Patents

Literature

107results about How to "Improve the efficiency of inbound and outbound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

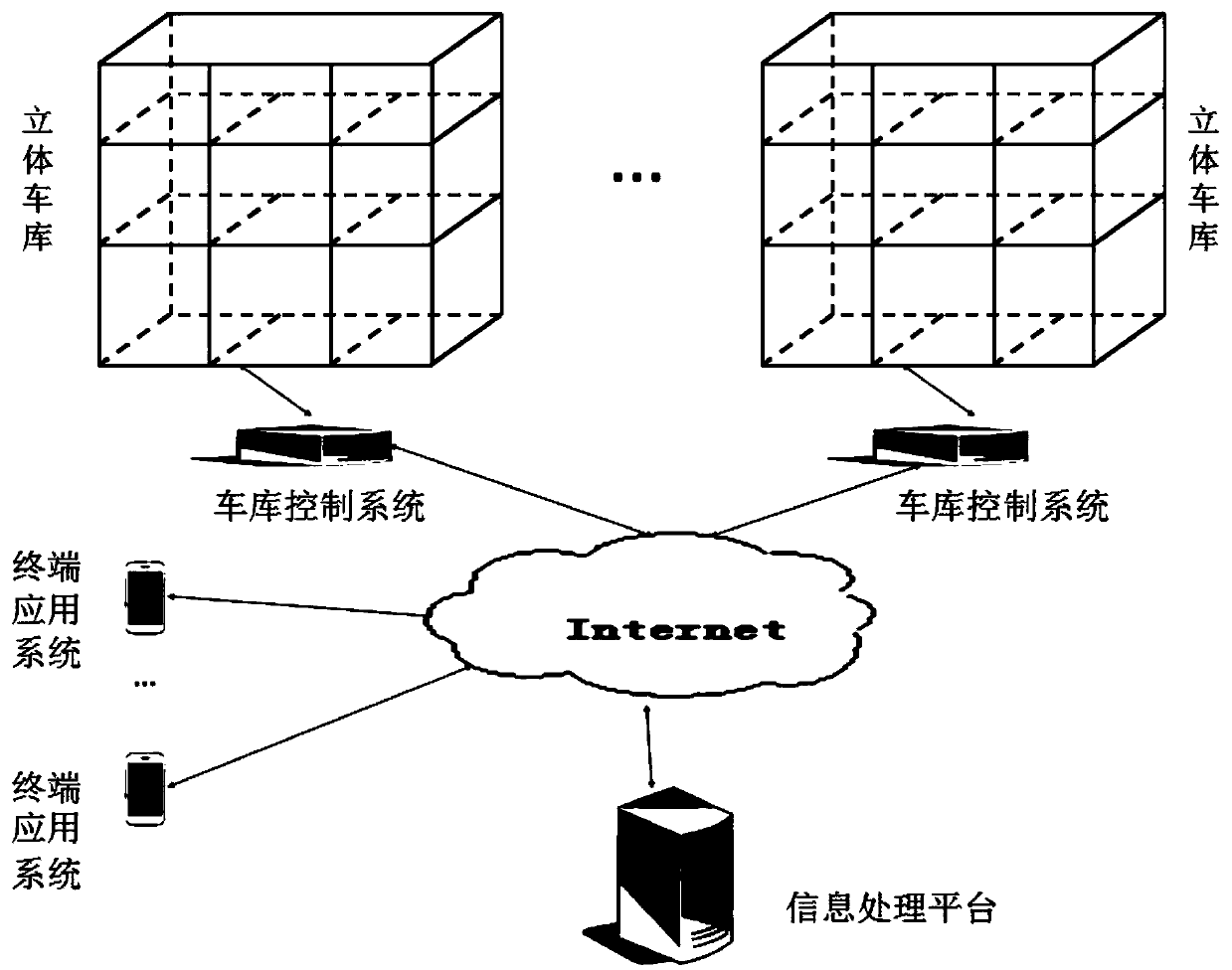

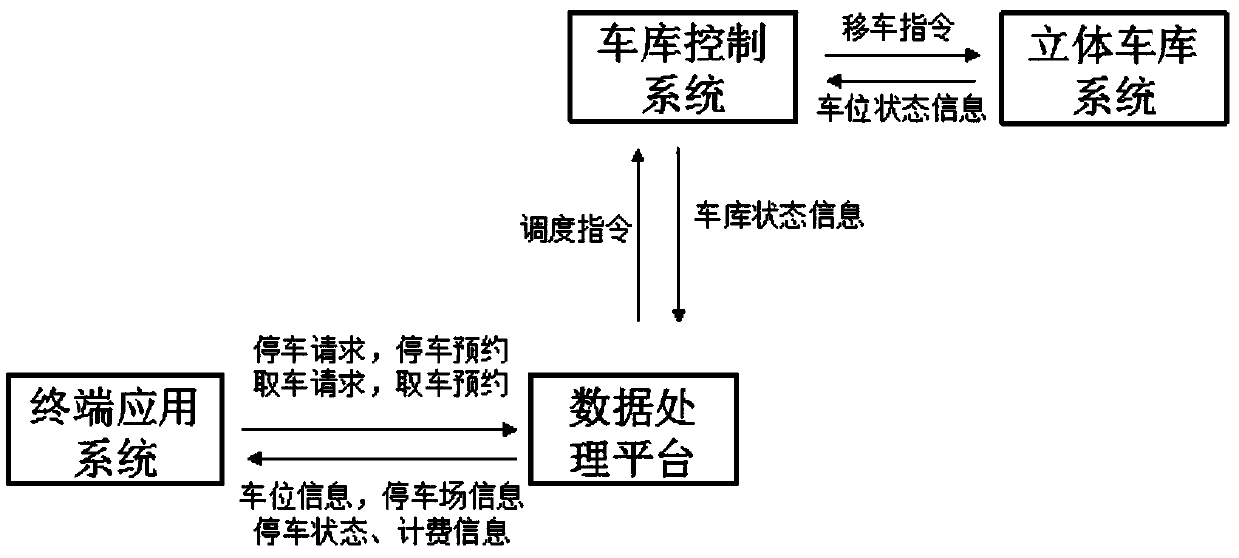

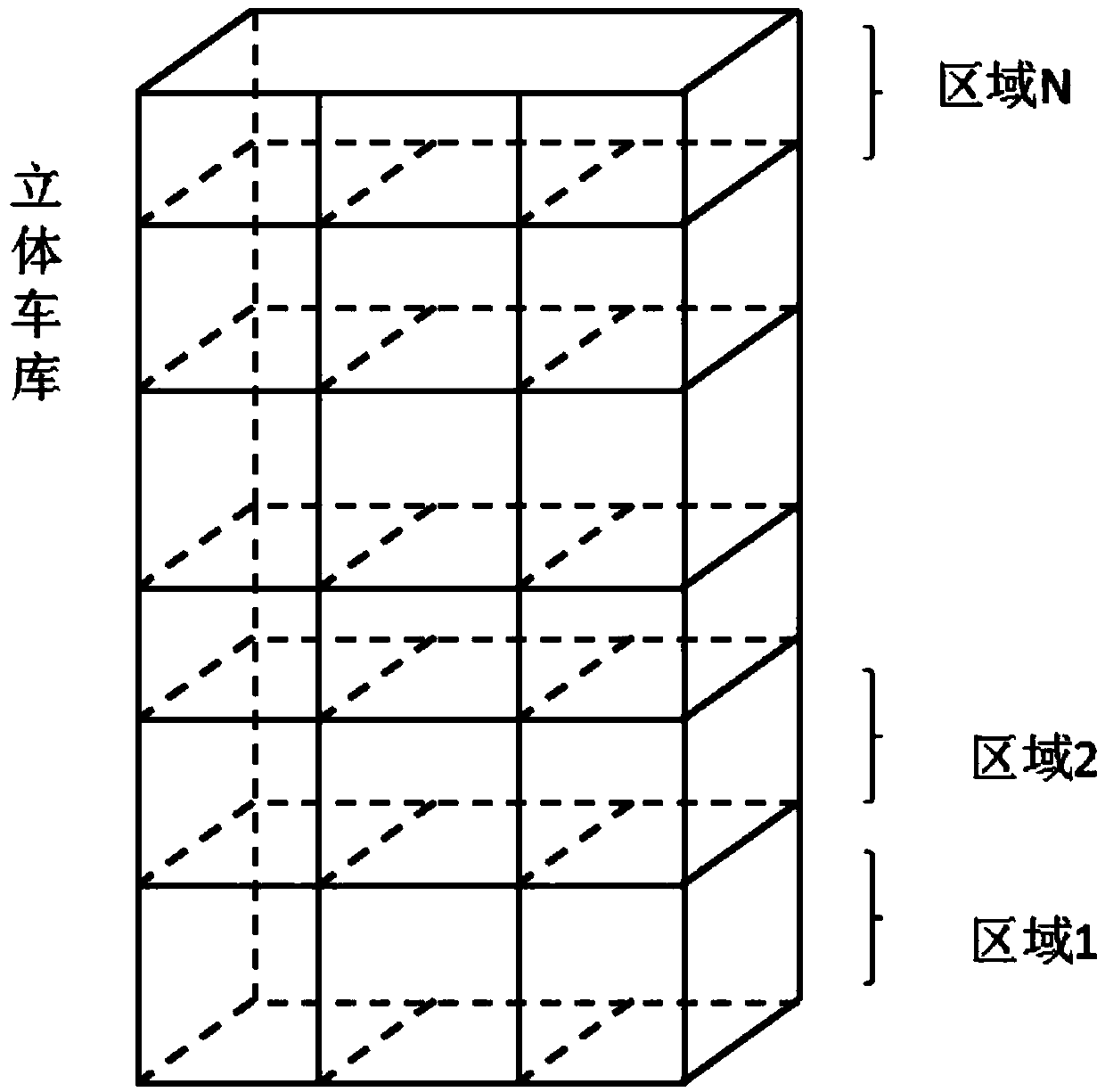

Mobile internet based control platform and method of automatic three-dimensional garage

InactiveCN105370075AImprove delivery experienceImprove the efficiency of inbound and outboundParkingsControl systemParking space

The invention relates to a mobile internet based control platform and method of an automatic three-dimensional garage. The control platform comprises the three-dimensional garage, garage control systems, a data processing platform and a terminal application system, wherein the garage control systems, the data processing platform and the terminal application system are connected through network; the garage control systems are connected to the three-dimensional garage and used for controlling the three-dimensional garage; the data processing platform is used for sending command information to each garage control system through the network in order to inform the specific location where a vehicle is to be moved in the three-dimensional garage; the garage control systems can feed back the location of each vehicle to the data processing platform. The mobile internet based control platform and method have the beneficial effects that a user can remotely operate the three-dimensional garage through an internet terminal, query the parking space information and the vehicle parking information in real time, and order and early operate the three-dimensional garage, so that the vehicle in and out efficiency can be improved; the corresponding system can calculate the optimal parking space distribution according to the user requirement information and the parking space state, so that the overall performance can be optimized.

Owner:INTELLIGENT INTER CONNECTION TECH CO LTD

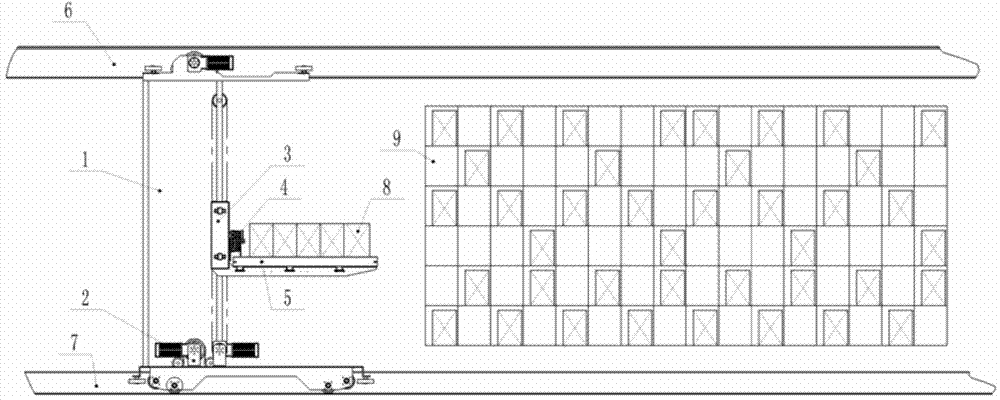

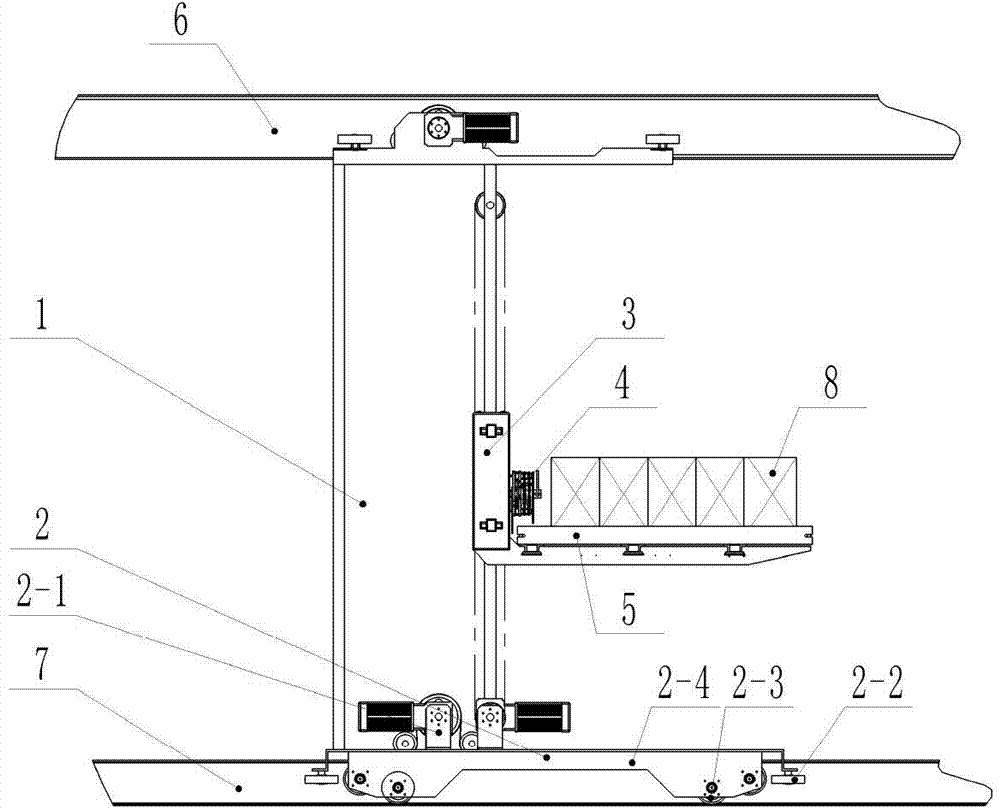

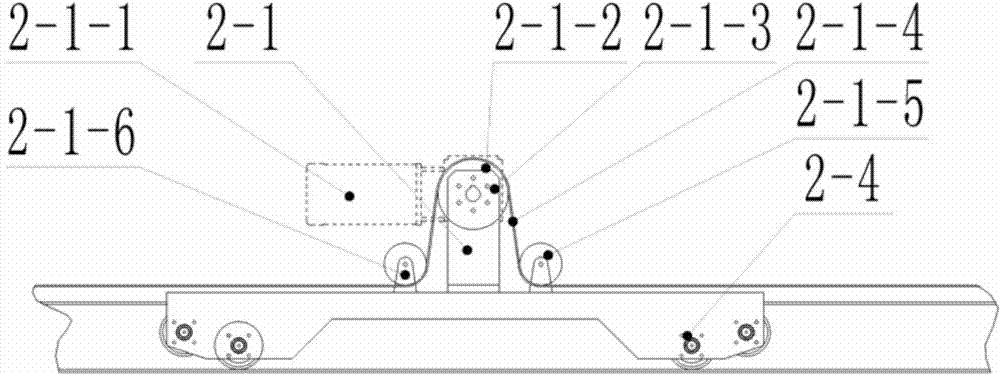

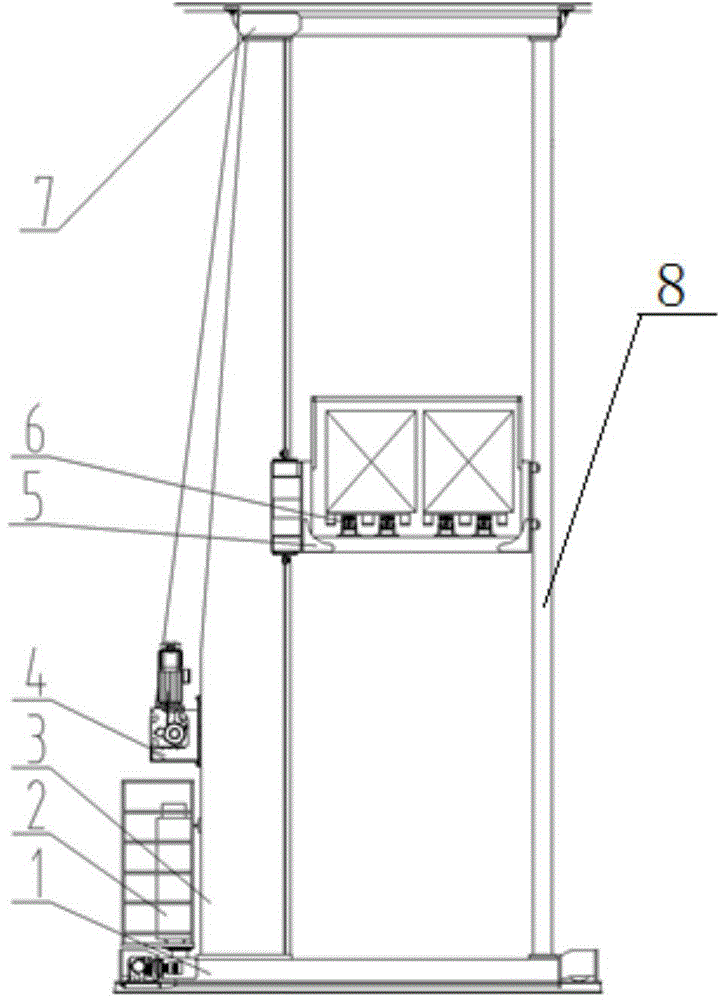

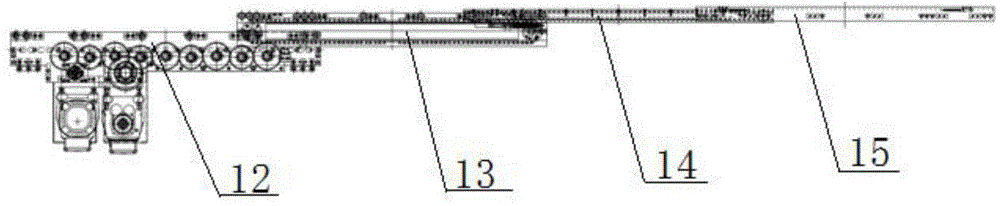

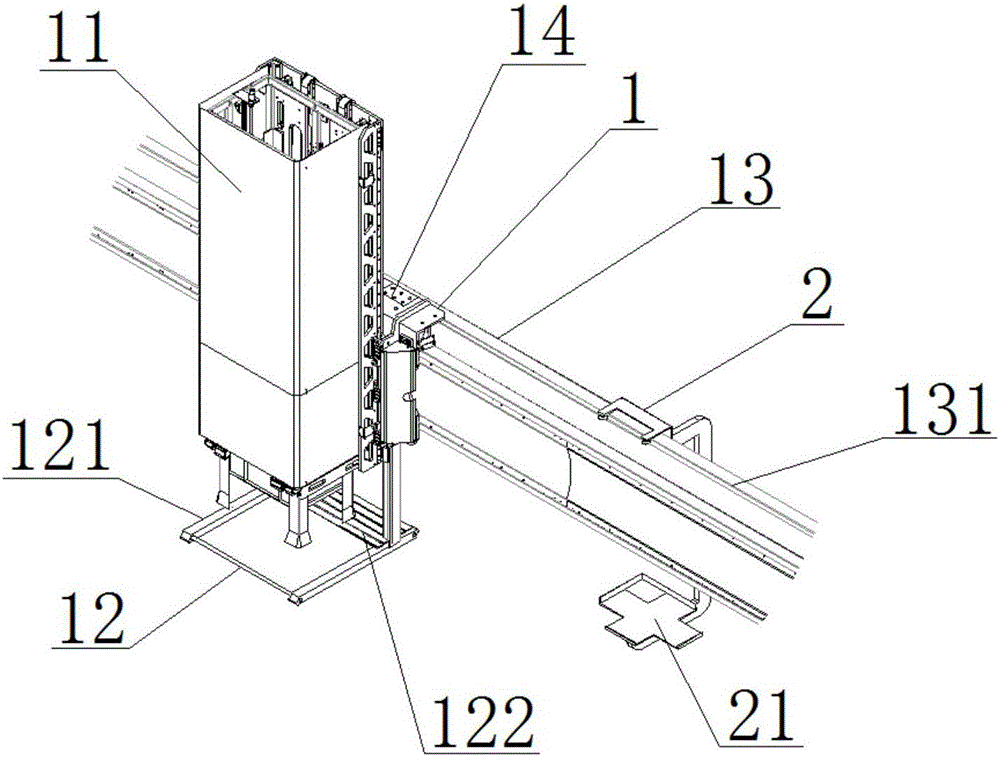

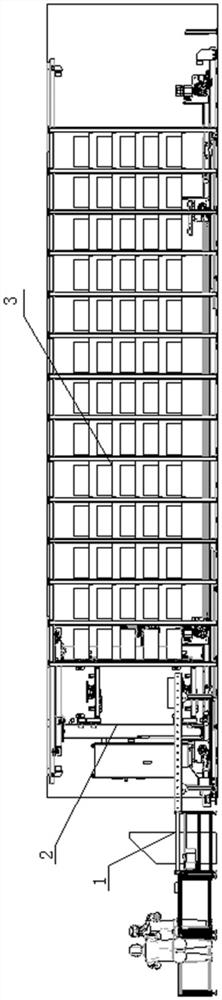

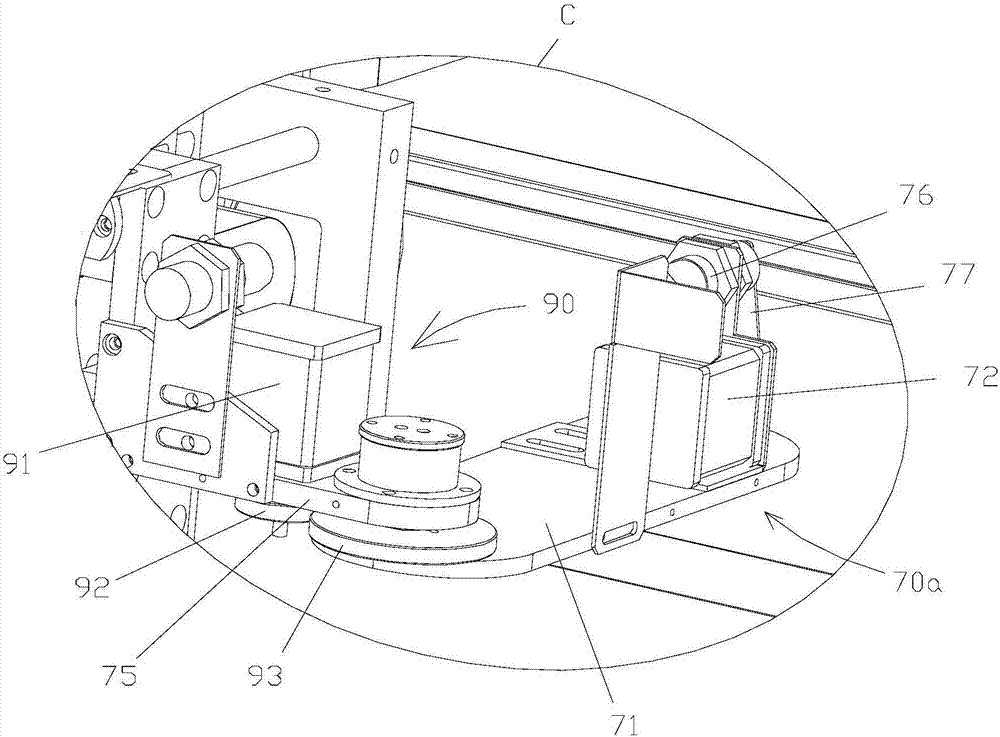

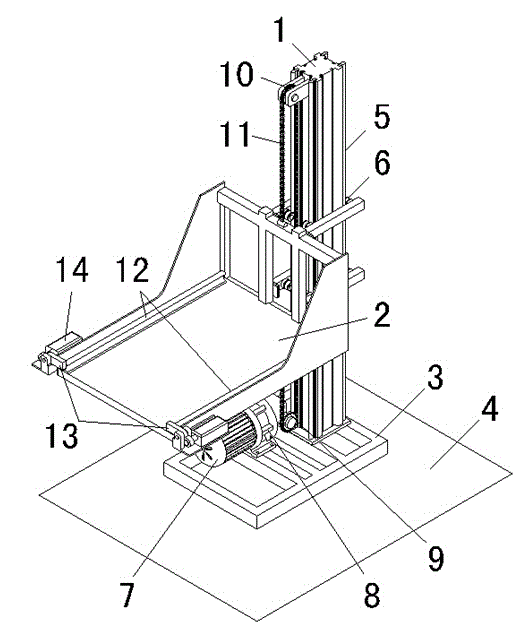

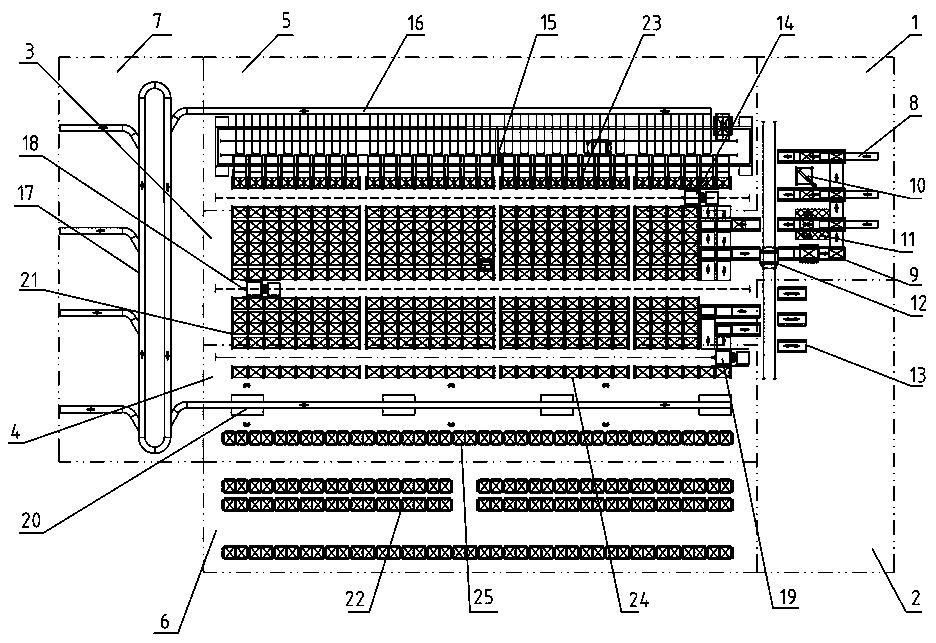

High-speed stacking machine for light material boxes

ActiveCN103879704AHigh positioning accuracyFast positioning accuracyStorage devicesMachineTransfer mechanism

The invention relates to a high-speed stacking machine for light material boxes, in particular to a high-speed stacking machine for light material boxes used for intensive storage of an elevated stereoscopic warehouse. The high-speed stacking machine for light material boxes is characterized by comprising a running device, a lifting mechanism driven by a synchronous belt, a telescopic fork claw shifting mechanism and a material box transferring mechanism, wherein the running device is composed of an upper set of synchronous belt driving mechanism and a lower set of synchronous belt driving mechanism, the running device and the lifting mechanism are arranged on a running framework, and the telescopic fork claw shifting mechanism and the material box transferring mechanism are fixed on a lifting platform of the lifting mechanism. A traditional stacking machine can only transfer one material box every time and is low in efficiency, and a fork of the traditionally stacking machine is large and heavy due to the fact that the material boxes need to be lifted and the gravity of the material boxes needs to be overcome through the commodity taking method. Compared with the traditional stacking machine, the high-speed stacking machine for light material boxes has the advantages of being high in operation speed, high in positioning accuracy, stable in operation, small in noise, high in efficiency, small in size and the like.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

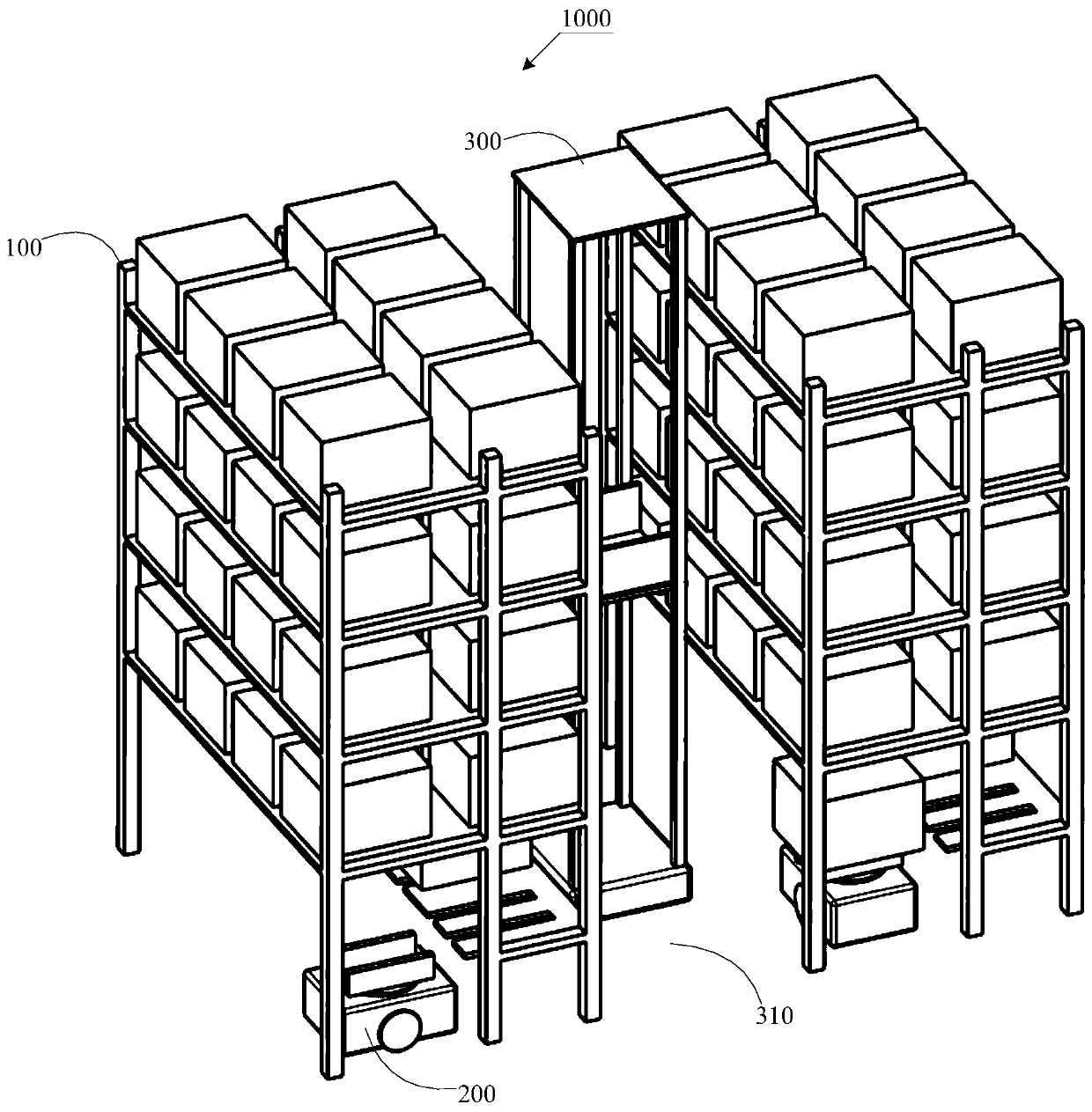

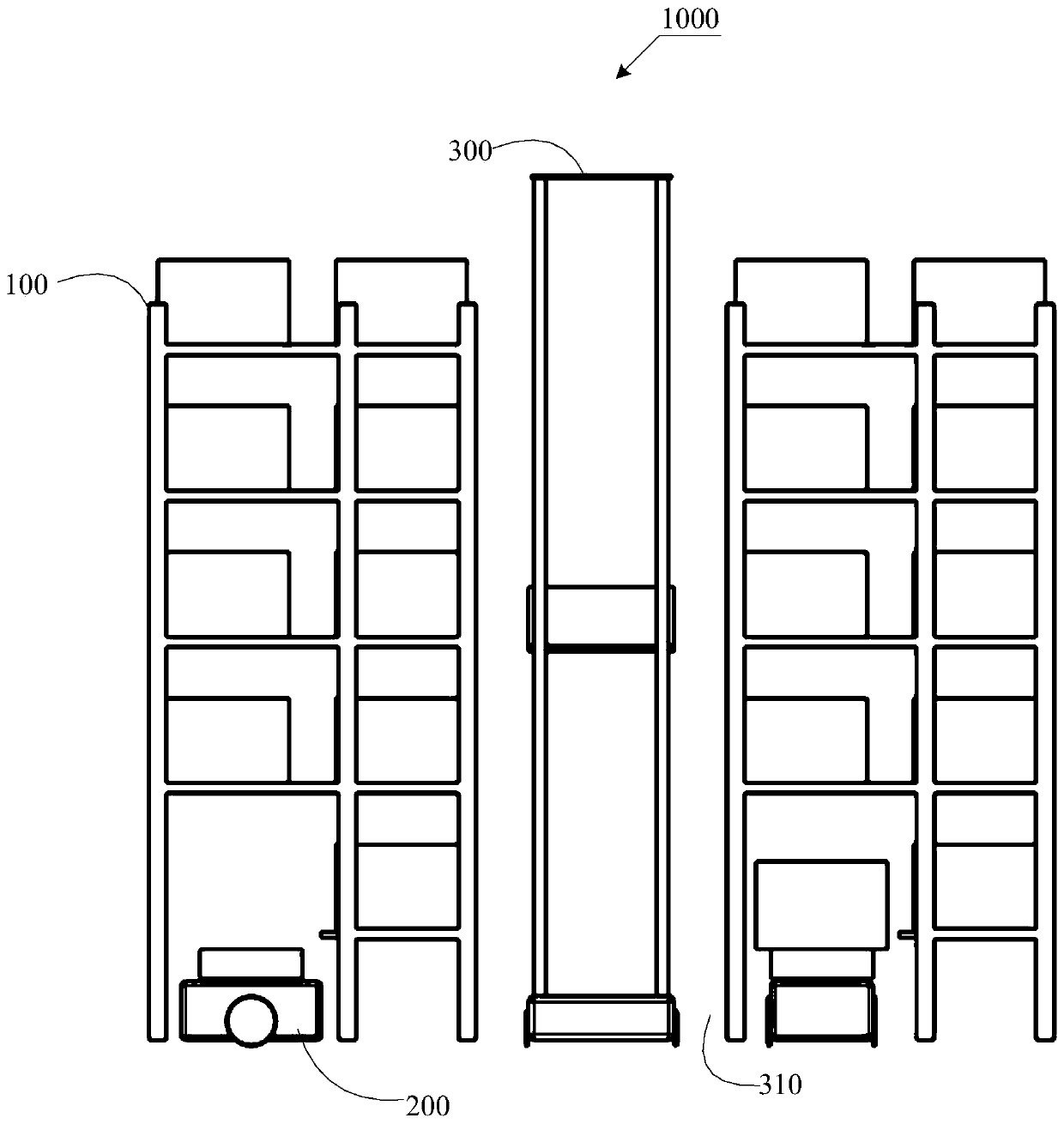

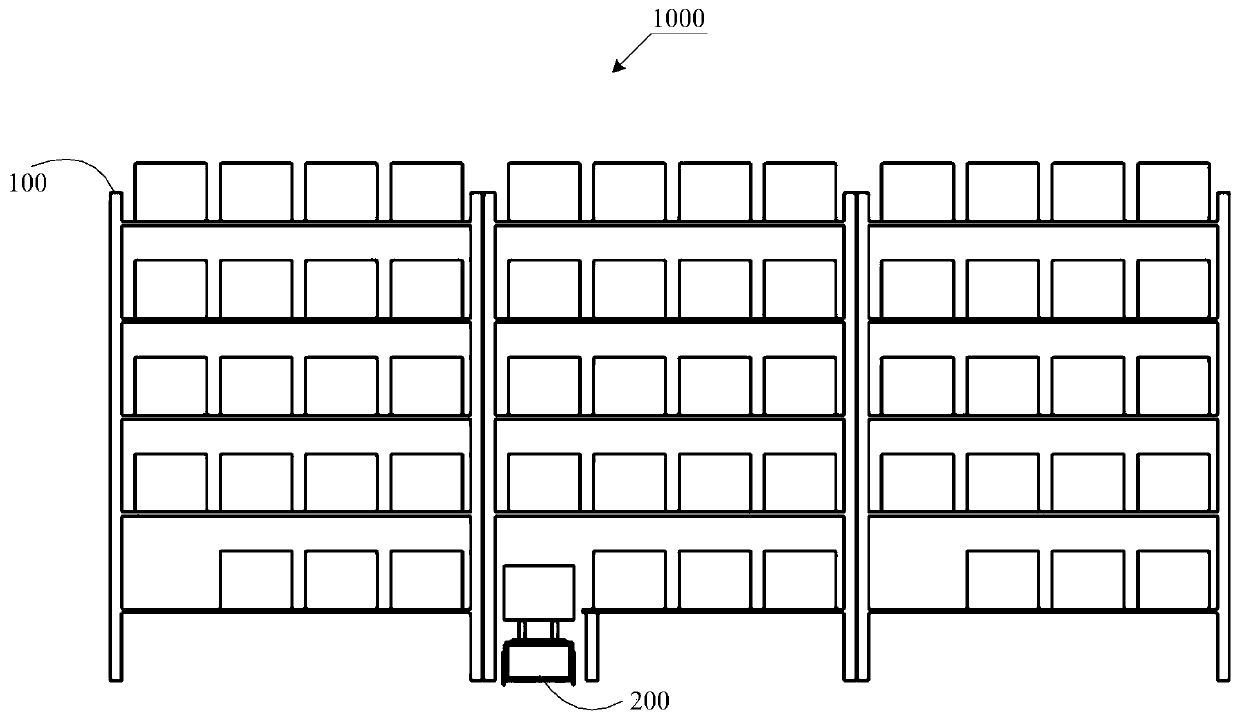

Storage device and system and control method

ActiveCN111361908AEasy to understand implementationEasy to understandStorage devicesControl engineeringMechanical engineering

The embodiment of the invention provides a storage device and system and a control method. The storage device comprises multiple goods shelves, a first robot channel and a second robot channel. Each goods shelf comprises at least one temporary storage laminate, at least one storage laminate and multiple stand columns arranged in the horizontal direction at intervals. The storage laminates and thetemporary storage laminates are arranged in the vertical direction at intervals through the stand columns. The temporary storage laminates are used for providing multiple temporary storage stations, and the storage laminates are used for providing multiple storage stations. The first robot channel is used for allowing a first robot to run, and the first robot is used for storing goods on the temporary storage laminates. The second robot channel is used for allowing a second robot to run, and the second robot is used for carrying goods between the temporary storage laminates and the storage laminates. By means of the technical scheme, the efficiency of putting cargoes in and out of warehouses can be improved.

Owner:SHANGHAI QUICKTRON INTELLIGENT TECH CO LTD

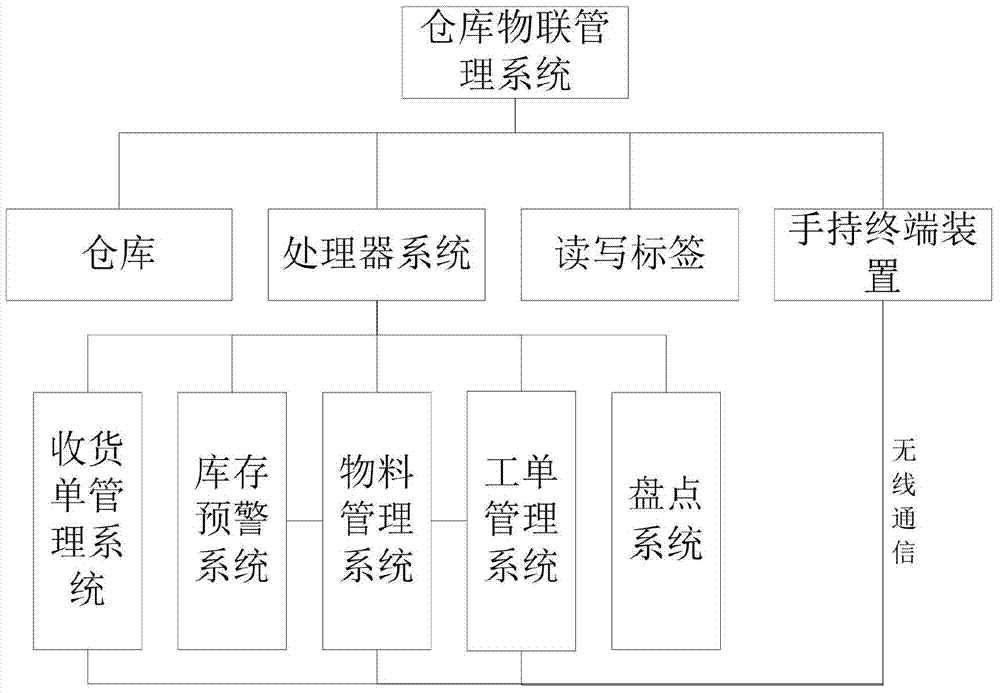

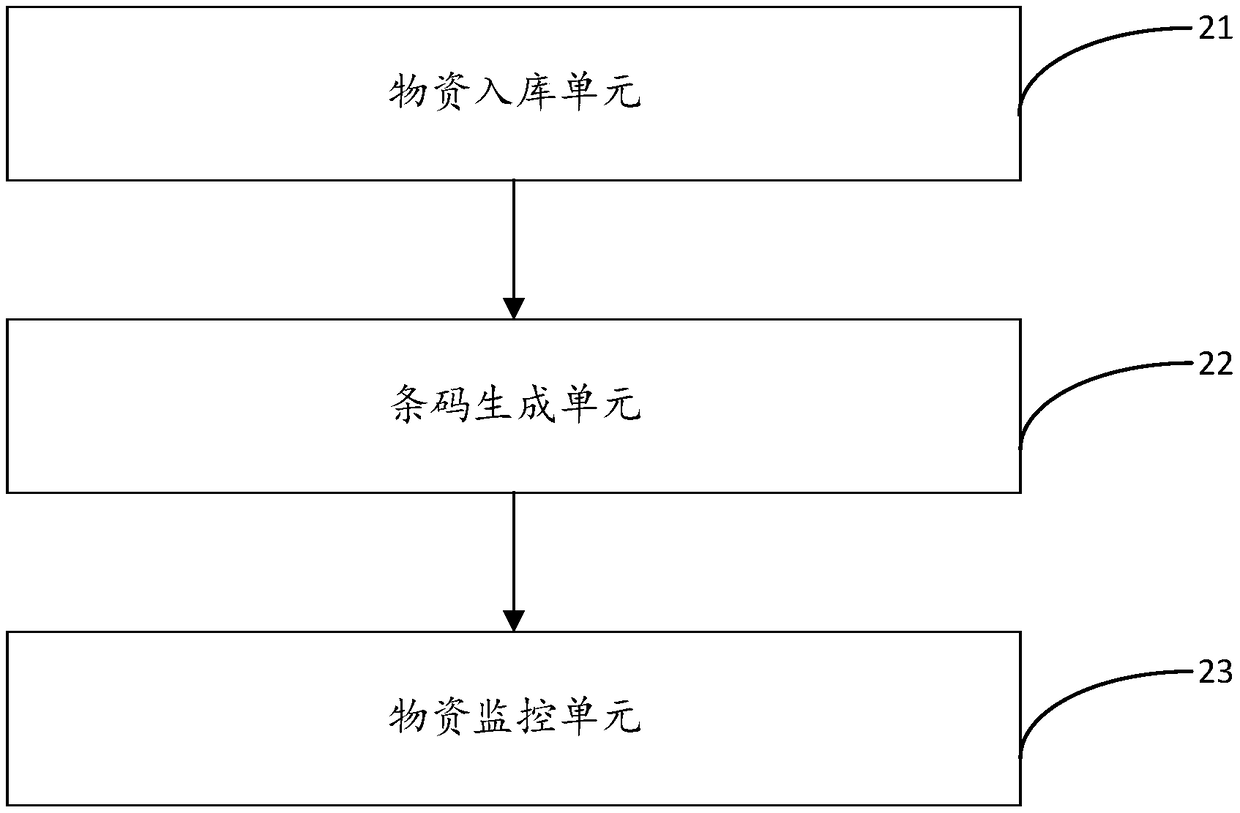

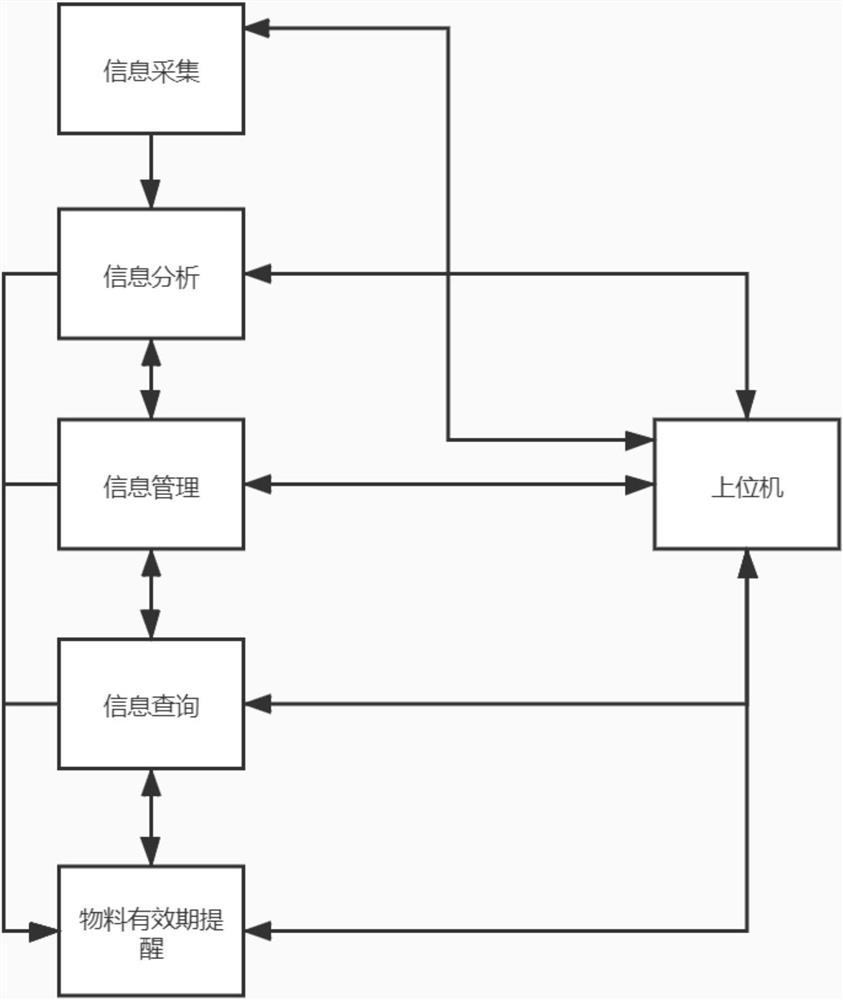

Warehouse material linkage management system and method

InactiveCN103886443AImprove the efficiency of inbound and outboundImprove work efficiencyLogisticsPersonalizationTelecommunications equipment

The invention relates to a warehouse material linkage management system and method. The system comprises a warehouse, a processor system, a handheld terminal device and a reading-writing label. The warehouse comprises a material storing shelf and a material temporary storage shelf. A material management system, an inventory warning system, a receiving note management system, a workorder management system and a checking system are arranged in the processor system. The processor system is further provided with a wireless communication device. The warehouse material linkage management method mainly comprises the steps of order and receiving note recording, receiving management, material adding, material delivery, material checking and the like. The material linkage management system is suitable for personalized customization production management, and the management efficiency of material personalized customization production can be improved.

Owner:青岛酷特智能股份有限公司

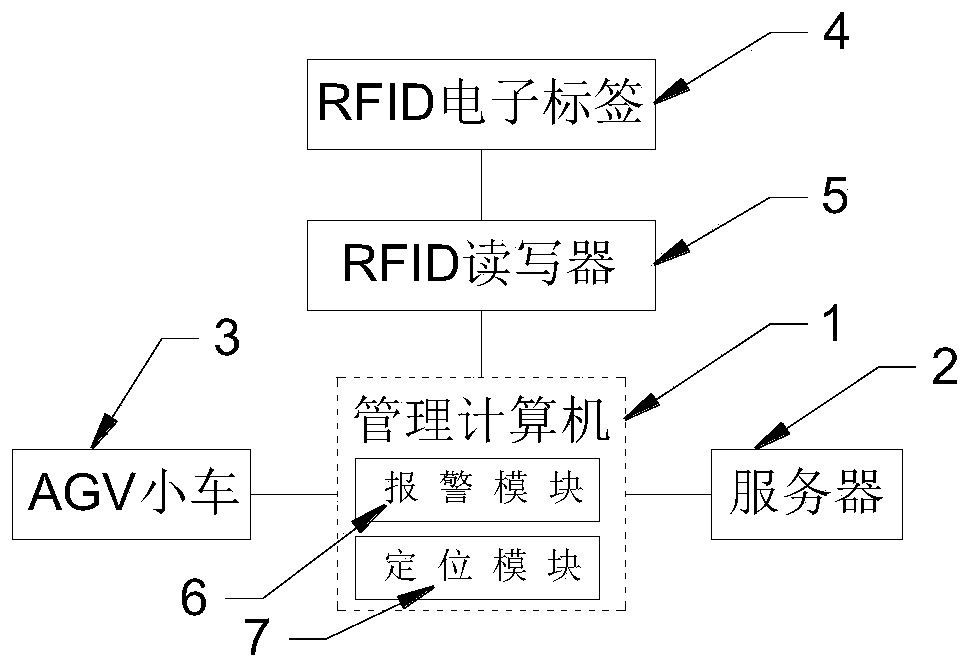

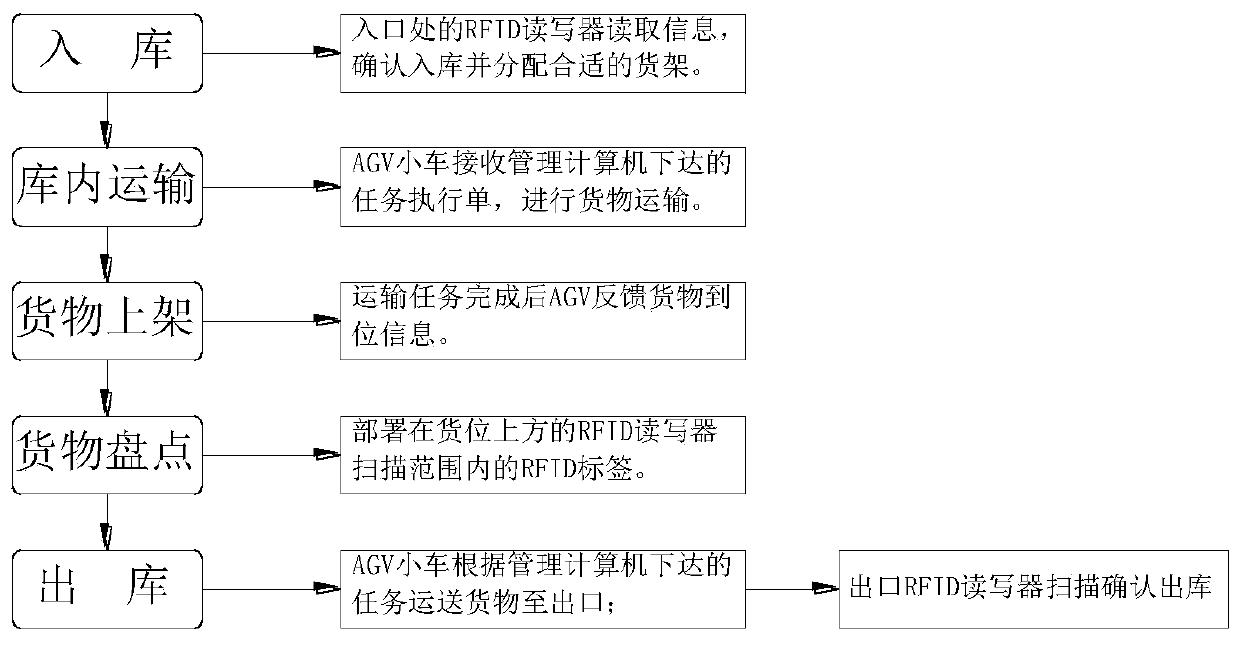

Three-dimensional warehouse management system and method based on RFID

ActiveCN110414638AImprove turnover rateHigh transparencyCo-operative working arrangementsElectric/hybrid propulsionStorage managementReader writer

The invention relates to the technical field of warehouse management, and discloses a three-dimensional warehouse management system and method based on RFID, and the system comprises a management computer, a server, an AGV, an RFID electronic tag which can be pasted on a cargo, and an RFID reader-writer. The RFID reader-writer and the AGV are in communication connection with the management computer, the management computer is in communication connection with the server, and an alarm module is arranged in the management computer. According to the invention, the RFID electronic tag containing the cargo identifier is pasted on the surface of the cargo, and the RFID reader-writer is adopted to complete the input work of a large number of cargos, so that the warehouse-in and warehouse-out efficiency is greatly improved, and the labor cost is saved. Proper goods allocations are distributed to warehoused goods, so that the turnover rate of warehousing is greatly increased; and for intelligentalarming of abnormal conditions, occurred errors can be handled in time, so that the management cost of storage is reduced, and further improvement of storage management is facilitated.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

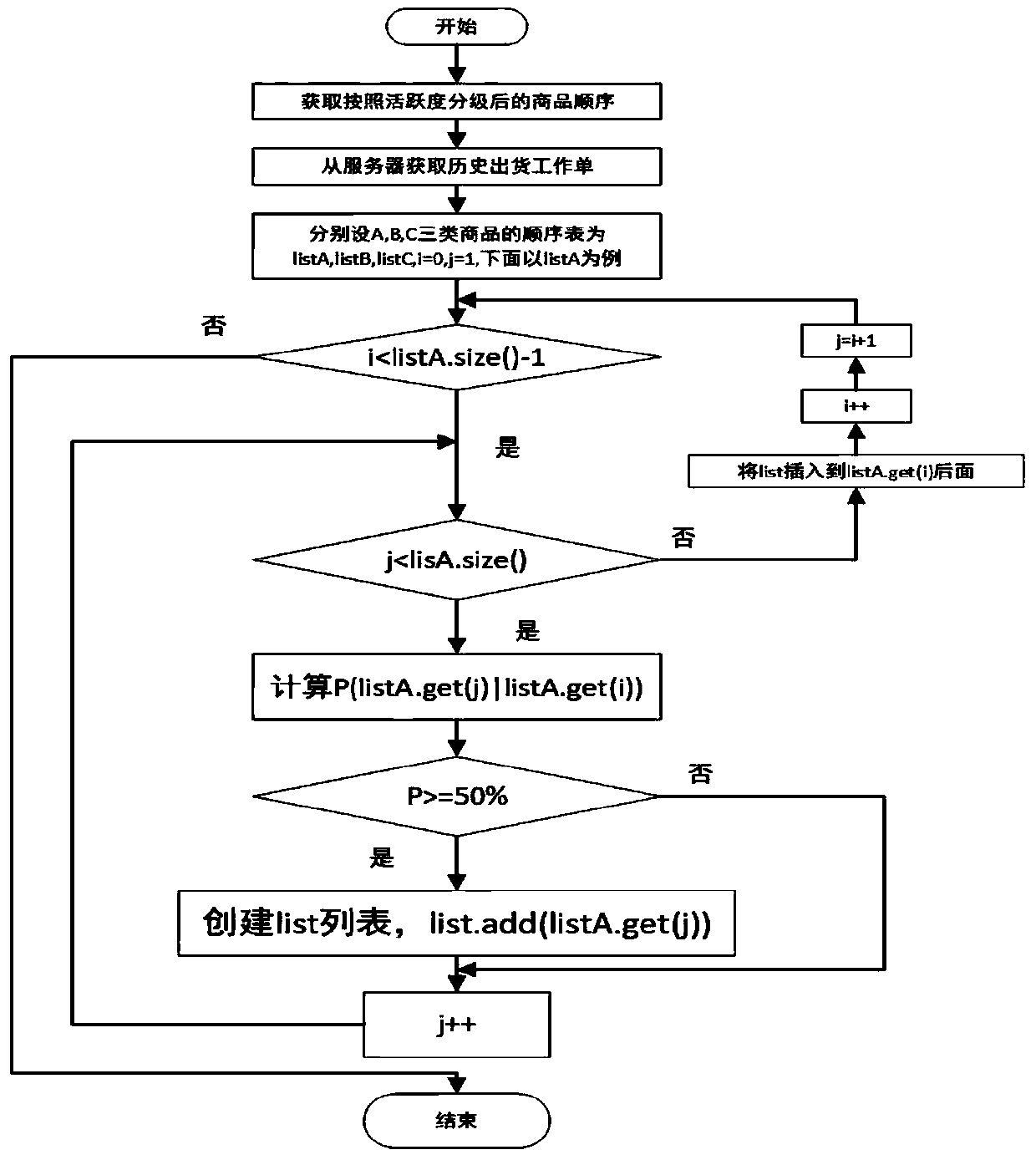

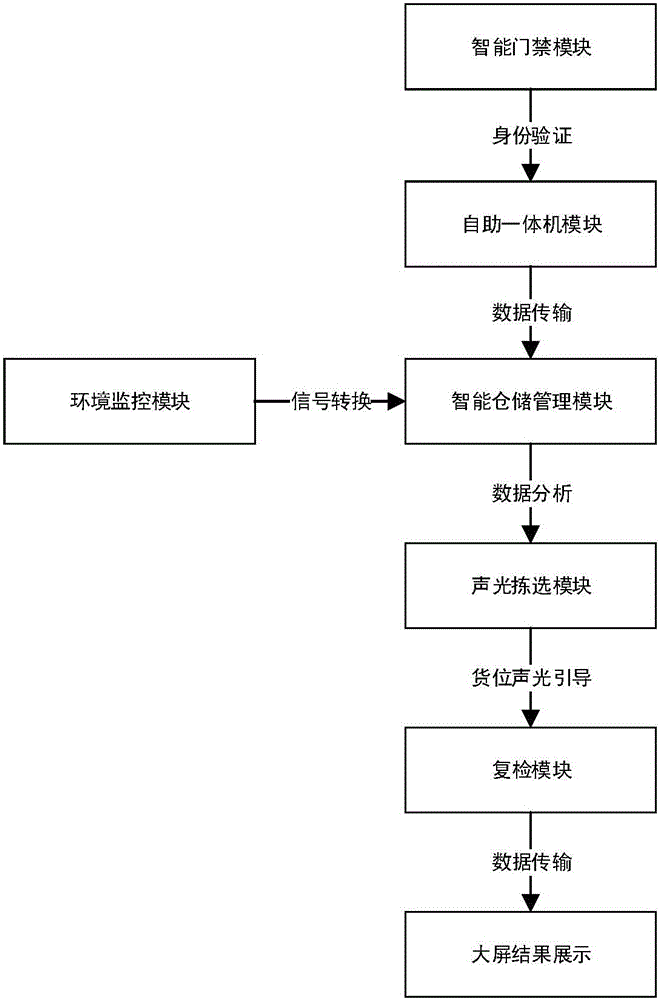

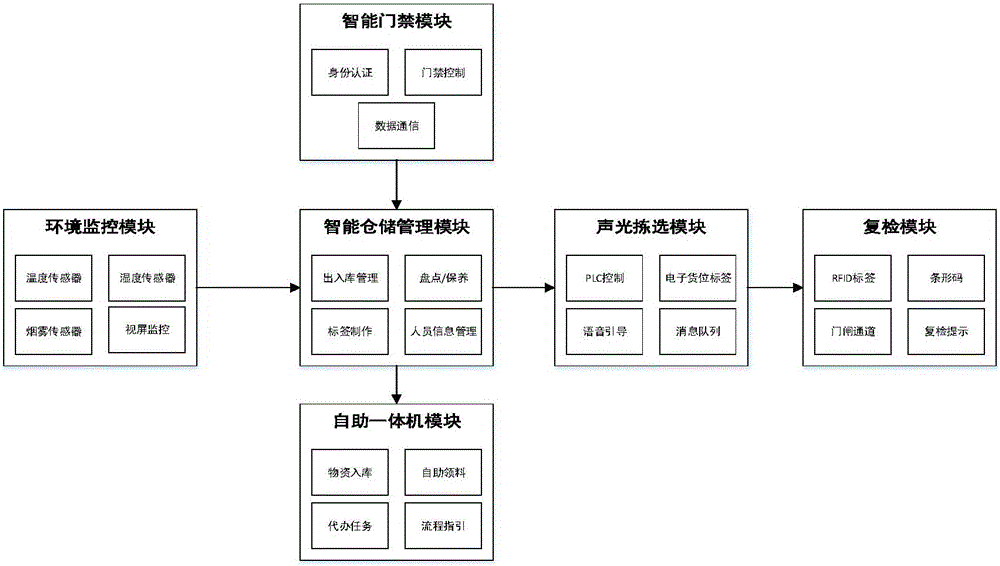

Self-service unattended warehousing system based on acousto-optic picking and control method thereof

InactiveCN106408230ARealize intelligent managementImprove the efficiency of inbound and outboundIndividual entry/exit registersLogisticsLogistics managementThe Internet

The invention provides a self-service unattended warehousing system based on acousto-optic picking and a control method thereof, and is used for warehouse field operation in the warehousing logistics management process. The control method comprises output and input of the warehouse and intellectualization of the inventory process. According to the system, the internet of things technology acts as the core, the unattended, self-service picking and acousto-optic cargo location guidance technologies are introduced, the conventional warehouse management mode is innovated, the management mode for the materials of high output and input frequency is improved and the unattended and self-service warehouse management mode is established so that the management level and the service quality can be enhanced and the human resource and operation cost can be greatly reduced.

Owner:CHUXIONG POWER SUPPLY BUREAU OF YUNNAN POWER GRID CO LTD +1

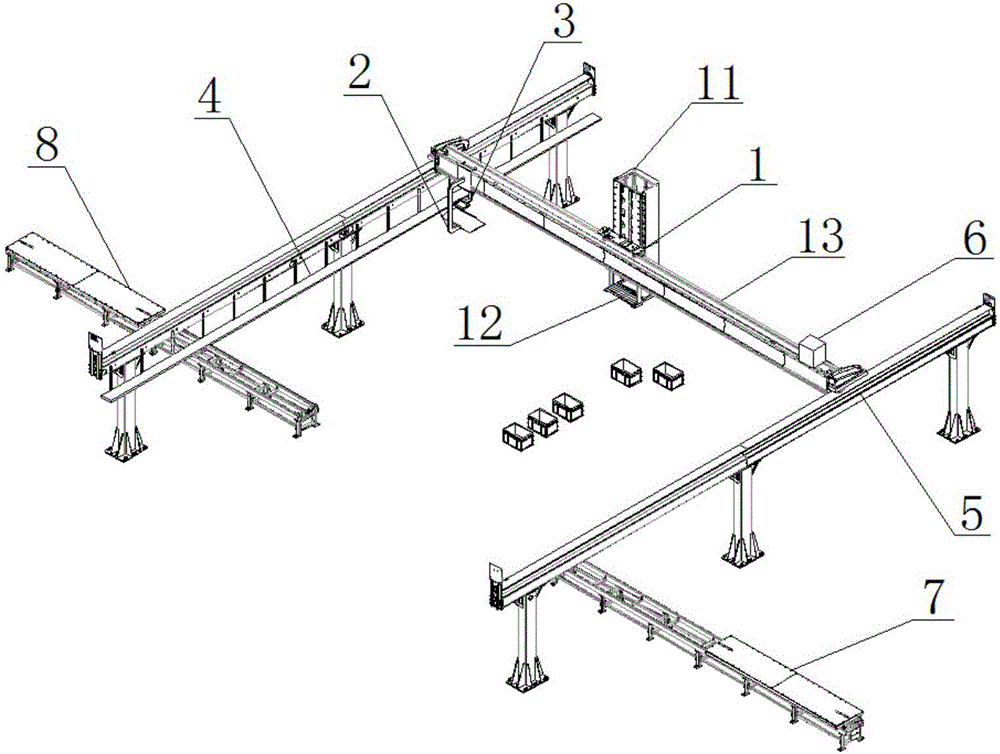

Railroad aisle stacking crane

ActiveCN104973540AImprove the efficiency of inbound and outboundImprove space utilizationLifting devicesWork cycleTransportation technology

The invention relates to the technical field of material storage and transportation, in particular to a railroad aisle stacking crane. The railroad aisle stacking crane comprises a traveling mechanism and a hoisting mechanism and a post mechanism which are arranged at the top of the traveling mechanism, and the traveling mechanism can drive the hoisting mechanism and the post mechanism to move in the horizontal direction; a double-goods-allocation carrying platform is horizontally arranged on the post mechanism and connected with the hoisting mechanism, and the hoisting mechanism can drive the double-goods-allocation carrying platform to move up and down along the post mechanism; two pairs of double deep forks are arranged on the double-goods-allocation carrying platform, and the double deep forks can do telescopic movement on the double-goods-allocation carrying platform. According to the railroad aisle stacking crane, the problems that in the prior art, the space utilization ratio is low due to the structure, one pallet of goods can only be fetched in one working cycle, and the efficiency is low are solved.

Owner:BEIJING MATERIALS HANDLING TECH INST CO LTD

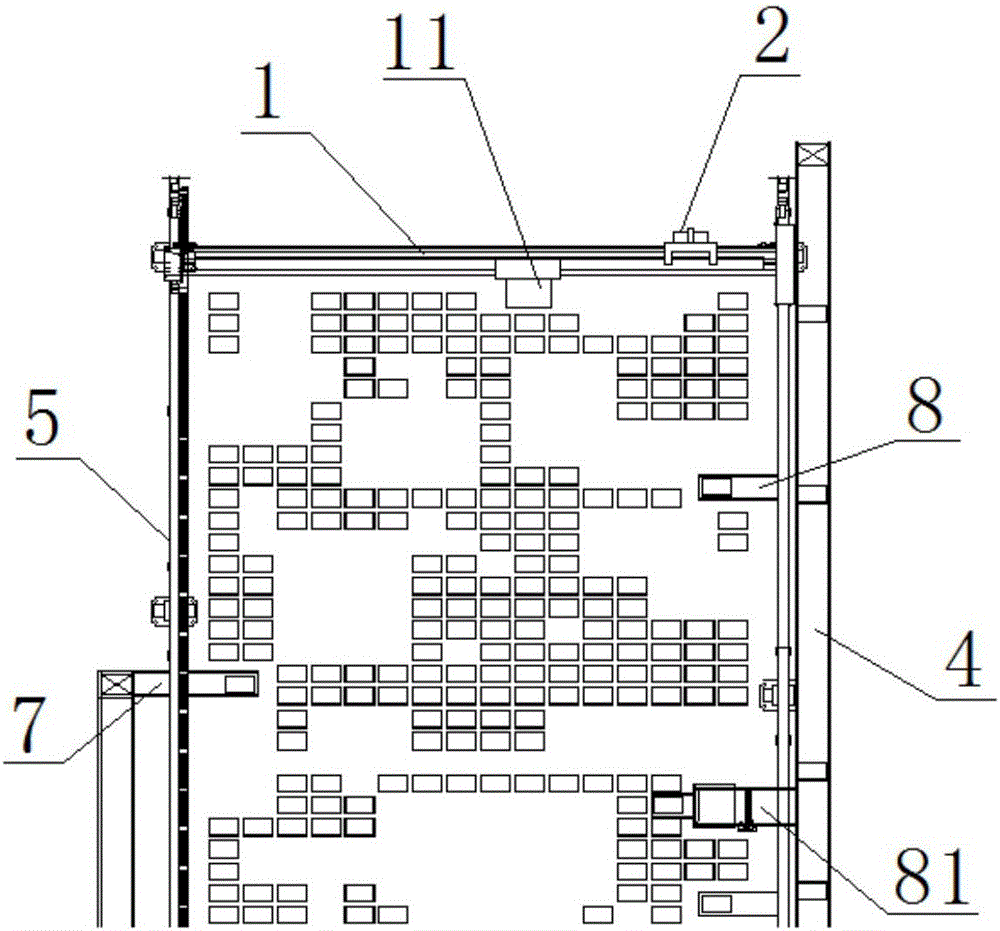

Automatic logistics warehouse-in and warehouse-out system

ActiveCN106429161AHigh degree of automationImprove operational efficiencyStorage devicesLogistics managementEngineering

The invention relates to a warehouse-in and warehouse-out system, in particular to an automatic logistics warehouse-in and warehouse-out system. The automatic logistics warehouse-in and warehouse-out system comprises a portal manipulator, a shuttle car, a cleaning mechanism, an aerial conveying line body, aerial rails, a control box, a warehouse input line body and a warehouse output line body; the portal manipulator includes a grabbing tool, a transplantation mechanism, a mobile cross beam and a mobile holding platform; the aerial rails are arranged on two sides of a warehouse; the mobile cross beam can move on the aerial rails; the mobile holding platform can slide on the mobile cross beam; and the grabbing tool is mounted on the side part of the mobile holding platform. The automatic logistics warehouse-in and warehouse-out system has the following advantages: the logistics operation is standardized through operation of stackable standard goods frames, so that the automatic application is convenient; the goods frames are grabbed by the portal manipulator, so that the positioning is quick, the operation is accurate, and the warehouse-in and warehouse-out efficiency is improved; and the system can quickly stack the goods frames on the warehouse-in line body to corresponding warehouse positions according to preset warehouse-in tracking information and related control instructions.

Owner:青岛科捷机器人有限公司

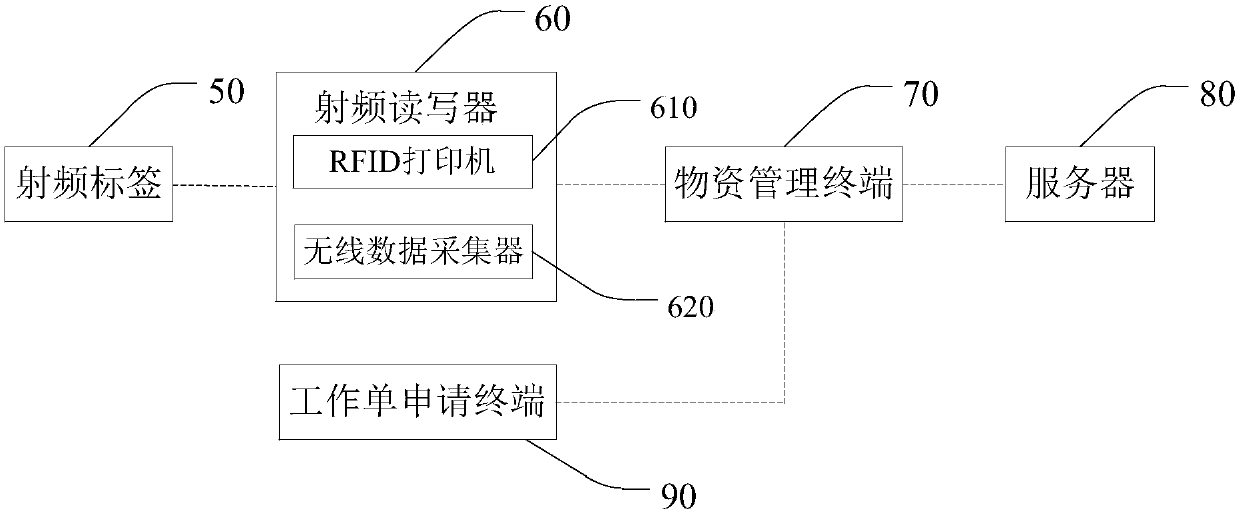

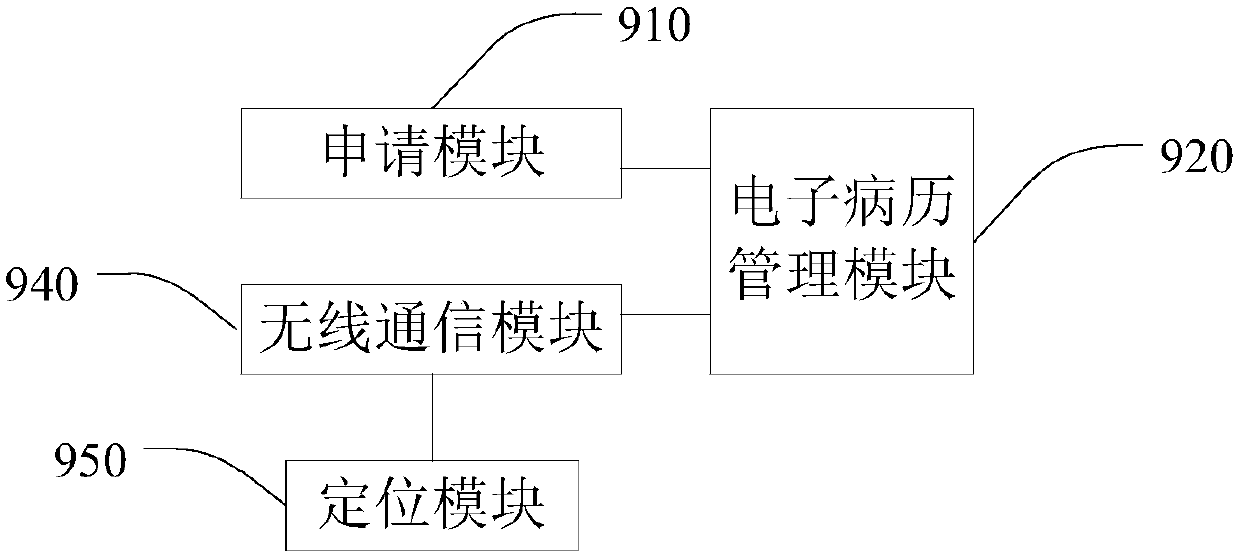

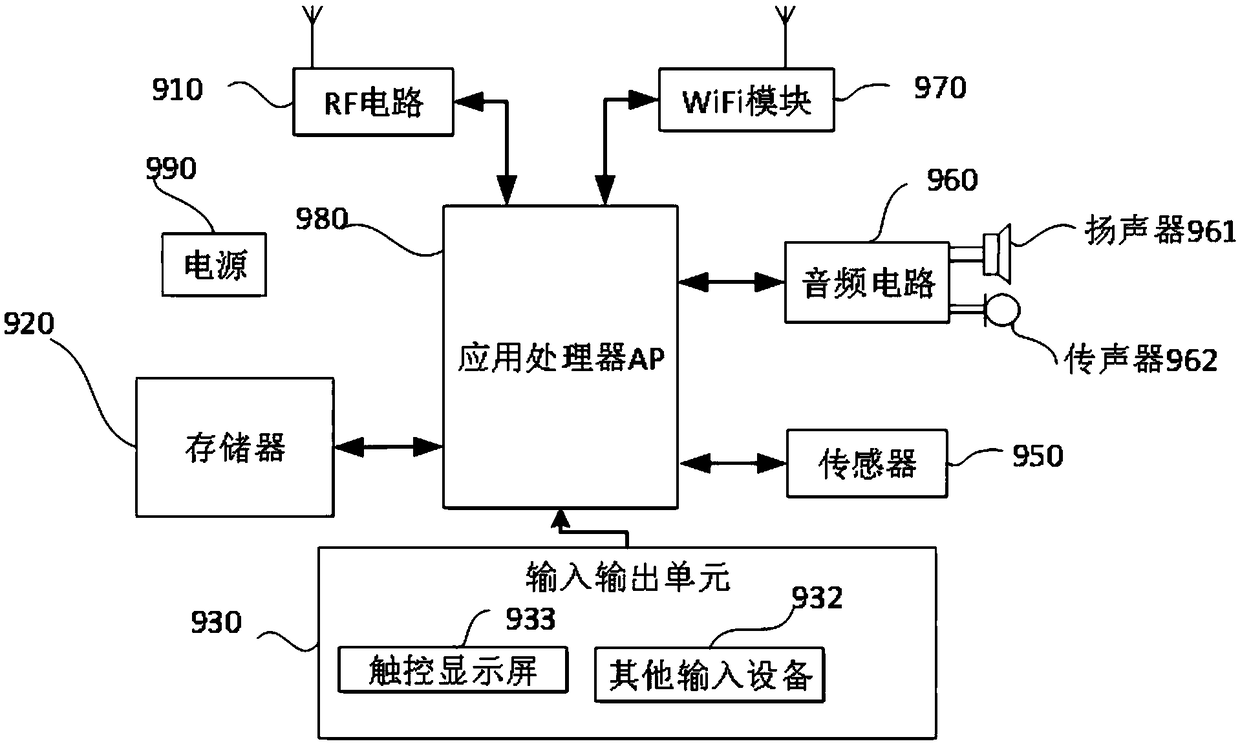

Material warehouse management system

InactiveCN107609825AImprove acquisition efficiencyNo manual recording requiredLogisticsUnique identifierComputer terminal

The invention discloses a material warehouse management system. Radio frequency tags are adopted to mark various materials in a warehouse. The tag information of corresponding materials and the uniqueidentifier ID of the corresponding material are stored in each radio frequency tag, wherein the tag information of each radio frequency tag and the unique identifier ID correspond to each other. Thetag information of materials can be generated and obtained by means of a radio frequency reader-writer. The manual recording is not needed, and the information acquisition efficiency is improved. A work order application terminal generates various work orders. A material management terminal takes a work order as a reference and judges whether to execute material ex-warehouse and warehousing operation or not through checking the identifier ID of the radio frequency reader-writer. As a result, the manual checking is not needed, and the warehouse-in and warehouse-out efficiency is improved.

Owner:DOTT MEDICAL

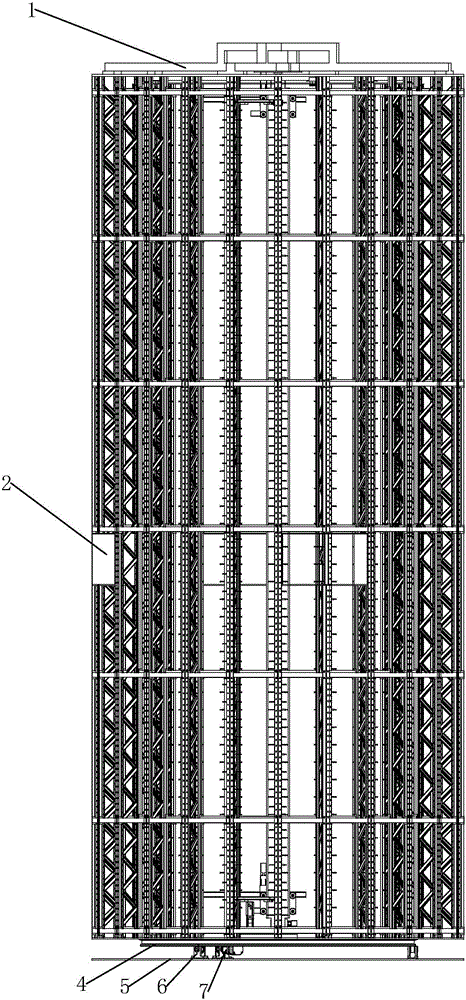

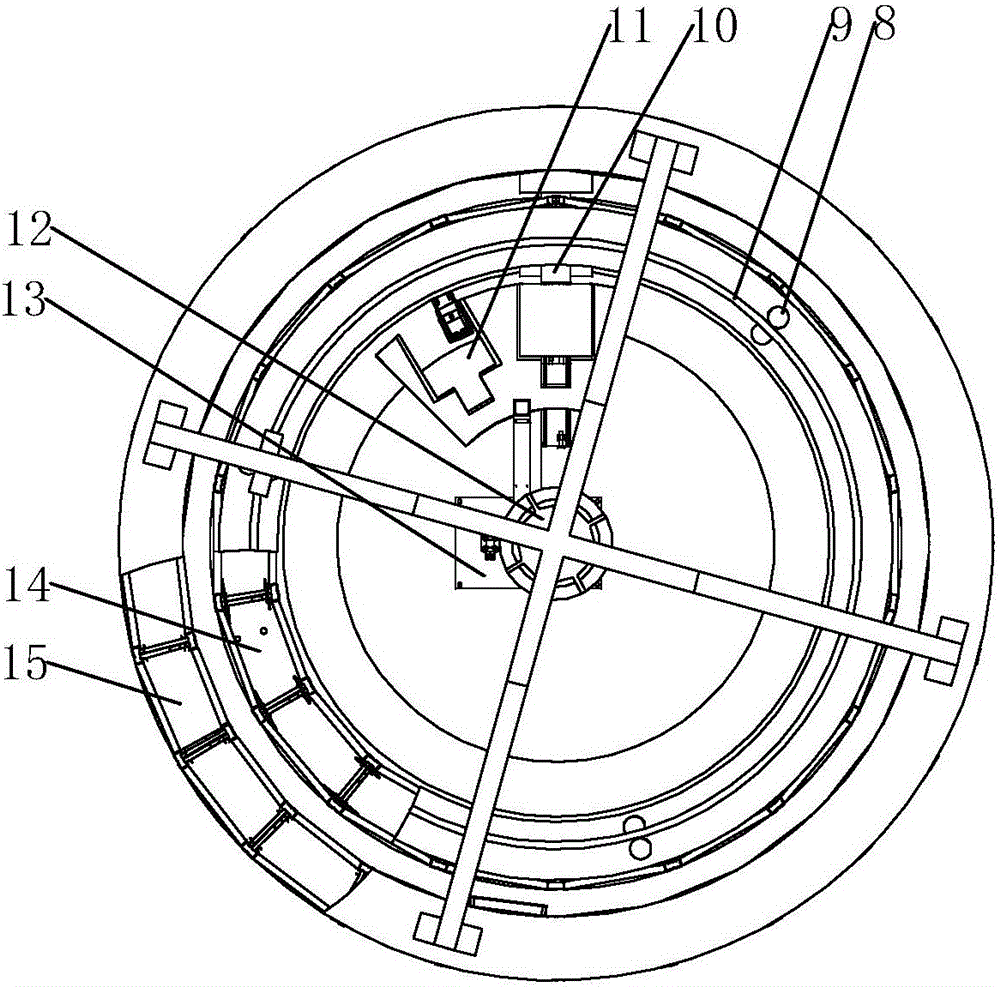

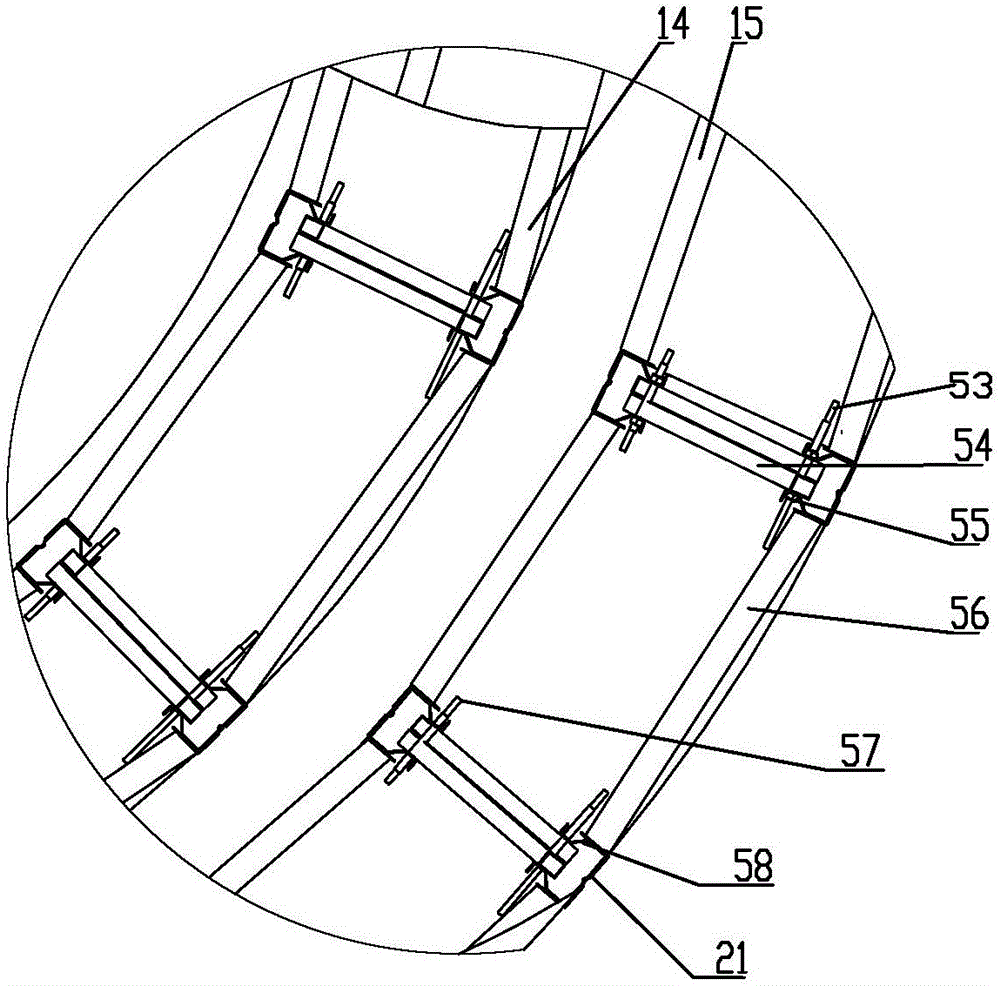

Logistics tower equipment

The invention provides logistics tower equipment and belongs to the technical field of warehouse logistics. The logistics tower equipment comprises an adjusting rack, windows, an outer layer goods shelf, an inner layer rotary goods shelf, a center rotation mechanism, a lifting mechanism, a buffer storage mechanism and a manipulator assembly. The adjusting rack is arranged at the top ends of the outer layer goods shelf and the inner layer goods shelf and connected with the outer layer goods shelf, the inner layer goods shelf, the center rotation mechanism and the lifting mechanism which are arranged in sequence. The inner layer goods shelf is connected with the adjusting rack through a top rail assembly and connected to the ground through a ground rail assembly and does circular rotational motion along top rails and ground rails. A center rotation stand column is mounted in the middle of the inner layer goods shelf. The buffer storage mechanism and the manipulator assembly are both mounted on the center rotation stand column through a vertical driving mechanism and move up and down along the center rotation stand column. A goods taking passage is formed longitudinally along the diameter, where the manipulator assembly is mounted, of the inner layer goods shelf. The outer layer goods shelf is provided with the goods taking and sending windows. According to the logistics tower equipment, the number of goods locations on the goods shelves is large, and the space utilization rate is high; and goods on the outer layer goods shelf are taken through the inner layer rotary goods shelf, and accordingly the output and input efficiency of a warehouse is improved.

Owner:SHENYANG GENERAL ROBOT TECH

Honeycomb system and workbin storage and sorting system

PendingCN107720066AImprove the efficiency of inbound and outboundImprove storage densityLifting devicesSensing record carriersPower stationHoneycomb

The invention provides a honeycomb system and a workbin storage and sorting system and relates to the technical field of storage. The honeycomb system comprises at least one modular storage unit and also comprises a layer exchanging lifter. The layer exchanging lifter is arranged at any end of a double-cargo-position cargo rack; the plurality of modular storage units correspond to one piece of sorting equipment; each of the modular storage units comprises a group of double-cargo-position cargo racks, at least one lifter, at least one shuttle vehicle and at least one power station; a group of double-cargo-position workbin access cargo racks are parallel one another to form a lane, and the shuttle vehicle operates in the lane; the power stations are arranged at two ends or in the middle of the double-cargo-position cargo racks; the power stations are integrated with transmisson mechanisms and supporting frames; the transmission mechanisms are connected to the shuttle vehicles and the lifting mechanism, so as to transfer cargoes between the shuttle vehicles and the lifters. According to the honeycomb system and the workbin storage and sorting system provided by the invention, the storage in and out efficiency and the storage density of the cargo racks can be improved and increased, the occupied space is saved, and the sorting efficiency of the storage cargo racks is finally improved.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

Intelligent warehousing system used for vehicle production line

ActiveCN104076775AImprove the efficiency of inbound and outboundPrecise positioningTotal factory controlProgramme total factory controlProduction lineComputer module

The invention relates to an intelligent warehousing system used for a vehicle production line. According to the intelligent warehousing system used for the vehicle production line, a controller program is combined with a hardware control module and operation logic, warehouse going in-out positions of vehicles can be tracked automatically and accurately in real time, and tracking can be achieved under the control of a controller or under manual control. The positions of the vehicles are tracked by the controller by monitoring actuating signals of a roller bed and displaying the signals through an interface, so that the vehicles going in or out of the warehouse can be accurately and visually positioned, every step is accurately mastered, the vehicles can go in or out of the warehouse more accurately and rapidly, the trajectory of each vehicle is tracked and recorded, and thus the warehouse going in-out efficiency of the vehicle production line is improved to a large extent. The whole system for control and scheduling can be applied as other warehousing going in-out systems or similar systems, real-time tracking and recording are achieved, scientific scheduling is achieved according to an algorithm, and the working efficiency is improved.

Owner:北海恒久天成技术开发有限公司

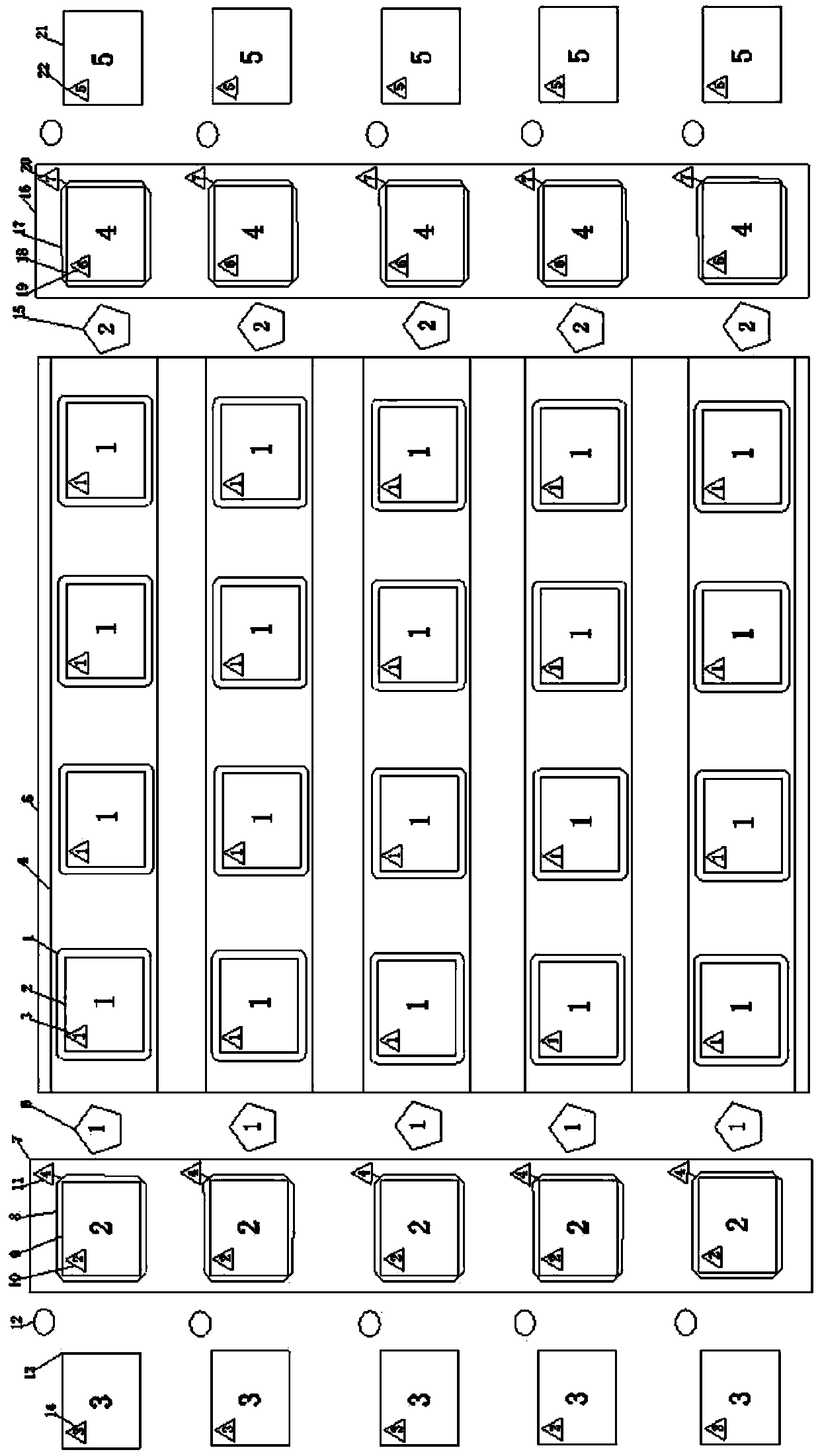

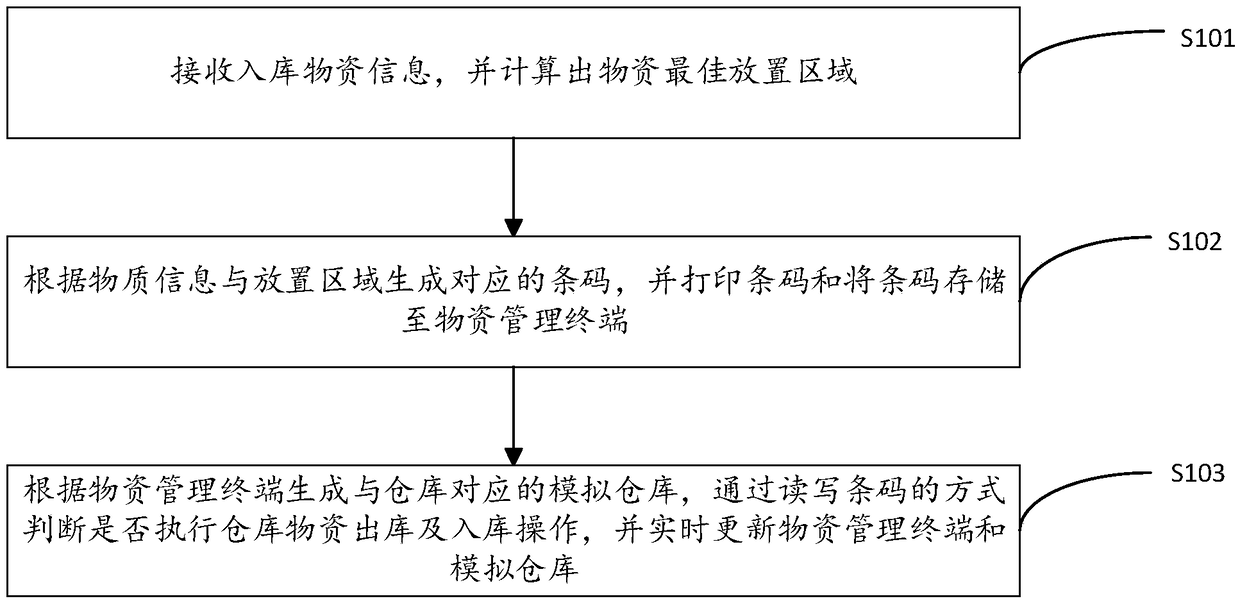

Warehouse management method and device

InactiveCN108846600AImprove acquisition efficiencyImprove management efficiencyCo-operative working arrangementsLogisticsLogistics managementBarcode

The invention relates to the technical field of intelligent logistics and particularly relates to a warehouse management method and device. The method comprises a step of receiving warehouse entry material information and calculating an optimal placement area of a material, a step of generating a corresponding barcode according to the material information and the placement area and printing the barcode and storing the barcode to a material management terminal, and a step of generating a simulation warehouse corresponding to a warehouse according to the material management terminal, determiningwhether to execute warehouse material delivery and storage operations by reading and writing the barcode, and updating the material management terminal and the simulation warehouse in real time. Through the calculation of the placement area, the corresponding management of goods and barcodes and the display and management of the simulation warehouse, the efficiency of warehouse management is improved, the labor cost is saved, an inaccurate inventory and no finding of the goods are prevented, first in and first out are achieved, and the management effect of the warehouse is improved.

Owner:SICHUAN HONGTU LOGISTICS +1

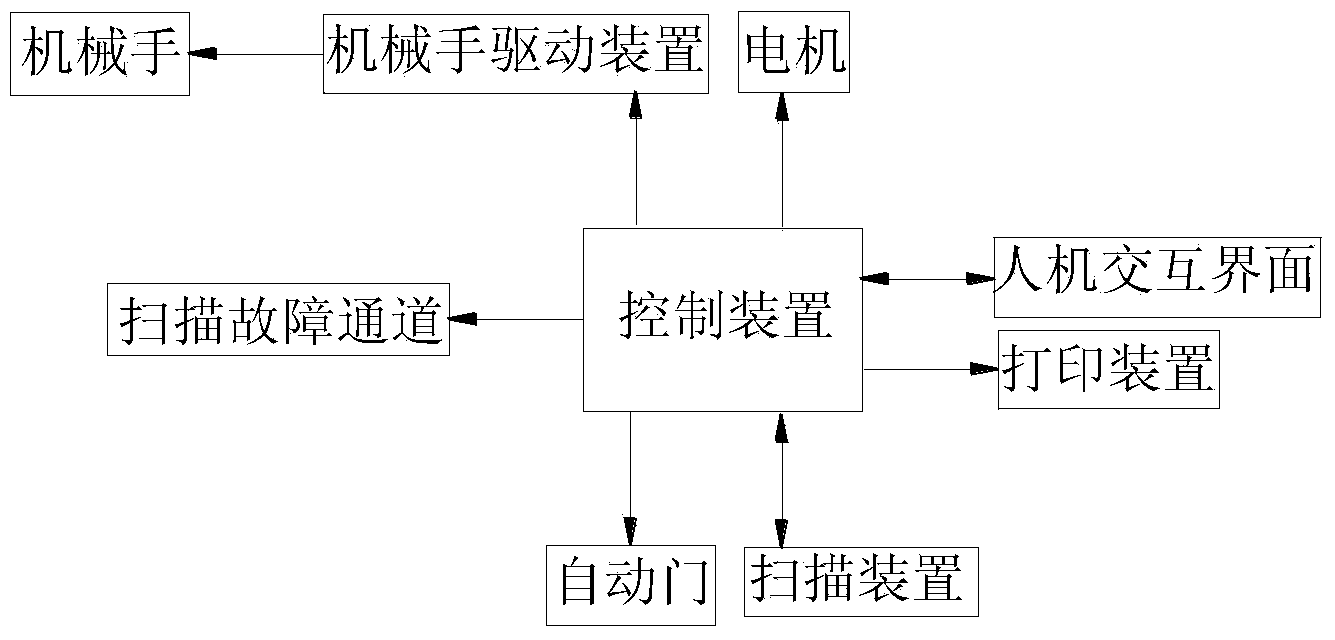

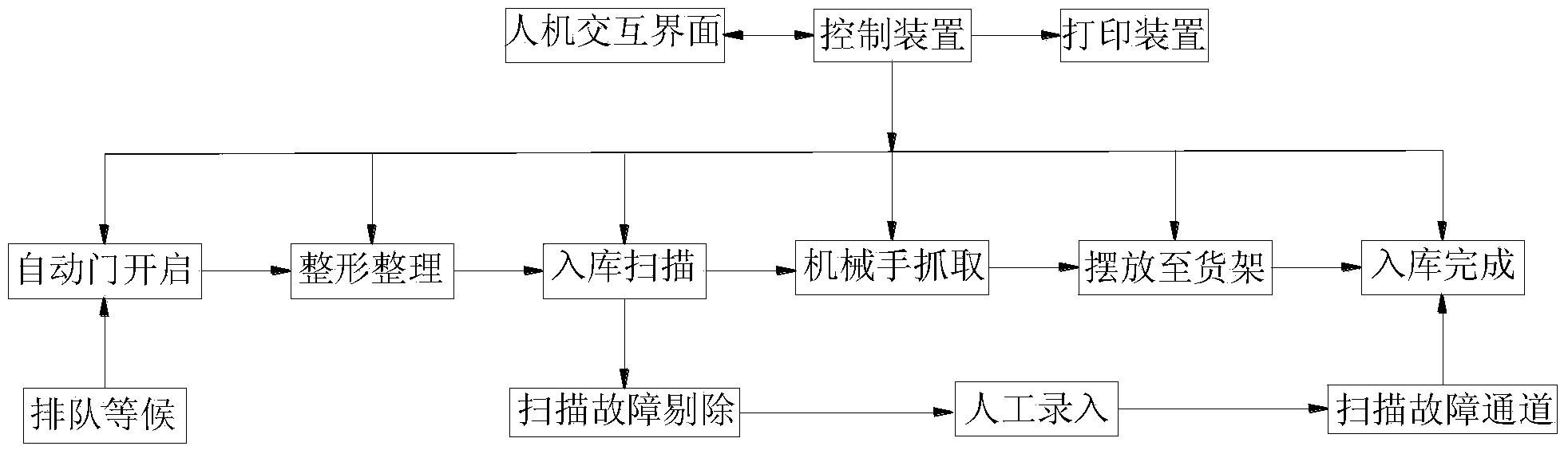

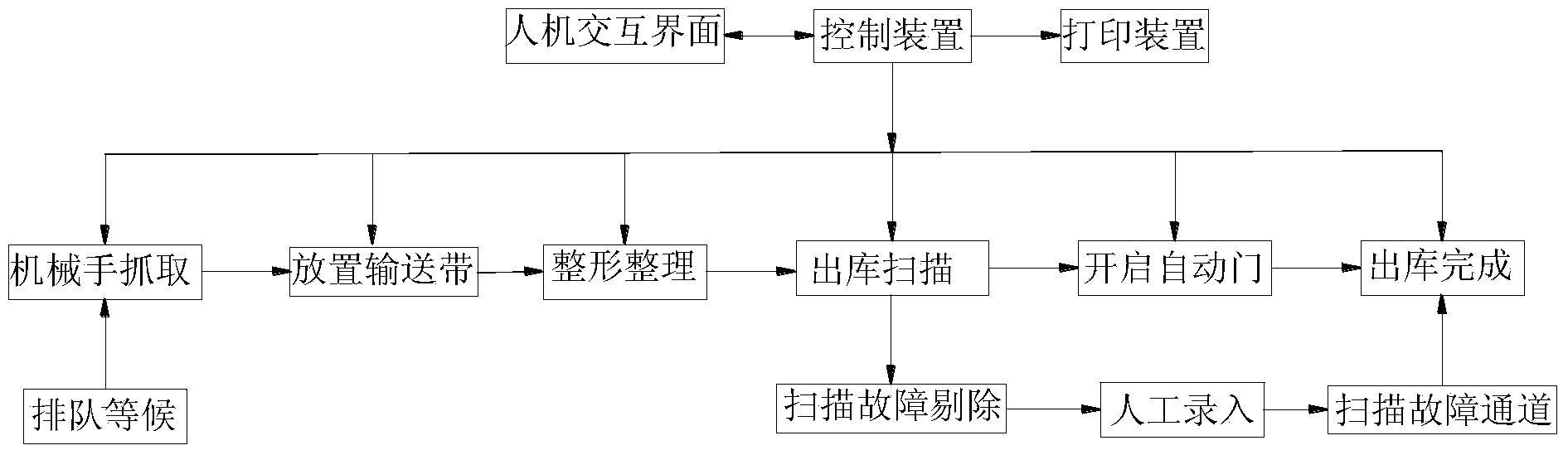

Fully-automatic storage system for blood bank

InactiveCN103530747AEnsure safetyRealize automatic storageLogisticsWhole blood productElectronic identification

The invention provides a fully-automatic storage system for a blood bank. The system comprises electronic identifiers adhered to blood bags, a mechanical hand, a conveyor belt, a storage rack, a scanning device, a control device and a human-computer interaction interface. The fully-automatic storage system for the blood bank can be used for automatically finishing the automatic warehousing and delivery of blood products and the scanning, identifying, storing and recording of blood product information in a low-temperature environment.

Owner:ZHENGZHOU FEILONG MEDICAL EQUIP CO LTD

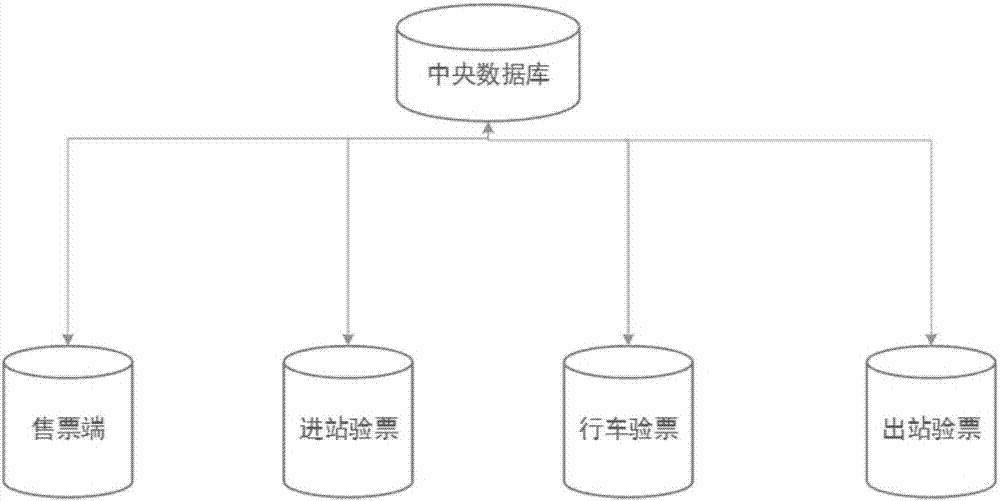

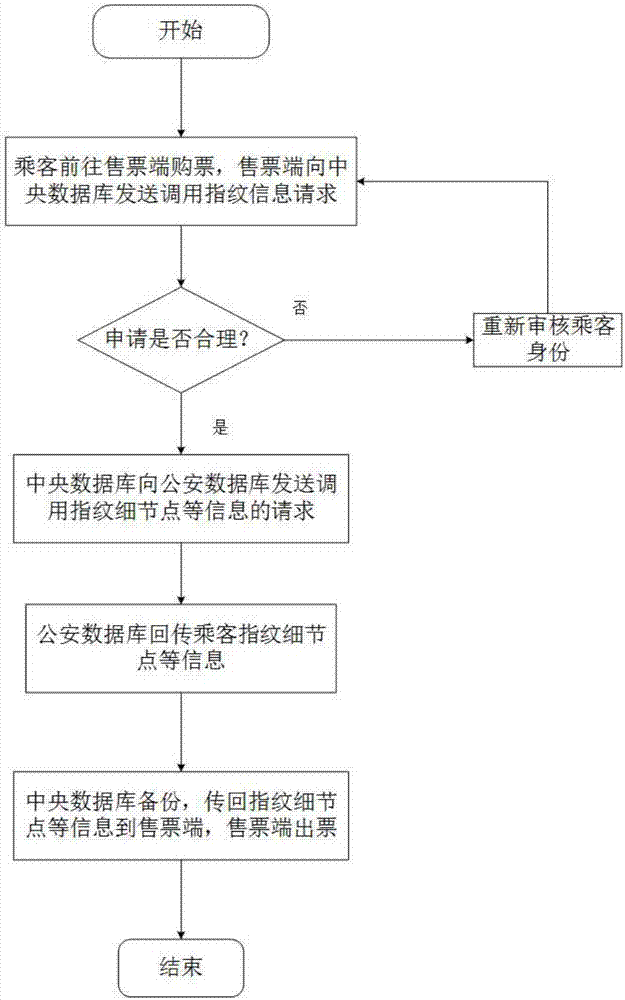

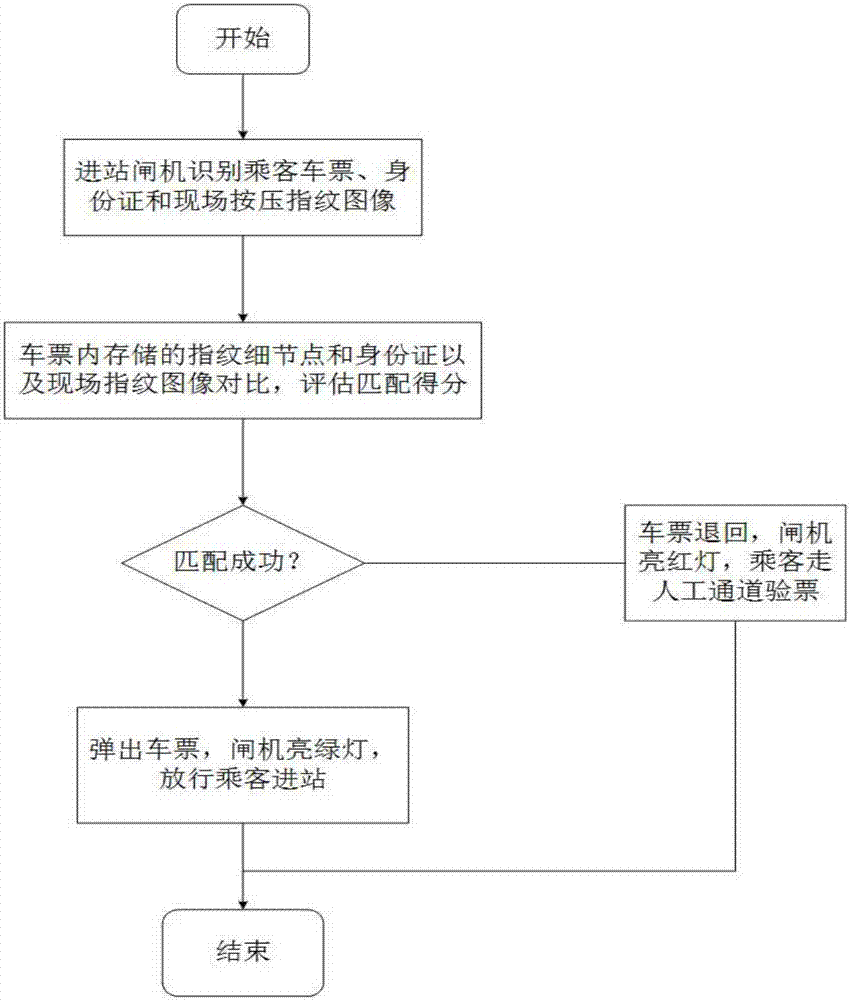

Fast ticket checking system and method based on automatic fingerprint identification technology

InactiveCN107016735AEnsure safetySimplify the process of ticket check-inTicket-issuing apparatusCo-operative working arrangementsFingerprintHand held

The invention discloses a fast ticket checking system and method based on automatic fingerprint identification technology. When a passenger buys a ticket for the first time, a central server retrieves the passenger's fingerprint detail points from a public security system database and makes a backup, when the passenger takes the ticket, a ticket-side database saves the backup of the fingerprint detail points and train number information in the RFID tag in the ticket in the form of EPC coding; when the passenger enters the station with the ticket, an entrance ticket checking system performs the comparison and verification on the passenger's ID card, ticket and the on-site pressed fingerprint image, and the passenger can be released if the matching number reaches the threshold; when a steward checks tickets during the trip, the steward scans the passenger's ticket and check the pre-stored information with a hand-held ticket checking instrument; and when the passenger leaves the station, an exit ticket checking system checks the ticket destination station and ticket validity period, if the information is correct, the ticket is taken back and the passenger can leave the station. The fast ticket checking can be realized by the automatic fingerprint identification technology, the manpower cost is saved, the ticket with the built-in RFID label can be recovered and reused, and the paper cost is saved.

Owner:CENT SOUTH UNIV

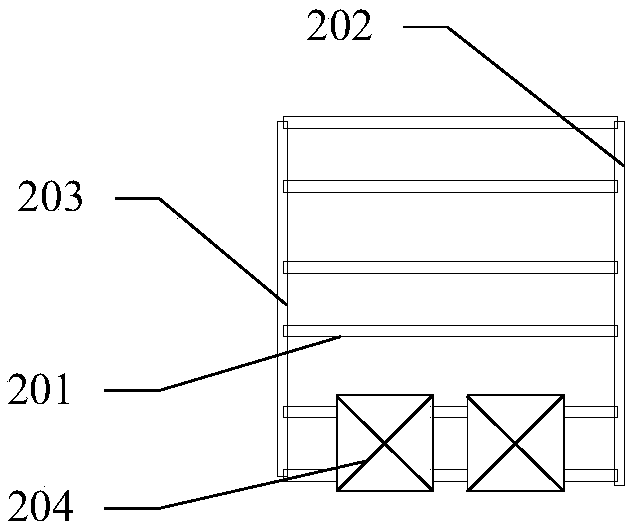

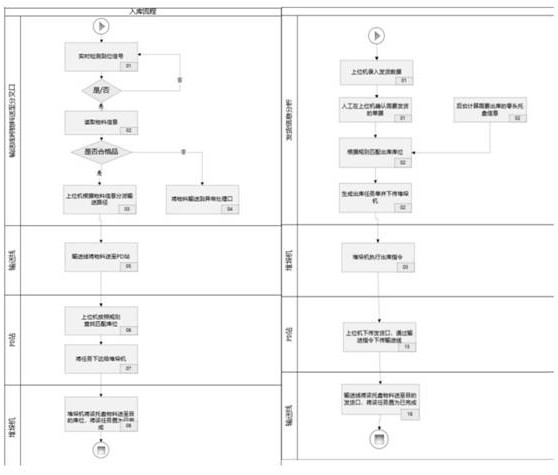

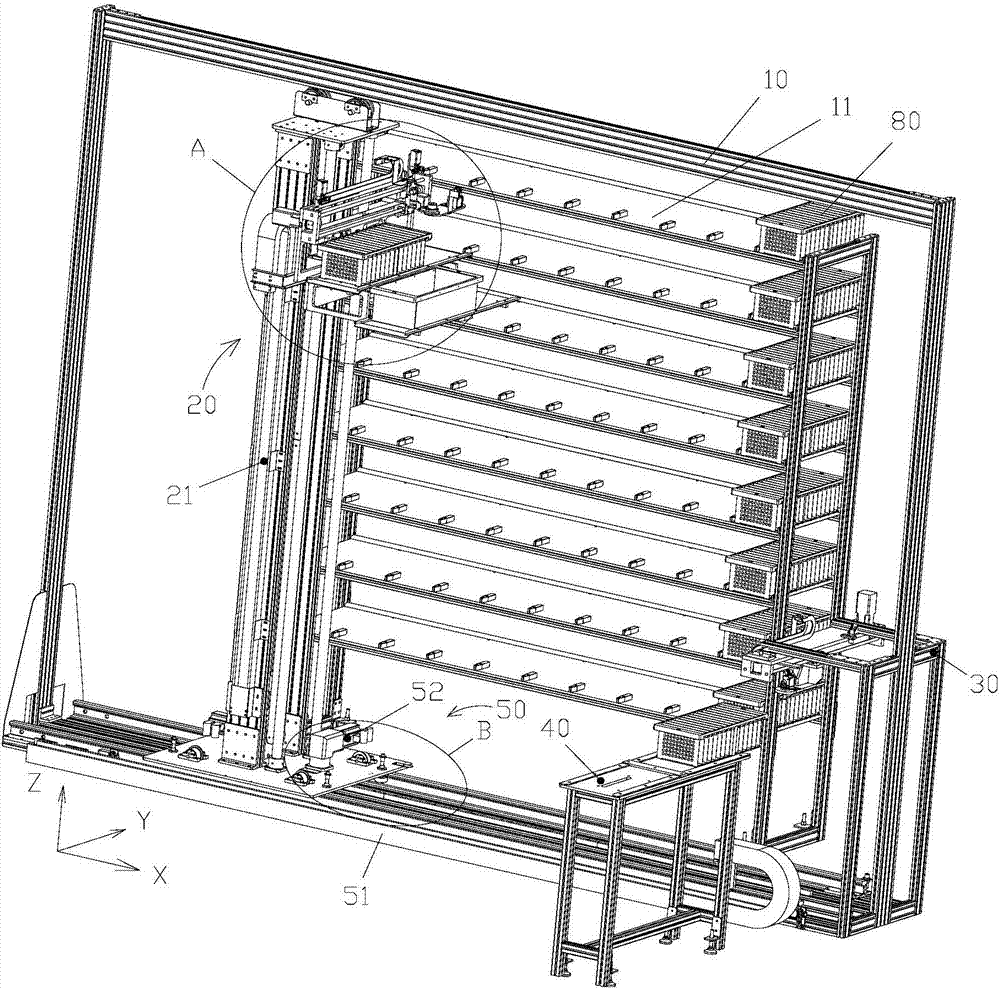

Material warehouse-in and warehouse-out device and system thereof

InactiveCN112249574ASolve the labor-intensiveReduce backlogStorage devicesSoftware systemControl system

The invention discloses a material warehouse-in and warehouse-out device which comprises a conveying line, a transfer device and a roadway stacking machine, the conveying line, the transfer device andthe stacking machine are all connected with an upper computer through a PLC and a network server, and a WMS-based material warehouse-in and warehouse-out system and a WCS control system are arrangedin the upper computer. The material warehouse-in and warehouse-out device and the material warehouse-in and warehouse-out system therein are used for carrying out material warehouse-in, inventory andwarehouse-out work, all products and equipment are connected with product storage labels in series through a software system, the whole warehouse-in and warehouse-out process is digitized and displayed through the software system, the warehouse-in and warehouse-out conditions of materials or cargos in a storage workshop are reflected in detail, the materials or the cargos are sequentially discharged according to the length of storage time, the problem of material or cargo overstock caused by long-term storage is reduced, the materials are evenly distributed at different warehouse positions ina warehouse through storage scheduling of inventory commodities, and multiple warehouse positions can work at the same time during warehouse-out working. The production efficiency is improved, and product tracing is facilitated.

Owner:青岛星华智能装备有限公司

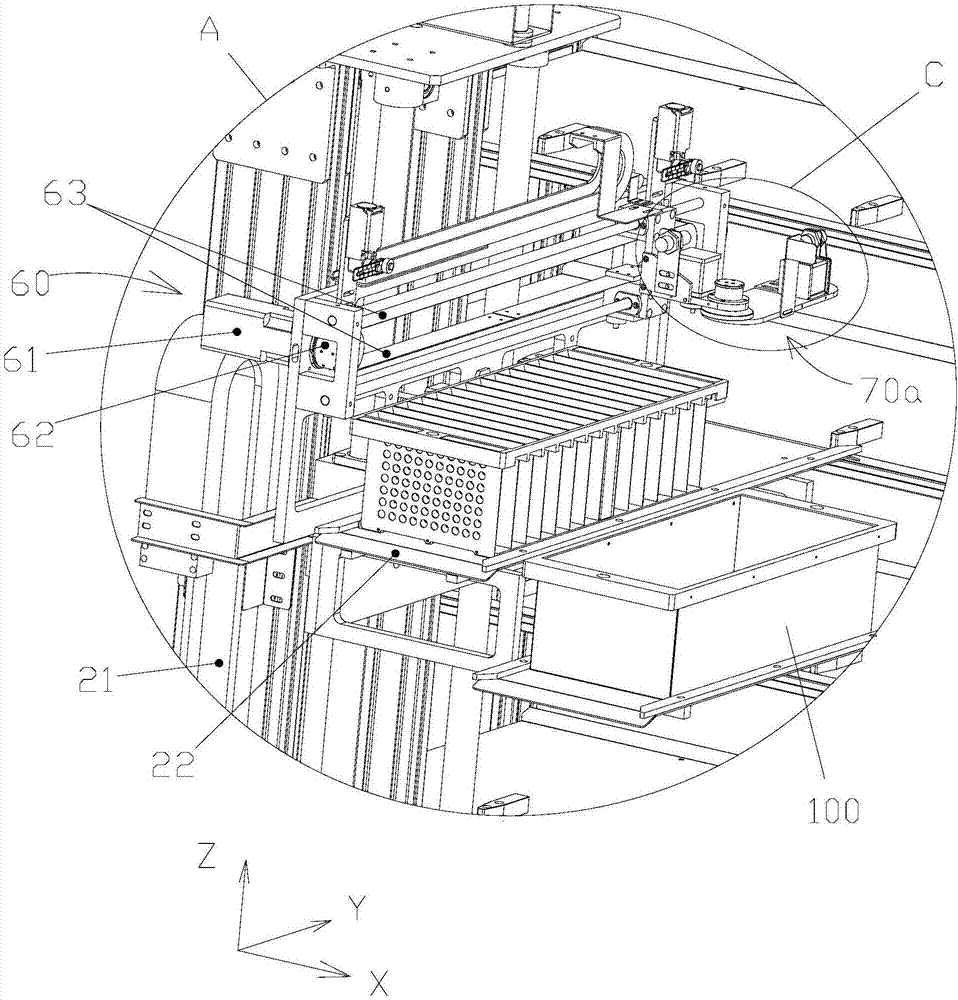

Warehouse-in and warehouse-out system for blood boxes

ActiveCN107472792AImprove efficiencyImprove the efficiency of inbound and outboundConveyorsStorage devicesEngineeringComputer hardware

The invention discloses a warehouse-in and warehouse-out system for blood boxes. The warehouse-in and warehouse-out system for blood boxes comprises a storage rack, a grabbing manipulator assembly, a warehouse-in and warehouse-out transferring frame and a blood box storage table, and multiple blood boxes are placed in the storage rack. The grabbing manipulator assembly comprises a supporting frame and a manipulator supporting plate, wherein a first hooking assembly is arranged on the manipulator supporting plate, and the supporting frame can move left and right; and the manipulator supporting plate moves up and down on the supporting frame, and the first hooking assembly moves front and back to transfer the blood boxes on the storage rack and the manipulator supporting plate back and forth. The manipulator supporting plate can be driven by a first driving assembly and a second driving assembly to move to the space below a second hooking assembly, and the second hooking assembly is arranged on the warehouse-in and warehouse-out transferring frame. The second hooking assembly can be driven by the second driving assembly to move front and back along the Y axis and can transfer the blood boxes on the blood box storage table and the manipulator supporting plate below the warehouse-in and warehouse-out transferring frame back and forth. By adoption of the warehouse-in and warehouse-out system for blood boxes, the labor intensity of workers is relieved, and the warehouse-in and warehouse-out efficiency of frozen blood plasma is improved.

Owner:苏州翊讯生物科技有限公司

Fork type shuttle vehicle sorting system

PendingCN107117424AEasy pick-upAutomated deliveryStorage devicesAutomatic controlLogistics management

The invention discloses a fork type shuttle vehicle sorting system comprising fork type shuttle vehicles, sorting goods shelves, sorting trolleys, an automatic stereoscopic warehouse and an automatic control system. Each two corresponding sorting goods shelves are one set. One fork type shuttle vehicle is arranged between the sorting goods shelves of each set. Automatic conveying lines used for material warehouse in-out are arranged between the fork type shuttle vehicles and the automatic stereoscopic warehouse. The sorting goods shelves are provided with bar code readers, and logistics goods trays are placed on the sorting goods shelves. The logistics goods trays are provided with material bar codes. The sorting trolleys are arranged on the outer sides of the sorting goods shelves. Through the fork type shuttle vehicle sorting system, batch sorting of production materials can be achieved, real-time distribution of materials in a distribution center is achieved, the sorting error rate is decreased, operation efficiency is improved, and manpower cost is reduced.

Owner:WUXI ZHONGDING INTEGRATION TECH CO LTD

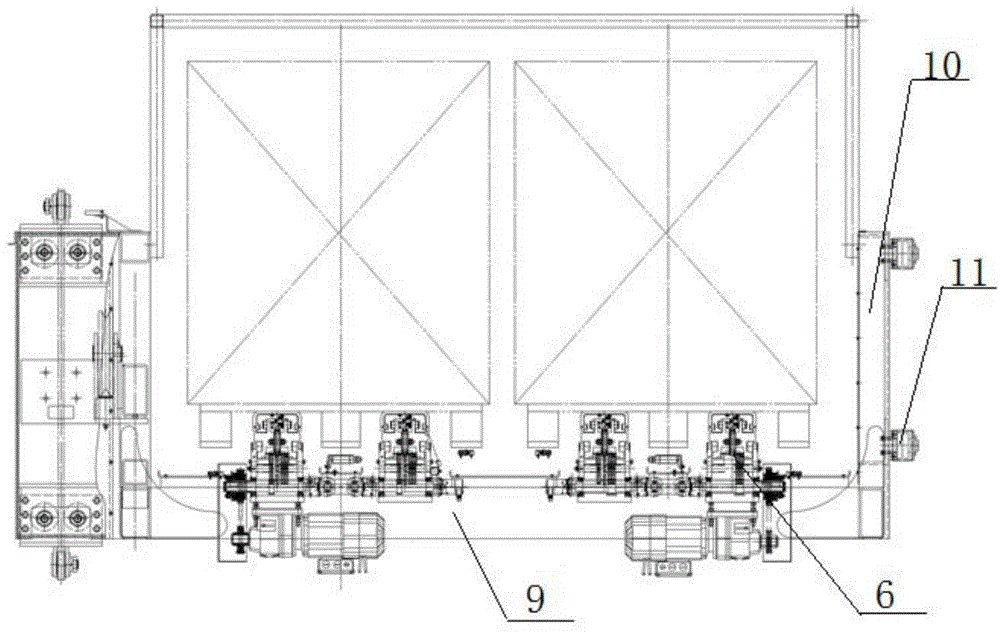

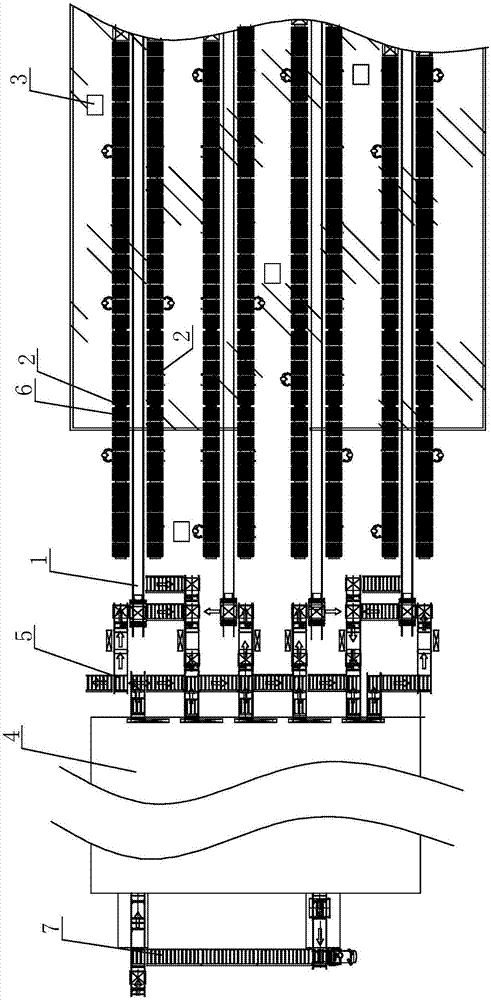

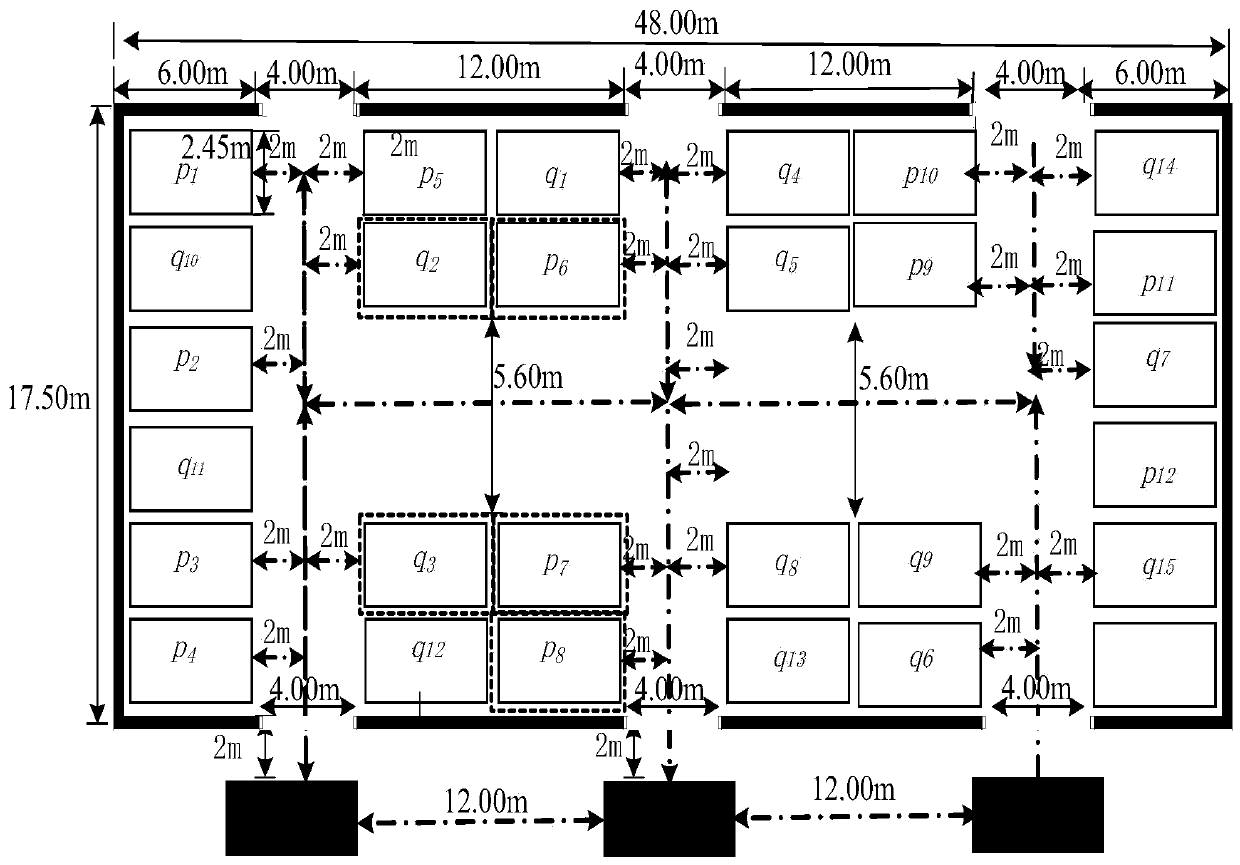

Cut tobacco box storage and delivery conveying system

ActiveCN103910158AImprove the efficiency of inbound and outboundSmall footprintStorage devicesStack machineEngineering

The invention provides a cut tobacco box storage and delivery conveying system which comprises a storage rack located in a storage base, a first stacking machine and a second stacking machine. The stacking machines are arranged on two sides of the storage rack of the system. Due to the fact that the work positions of the stacking machines can be moved vertically, the storage rack can be arranged in a multilayer mode, and storage rack occupation space can be effectively reduced. Two work positions are arranged on each stacking machine, compared with an original signal-work-position rail guide vehicle, storage and delivery of two cut tobacco boxes can be achieves simultaneously, and cut tobacco box storage and delivery efficiency is greatly improved, the device utilization rate is improved, and the whole cut tobacco box logistic system is efficient in operation. The stacking machines are better in starting and stopping performance compared with the original rail guide vehicle, the operation speed is greatly improved, and the stacking machines can meet the production requirement for high-flow high-efficiency fast storage and delivery of the project.

Owner:SHANGHAI TOBACCO GRP CO LTD

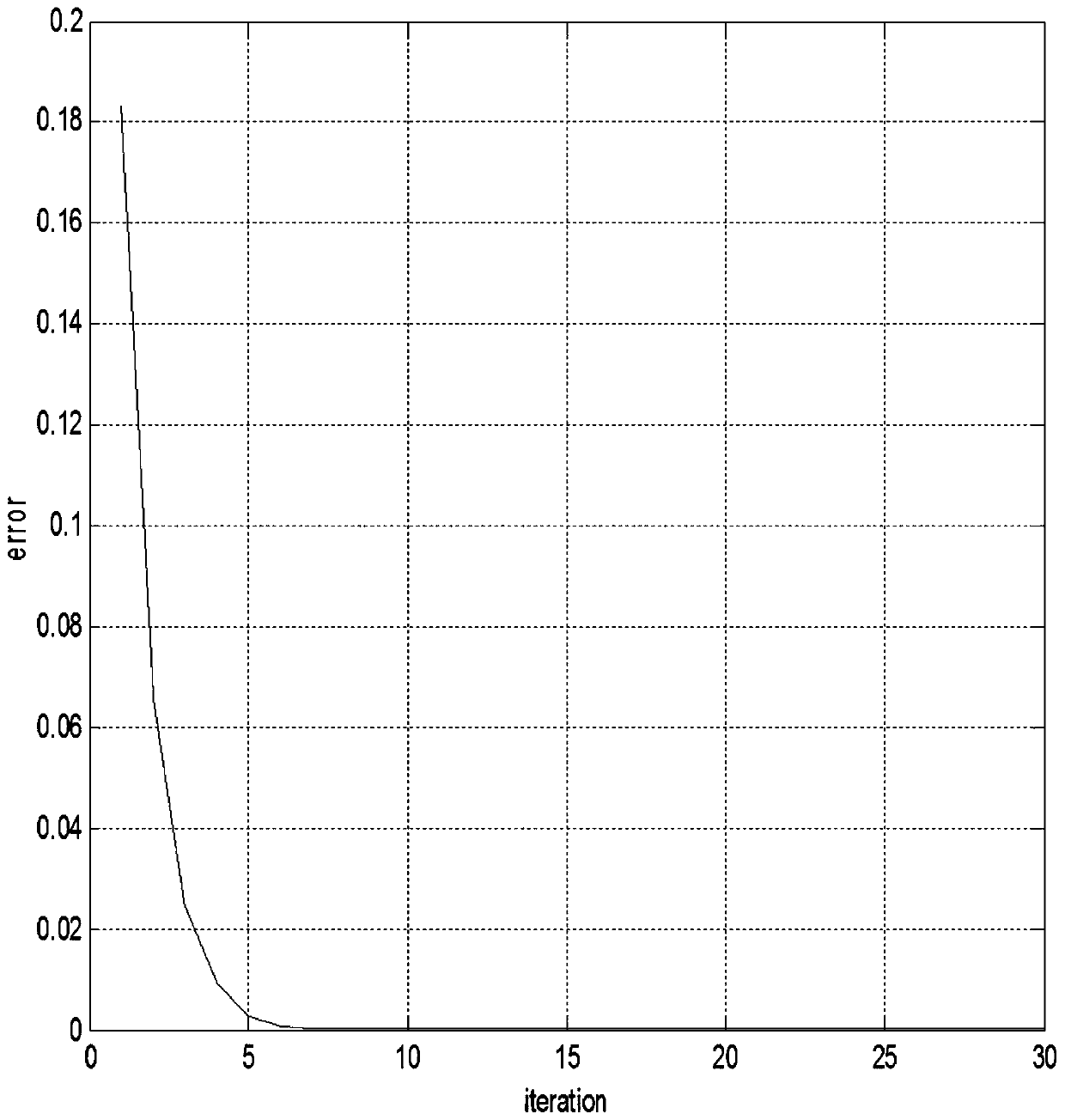

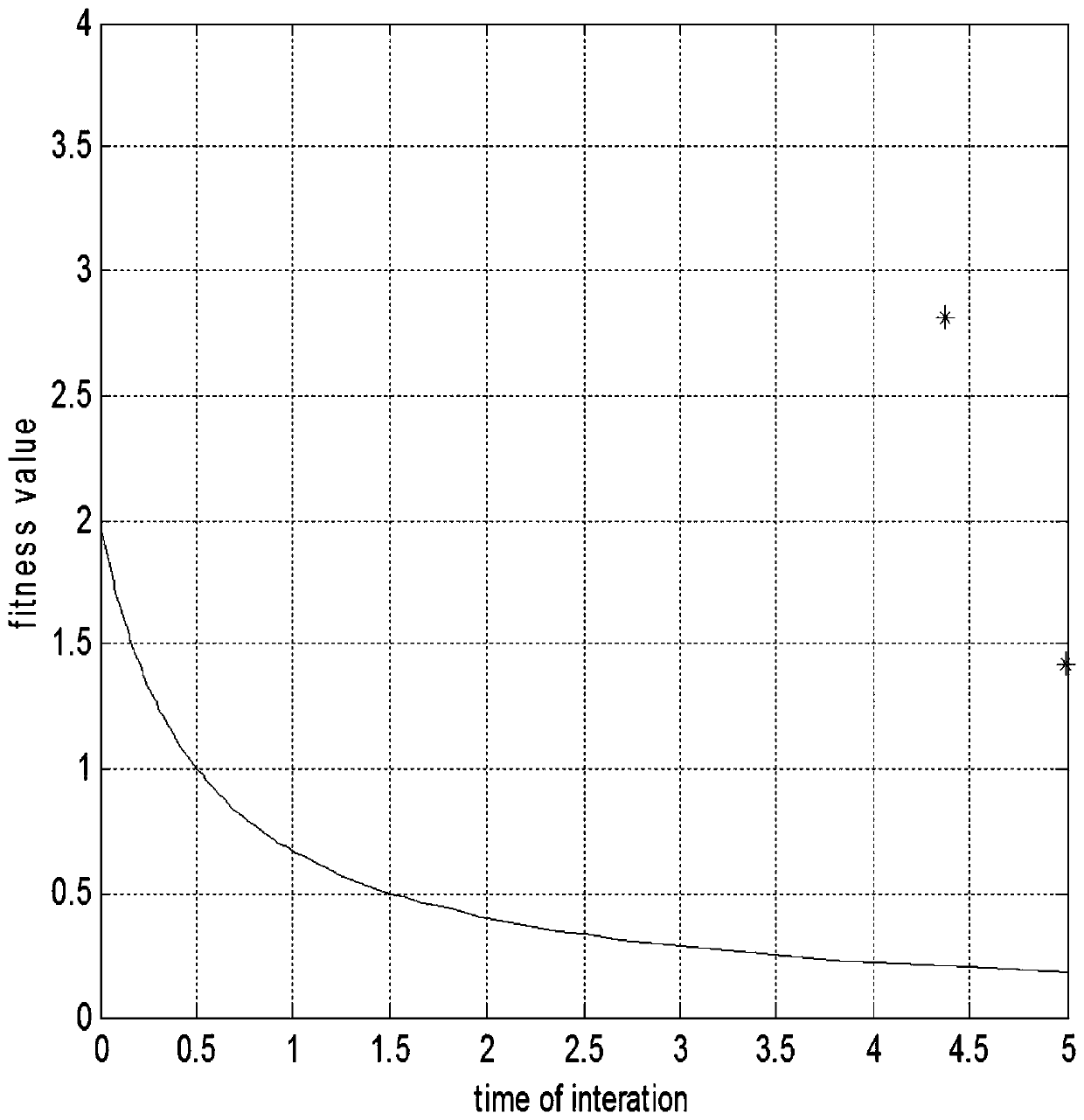

Intercommunication warehouse forklift operation route determination method for improving the warehouse-in and warehouse-out efficiency of packaging dangerous goods

InactiveCN109800913AImprove the efficiency of inbound and outboundInbound and outbound efficiency optimizationForecastingNeural architecturesDangerous goodsComputer science

The invention belongs to the field of hazardous article warehouse management, and relates to an intercommunication warehouse forklift operation line determination method for improving the operation efficiency of package hazardous article warehouse-in and warehouse-out. The method comprises the steps of transforming an existing dangerous goods flat warehouse is transformed into an intercommunicateddangerous goods warehouse with an isolation door; determining a forklift operation principle and a forklift operation path composition; establishing an optimal path model considering cost and efficiency according to the attribute parameters of the multi-forklift operation; employing genetics-BP neural network algorithm to determine a forklift operation optimization line in an environment with a plurality of forklifts and uncertain heap positions. Aiming at the problem that the existing double-door warehouse package dangerous goods warehouse-in and warehouse-out efficiency is low, the method is mainly used for determining the intercommunication warehouse forklift operation line for improving the operation efficiency of the dangerous goods warehouse, the optimization algorithm is used as atool, the purpose of optimizing the dangerous goods warehouse-in and warehouse-out operation is achieved, and positive influences on the aspects of improving the operation efficiency of the dangerousgoods warehouse and the like are achieved.

Owner:SHANGHAI MARITIME UNIVERSITY

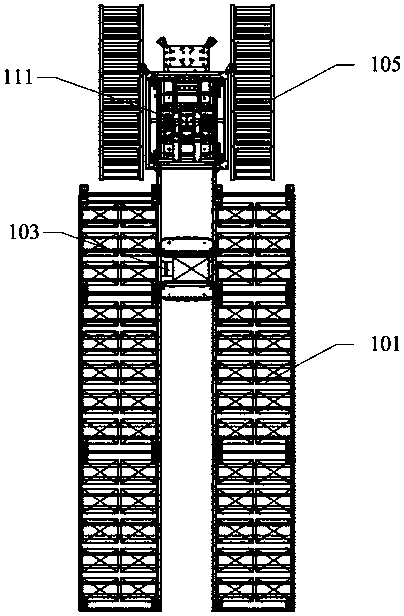

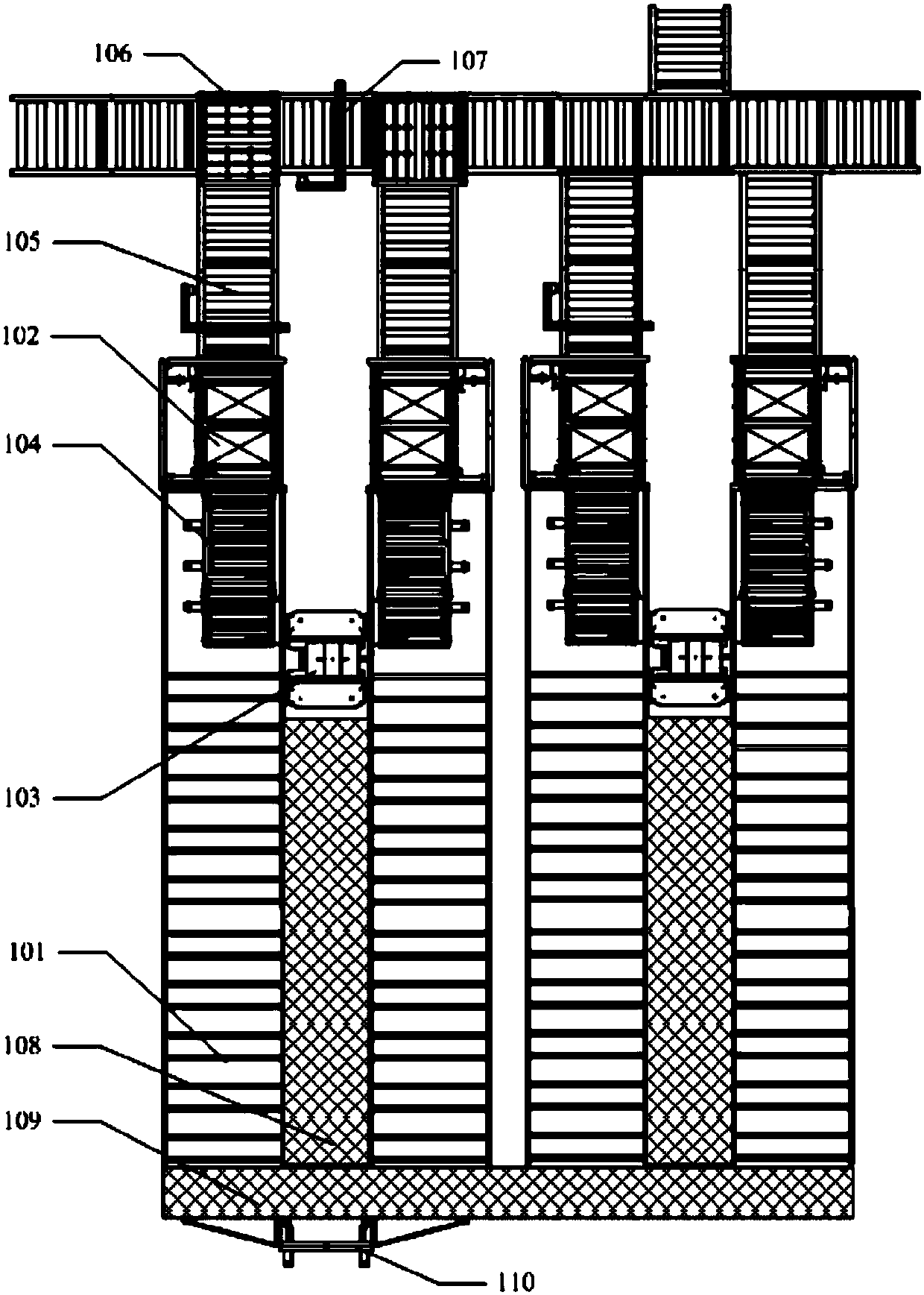

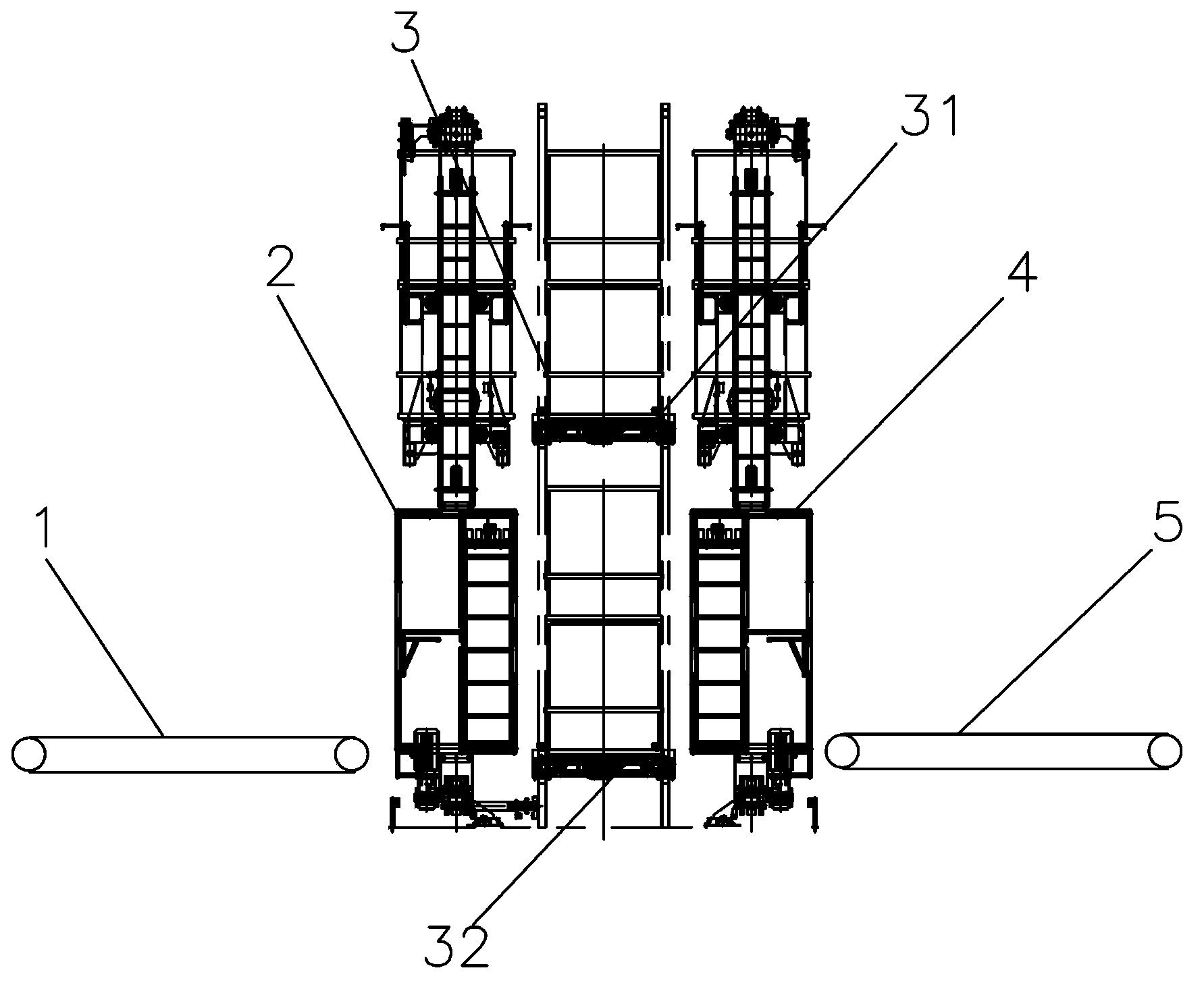

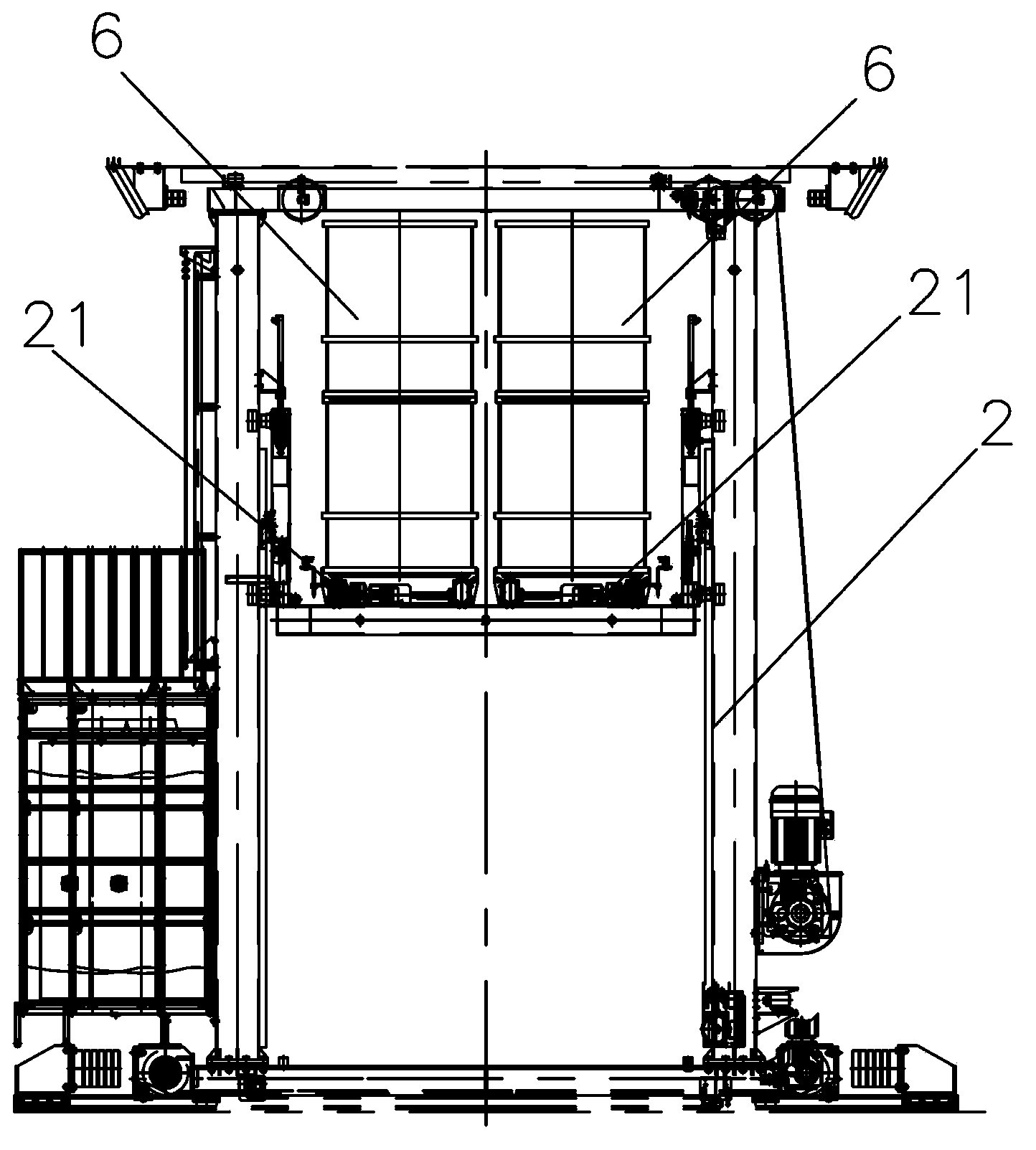

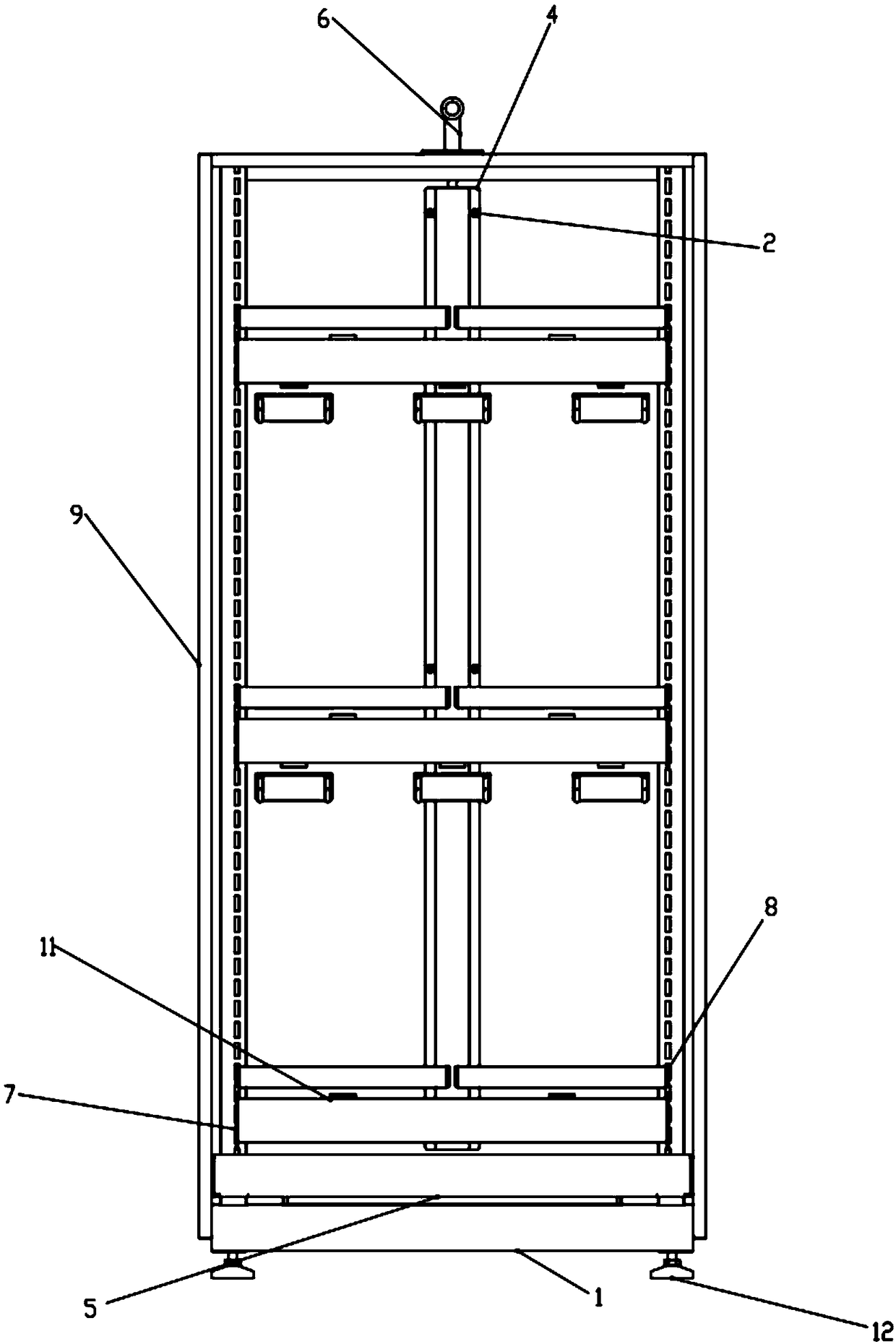

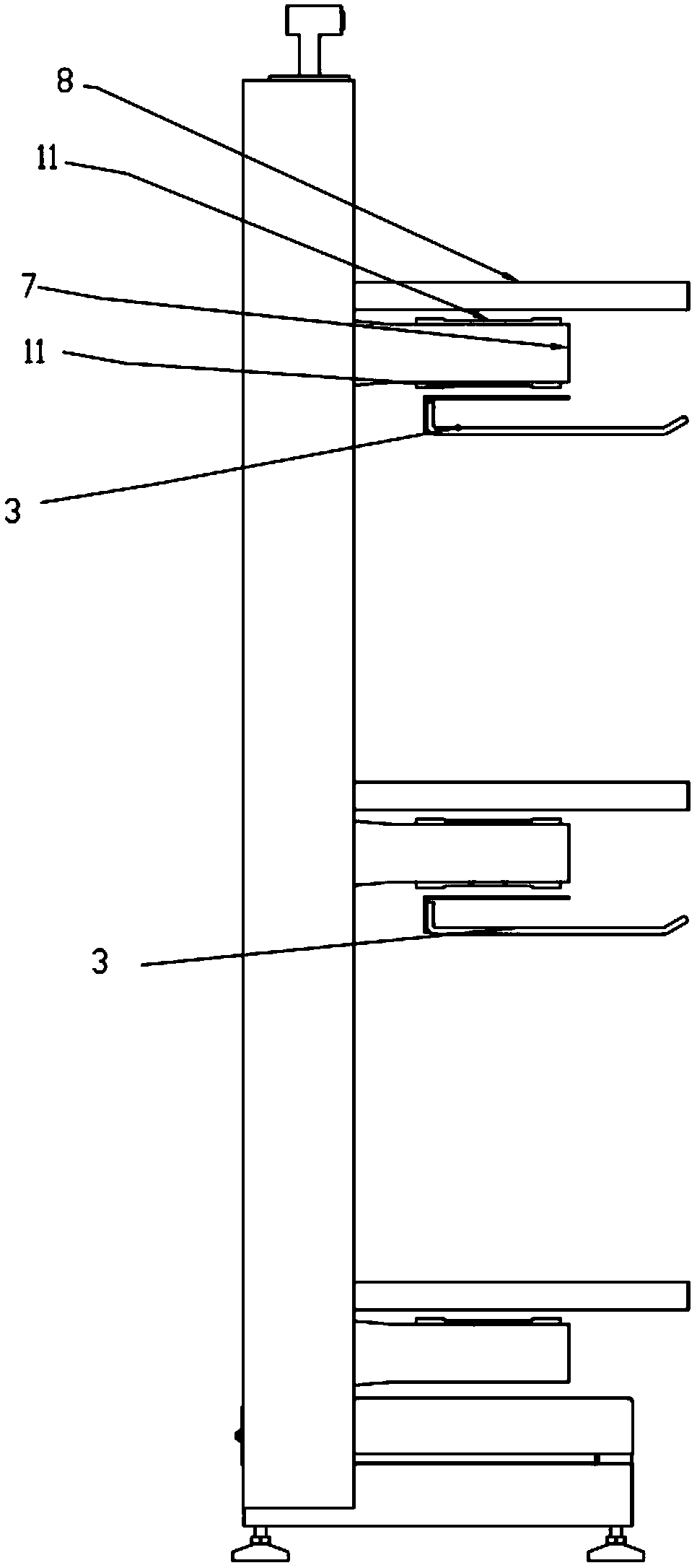

Layer switching method of intensive stereoscopic warehouse shuttle vehicle and single-column lifter adopted by method

InactiveCN104443976ASmall footprintImprove stabilityStorage devicesStructural engineeringMechanical engineering

The invention discloses a layer switching method of an intensive stereoscopic warehouse shuttle vehicle and a single-column lifter adopted by the method. The single-column lifter adopted by the layer switching method achieves layer switching operation of the intensive stereoscopic warehouse shuttle vehicle, a track is arranged on a lifting tray of the lifter, a tray opening of the lifting tray is provided with a safety door, and the safety door is controlled by an unlocking device. During layer switching operation, the lifting tray can stop on the track on the lifting tray on any layer of a stereoscopic warehouse and is aligned to a shuttle vehicle track on the layer, the safety door is opened, the safety door is closed after the shuttle vehicle staying on the layer moves to the lifting tray, the lifter vertically runs to the layer required to be switched, then the safety door is opened, the shuttle vehicle runs from the lifting tray to the required layer, and accordingly layer switching operation of the shuttle vehicle is completed. The single-column lifter is simple in structure and high in speed, achieves functions of an original mechanism by adopting the simple structure, can improve layer switching speed and accordingly greatly improves production and installation efficiency. In addition, cost is reduced, and the warehouse input-output efficiency of an intensive warehouse storage system can be improved.

Owner:GUIYANG PUTIAN LOGISTICS TECH

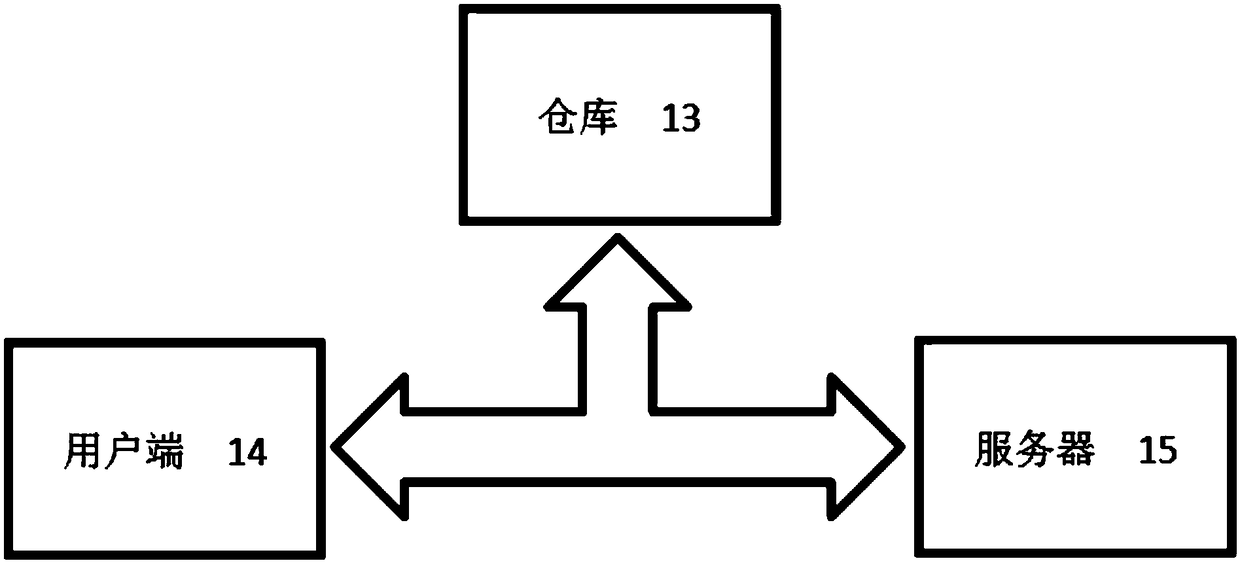

Intelligent warehouse and goods access method based on gravity sensing

PendingCN108891833AImprove the efficiency of inbound and outboundEasy to operateLogisticsStorage devicesAccess methodMoisture sensor

In order to solve the problems of the traditional warehouse system such as the difficulty of recording and counting goods and the low safety factor of the warehouse, the invention relates to an intelligent warehouse based on gravity sensing and a method for storing and storing goods, The intelligent warehouse based on gravity sensing comprises a warehouse, a user end and a server, wherein, the warehouse is provided with a shelf and a main control box in two-way communication; the shelf is provided with a bottom frame, a screw cushion cushion assembly, a hook, a rear cover plate, a bottom plate, a camera, a tray, a tray, a welding frame and a sensor; The camera is fixedly mounted on the upper surface of the welding frame, the tray and the rear cover plate are fixedly connected to the insideof the welded frame, A screw spring cushion assembly is fixedly connected to the rear cover plate, The tray is fixed under the tray, the sensors are fixed on the upper and lower sides of the tray, the hooks are arranged under the tray, the bottom plate is arranged at the bottom of the welding frame, the sensors on the upper and lower sides of the tray are the temperature and humidity sensors andthe vibration sensors, respectively, and the voice and light reminding devices are arranged in the warehouse.

Owner:SHENZHEN LINCHEN ZHANHUA TECH CO LTD

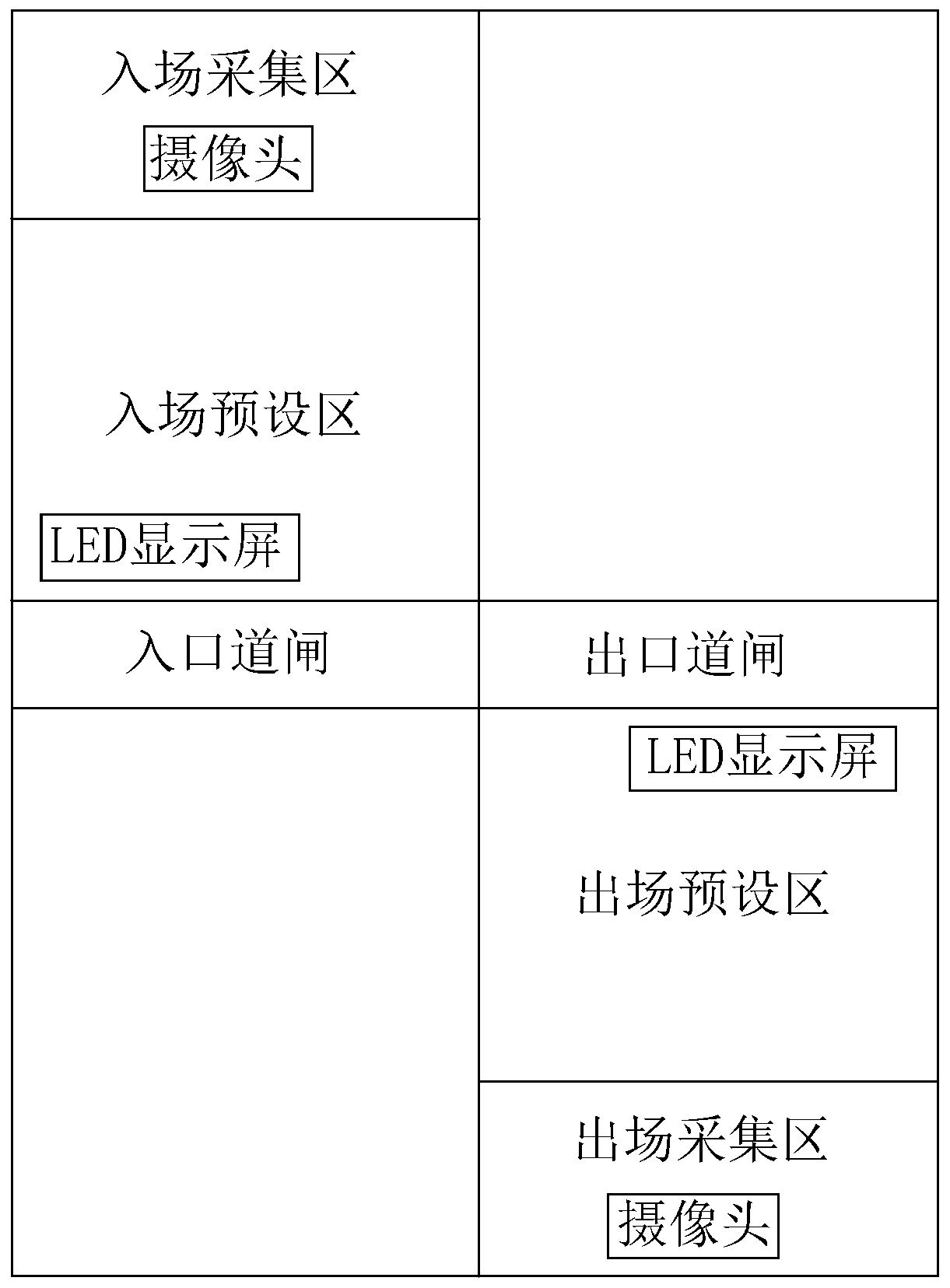

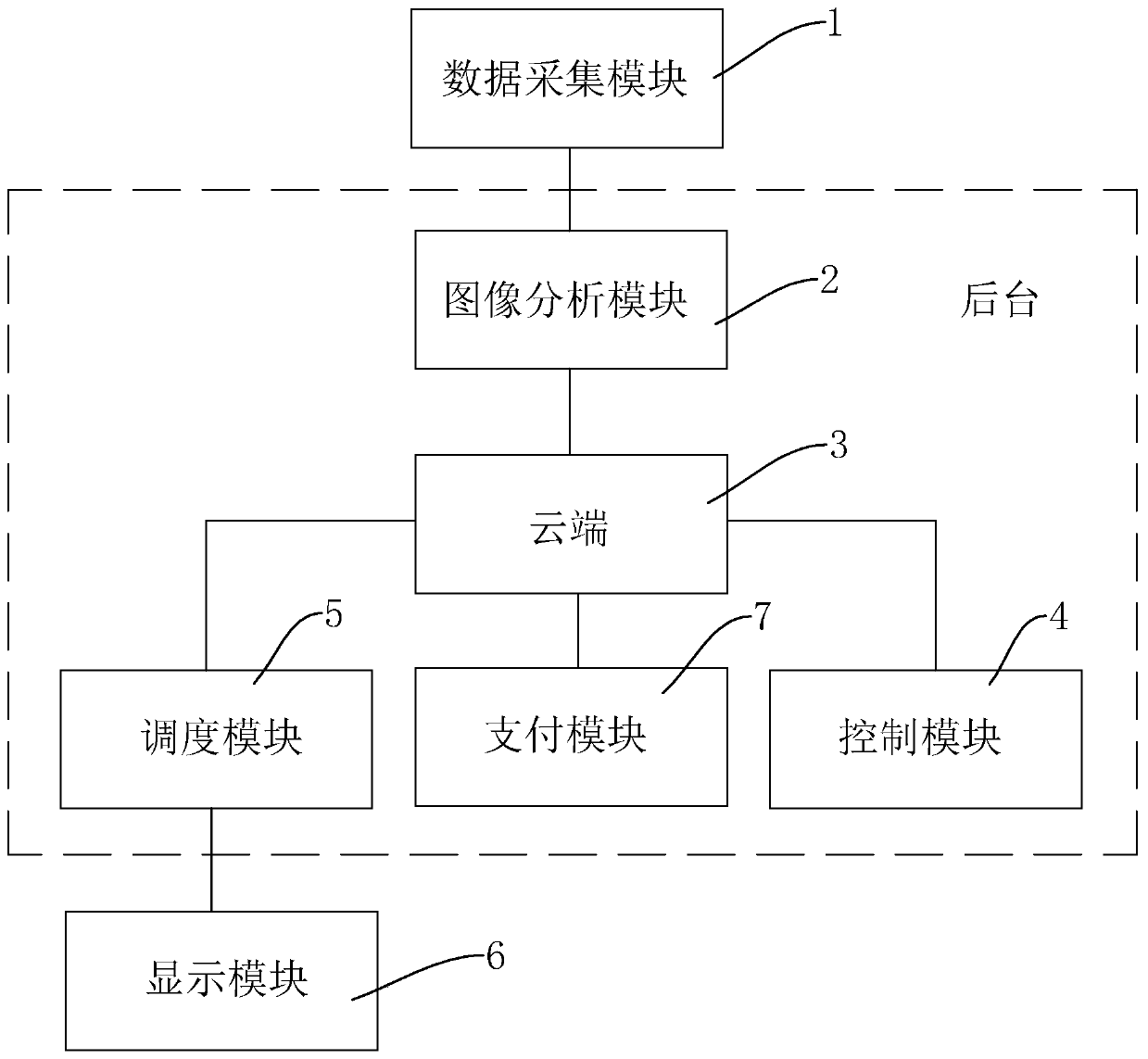

Noninductive payment method and system applied to parking place

InactiveCN110349275AAvoid prolonged entry and exit timesImprove the efficiency of inbound and outboundTicket-issuing apparatusPayment architectureUser needsPayment

The invention discloses a noninductive payment method and system applied to a parking place, and relates to the technical field of payment of charges of the parking place, aiming at solving the problem that in the prior art, a user needs to wait for a gate to open or close and thus time consumed for entering or quitting the parking place is prolonged. The main point of the technical scheme is as follows: when a vehicle is in an entrance collection area and an entrance preset area, the system performs information collection and identity identification on the vehicle, once the vehicle is successfully identified, the entrance gate is opened to release the vehicle. When the vehicle is driven out of the parking place, the system performs information collection and identification on the vehicleonce again, a background matches the information of the vehicle entering and quitting the parking place and compares the same, opens the entrance gate after the identity is identified, then computes apayment amount, and automatically deducts the corresponding amount from an account bound with the vehicle to complete payment. According to noninductive payment method and system, the effect that theuser time for waiting the gate to open or close is avoided and thus the efficiency of entering and quitting the parking place is improved is achieved.

Owner:宿迁硅基智能科技有限公司

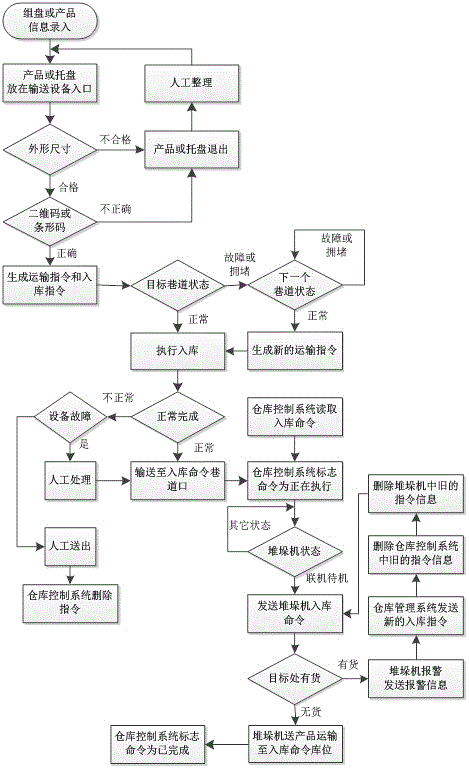

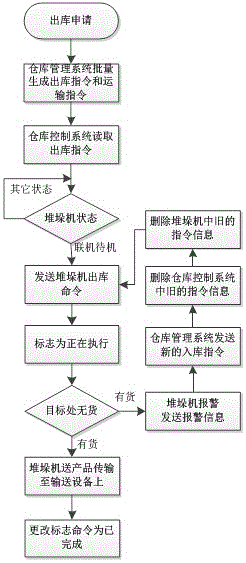

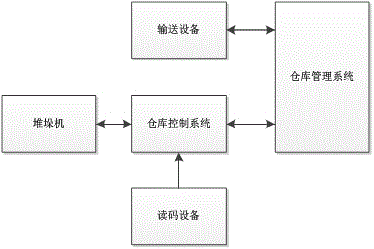

Product warehouse-in or warehouse-out address change method and system

InactiveCN106779535ASmooth entry and exitHigh degree of automationCo-operative working arrangementsLogisticsControl systemComputer science

The invention belongs to the technical field of stereoscopic warehouse management and particularly relates to a product warehouse-in or warehouse-out address change method and system. Through the product warehouse-in or warehouse-out address change method and system, when product warehouse-in or warehouse-out is abnormal, instruction address change can be automatically performed, and the automation degree is high. According to the adopted technical scheme, a warehouse control system executes a warehouse-in or warehouse-out instruction sent by a warehouse management system, wherein the warehouse-in or warehouse-out instruction contains storage location information; when a destination of the warehouse-in or warehouse-out instruction is abnormal, the warehouse control system sends an alarm information to the warehouse management system; the warehouse management system sends an alarm removal instruction to the warehouse control system; the warehouse management system regenerates a new warehouse-in or warehouse-out instruction with the highest priority and deletes the issued old warehouse-in or warehouse-out instruction, wherein the new warehouse-in or warehouse-out instruction comprises new storage location information; the warehouse control system executes the new warehouse-in or warehouse-out instruction, and a piler is transferred to deliver products to a specified storage location or conveying equipment.

Owner:赵铭竹

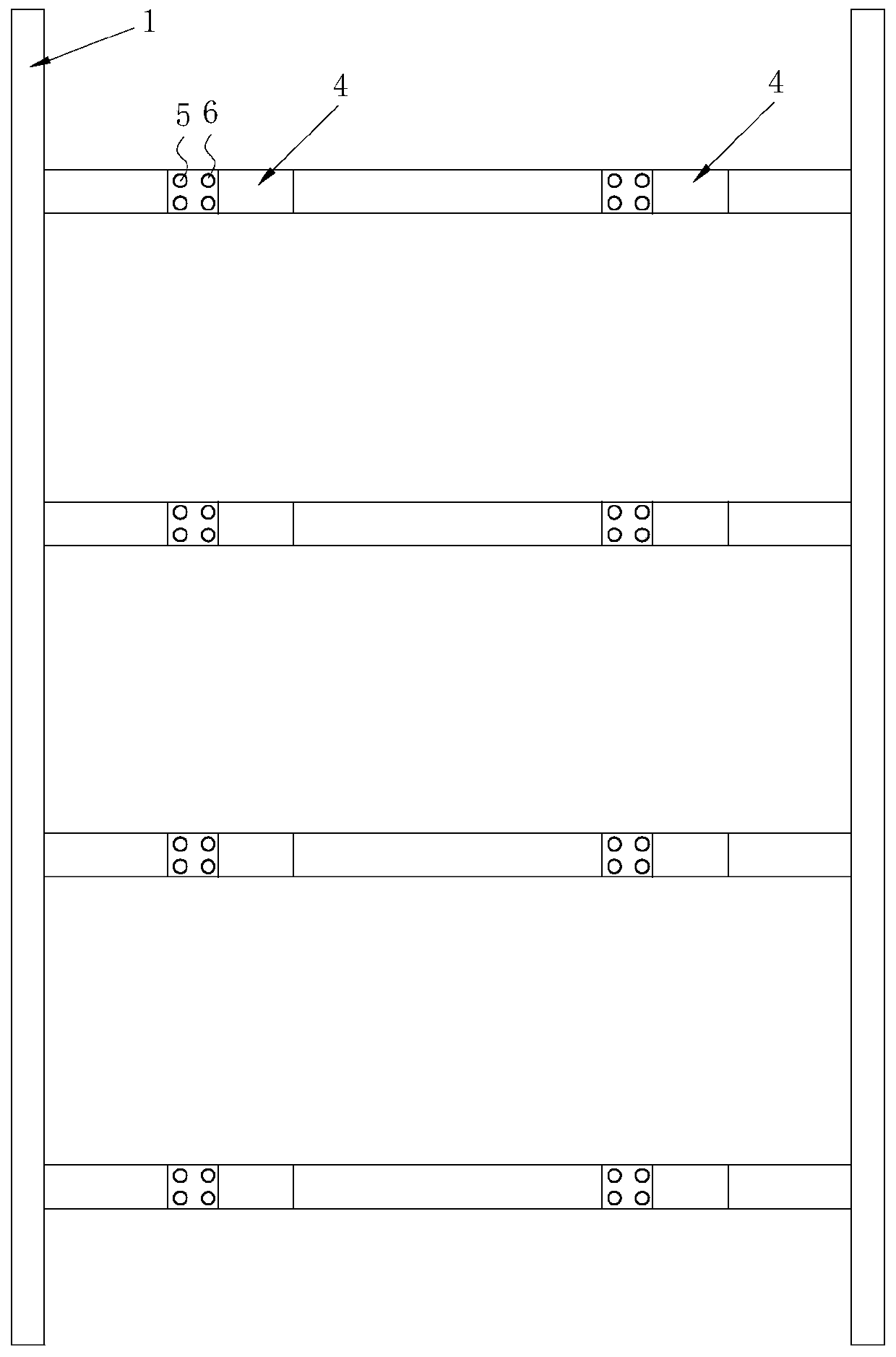

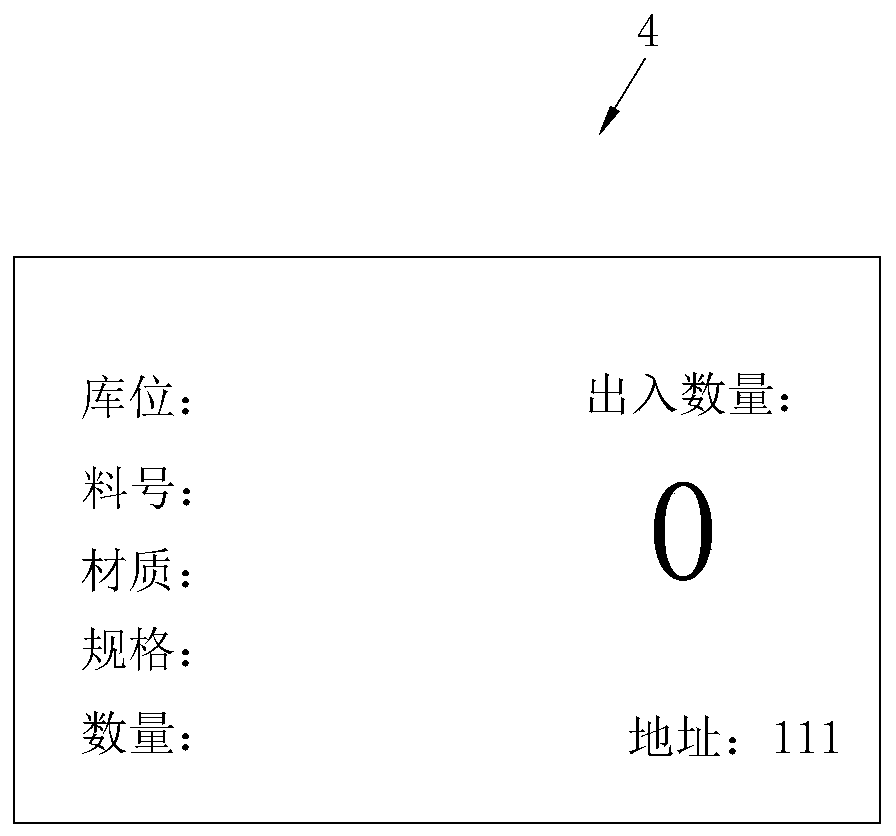

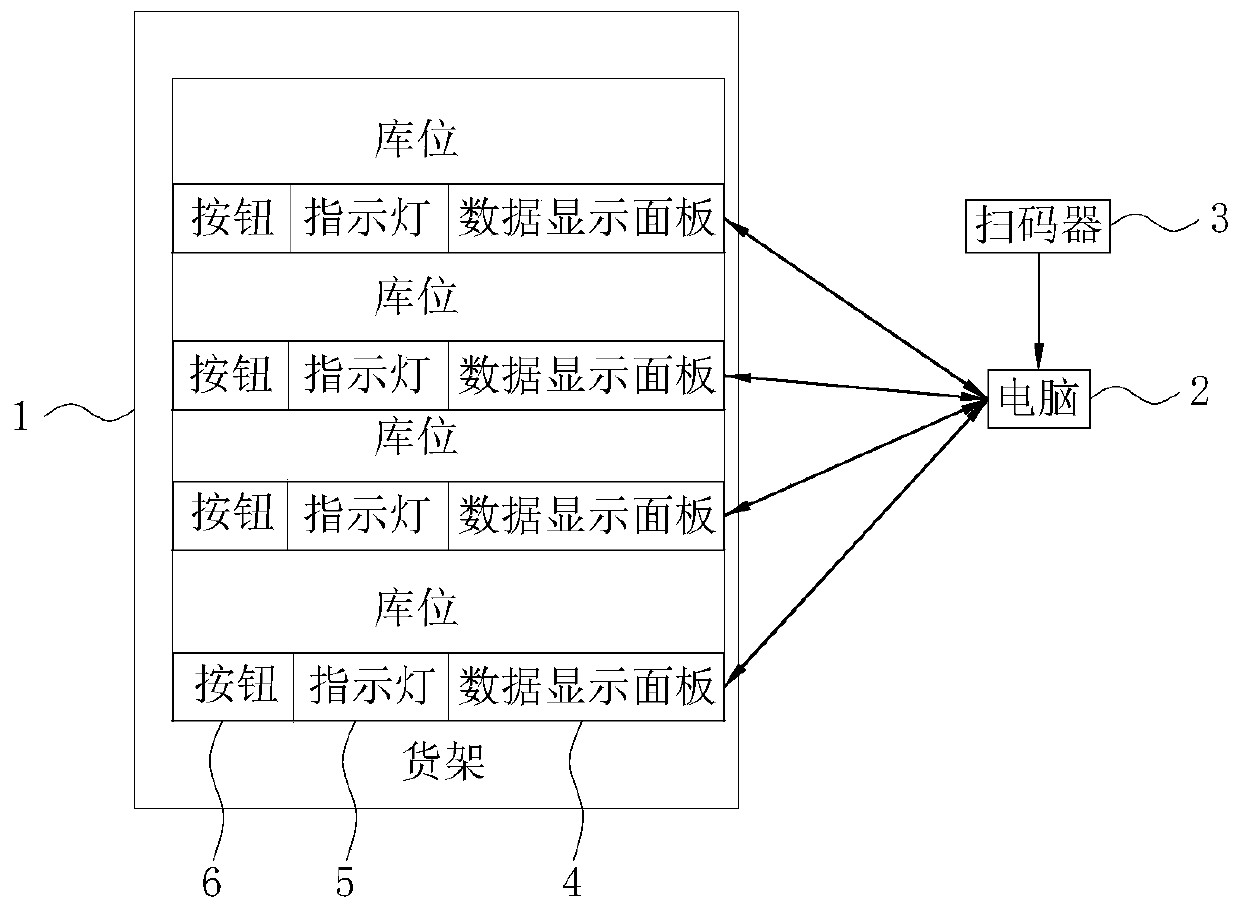

Warehouse, warehousing method thereof, and warehouse out method thereof

InactiveCN110428202AIntuitive warehouse operationsRealize visualizationLogisticsStorage devicesData displayRelevant information

The invention belongs to the technical field of warehouse management, and particularly relates to a warehouse, a warehousing method thereof, and a warehouse out method thereof. In order to overcome the defect that an existing warehouse is low in warehouse-in and warehouse-out efficiency, the following technical scheme is adopted: the warehouse comprises a goods shelf and a material management system connected with ERP; the goods shelf is provided with a plurality of warehouse locations; and the material management system comprises a computer, a data display panel which is controlled by the computer and is arranged at each storage location and the displays the storage location information, the material types and the material quantity, an indicating lamp which indicates a to-be-operated storage location, and a button which indicates the warehouse-in and warehouse-out completion condition of the corresponding warehouse location. The warehouse has the beneficial effects that the material management system can be additionally arranged on the basis of an existing site goods shelf, and warehouse-in and warehouse-out operation is more visual, and material related information is visualized,and warehouse area material management is clear at a glance, tidy and orderly, and the warehouse-in and warehouse-out efficiency is improved.

Owner:ZHEJIANG SUNON FURNITURE MFG

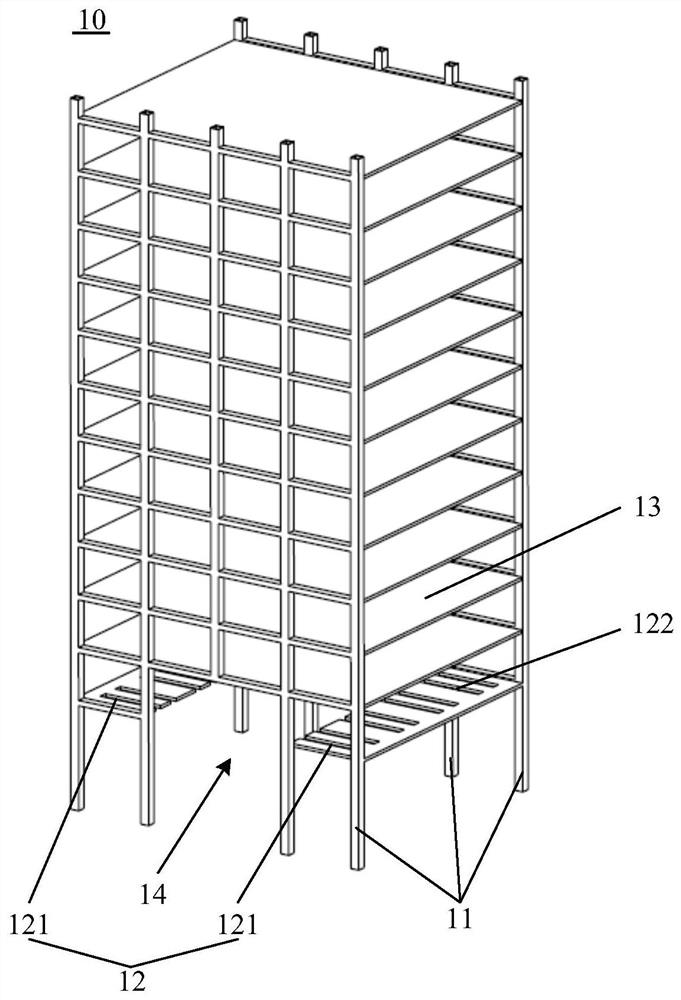

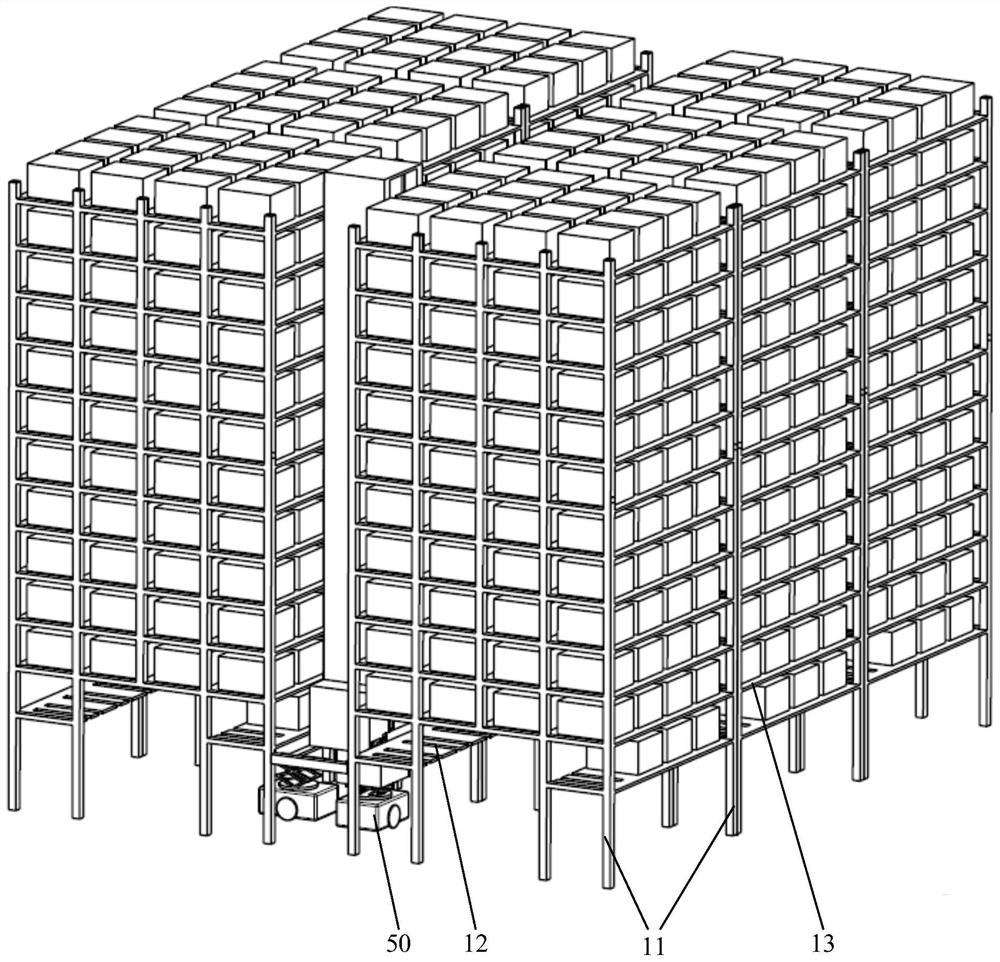

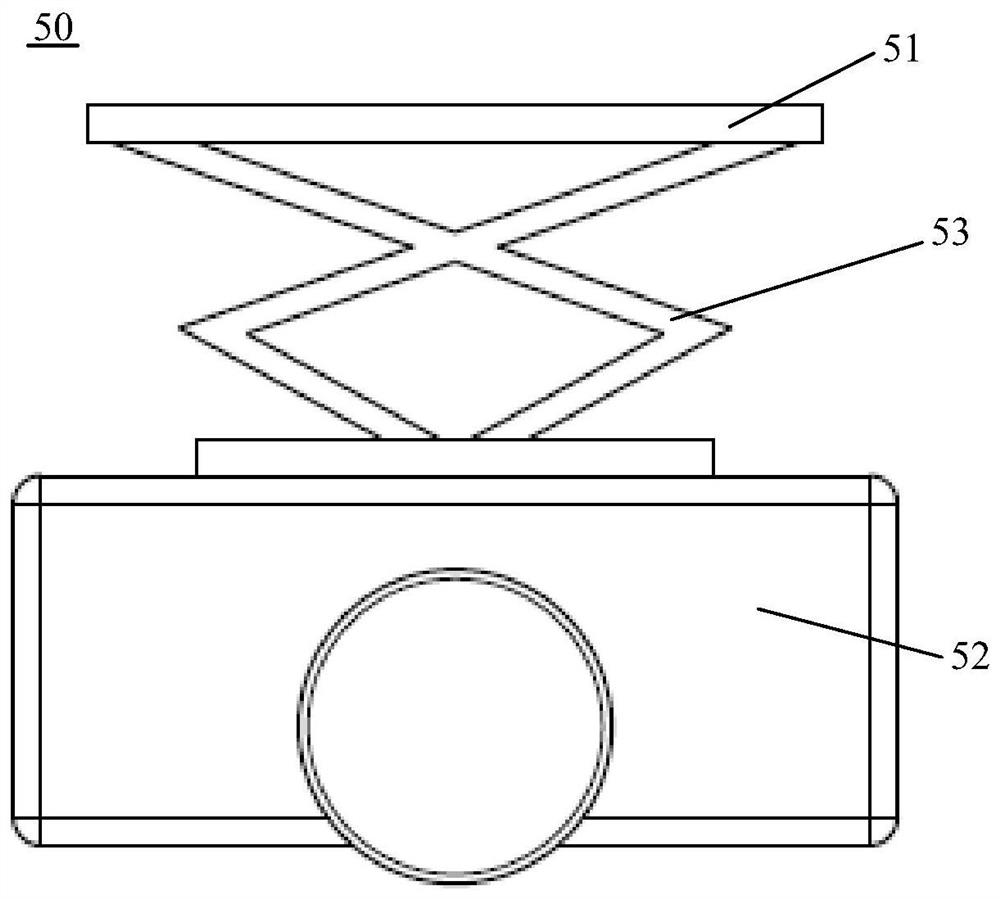

Goods shelf, storage device, control method, control equipment and storage system

PendingCN112830137AShorten the timeIncrease the number ofStorage devicesShow shelvesControl theoryMechanical engineering

The embodiment of the invention provides a goods shelf, a storage device, a control method, control equipment and a storage system. The goods shelf comprises a plurality of stand columns arranged at intervals in the horizontal direction, at least one temporary storage layer plate and at least one storage layer plate, wherein the at least one temporary storage layer plate and the at least one storage layer plate are located inside a space defined by the plurality of stand columns, the at least one storage layer plate and the at least one temporary storage layer plate are arranged at intervals in the vertical direction, the at least one storage layer plate is located above the at least one temporary storage layer plate, and at least part of a channel for a first robot to carry goods to run can be formed below the at least one temporary storage layer plate. According to the technical scheme, the on-load driving region area of the first robot is increased, the number of the on-load driving plannable routes of the first robot is increased, and the warehouse entering and exiting efficiency can be improved.

Owner:SHANGHAI QUICKTRON INTELLIGENT TECH CO LTD

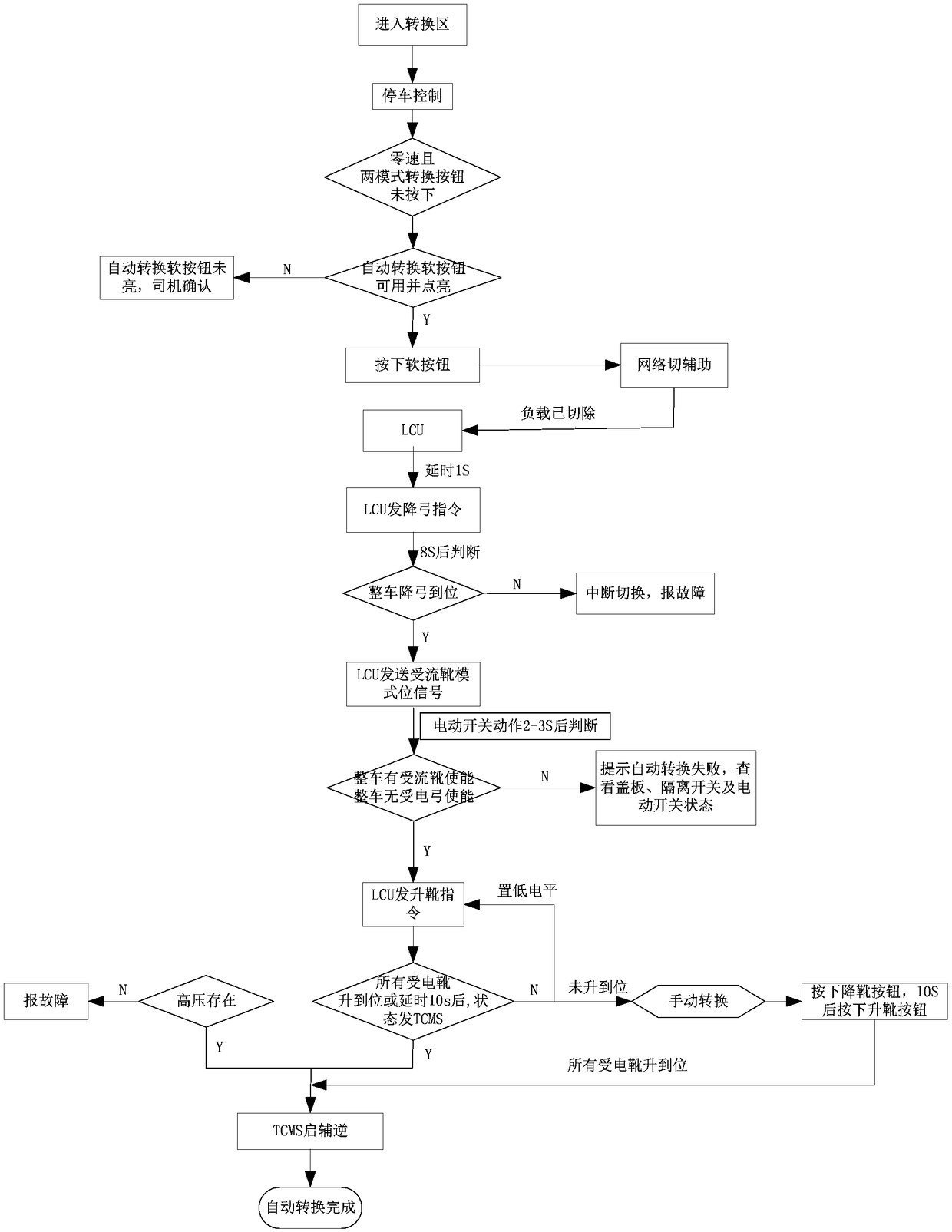

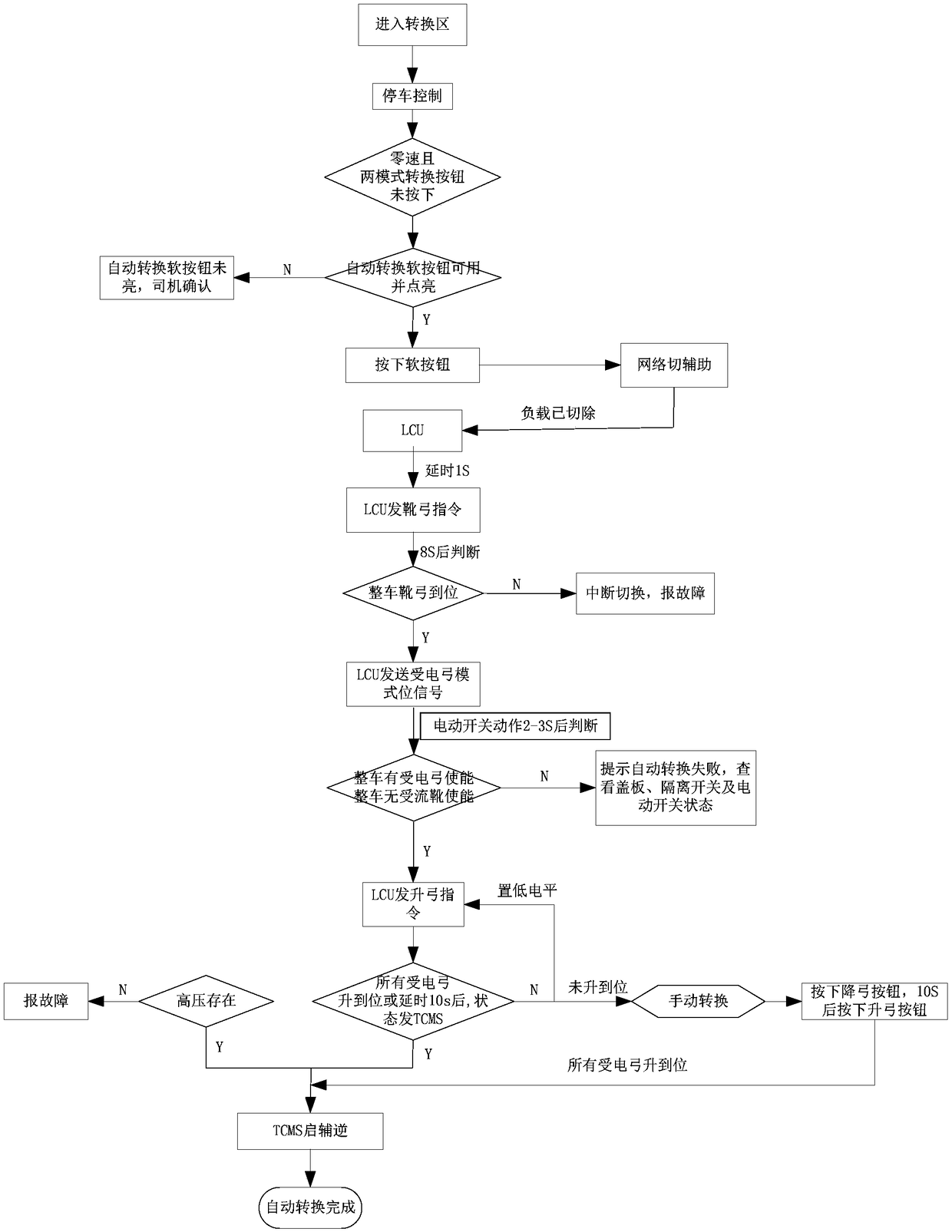

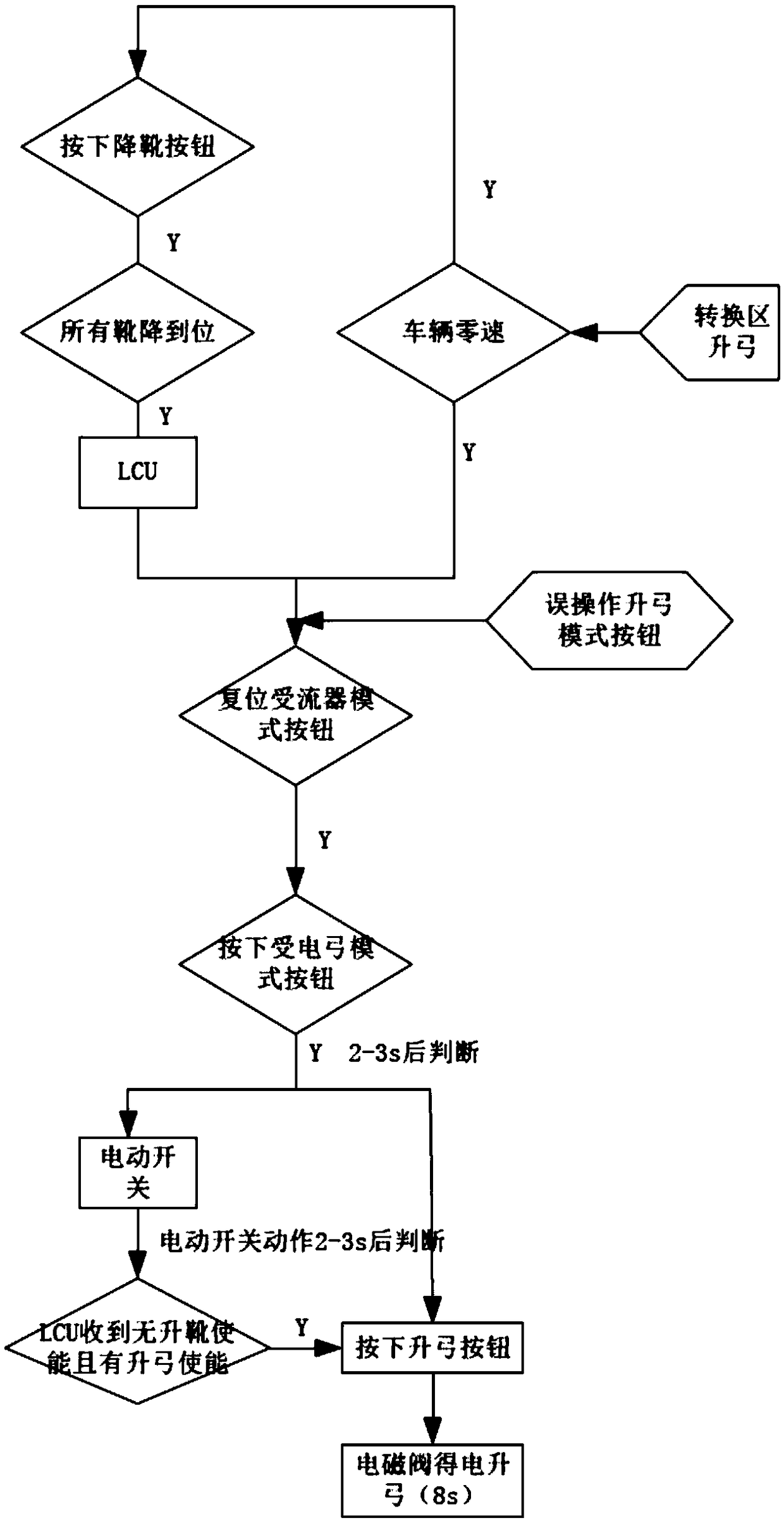

Current-receiving conversion automatic control method of metro vehicle

InactiveCN109501599AEnsure flow safetyImprove the efficiency of inbound and outboundRailway vehiclesElectric energy managementAutomatic controlEngineering

The invention relates to a current-receiving conversion automatic control method of a metro vehicle. The method comprises the following steps that the feasibility of switch is judged by TCMS accordingto vehicle location information; the vehicle activation, zero speed signal and current current-receiving enable signal are combined to give an operational interface by TCMS; an instruction is given to the LCU after driver's operation, and the LCU can complete the current-receiving conversion according to the specified process (including descending a boot or bow, descending a pantograph / current-receiving boot to judge the position, selecting the pantograph / current-receiving boot mode, enabling the pantograph / current-receiving boot to judge, ascending the pantograph / current-receiving boot, ascending the pantograph / current-receiving boot to judge the position, judging the high voltage, enabling assistant inverse and the like). If the previous conditions aren't met in the conversion process,the conversion process is interrupted, and two current-receiving modes in the conversion process have strict interlocking logic so as to ensure the safety of the vehicle current receiving. According to the scheme, the operation is simple, the conversion process is timely and reliable, and the efficiency of vehicles in and out of the warehouse is improved.

Owner:CRRC NANJING PUZHEN CO LTD

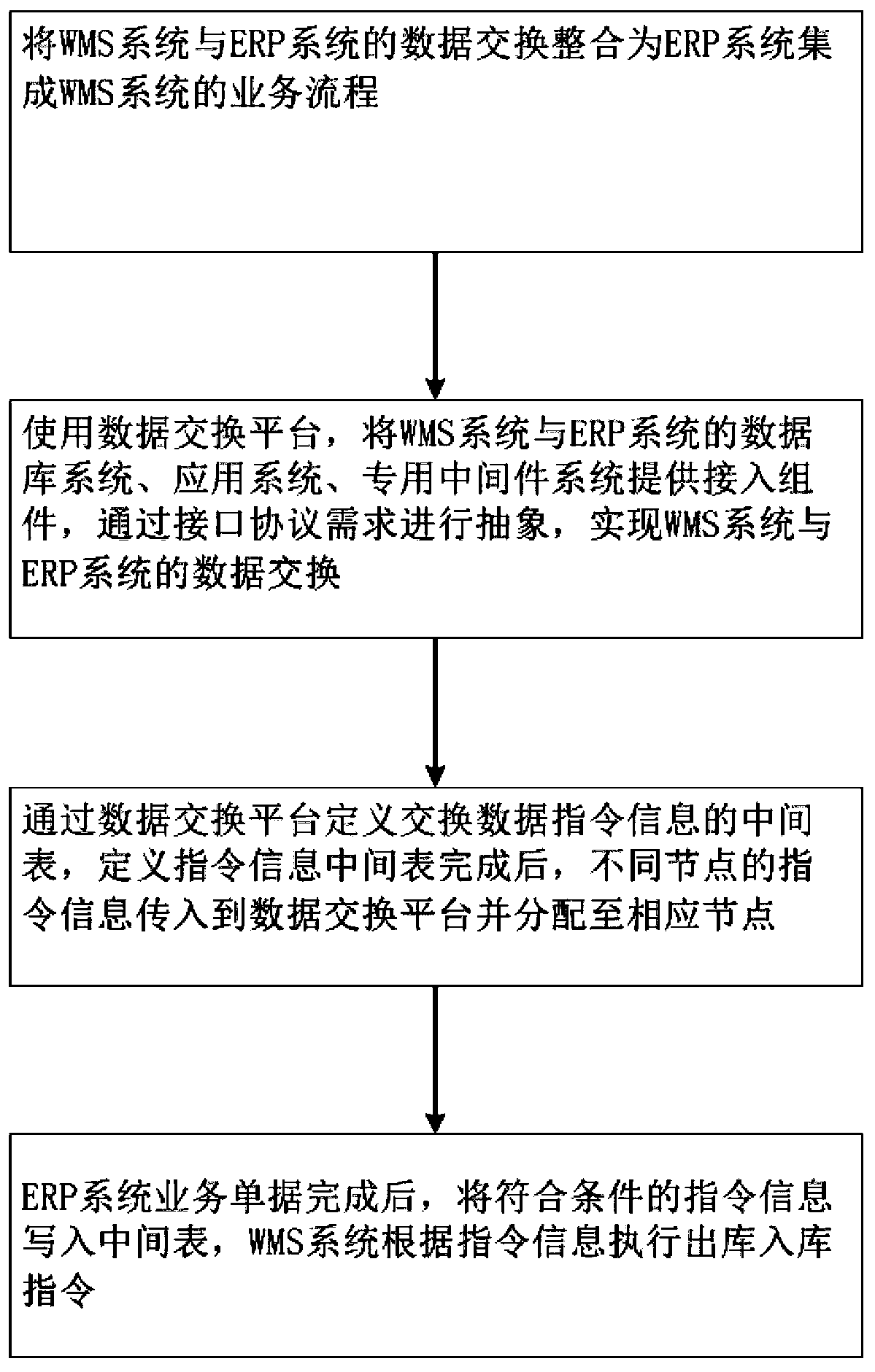

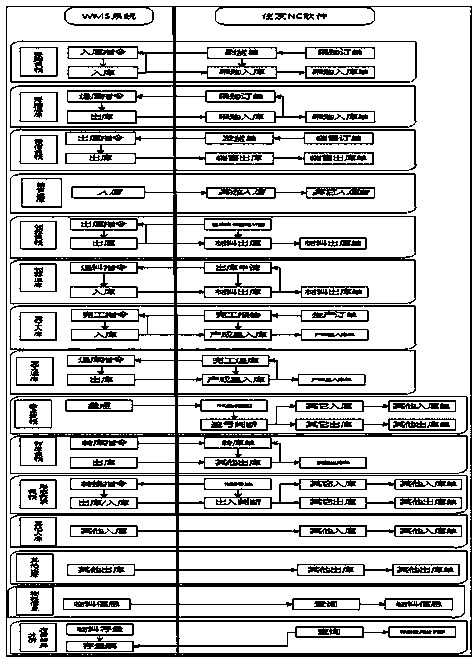

A method for docking of a WMS and a ERP system

InactiveCN108960745ARapid responseImprove the efficiency of inbound and outboundLogisticsBusiness documentsData exchange

The invention provides a method for docking of a WMS and an ERP system. The method comprises the following steps: data exchange between the WMS and the ERP system is integrated into a business processof the ERP system integrated with the WMS; a data exchange platform is used, and database systems, application systems and special middleware systems are provided with an access component to performabstraction through an interface protocol requirement to realize data exchange between the WMS and the ERP system; an intermediate table for exchanging data instruction information is defined throughthe data exchange platform, and after the instruction information intermediate table is defined, the instruction information at different nodes is transmitted to the data exchange platform and allocated to the corresponding nodes; after business documents in the ERP system are finished, the instruction information that meets a condition is written into the intermediate table, and the WMS system executes ex-warehouse and warehousing instructions according to the instruction information. In conclusion, the method of the invention brings the company's information management level and technical advantages into play, enhances the competitiveness and market position of the company, and raises the company's comprehensive strength and profitability.

Owner:FEILONG AUTO COMPONENTS CO LTD +2

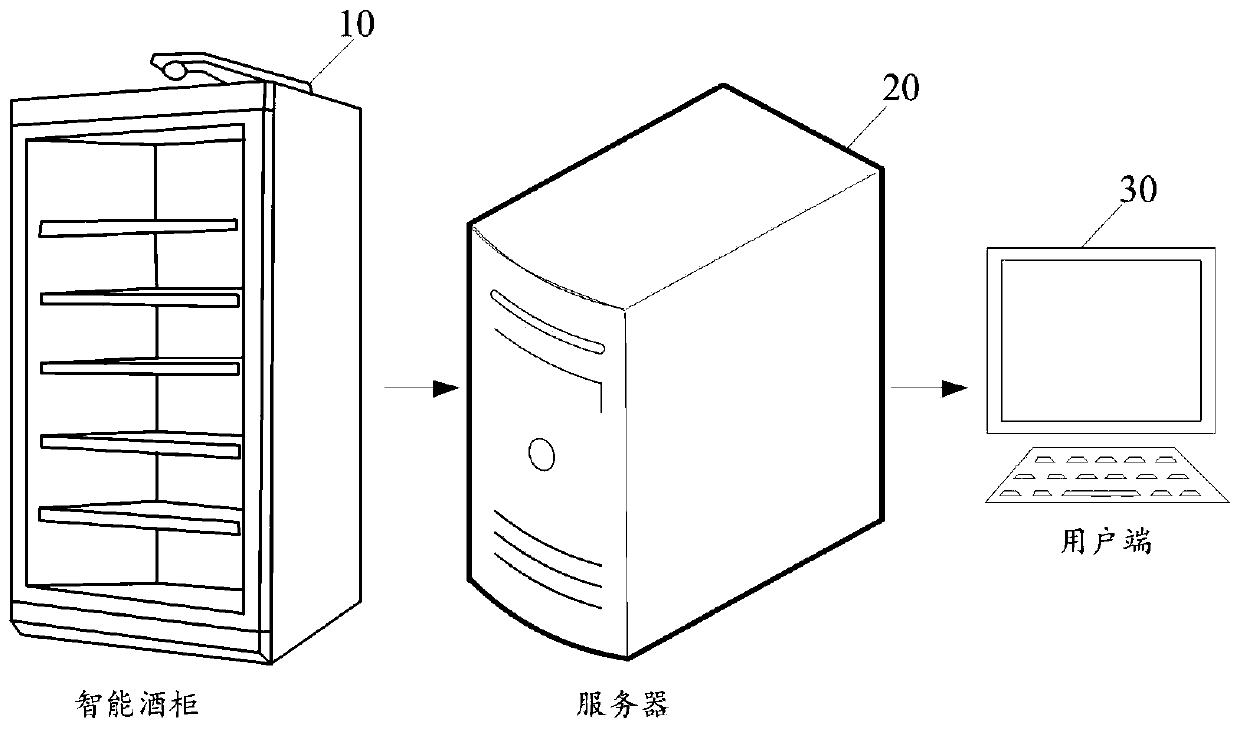

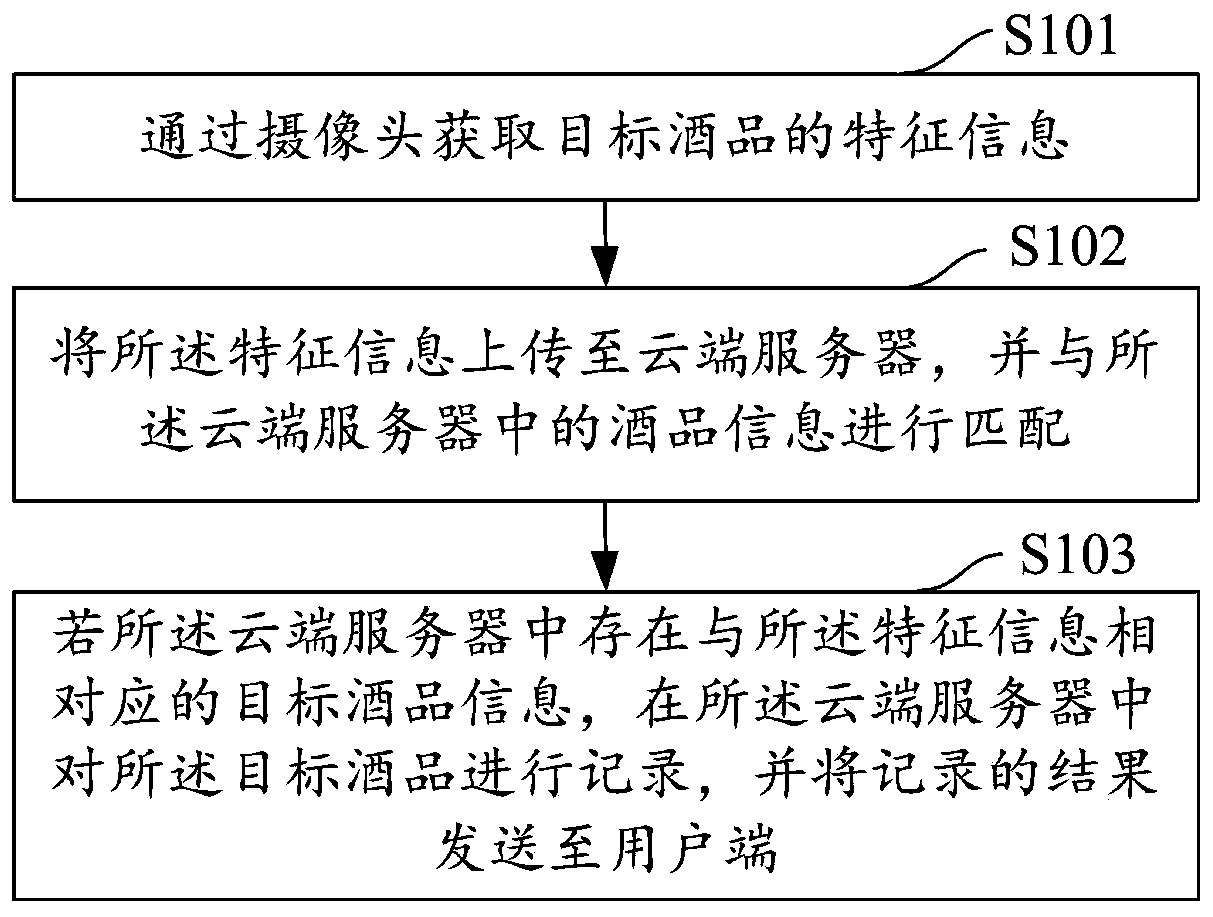

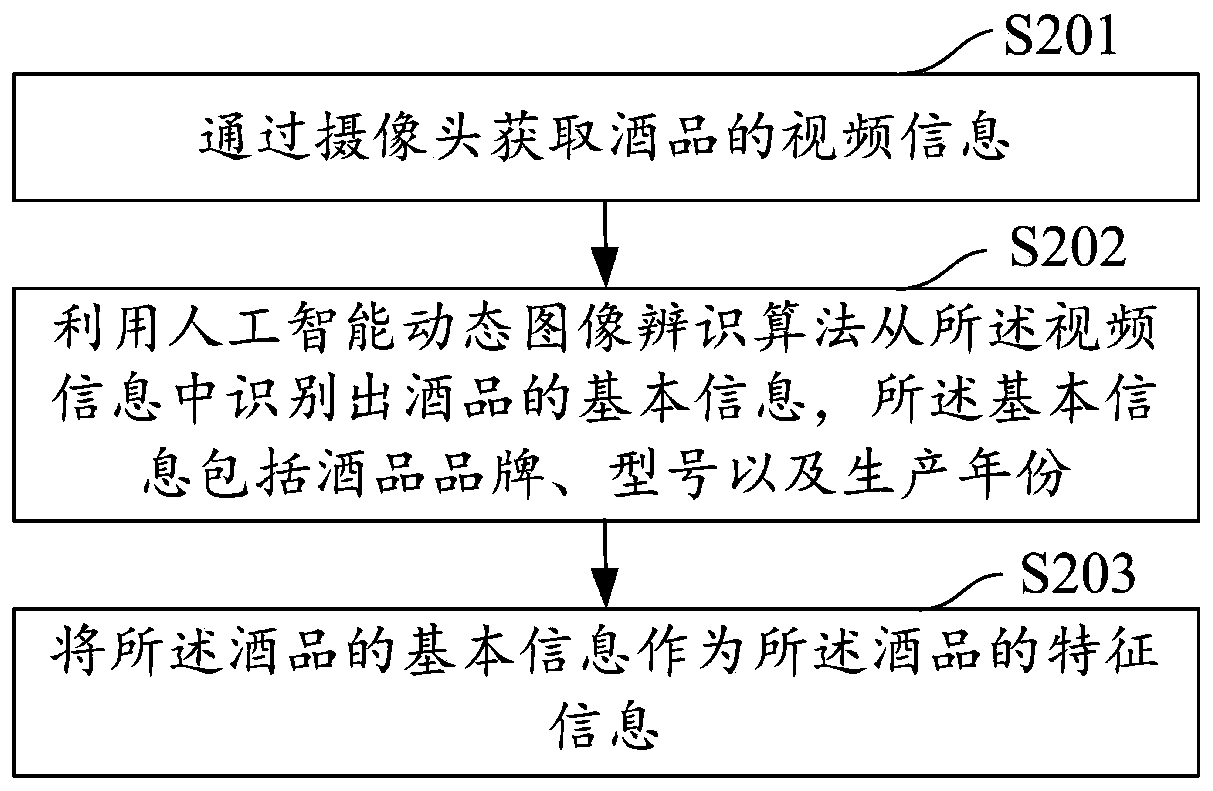

Wine information management method and device, computer equipment and storage medium

PendingCN111401461AReduce storage timeImprove the efficiency of inbound and outboundCharacter and pattern recognitionLogisticsEngineeringServer

The embodiment of the invention discloses a wine information management method and device, computer equipment and a storage medium. The method comprises the steps: acquiring the feature information ofa target wine through a camera; uploading the feature information to a cloud server, and matching the feature information with wine information in the cloud server; if the target wine product information corresponding to the feature information exists in the cloud server, recording the target wine product in the cloud server, and sending a recording result to a user side. According to the invention, the wine information can be automatically recorded, a user does not need to carry out any additional process when the wine is warehoused or delivered, the wine warehouse-in and warehouse-out timecan be greatly saved, and the wine warehouse-in and warehouse-out efficiency can be greatly improved.

Owner:郭俊

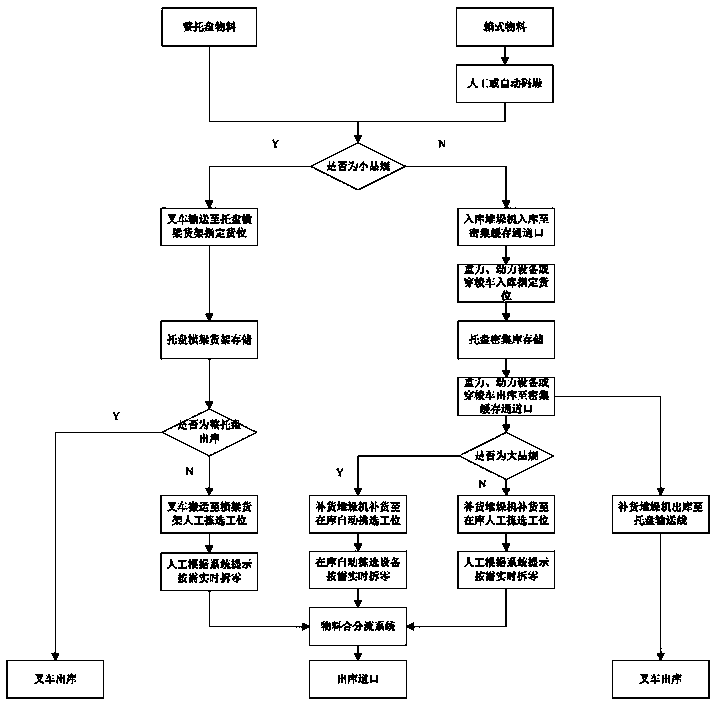

Storage splitting method with tray compact warehouse combined with tray transverse beam goods shelves and system

ActiveCN109775214ASolve the problem of poor dismantling abilityImprove work efficiencyStorage devicesEngineeringStorage cell

The invention discloses a storage splitting method with a tray compact warehouse combined with tray transverse beam goods shelves. The storage splitting method comprises the steps that 1, incoming materials are judged; 2, large-medium-specification whole tray-type materials are conveyed to a warehouse inlet of a tray compact storage unit; 3, large-medium-specification box-type materials are conveyed to the warehouse inlet of the tray compact storage unit; 4, a warehouse management system (WMS) conducts goods allocation according to the goods allocation principle; 5, small-specification box-type materials are carried to tray transverse beam goods shelf stations; 6, small-specification whole tray-type materials are carried to the tray transverse beam goods shelf stations; 7, the WMS automatically arranges material discharge dispatching; 8, the large-medium-specification whole tray-type materials are discharged out of the warehouse through forklifts; 9, the small-specification whole tray-type materials are discharged out of the warehouse after code scanning; 10, large-specification box-type materials are split and supplemented to a large-specification material discharging conveying line; 11, medium-specification box-type materials are split and supplemented to a medium-small-specification material discharging conveying line; 12, the small-specification box-type materials are splitand supplemented to the medium-small-specification material discharging conveying line; and 13, the split materials are discharged out of the warehouse through a material combining and splitting unit. Through the storage splitting method, the problem that a tray compact warehouse is poor in splitting capacity is solved.

Owner:SIPPR ENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com