Stable high-precision workpiece fixing tool for stamping die

A technology for stamping dies and fixing tooling, which is applied in the field of stable and high-precision workpiece fixing tooling, and can solve problems such as easy generation of a large amount of residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

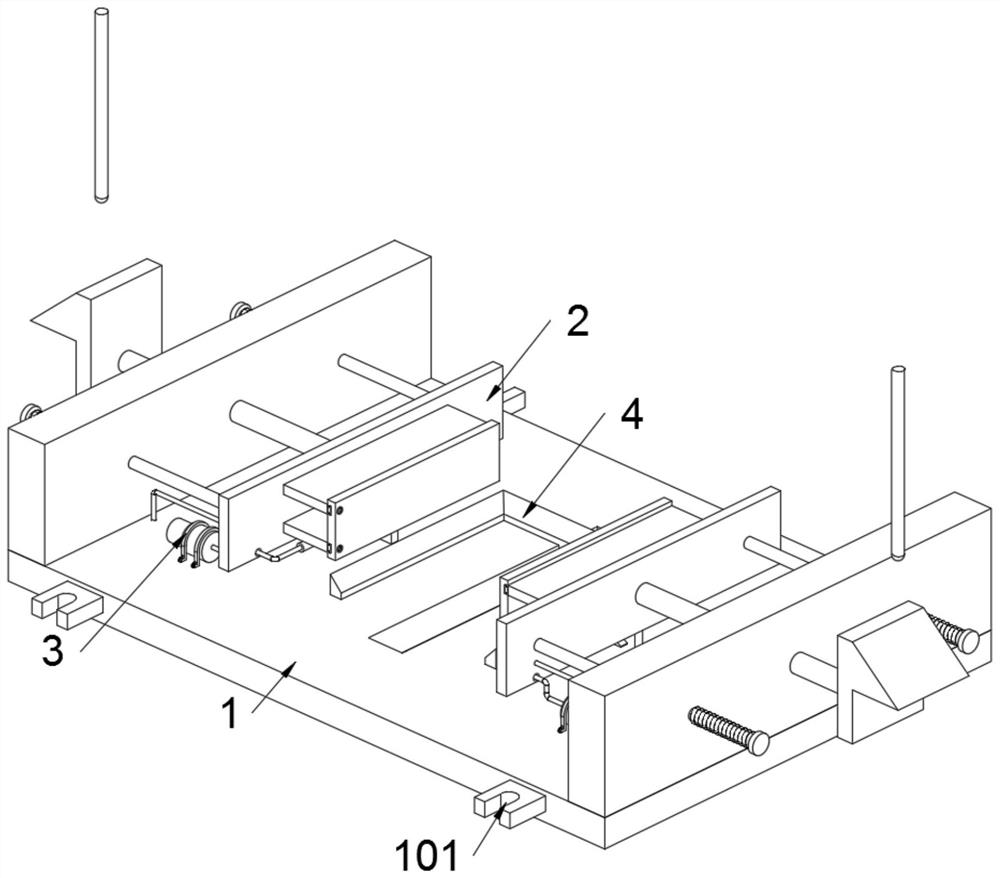

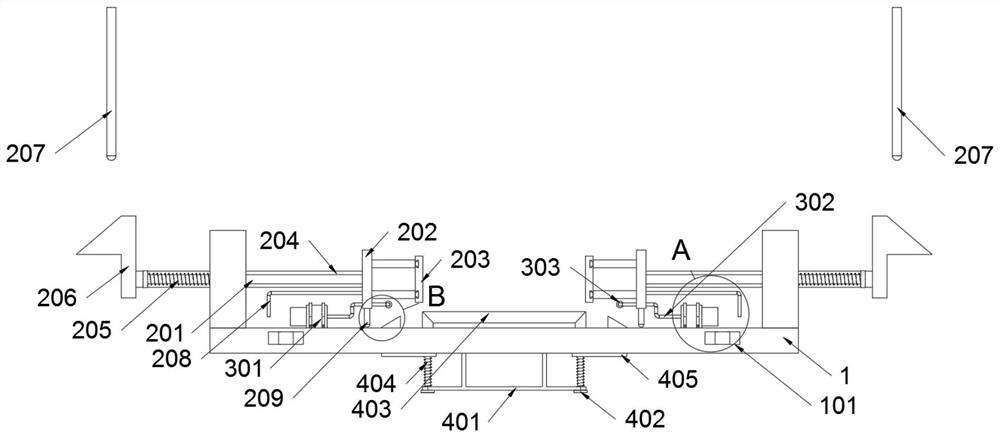

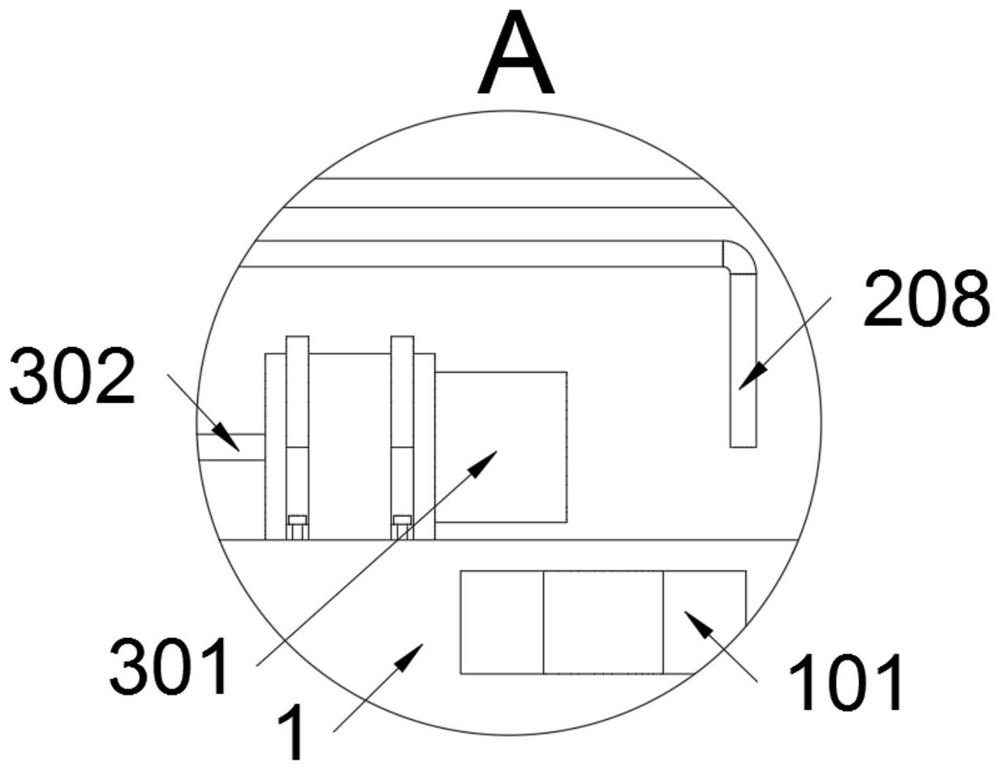

[0032] as attached figure 1 to attach Figure 7 Shown:

[0033] The invention provides a stable high-precision workpiece fixing tool for stamping dies, including a base 1; two clamp structures 2 are installed on the base 1, and two cleaning structures 3 are installed on the base 1, and the base 1 is installed There is positioning structure 4; refer to eg figure 2 and image 3, the fixture structure 2 includes a toggle rod B208, which is welded to the rear end surface of the fixture plate mounting seat 202, and the toggle rod B208 is an L-shaped rod-shaped structure; the toggle rod B208 is aligned with the head end of the telescopic bottle 301, And the toggling rod B208 constitutes the toggling and extruding structure of the telescopic bottle 301, so that when the toggling rod B208 follows the fixture plate mounting seat 202 to move to realize parts clamping, the telescopic bottle 301 can be squeezed synchronously to complete the cleaning of the residue on the base 1; Refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com