Auxiliary loading device for vertical continuous plating lines

A vertical continuous electroplating, axis technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of high labor intensity, low production efficiency, cumbersome operation, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

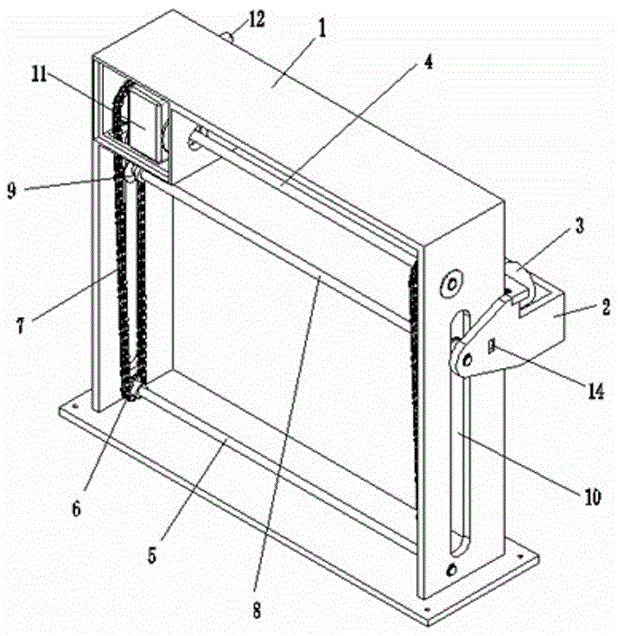

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following specific embodiments.

[0027] An auxiliary feeding device for a vertical continuous electroplating line, the auxiliary feeding device includes a bracket 1 and a lifting tray 2, the lifting tray can move up and down and be positioned on the bracket, and the upper end of the workpiece to be processed When the lower end of the fixture placed in the vertical continuous electroplating line is placed on the lifting pallet, the workpiece to be processed can move together with the fixture of the vertical continuous electroplating line.

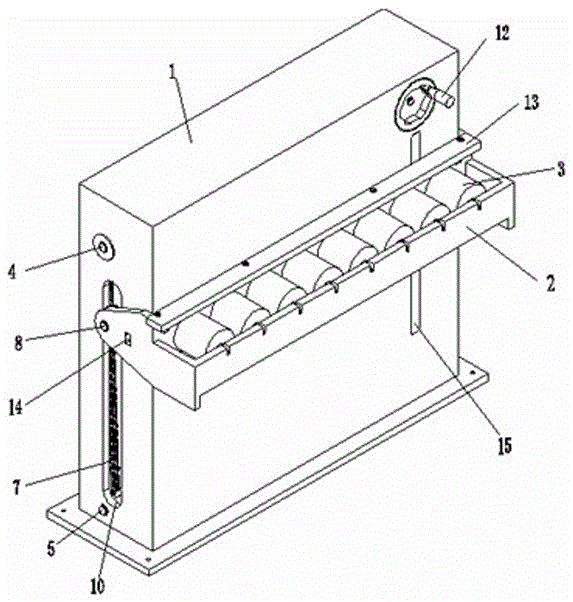

[0028] Such as figure 1 , 2 As shown, the structure that the workpiece to be processed can move together with the clamps of the vertical continuous electroplating line is: a number of supporting wheels 3 are horizontally spaced in the lifting tray, and each sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com