Warehouse material linkage management system and method

A technology of management system and processor system, which is applied in the field of automated warehouse management, can solve problems such as the inability to automatically transfer material warehouses, the inability to realize the raw material delivery plan, and the inability to adapt to the multi-level requirements of the warehouse management system, so as to save operating costs and inventory costs, fast and accurate order outbound links, and the effect of improving inbound and outbound efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Taking the clothing production enterprise as an example to illustrate the composition of the warehouse IOT management system and the warehouse IOT management method. The personalized customized production of clothing manufacturers refers to the production of individual consumers' customized orders. Different consumers have different information about the style, fabric and accessories of the clothing specified in the order.

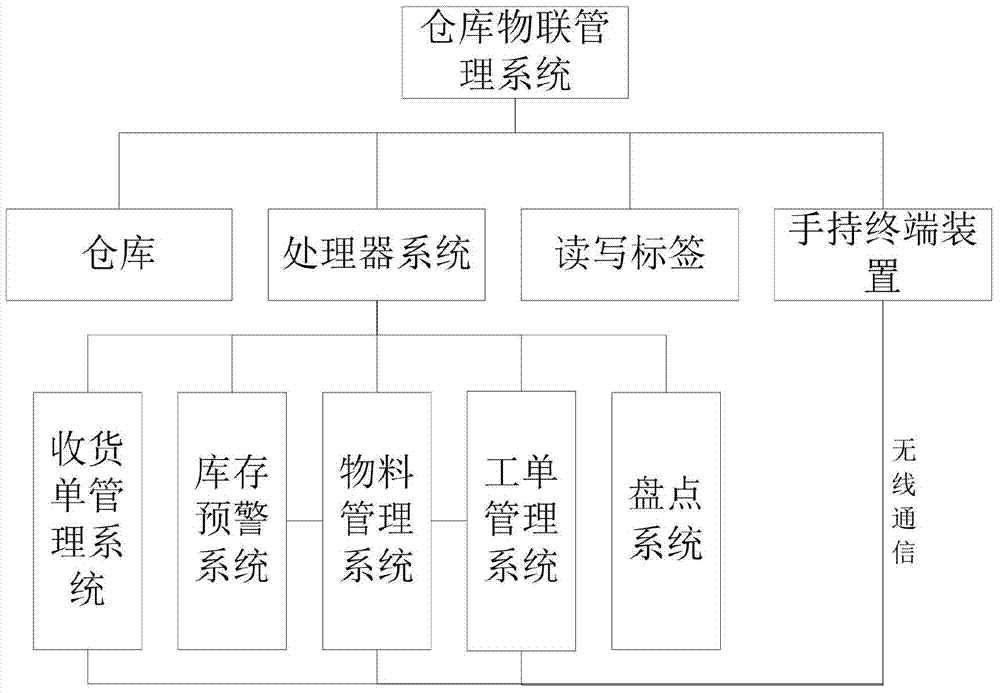

[0026] The warehouse IoT management system applied to garment production enterprises includes: warehouses, processor systems, handheld terminal devices and read-write tags;

[0027] The warehouse is equipped with material storage shelves and material temporary storage shelves;

[0028] Processor system. The processor system is equipped with a material management system, an inventory warning system, a receipt management system, a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com