Displacement-type spring chuck

A spring collet and displacement technology, applied in the direction of the chuck, can solve the problems of inconvenient clamping, and achieve the effect of convenient clamping, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

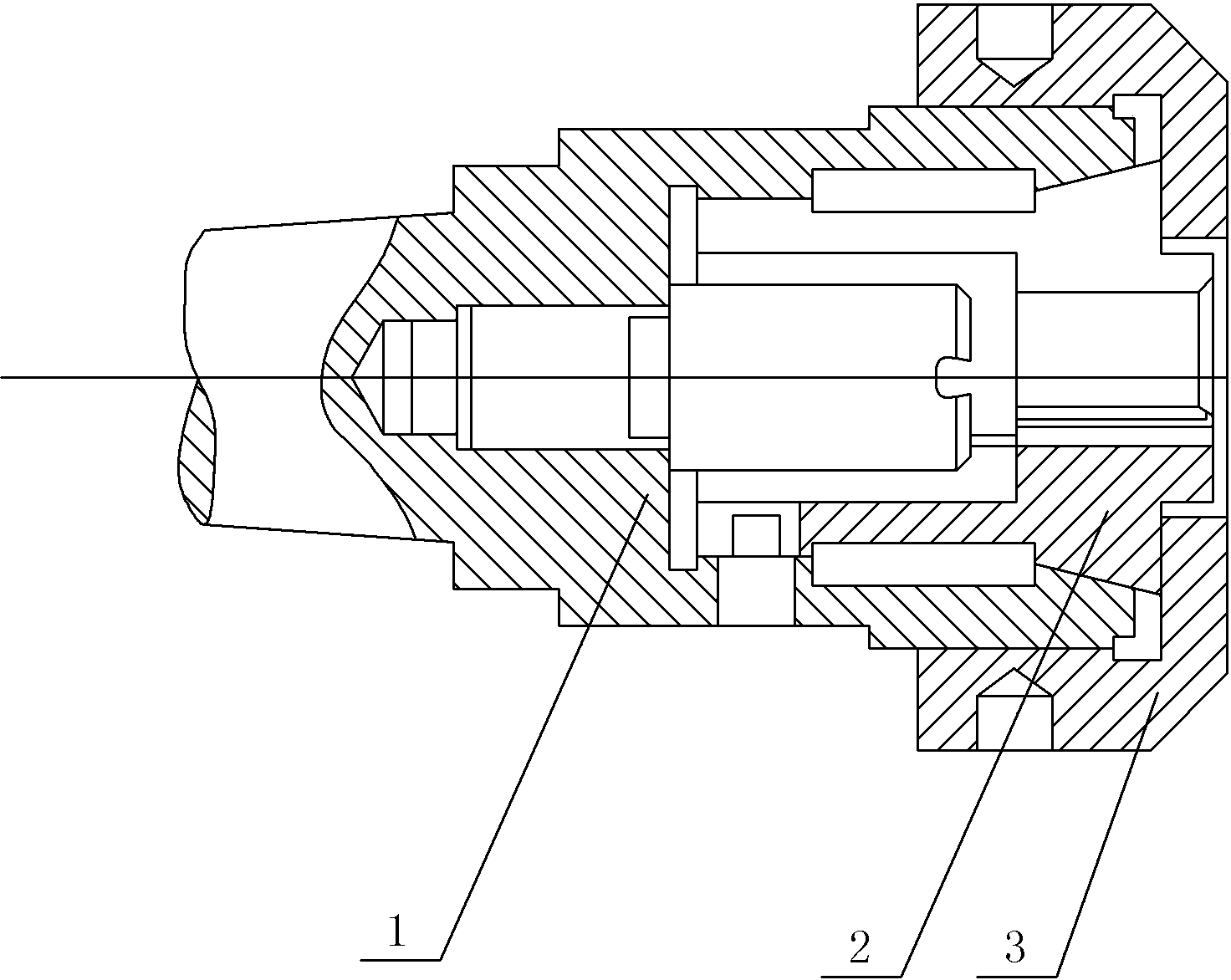

[0009] according to figure 1 As shown, the displacement spring collet in the embodiment of the present invention includes a hollow collet body 1 and a collet 2 provided with an open groove. The open groove extends axially from the head of the collet 2 to the middle of the collet 2. The collet 2 Match the cavity of the clamp body 1, the end of the clamp body 1 is provided with an inner tapered surface for compressing the collet 2, and also includes a nut 3 threaded on the outside of the collet 2 and the end of the collet 1, and an opening groove of the collet 2 The inside is filled with an elastic rubber layer, and the side wall of the clip body 1 is also provided with supporting nails for axial positioning of the workpiece.

[0010] In the working state, when the nut 3 is turned, the collet 2 moves into the cavity of the clamp body 1, and the collet 2 shrinks and clamps the workpiece under the action of the inner cone of the clamp body 1; when the nut 3 is reversed, the collet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com