Friction stir spot welding equipment with automatic clamping device

A technology of friction stir and spot welding equipment, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of flexural deformation around the welding point, and achieve the effect of preventing flexural deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

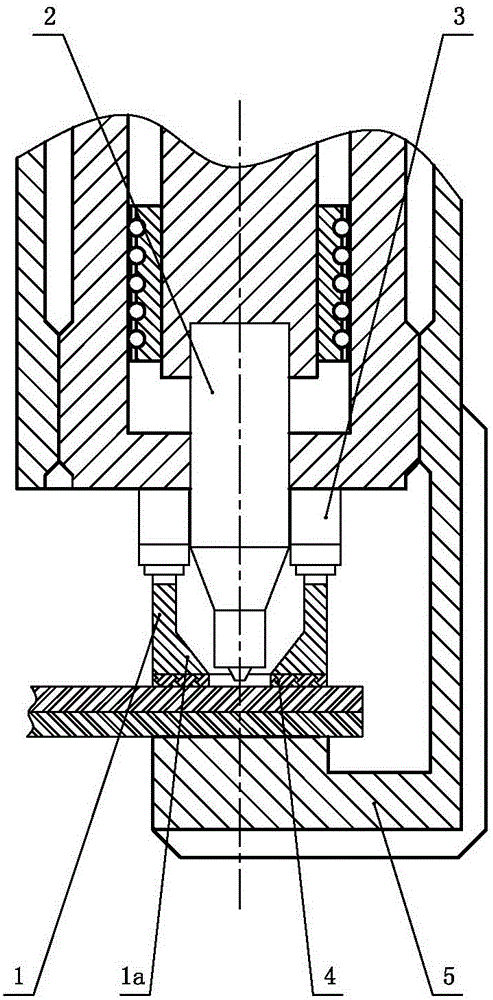

[0014] Such as figure 1 Shown is a schematic structural view of the present invention, including: a host computer, an annular upper splint 1, a lower splint 5 corresponding to the upper splint 1, and a driving mechanism 3 for driving the upper splint 1 to move up and down. A protruding ring 1a is provided on the inner wall of the lower end of the upper splint 1 to increase the contact area between the upper splint 1 and the workpiece, and further reduce the deflection of the workpiece during welding. The driving mechanism 3 is fixedly connected with the friction stir spot welding equipment; the stirring head 2 of the friction stir spot welding equipment penetrates the upper splint 1 and is arranged vertically to the welding seam. Preferably, the driving mechanism 3 is an air cylinder.

[0015] When working, the upper computer starts the driving mechanism 3, the upper splint 1 moves downward and cooperates with the lower splint 5 to clamp the workpiece to be welded, and starts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com