Automatic logistics warehouse-in and warehouse-out system

An animal, moving beam technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of manual operation, such as difficult in and out of the warehouse, high labor intensity, time-consuming and labor-intensive, etc. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

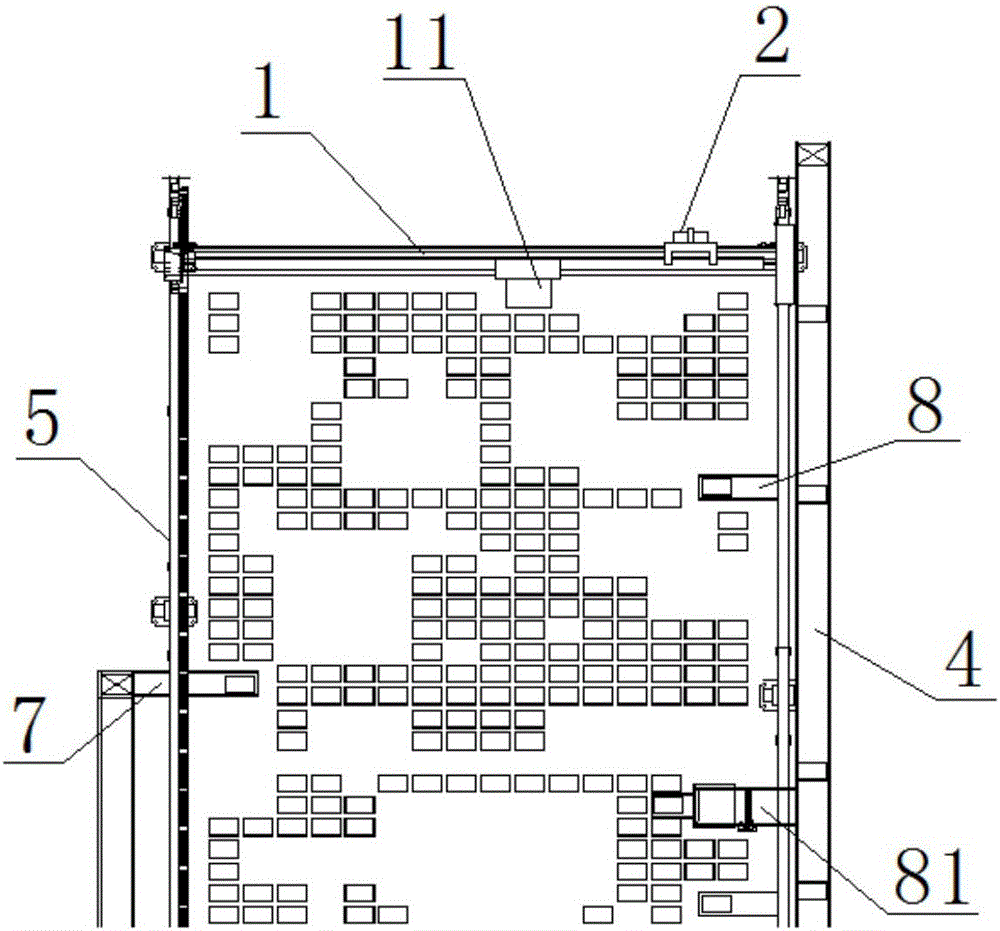

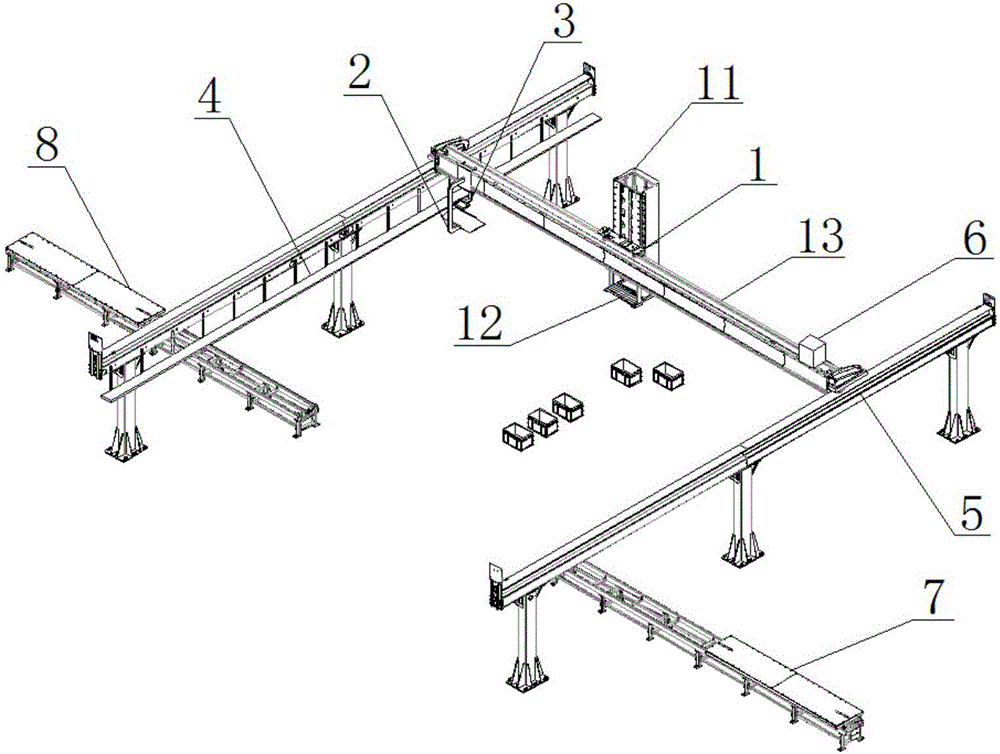

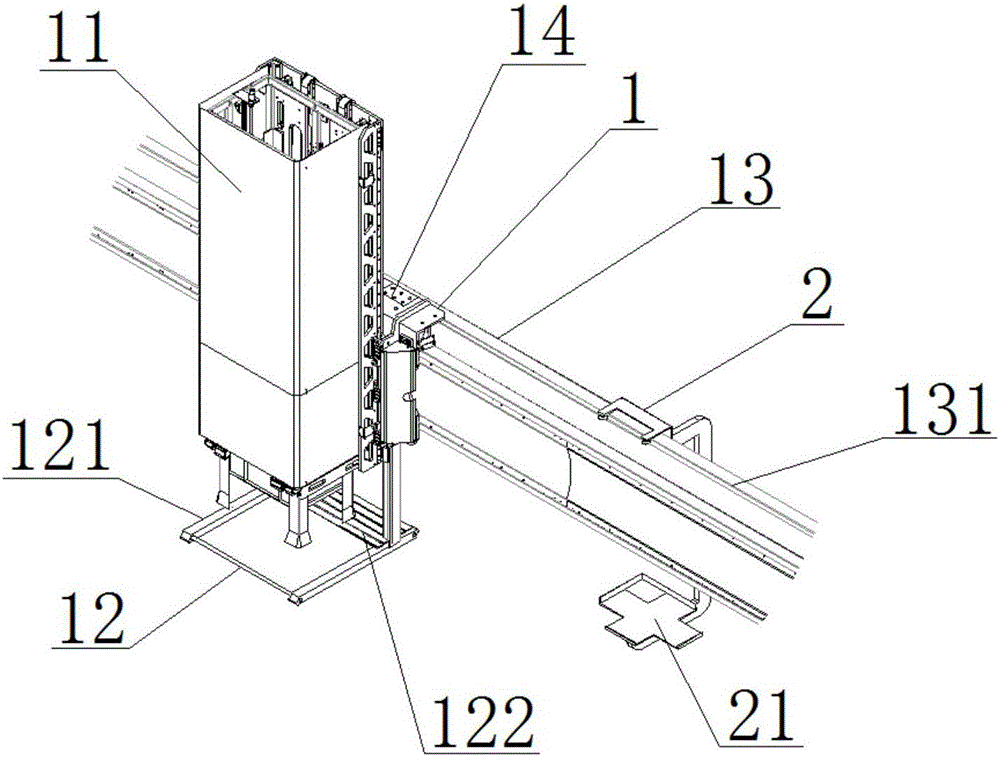

[0018] Such as Figure 1-7 As shown, an automatic logistics storage system includes a gantry manipulator 1, a shuttle car 2, a cleaning mechanism 3, an aerial conveying line body 4, an aerial track 5, a control box 6, a storage line body 7, and a storage line body 8, The gantry manipulator 1 includes a grabbing fixture 11, a transplanting mechanism 12, a moving beam 13, and a mobile holding platform 14. The aerial track 5 is mounted on both sides of the warehouse, and the moving beam 13 can move along the aerial track 5. , the mobile holding platform 14 can slide on the moving beam 13, the grasping fixture 11 is installed on the side of the mobile holding platform 14, and the grasping fixture 11 can use the driving system on the mobile holding platform 14 to go up and down Sliding, the gantry manipulator 1 realizes the grabbing action by grabbing the fixture 11; the transplanting mechanism 12 is installed below the mobile holding platform 14, and the two sides of the lower bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com