Spring chuck with bevel gears

A technology of collets and bevel gears, which is applied in the field of collets, can solve problems such as inconvenient clamping, and achieve the effects of convenient clamping, easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

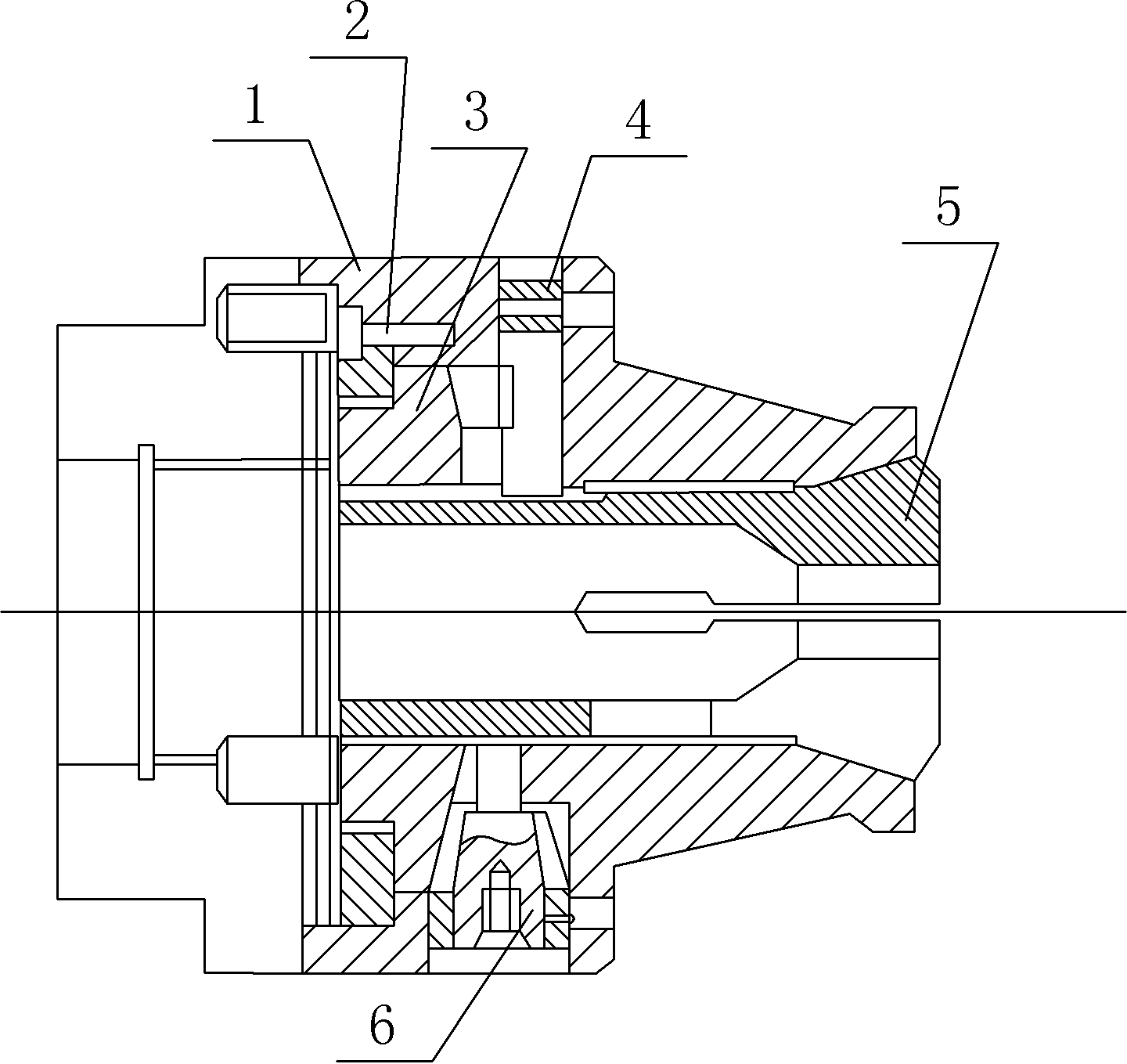

[0009] according to figure 1 As shown, the spring collet with bevel gear in the embodiment of the present invention includes a hollow collet body 1 and a collet 5 provided with an open groove, and the open groove extends axially from the head of the collet 5 to the middle of the collet 5, One end of the collet 5 matches the cavity of the clamp body 1, and the other end of the collet 5 protrudes from the clamp body 1, and also includes a large bevel gear 3 with a screw hole in the center of the cavity of the clamp body 1, and cooperates with the large bevel gear 3 The small bevel gear 6 and the snap ring 2 that axially fix the large bevel gear 3 in the clamp body, one end of the small bevel gear 6 protrudes from the clamp body 1, and the end of the clamp body 1 away from the large bevel gear 3 is provided with a collet 5 matching One end of the collet 5 is threadedly connected with the screw hole of the large bevel gear 3, and the opening groove is filled with an elastic rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com