Inductive sensor separated buoy applicable to viscous liquid level measurement

An inductive, split-type technology, applied in the direction of the buoy liquid level indicator, etc., can solve the problems of not being able to reflect the change of the liquid level in time, the overall replacement is time-consuming, laborious and expensive, and the sensitivity of the buoy response is reduced, so as to reduce the relative movement area, The effect of reducing the coefficient of friction and increasing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

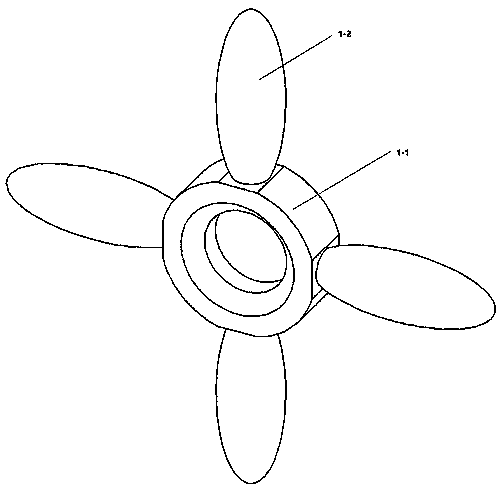

[0037] Embodiment 1: a kind of stainless steel, or aluminum alloy, or polyethylene PE, or polypropylene PP, or polyvinyl chloride PVC, or polystyrene PS, or ABS resin, or polycarbonate PC, or polyamide PA, or Buoys made of polyoxymethylene POM or modified polyphenylene ether PPS. The shape of the float is a sphere, or a spheroid, or a cylinder, or a cylinder, or a prism, or a prism, or a prism, or a prism, or a gear tooth, or an outer contour It is a smooth solid of non-circular curve / variable curvature curve, or dish-shaped, or teardrop-shaped, or petal-shaped, and there are 1 or 2 or 3 or 4...or k cavities in the float, where k is greater than A natural number equal to 5. Or there is no cavity in the float, but a homogeneous solid. At this time, the density of the material of the float is less than that of the liquid in which it is located. The thickness of the socket ring is between 1mm and 100mm. The projection shape of the center hole of the socket ring on the horizont...

Embodiment 2

[0038] Embodiment 2: a kind of stainless steel, or aluminum alloy, or polyethylene PE, or polypropylene PP, or polyvinyl chloride PVC, or polystyrene PS, or ABS resin, or polycarbonate PC, or polyamide PA, or Buoys made of polyoxymethylene POM or modified polyphenylene ether PPS. The shape of the float is a sphere, or a spheroid, or a cylinder, or a cylinder, or a prism, or a prism, or a prism, or a prism, or a gear tooth, or an outer contour It is a smooth solid of non-circular curve / variable curvature curve, or dish-shaped, or teardrop-shaped, or petal-shaped, and there are 1 or 2 or 3 or 4...or k cavities in the float, where k is greater than A natural number equal to 5. Or there is no cavity in the float, but a homogeneous solid. At this time, the density of the material of the float is less than that of the liquid in which it is located. The thickness of the sleeve ring is between 1mm and 100mm. The projection shape of the center hole of the sleeve ring on the horizont...

Embodiment 3

[0039] Embodiment 3: a kind of stainless steel, or aluminum alloy, or polyethylene PE, or polypropylene PP, or polyvinyl chloride PVC, or polystyrene PS, or ABS resin, or polycarbonate PC, or polyamide PA, or Buoys made of polyoxymethylene POM or modified polyphenylene ether PPS. The shape of the float is a sphere, or a spheroid, or a cylinder, or a cylinder, or a prism, or a prism, or a prism, or a prism, or a gear tooth, or an outer contour It is a smooth solid of non-circular curve / variable curvature curve, or dish-shaped, or teardrop-shaped, or petal-shaped, and there are 1 or 2 or 3 or 4...or k cavities in the float, where k is greater than A natural number equal to 5. Or there is no cavity in the float, but a homogeneous solid. At this time, the density of the material of the float is less than that of the liquid in which it is located. The thickness of the sleeve ring is between 1mm and 100mm. The projected shape of the center hole of the sleeve ring on the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com