Fork type shuttle vehicle sorting system

A shuttle car and fork technology, applied in the field of warehousing and logistics, can solve the problems of large storage area, low picking efficiency, and untimely replenishment, etc., and achieve the effects of improving operation efficiency, saving labor costs, and high efficiency of warehouse entry and exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

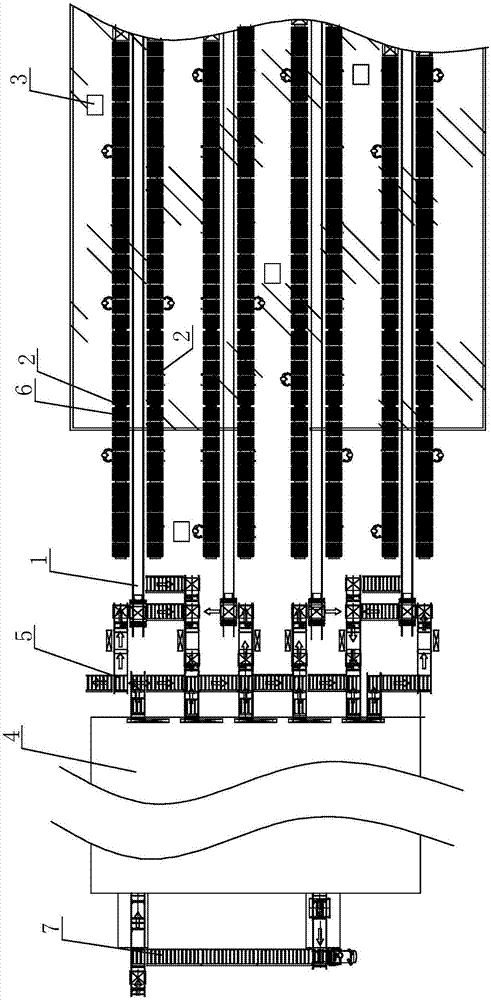

[0012] see figure 1 as shown, figure 1 It is a schematic structural diagram of the fork-type shuttle picking system provided in Embodiment 1 of the present invention.

[0013] In this embodiment, a sorting system of a fork-type shuttle vehicle includes a fork-type shuttle vehicle 1, a picking shelf 2, a picking trolley 3, an automated three-dimensional warehouse 4 and an automatic control system, and two of the picking shelves 2 form a group Each group of picking shelves 2 is provided with a fork-type shuttle car 1, the track of the fork-type shuttle car 1 adopts the ground sinking type, and the installation level of the track is 450mm lower than the ground level, which can facilitate the connection of the picking shelves, and the material The outbound and back out of the warehouse are automated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com