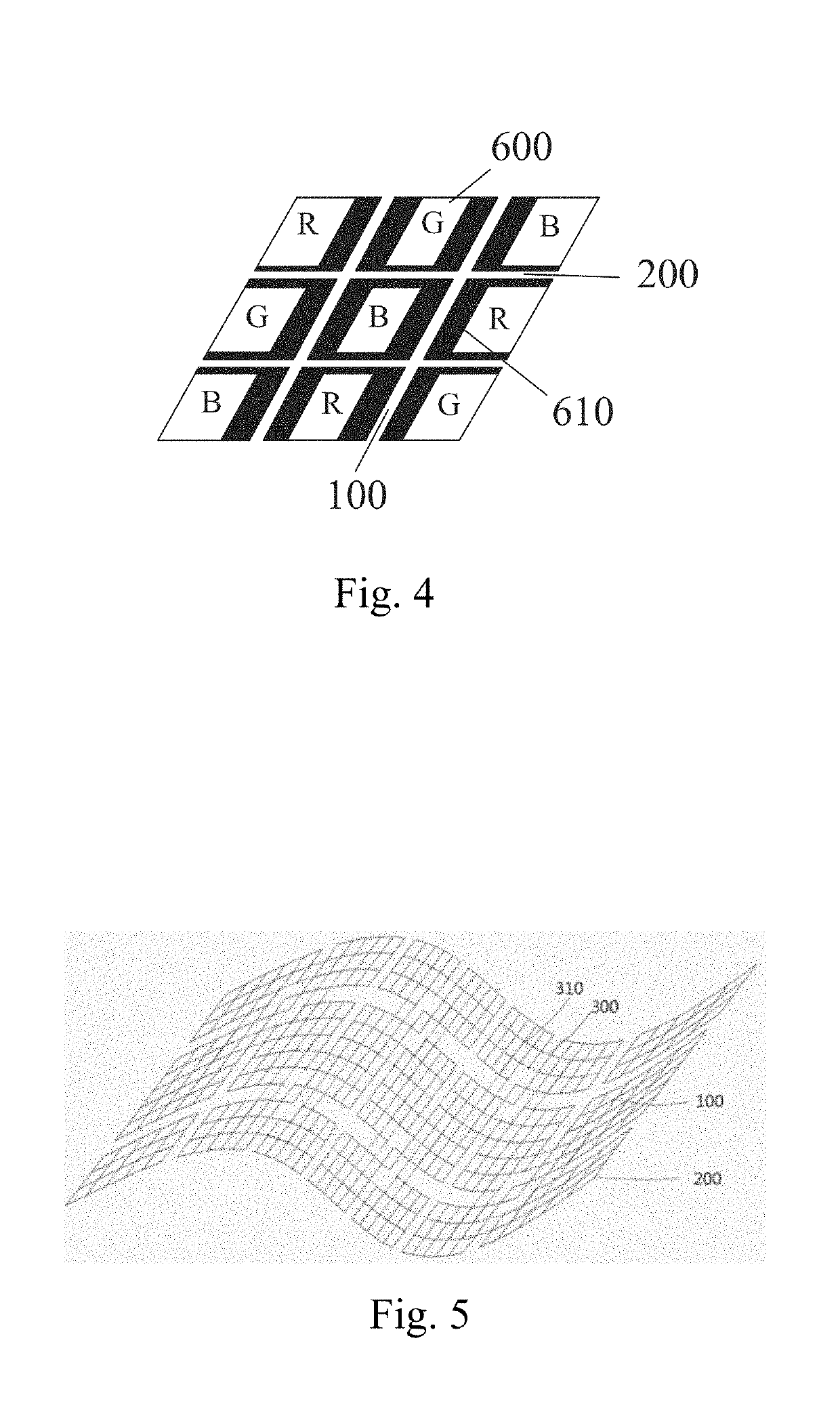

Metal mesh touch display structure and manufacturing method thereof

InactiveUS20190317631A1Increase touch resolutionSensitive and preciseSolid-state devicesNon-linear opticsGrid patternDisplay device

The invention provides a metal mesh touch display structure. The metal mesh touch display structure includes: a display device and a metal mesh structure; the metal mesh structure includes a bridge point, a first protective layer, first and second metal wires, and a second protection layer; the first and second metal wires are mutually insulated, the first metal wire forms a grid pattern corresponding to the shape of the first direction electrode of mutual capacitance, the second metal wire forms a grid pattern corresponding to the shape of the second direction electrode of mutual capacitance The first protective layer is provided with a via corresponding to the bridge point, and the second metal wire is connected to the bridge point through the via; the grid of the grid pattern is formed on light-shielding layer between the pixels of the display device. The invention also provides a corresponding manufacturing method.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

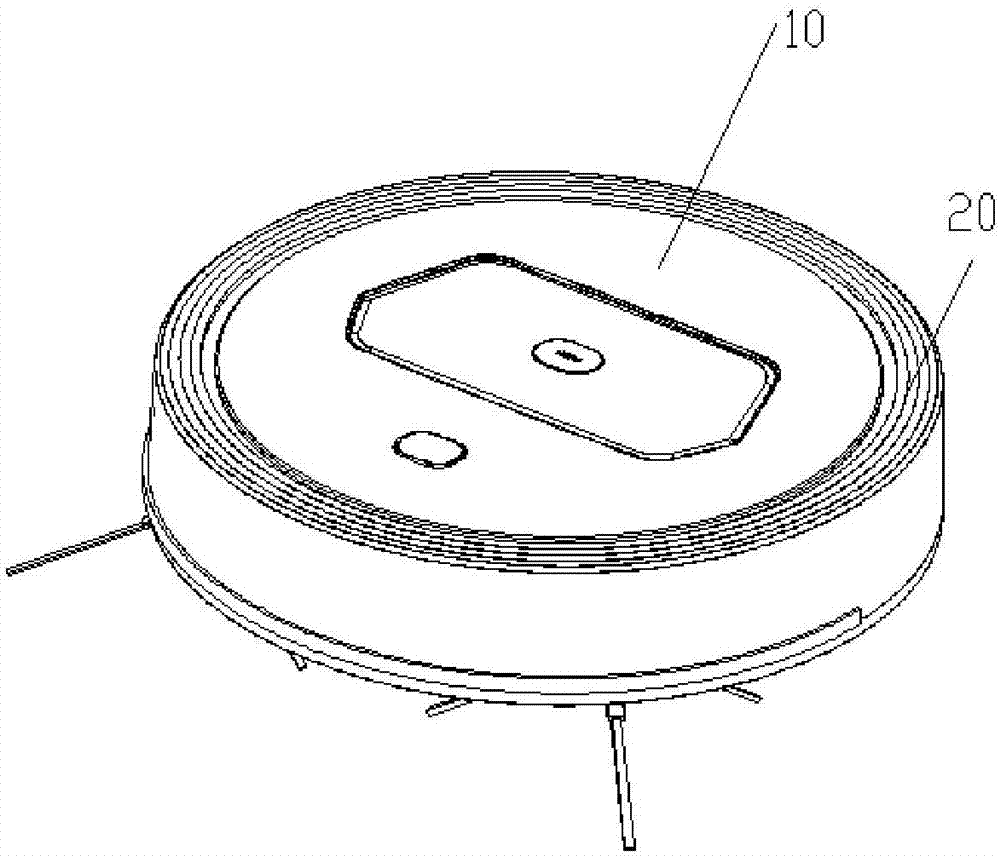

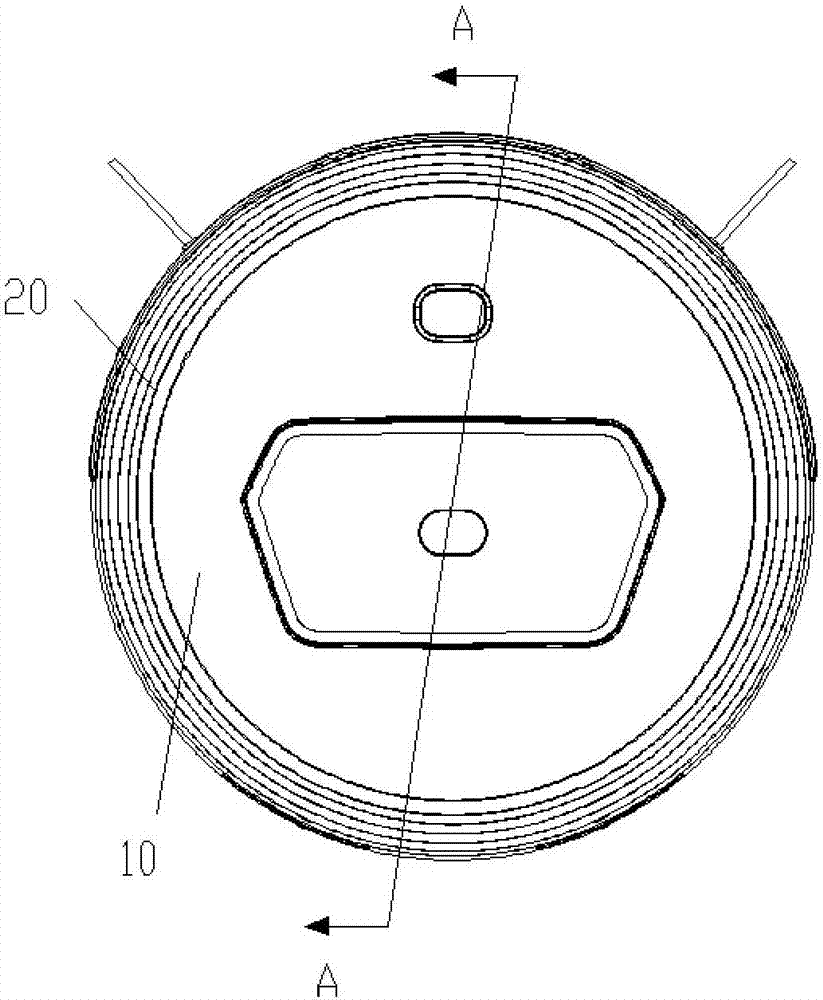

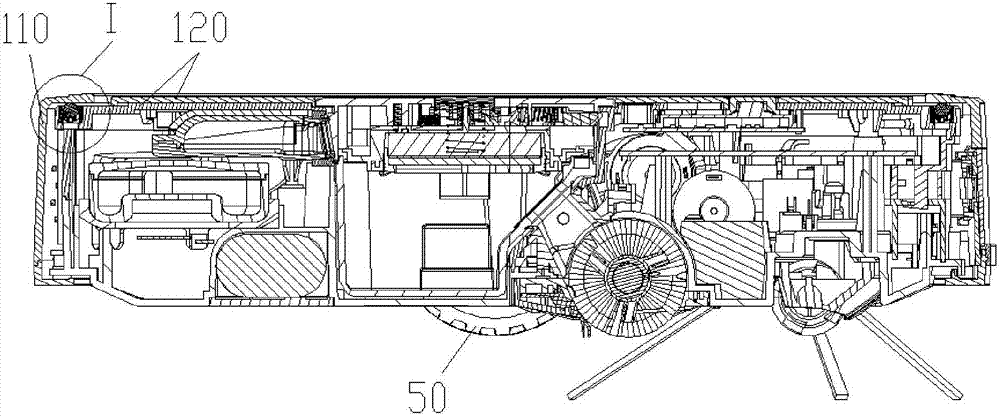

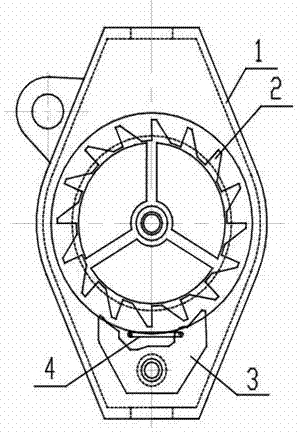

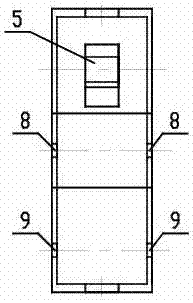

Mobile robot

PendingCN107336267AReduce sensing dead zoneSensitive and accurateManipulatorControl systemSimulation

The invention discloses a mobile robot. The mobile robot comprises a robot body and a collision sensing device, the robot body further comprises a control system, and the collision sensing device comprises a device shell and one or more inductive switches; the device shell at least surrounds the robot body for one circle, when the device shell is collided, one or more inductive switches are triggered and send signals, and the control system controls the mobile robot according to the signals; the inductive switches are arranged on the robot body and / or the device shell and used for sensing the collision condition of the collision sensing device. The mobile robot can sense the collision of the mobile robot in multiple directions.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

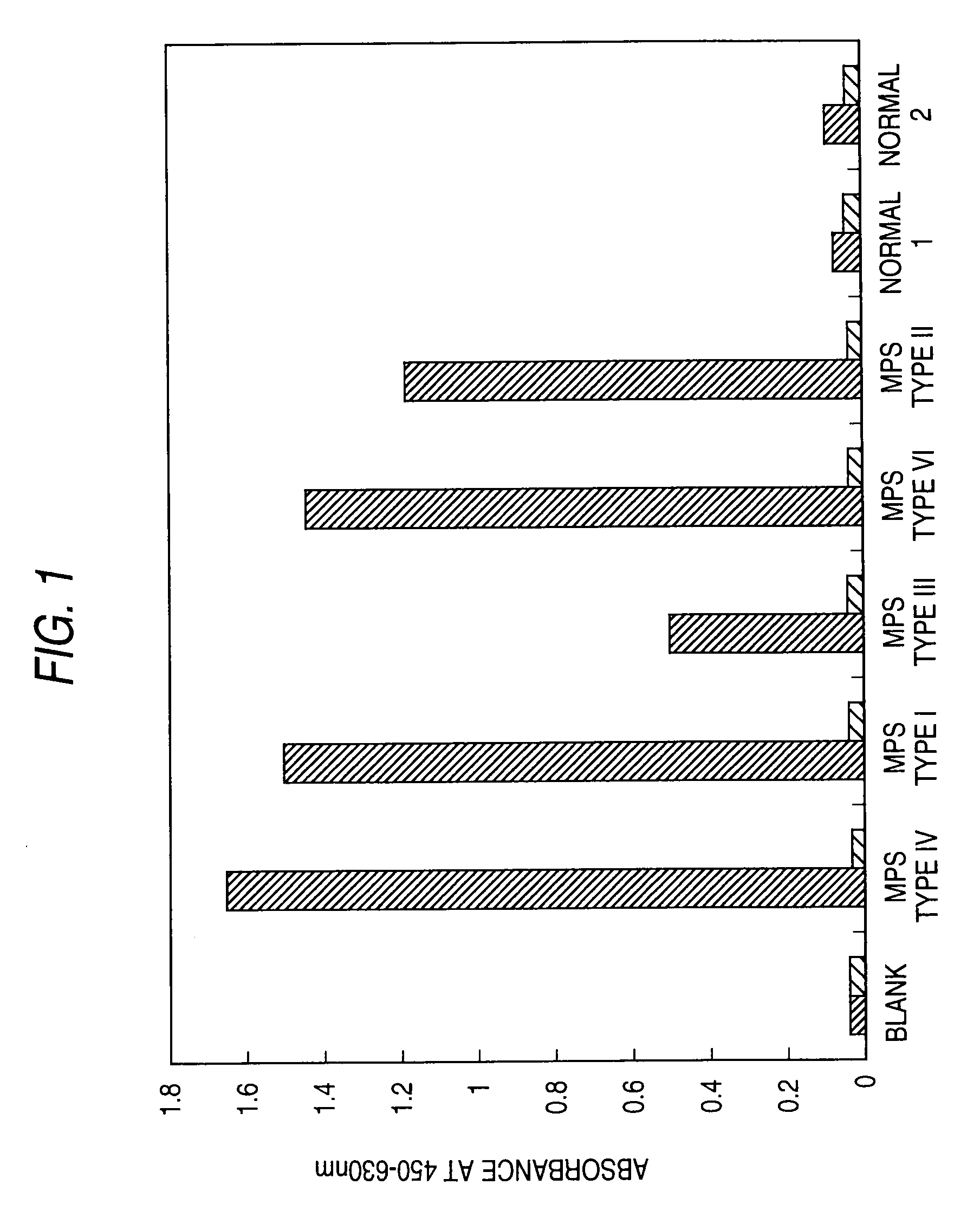

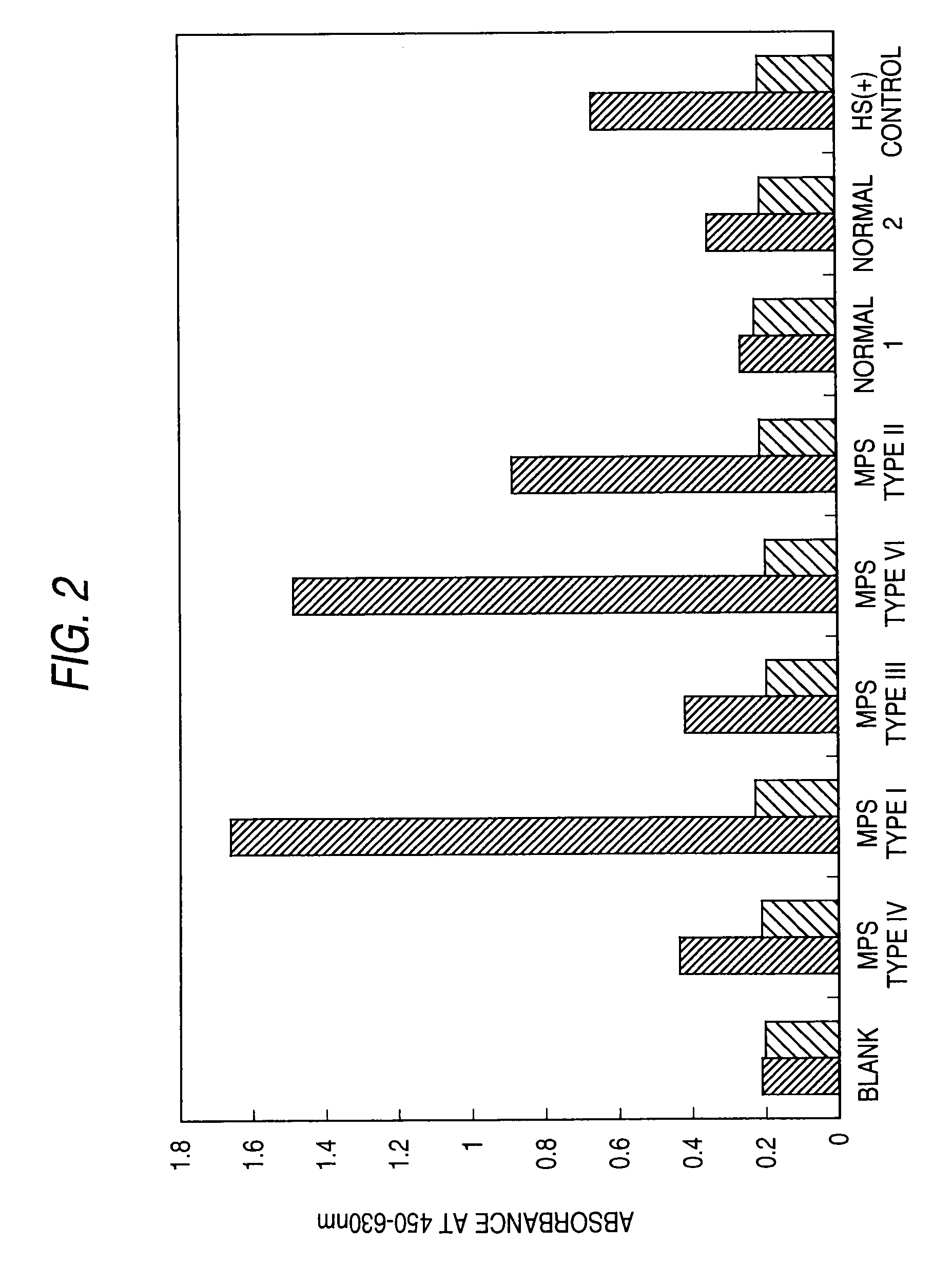

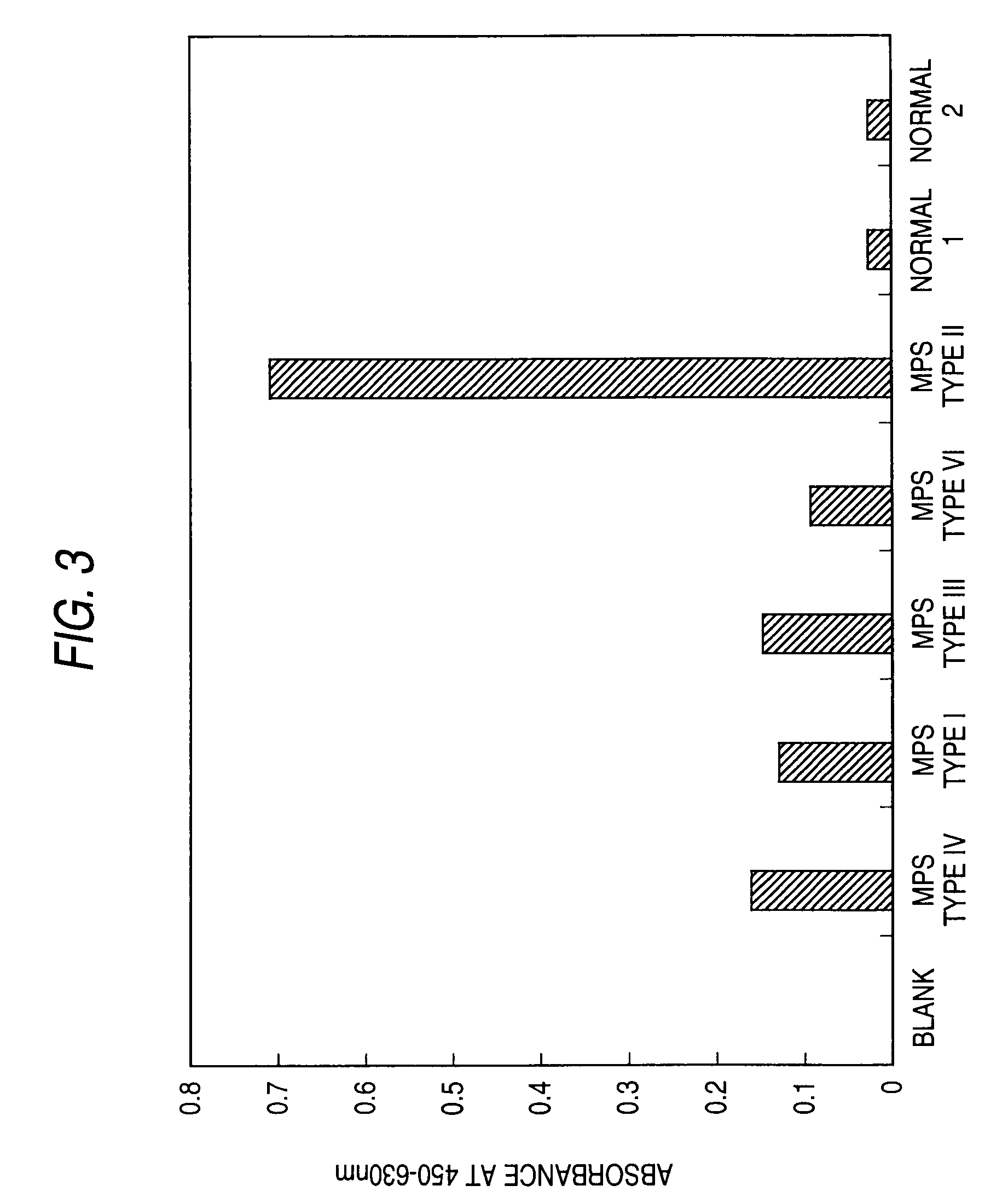

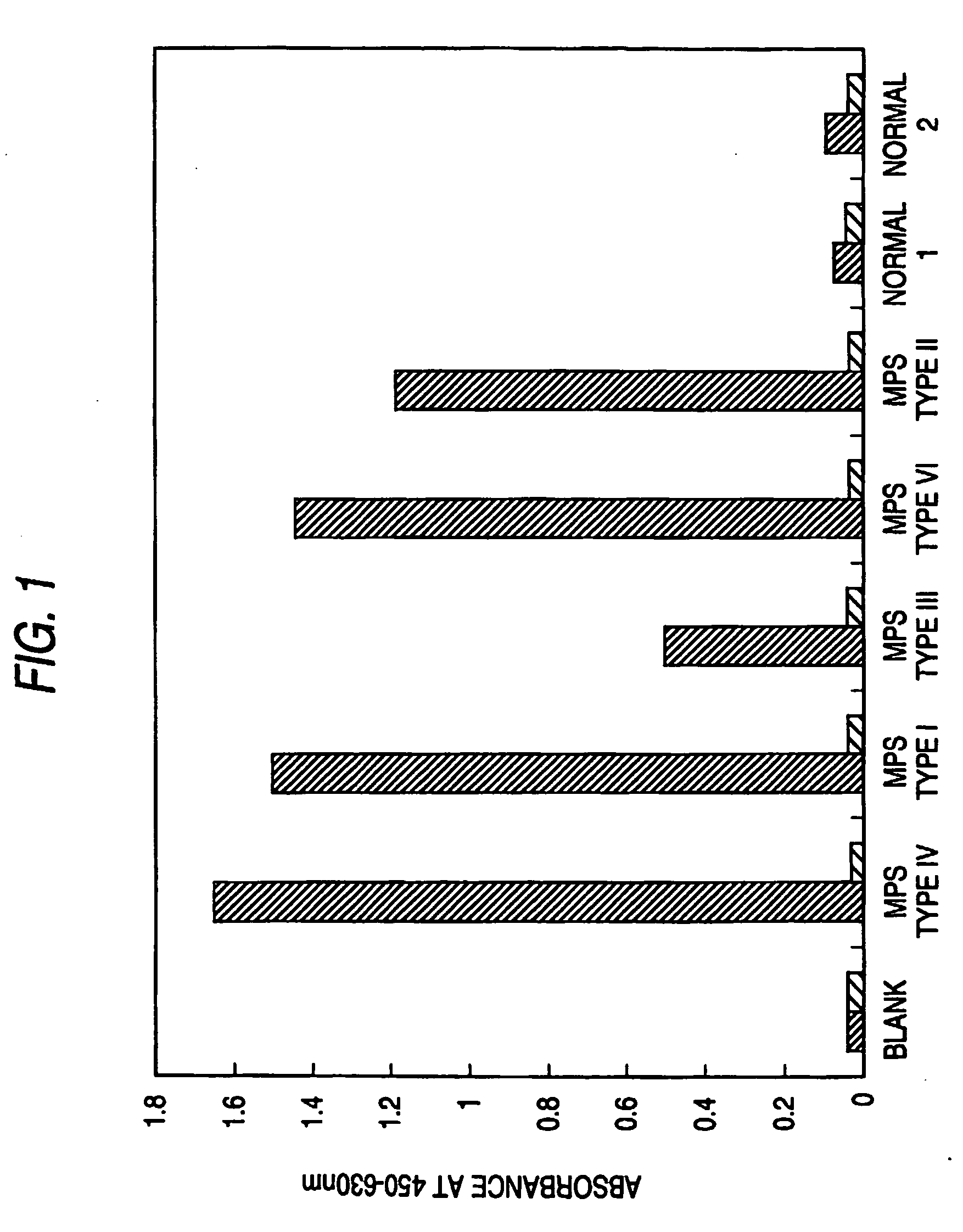

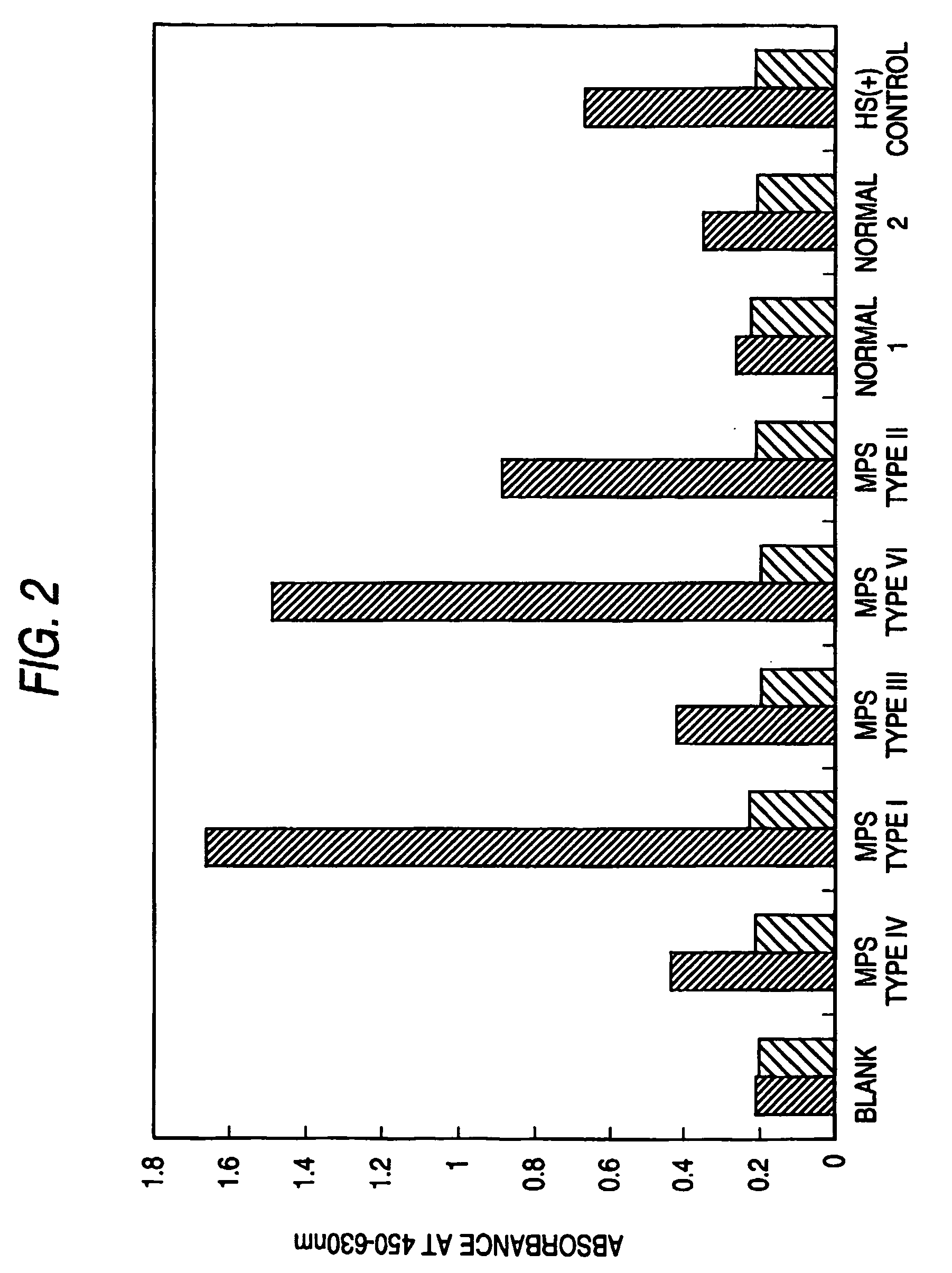

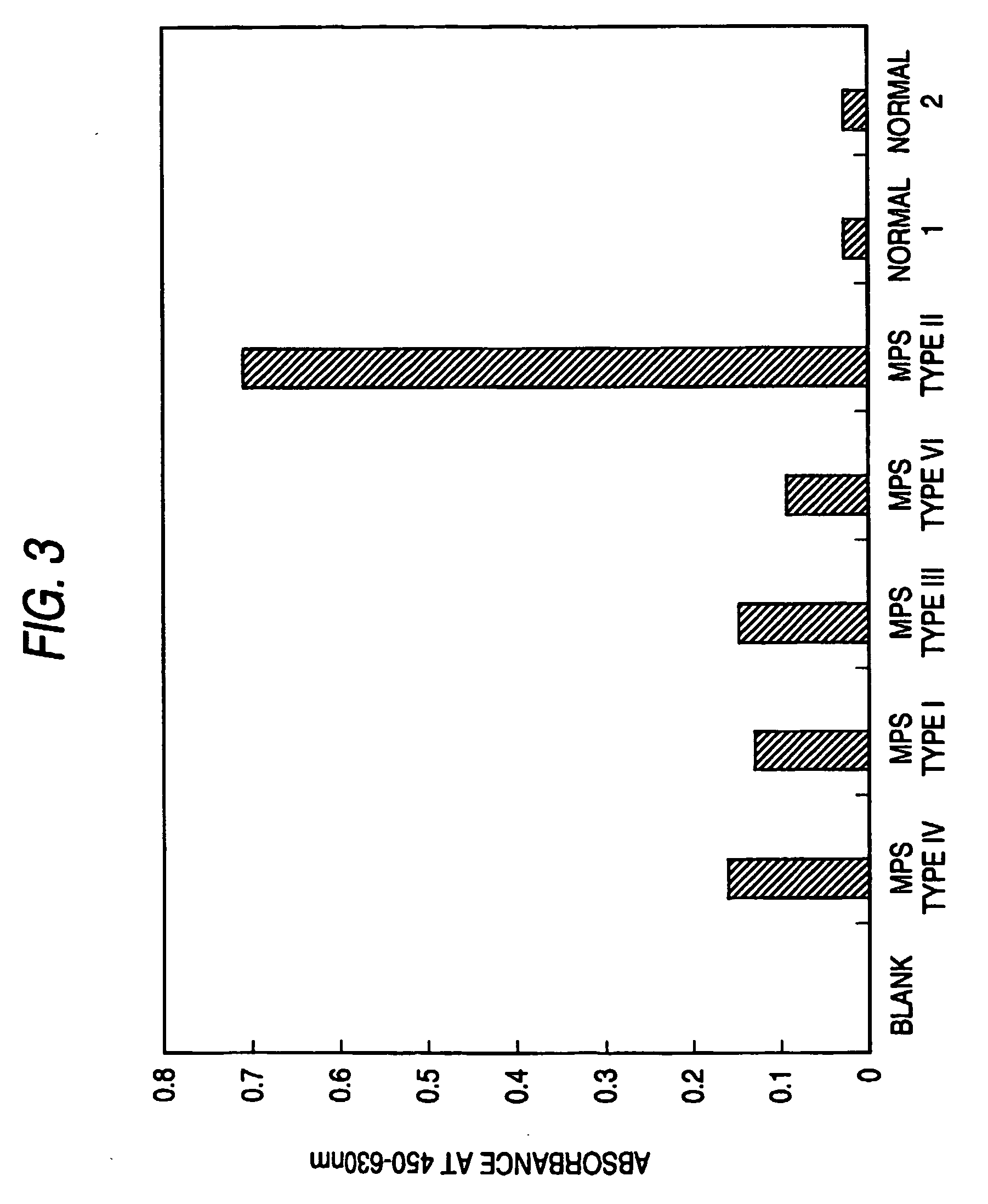

Method for detecting lysosomal storage diseases

InactiveUS20090280505A1Sensitive and accuratePerformed quickly and convenientlyMicrobiological testing/measurementDisease diagnosisLysosomeBinding site

A method for detecting lysosomal storage diseases including the steps of performing an assay for a single species of glycosaminoglycan contained in a specimen and correlating results of the assay with lysosomal storage diseases. A body fluid such as urine or blood can be employed as a specimen. The assay can be performed by use of a polypeptide that is capable of specifically binding to a glycosaminoglycan-containing molecule. The polypeptide may be an antibody, or a polypeptide having an antigen-binding site of an antibody.

Owner:SEIKAGAKU KOGYO CO LTD +1

Force application-adjustable manipulator and robot using same

ActiveCN107283396AAvoid damagePlay a buffer roleProgramme-controlled manipulatorJointsRobotic armEngineering

The invention discloses a force application-adjustable manipulator and robot using the same. The manipulator comprises a mechanical arm and a mechanical wrist; the mechanical wrist comprises a wrist shaft and a gripper; the gripper is mounted at one end of the wrist shaft; the other end of the wrist shaft is movably connected with one end of the mechanical arm; the mechanical arm comprises a trigger baffle plate; one side of the trigger baffle plate is connected with one end of the mechanical arm; and the mechanical wrist comprises a trigger sensor, a sensor mounting base, a force application spring and a force application adjusting nut. The force application-adjustable manipulator and the robot using the same can adjust the pressure of the gripper to contacted objects through the force application spring and the force application adjusting nut, so that the force application allowing range of the mechanical wrist can be adjusted according to the pressure requirements of different contacted objects.

Owner:FOSHAN HECAI TECH SERVICE +1

Protection device used for electric transmission line tower climbing operation

InactiveCN107497073AGuaranteed safe operationEliminate psychological fearSafety beltsTowerBuilding construction

The invention relates to a protection device used for electric transmission line tower climbing operation, is particularly suitable for being used in overhead transmission line construction, interruption maintenance, operation with power uninterrupted and other tower climbing operation and belongs to the technical field of electric transmission line pole and tower field operation tools. The protection device comprises a safety rope with one end being hung on the human body, a plurality of short tying ropes which are arranged at intervals in the height direction of an electric transmission line pole and tower, and a differential speed blocking device which is used for clamping the safety rope which rapidly rotates anticlockwise. The differential speed blocking device is provided with a wire inlet which is used for penetrating the safety rope, a wire outlet and a clamping mechanism. The protection device is simple in structure, convenient to use, safe, reliable, wide in application range and high in operation efficiency.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

Inductive sensor separated buoy applicable to viscous liquid level measurement

ActiveCN109163784AReduce frictionAvoid stickingLevel indicators by floatsViscous liquidLevel measurement

The invention discloses an inductive sensor separated buoy applicable to viscous liquid level measurement. Through separated design of a sleeving ring and a floater, gaps between the buoy and a measurement rod are increased, a superposition area is reduced, when the buoy and the measurement rod carry out relative motion in viscous liquid, viscous force is reduced, and the motion is free and smooth.

Owner:南京西巨电子技术有限公司

Method for detecting lysosomal storage diseases

InactiveUS20050221407A1Accurate and sensitive methodPerformed quickly and convenientlyDisease diagnosisBiological testingBinding siteLysosome

A method for detecting lysosomal storage diseases including the steps of performing an assay for a single species of glycosaminoglycan contained in a specimen and correlating results of the assay with lysosomal storage diseases. A body fluid such as urine or blood can be employed as a specimen. The assay can be performed by use of a polypeptide that is capable of specifically binding to a glycosaminoglycan-containing molecule. The polypeptide may be an antibody, or a polypeptide having an antigen-binding site of an antibody.

Owner:SAINT LOUIS UNIVERSITY +1

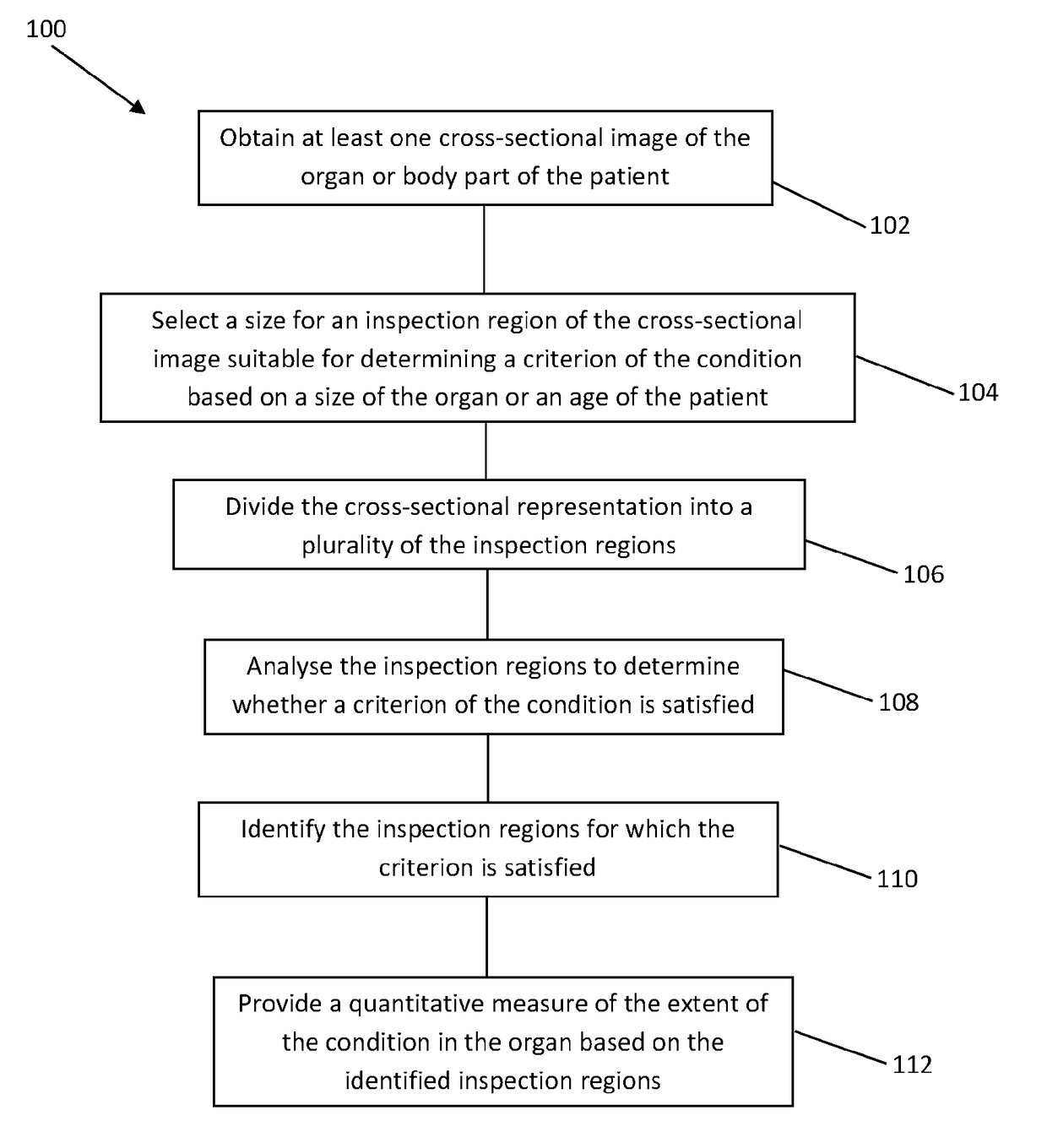

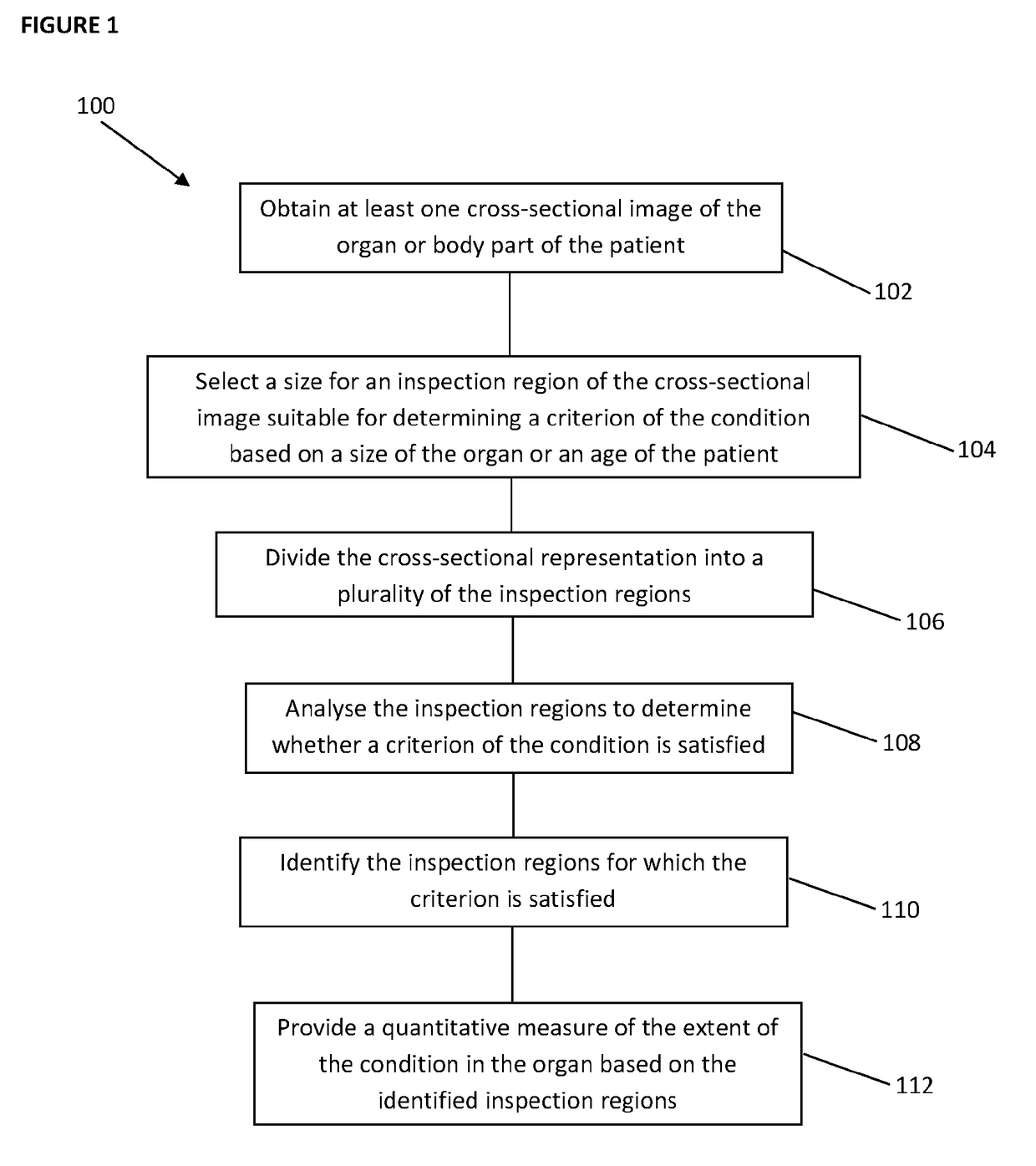

A Method of Analysing an Image for Assessing a Condition of an Organ of a Patient

InactiveUS20180137621A1Sensitive and accurateImprove spatial resolutionImage enhancementImage analysisImage resolutionSpace resolution

A method is disclosed for analysing an image to assess a condition of an organ of a patient represented in the image. The method includes initially selecting a spatial resolution for an inspection matrix having a number of inspection regions each delimiting a part of the image. The inspection matrix is applied to the image and the part of the image within each of the inspection regions is analysed to determine a condition thereof. The condition is compared with a predetermined criterion and, if the condition is deemed to satisfy the criterion, the inspection region is identified, e.g. by annotating it with a colour. Finally a quantitative measure of an extent of the condition in the image is provided that is based on a number of the identified or annotated inspection regions.

Owner:ERASMUS UNIV MEDICAL CENT ROTTERDAM ERASMUS MC +1

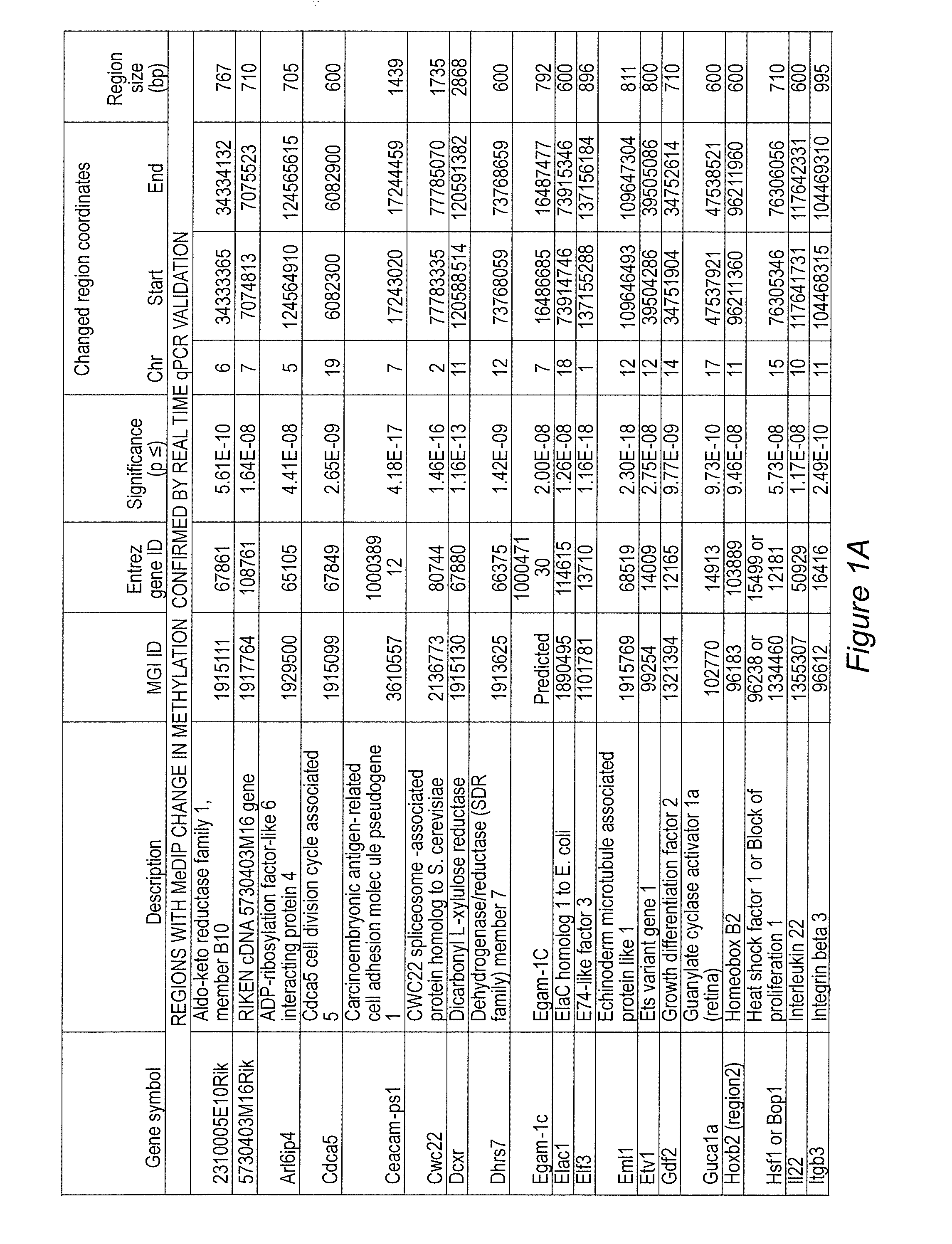

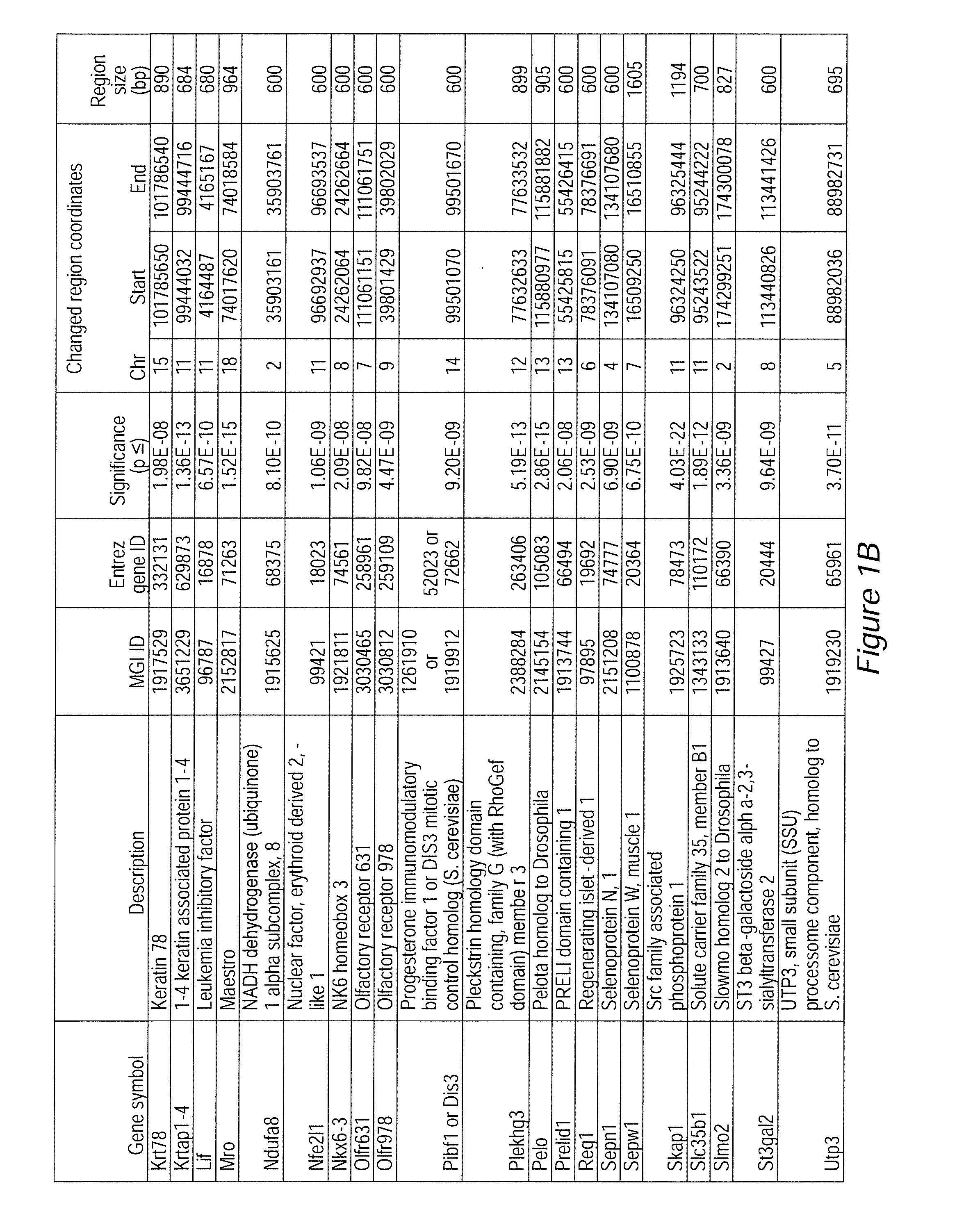

Genomic features associated with epigenetic control regions and transgenerational inheritance of epimutations

ActiveUS20130226468A1Increased and decreased in DNA methylationSensitive and accurateMicrobiological testing/measurementProteomicsEpigenetic ProfileGenome

CpG densities and sequence motifs that are characteristic of regions of DNA associated with epimutations and control of epimutations are provided. Such regions include, within approximately 400 (or fewer) base pairs, at least one, usually two, and preferably all three of the following features: i) a CpG density of 15% or less; ii) the presence of the sequence motif ATTTGTTTTTTCTTTTnT (SEQ ID NO: 1) where n is A, T, C or G, and statistically relevant variants thereof; and iii) the presence of the sequence motif GGGGGnGGGG (SEQ ID NO: 2), where n is A, T, C or G, and statistically relevant variants thereof.

Owner:WASHINGTON STATE UNIVERSITY

Compositions and methods for early pregnancy diagnosis

Disclosed are antibodies and methods for detecting pregnancy in an animal. In certain aspects antibodies used binds immunologically to at least two PAGs selected from PAG4, PAG6, PAG9, PAG16, PAG17, PAG19, PAG20 and PAG21. Antibody encoding nucleic acids are also provided, as are kits, methods of use and additional antibody related compositions.

Owner:MONSANTO TECH LLC +1

Calibration verification for optical particle analyzers

ActiveUS11181455B2Increase probabilitySensitive and accurateLaser detailsParticle size analysisSignal waveCollection system

Provided are particle analyzers and related methods for verifying calibration status of the particle analyzer. The method includes the steps of providing an optical particle analyzer and modulating a power applied to a source of EMR. The method includes the steps of, in response to the modulating step, inducing a detector signal waveform and analyzing the detector signal waveform to determine a value of at least one diagnostic parameter associated with one or more of the source of EMR, an optical assembly, a chamber, a detector, and an optical collection system of the optical particle analyzer. The method includes the step of determining a calibration status of the optical particle analyzer based on the one or more determined values of the at least one diagnostic parameter.

Owner:PARTICLE MEASURING SYST

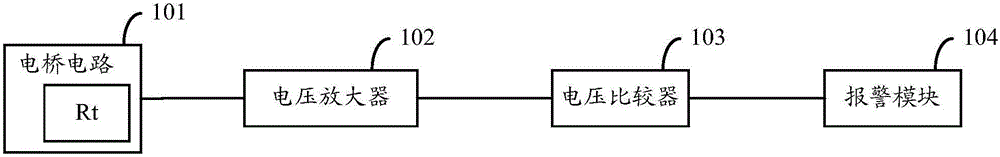

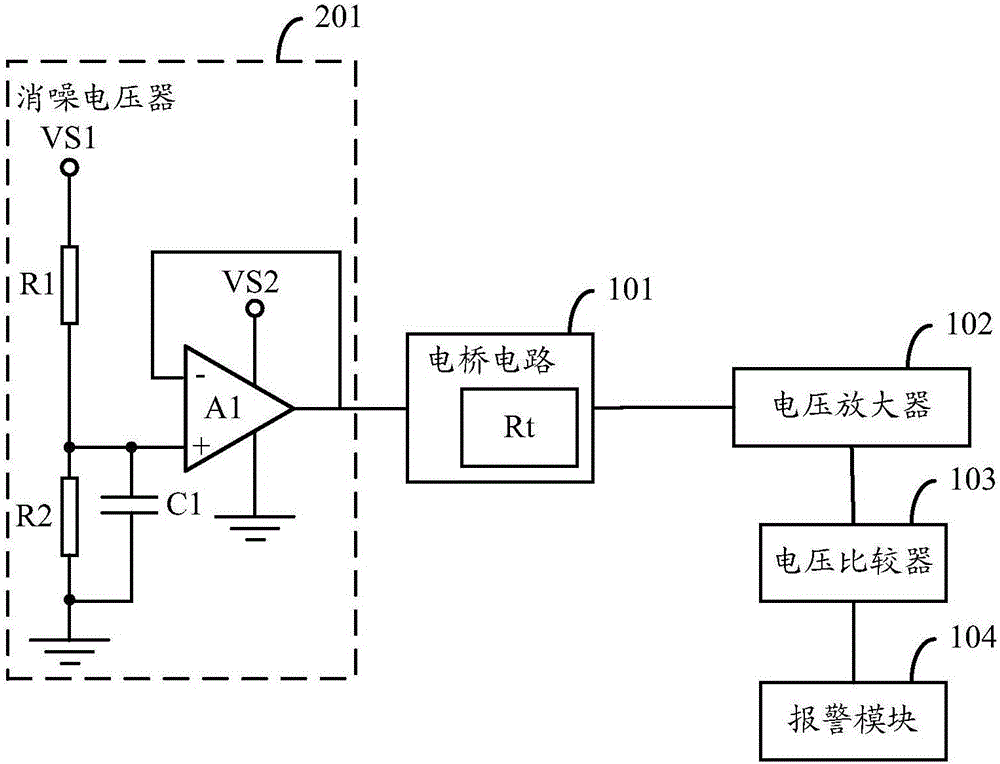

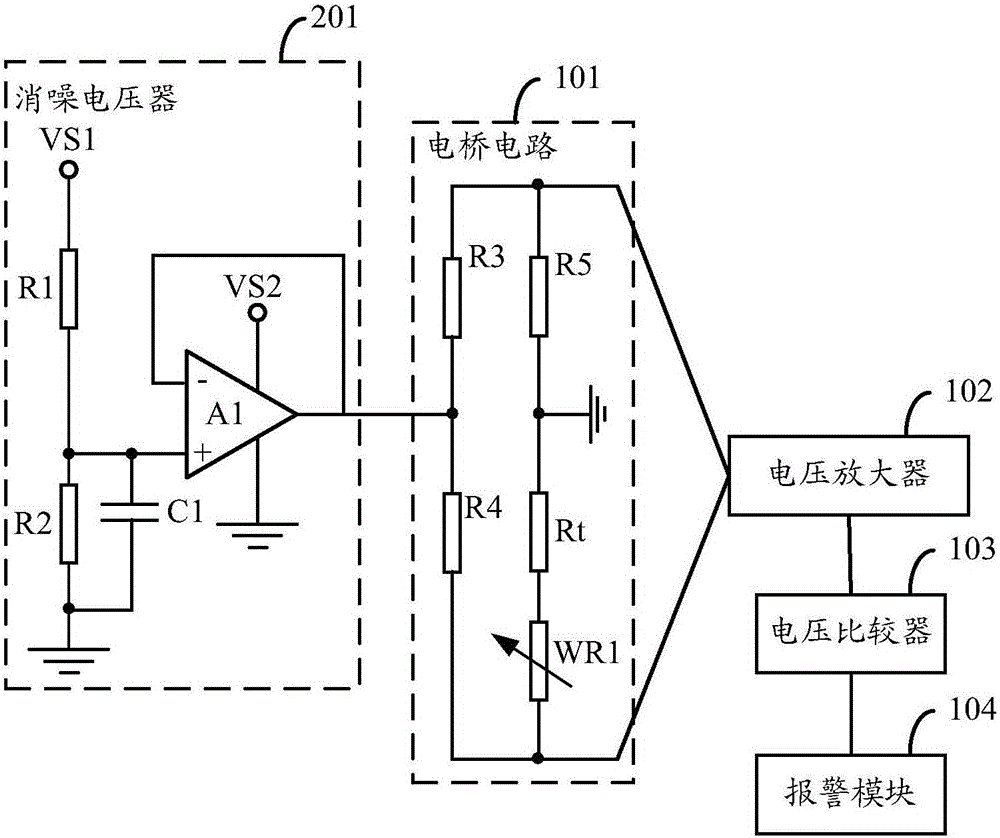

Motor high temperature alarm and method implementing high temperature alarm

InactiveCN106017715AHigh resistivityHigh temperature sensitivityThermometer detailsThermometers using electric/magnetic elementsElectrical resistance and conductanceAudio power amplifier

The invention provides a motor high temperature alarm and a method implementing high temperature alarm. The motor high temperature alarm includes a bridge circuit containing a platinum resistor and used for generating a corresponding first voltage by utilizing between-bridge-arm resistance unbalance caused by change of the resistance value of the platinum resistor; the platinum resistor embedded in a target position, used for monitoring the temperature of the target position and generating resistance change when the temperature of the target position changes; a voltage amplifier used for amplifying the first voltage output by the bridge circuit and outputting the amplified first voltage to a voltage comparator; the voltage comparator used for determining voltage threshold value, comparing the amplified first voltage with the voltage threshold value and triggering an alarm module for high temperature alarm when the amplified first voltage is greater than the voltage threshold value. The scheme provided by the invention can improve high temperature alarm accuracy effectively.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com