Use method for bagging device of automatic garbage packaging unit

An automatic packaging and bagging device technology, applied in packaging and other directions, can solve the problems of labor-intensive manual bagging, labor-intensive manual garbage bagging, poor sanitary conditions, etc., so as to save labor costs, protect physical health, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

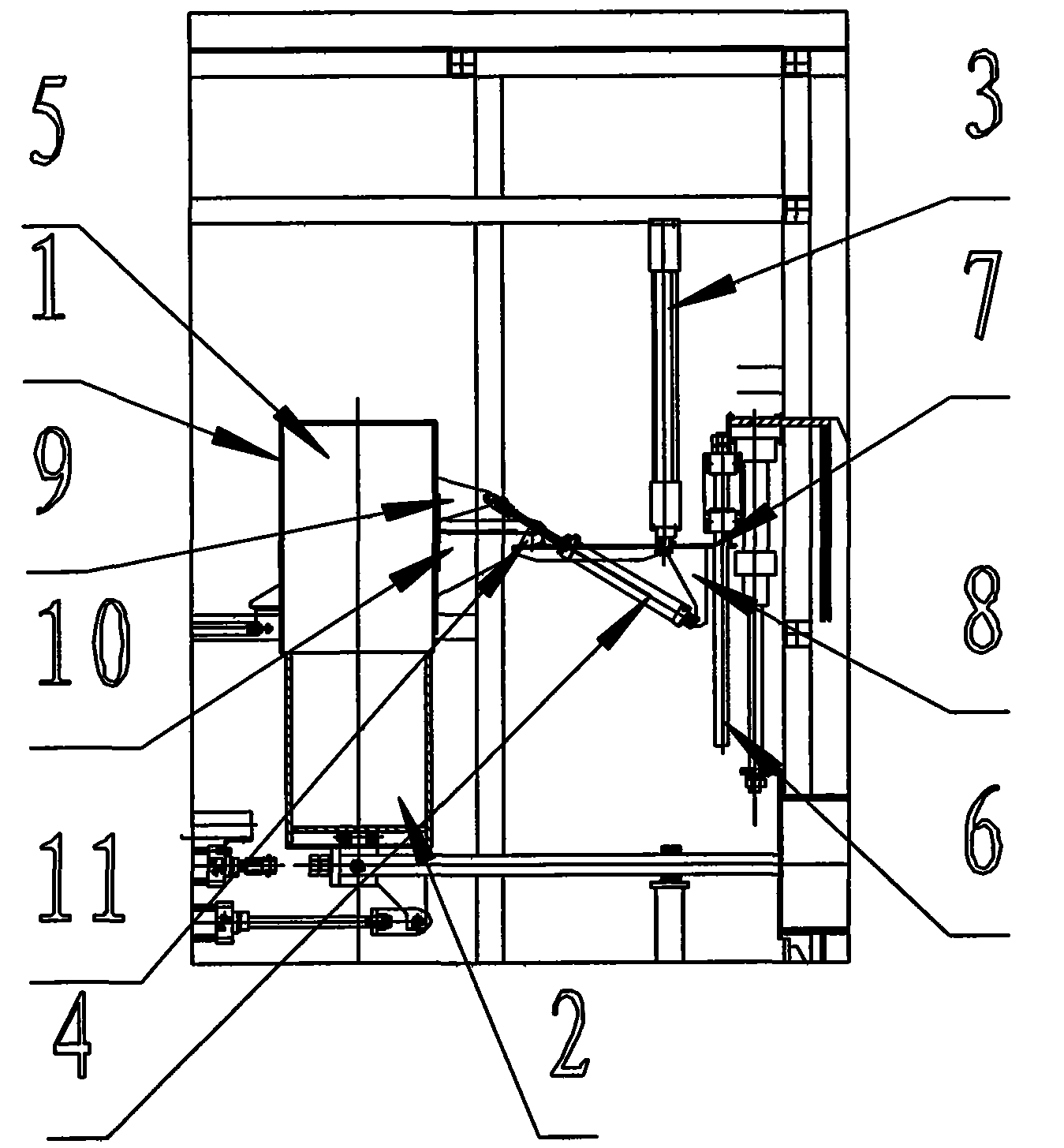

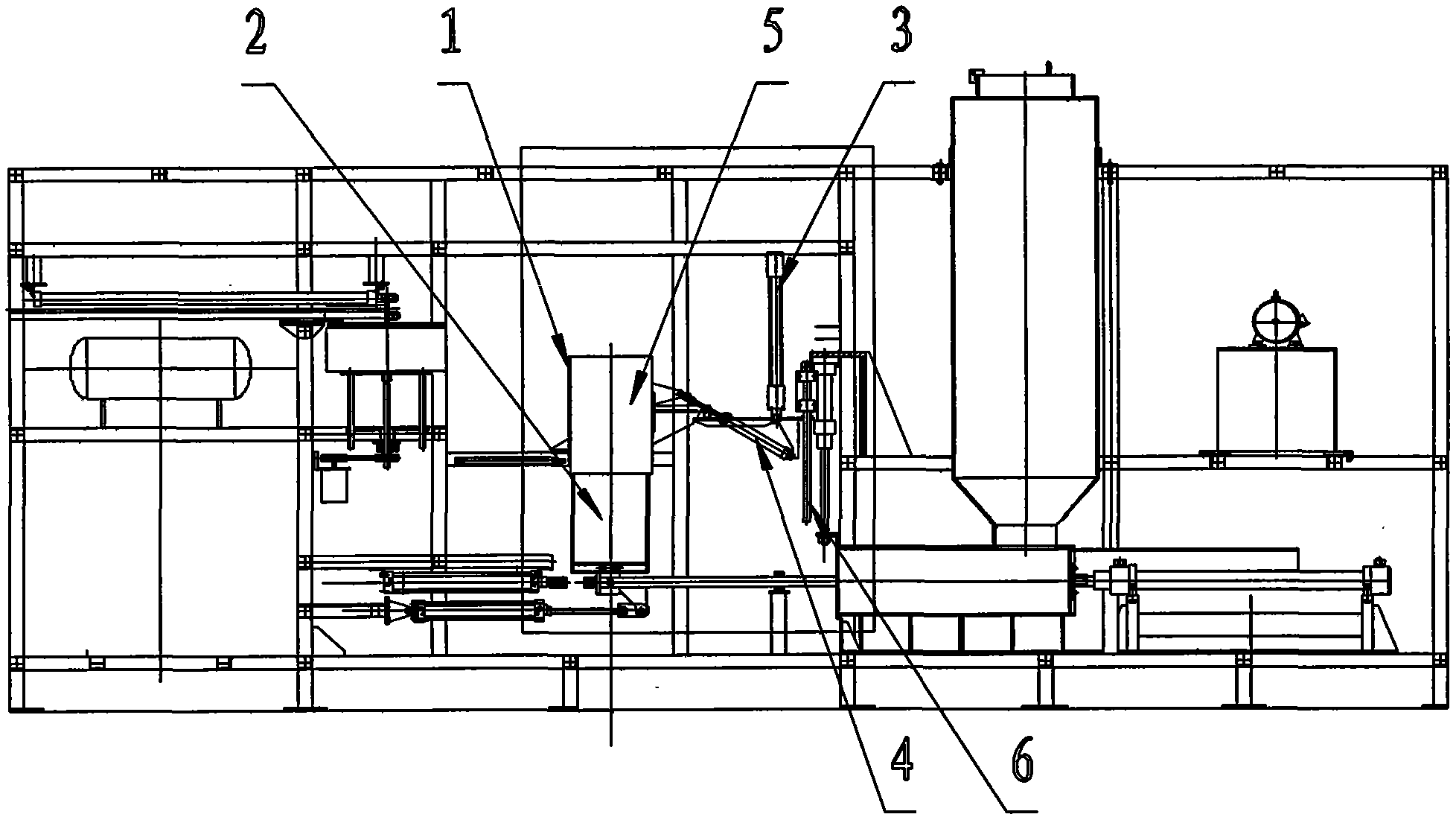

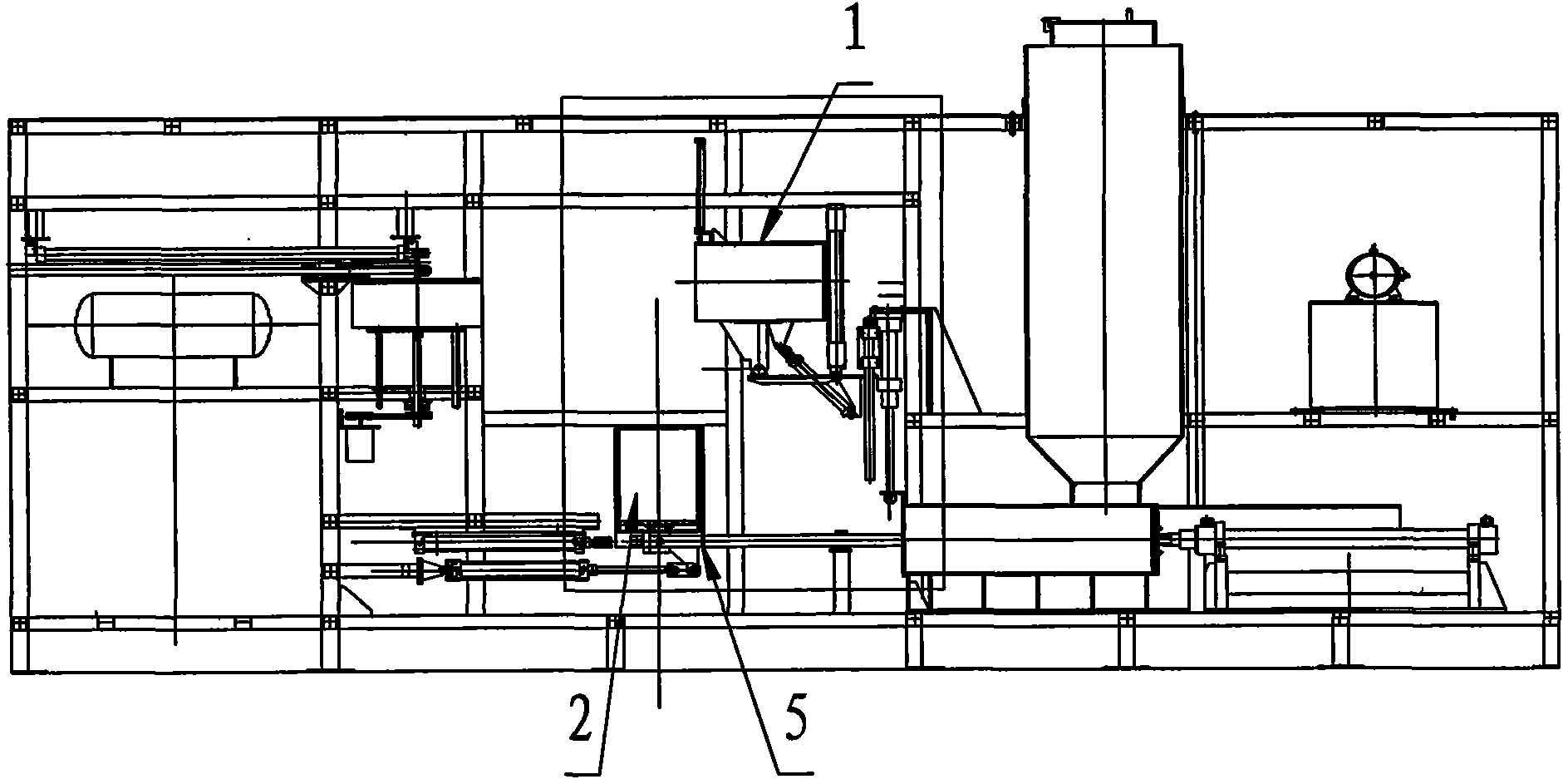

[0022] As shown in the figure; the bag opening box 1 side of the bagging device is provided with a bag opening guide rod 6, the lower opening of the bag opening box 1 is set corresponding to the upper opening of the packing box 2, and garbage bags 5 are arranged in the bag opening box 1; bag opening One side of the box guide rod 6 is provided with a guide rod slider 7, and the upper and lower cylinders 3 are arranged between the guide rod slider 7 and the upper frame; the bottom of the guide rod slider 7 is provided with a turning cylinder bracket 8, and the side of the bag opening box 1 is provided with an opening bag The box turning plate 9, the turning cylinder support 8 and the bag opening box turning plate 9 are provided with the turning cylinder 4; The connecting plate 10 is provided with a rotating shaft between the connecting plate 10 and the connecting seat 11 .

Embodiment 2

[0024] Before the bagging device is in operation, the guide rod sliding lever 7 is on the upper part of the guide rod 6 of the bag opening box, and the garbage bag 5 is installed in the bag opening box 1 of the bagging device, which is adsorbed on the inner wall by the vacuum device in the bag opening box 1 , when completing the process of opening the bag; the overturning cylinder 4 between the overturning cylinder support 8 and the overturning plate 9 of the bag-opening box promotes the overturning of the bag-opening box 1; at the same time, the mouth of the packing box 2 is turned upwards by the oil cylinder; when the packing box When the mouth of the 2 case corresponds to the mouth of the bag-opening case 1, the oil cylinder of the overturning cylinder 4 and the packing case 2 stops running.

Embodiment 3

[0026] When the bag opening box 1 and the packing box 2 are coaxial, the upper and lower cylinders 3 between the guide rod sliding lever 7 and the upper frame are activated, and the upper and lower cylinders 3 push down the guide rod sliding lever 7 to drive the bag opening box 1 to move downward. Garbage bag 5 in the bag opening box 1 is enclosed within packing box 2 outsides completely, and cylinder 3 stops running up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com