Material warehouse-in and warehouse-out device and system thereof

A technology for entering and exiting warehouses and materials, which is applied in the field of equipment and systems for entering and exiting materials. It can solve the problems of affecting the reading rate, stains are easy to stick, and takes up a large space, so as to optimize the storage structure and reduce the cost of materials or goods. Backlog, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

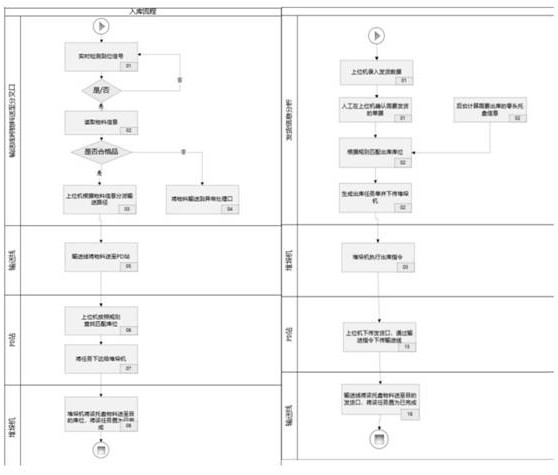

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

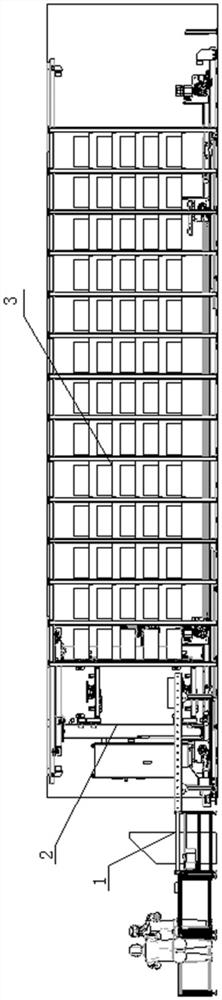

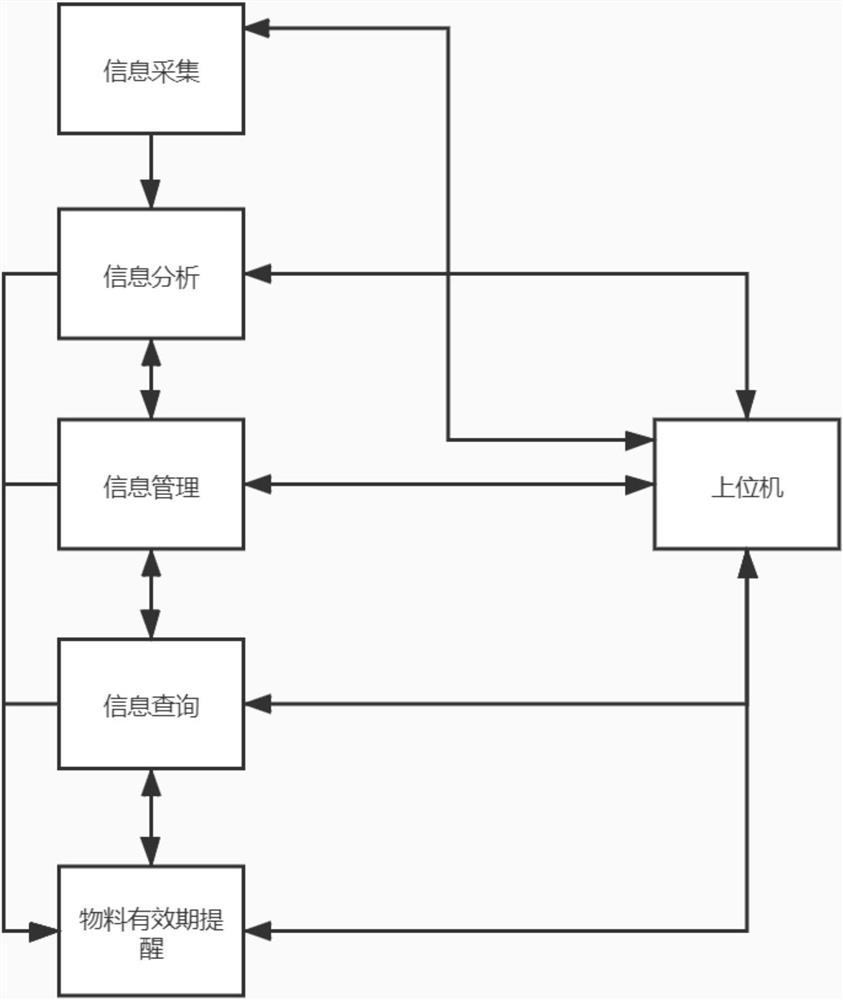

[0037] A device for materials entering and leaving the warehouse, characterized in that it includes a conveying line for conveying materials, a transfer device for transferring materials from the conveying line to a three-dimensional warehouse, and a roadway stack for conveying materials to a designated position in the three-dimensional warehouse stacker, the storage entrance of the three-dimensional warehouse is provided with a storage read-write terminal, and the storage exit of the three-dimensional warehouse is provided with a storage read-write terminal, and the conveying line, the transfer device and the stacker are all Through the connection between the PLC controller and the network server and the host computer, the materials in the three-dimensional warehouse are allocated to different storage positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com