Live lead clip

A technology of wire clips and wire clips, applied in the direction of electrical connection seat, connection, circuit, etc., can solve the problems of inability to install the insulating rod, troublesome installation of C-type wire clips, and provide elastic deformation, so as to prevent damage caused by excessive locking. , The effect of excellent connection performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

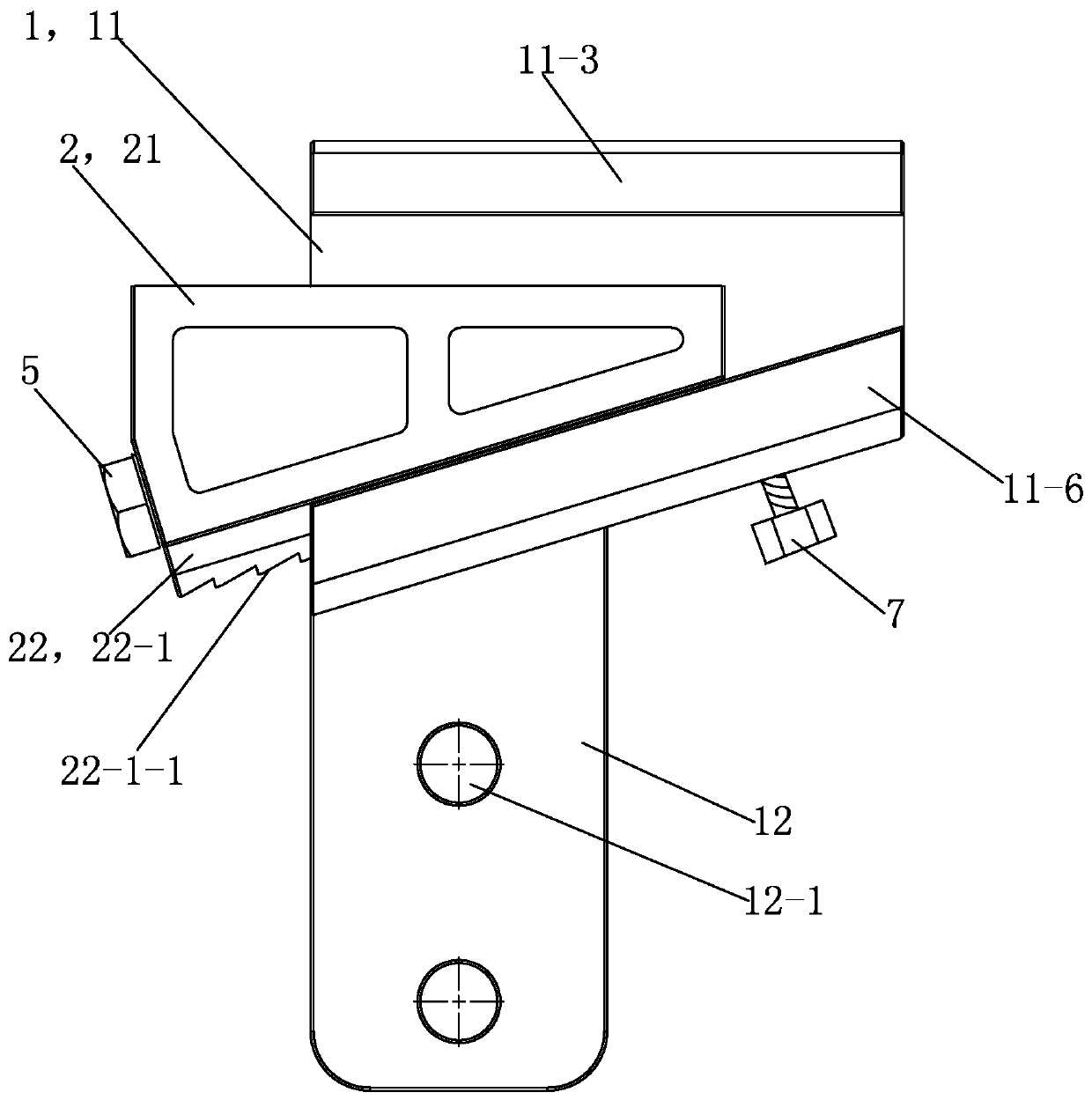

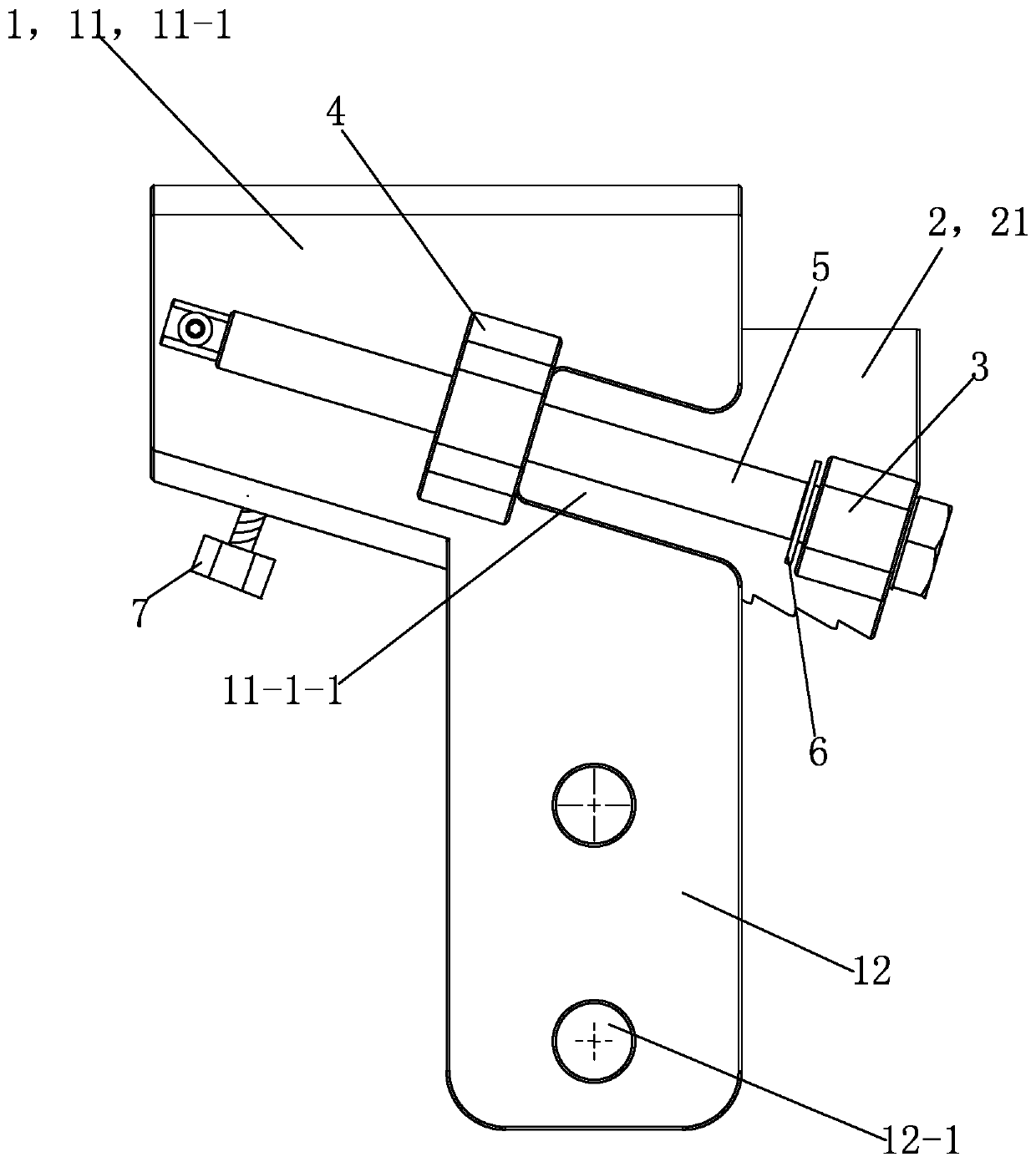

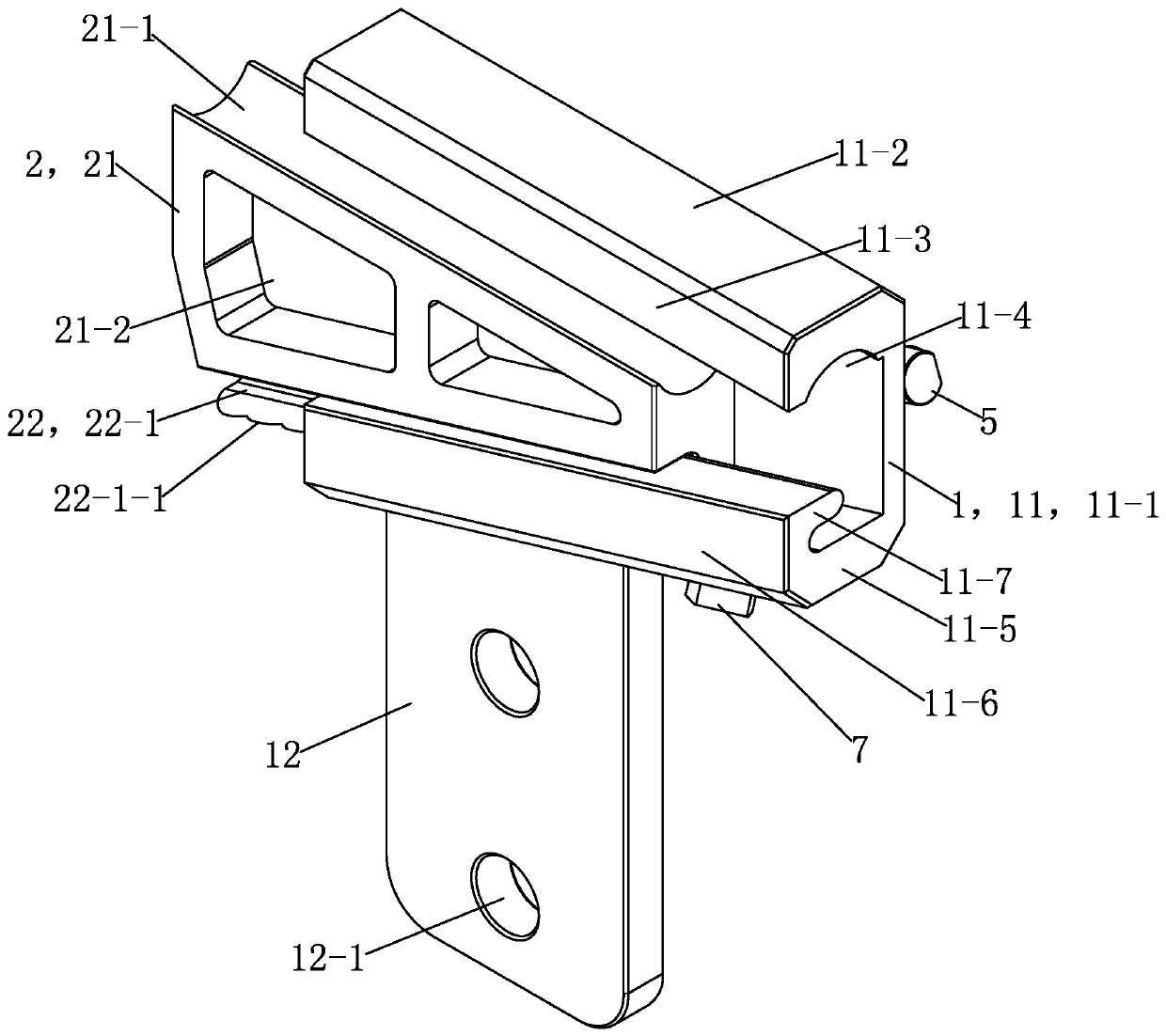

[0026] In this embodiment, when describing the orientation, the figure 1 The direction facing is the front in the description, with the back facing figure 1 The direction it is facing is the rear in the description, figure 1 The up and down, left and right directions of are still the up and down, left and right directions in the description.

[0027] See Figure 1 to Figure 4 , The live lead clamp of this embodiment is mainly composed of a main body 1, a clamp slider 2, a first nut 3, a second nut 4, a driving bolt 5, a retaining ring 6 and a non-return bolt 7.

[0028]The main body 1 is mainly composed of a wire clamping portion 11 on the upper side and a drain wire connecting portion 12 on the lower side. The wire clamping portion 11 is mainly composed of a rear plate 11-1, an upper plate 11-2, an upper front side plate 11-3, a lower plate 11-5, a lower front side plate 11-6 and a sliding sleeve plate 11-7; The plate 11-1 is an overall wedge-shaped plate body whose left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com