Method for determining sensitivity of each sensor in mechanical equipment vibrating sensor network

A technology of vibration sensors and mechanical equipment, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems that cannot be used to determine the importance or sensitivity of sensor nodes, and are not suitable for research purposes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

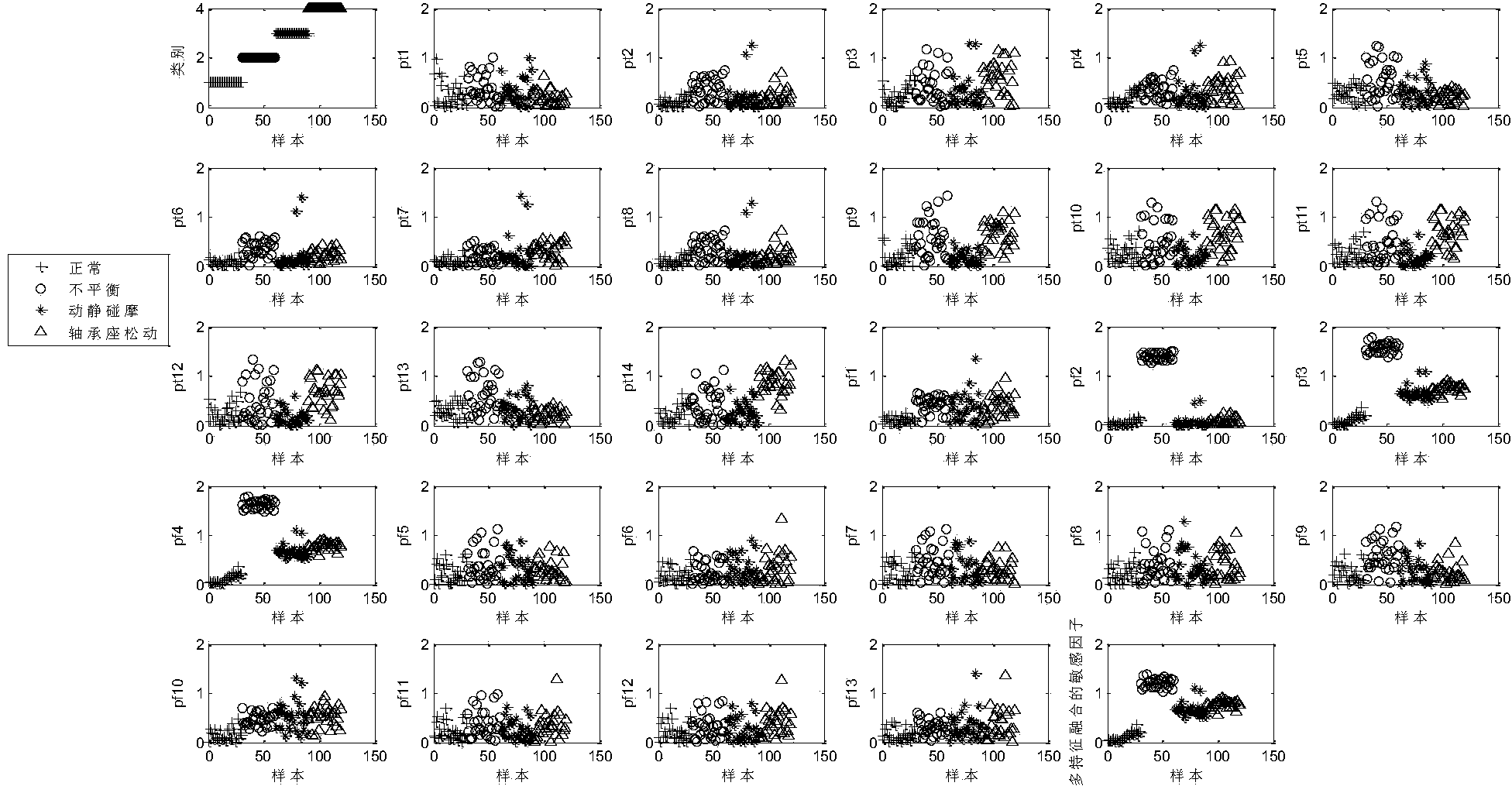

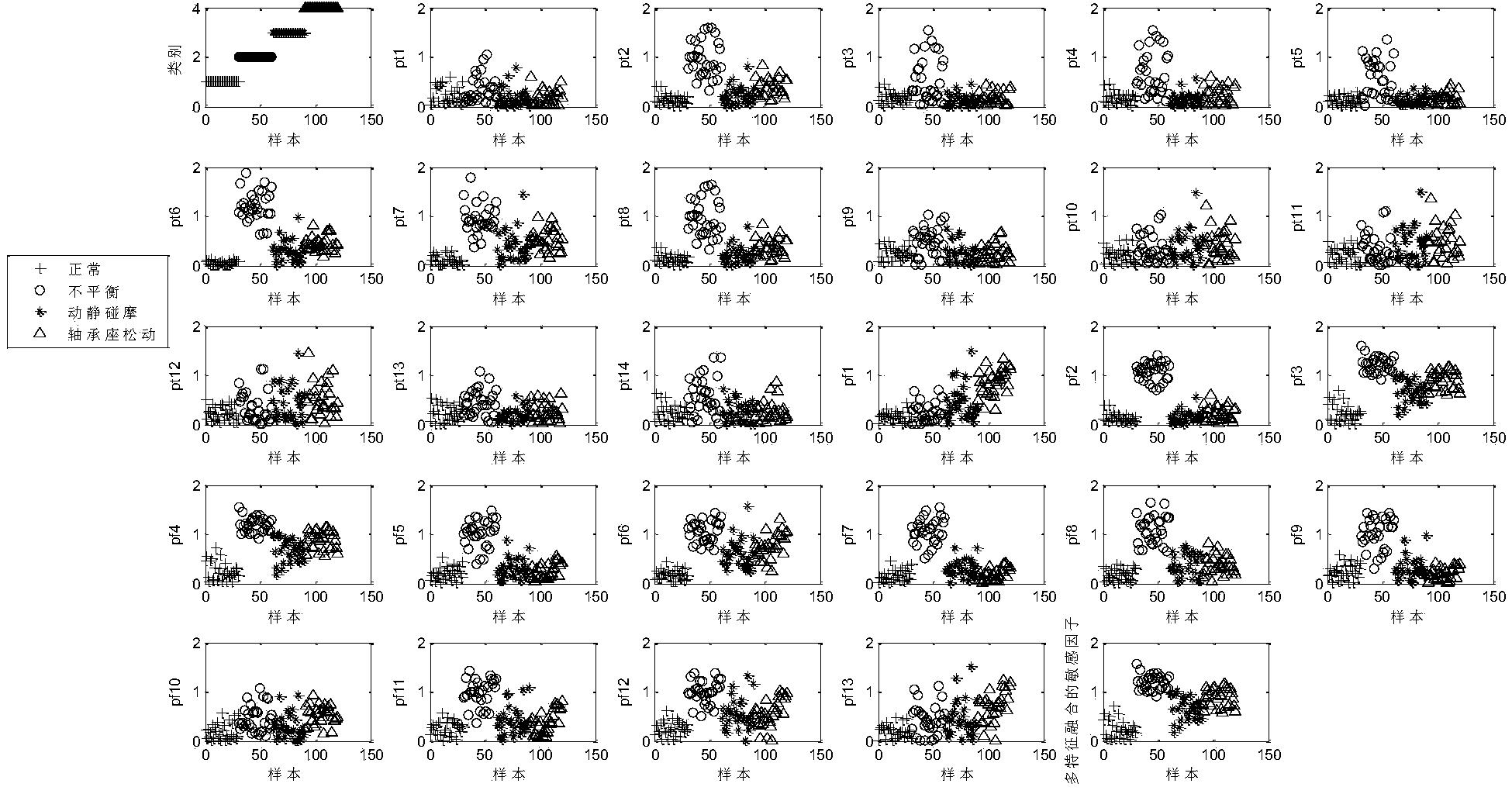

[0104] The effect of the method for evaluating the sensitivity of each node of the mechanical vibration sensor network proposed by the present invention is tested and verified with the fault simulation experiment data of the aeroengine rotor.

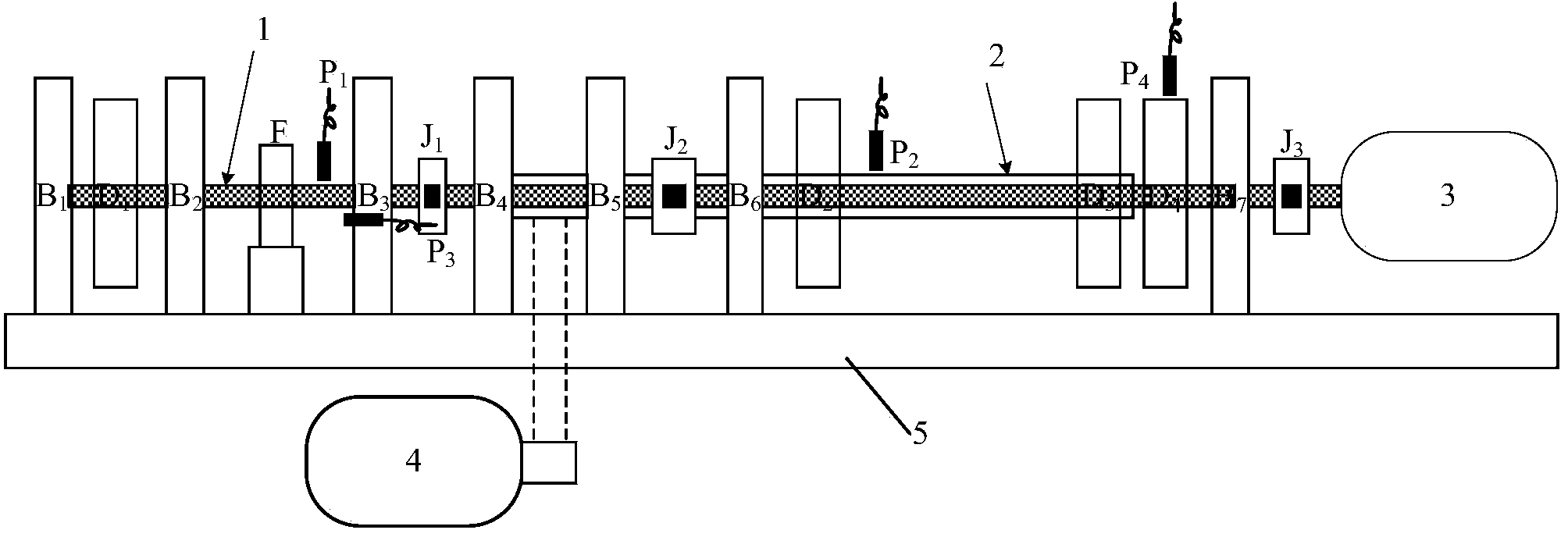

[0105] The rotor fault simulation experiment uses the figure 1 The basic components of the double-span rotor test bench shown include: base, two motors, two bearings, couplings, discs, etc. Among them, B i (i=1,...,7) is the bearing seat, D i ((i=1,…,4) is the rotor disk, P 1 ,P 2 , P 3 is the vibration sensor, P 4 is the speed sensor, J 1 、J 2 、J 3 for the coupling.

[0106] The shafts are connected by a flexible coupling, and the motor and the shaft are also connected by a flexible coupling. In order to improve the installation accuracy of the rotor, so that the rotor can run at high speed, and also to solve the lubrication problem of the high-speed rotor, the bearings are all low-friction deep groove ball bearings with self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com