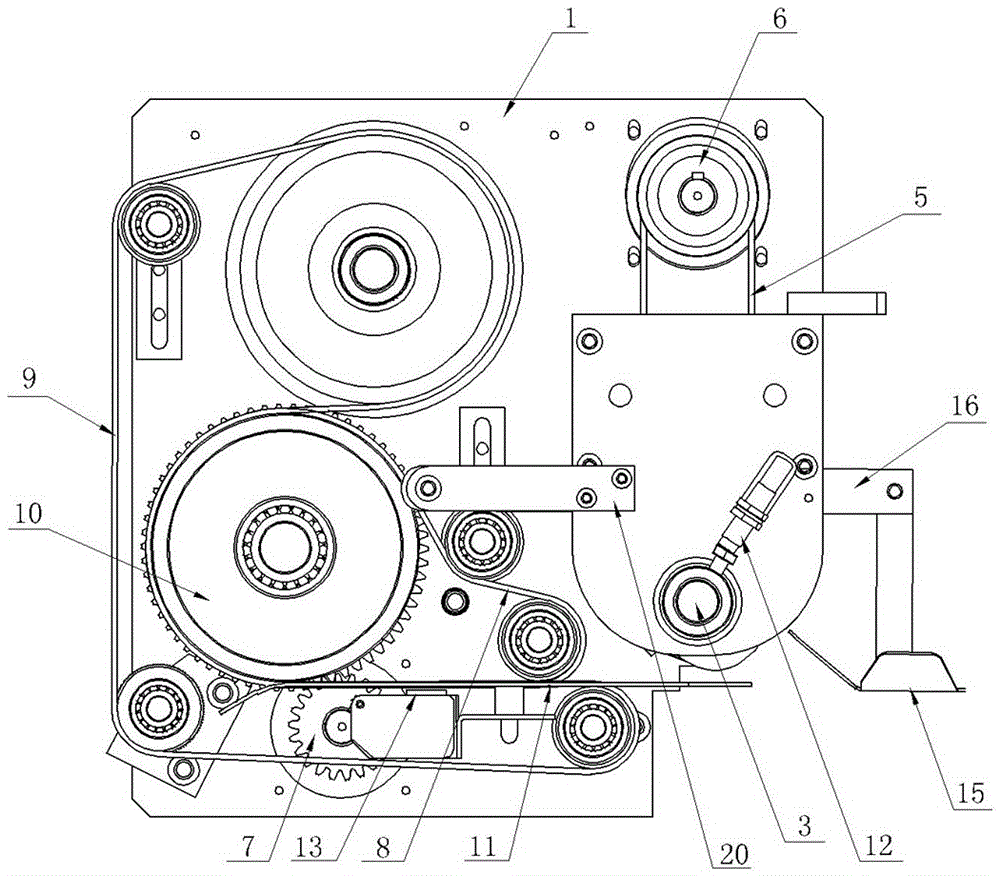

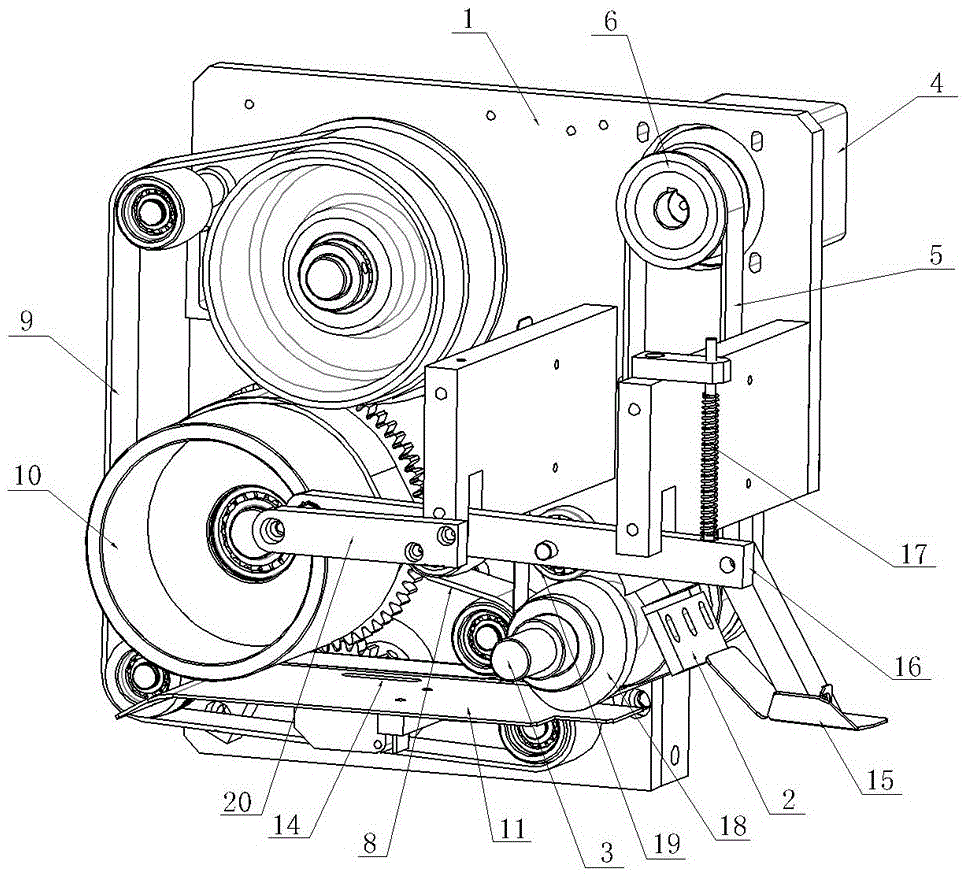

Full-automatic bag making machine handle feeding and cutting device

A technology of material cutting device and bag making machine, which is applied in the direction of bag making, packaging, transportation and packaging, etc. It can solve the problems of cost increase, damage to the handle material, and handle material scrapping, etc., and achieve the effect of convenient machine adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Referring to the accompanying drawings, the handle feeding and cutting device of the automatic bag making machine includes a frame 1, and the frame 1 is provided with a handle feeding mechanism and a handle cutting mechanism, and the handle cutting mechanism includes a paper cutting mechanism. Knife 2, the handle feeding mechanism is connected with the feeding power source, the paper cutter is connected with the cutting power source 4, and the handle feeding mechanism and the handle cutting mechanism are driven by their respective power sources to cooperate with each other for feeding and Cutting work, that is to say, the handle feeding mechanism and the handle cutting mechanism can be controlled separately, and the controllability is high.

[0019] In this embodiment, the handle feeding mechanism stops feeding during material cutting, and continues feeding after the material cutting is completed, so as to improve the coordination between the handle feeding mechanism and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com