Intelligent warehouse and goods access method based on gravity sensing

A technology of gravity sensing and access methods, which is applied in the field of storage systems, can solve the problems of difficult inventory and low safety factor of warehouses, and achieve the effect of improving efficiency, improving safety factor, and avoiding cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

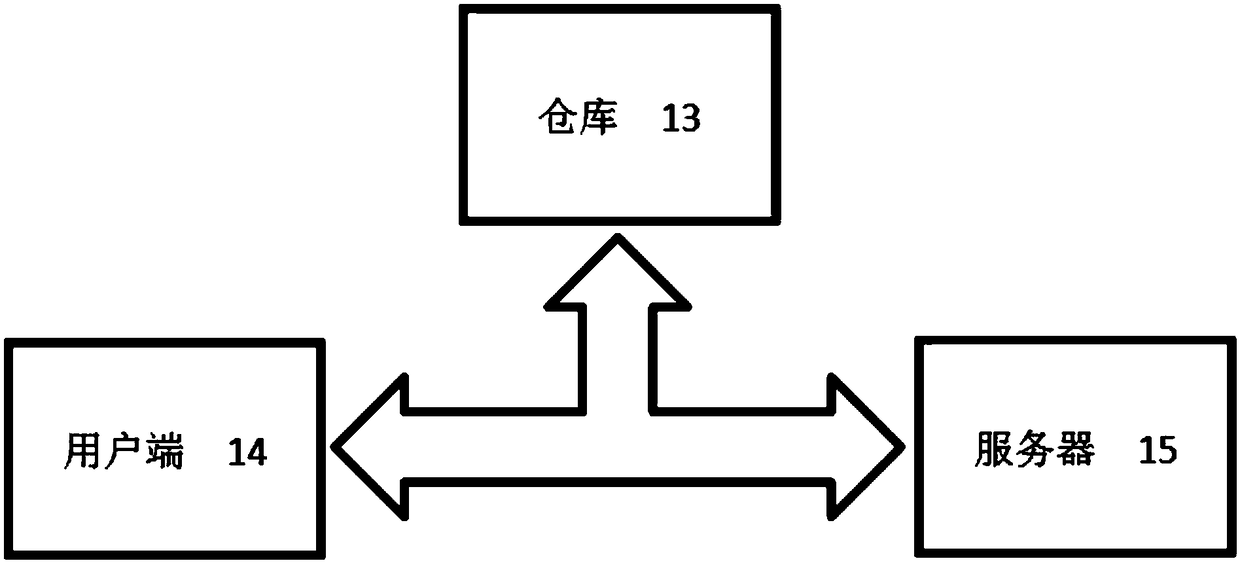

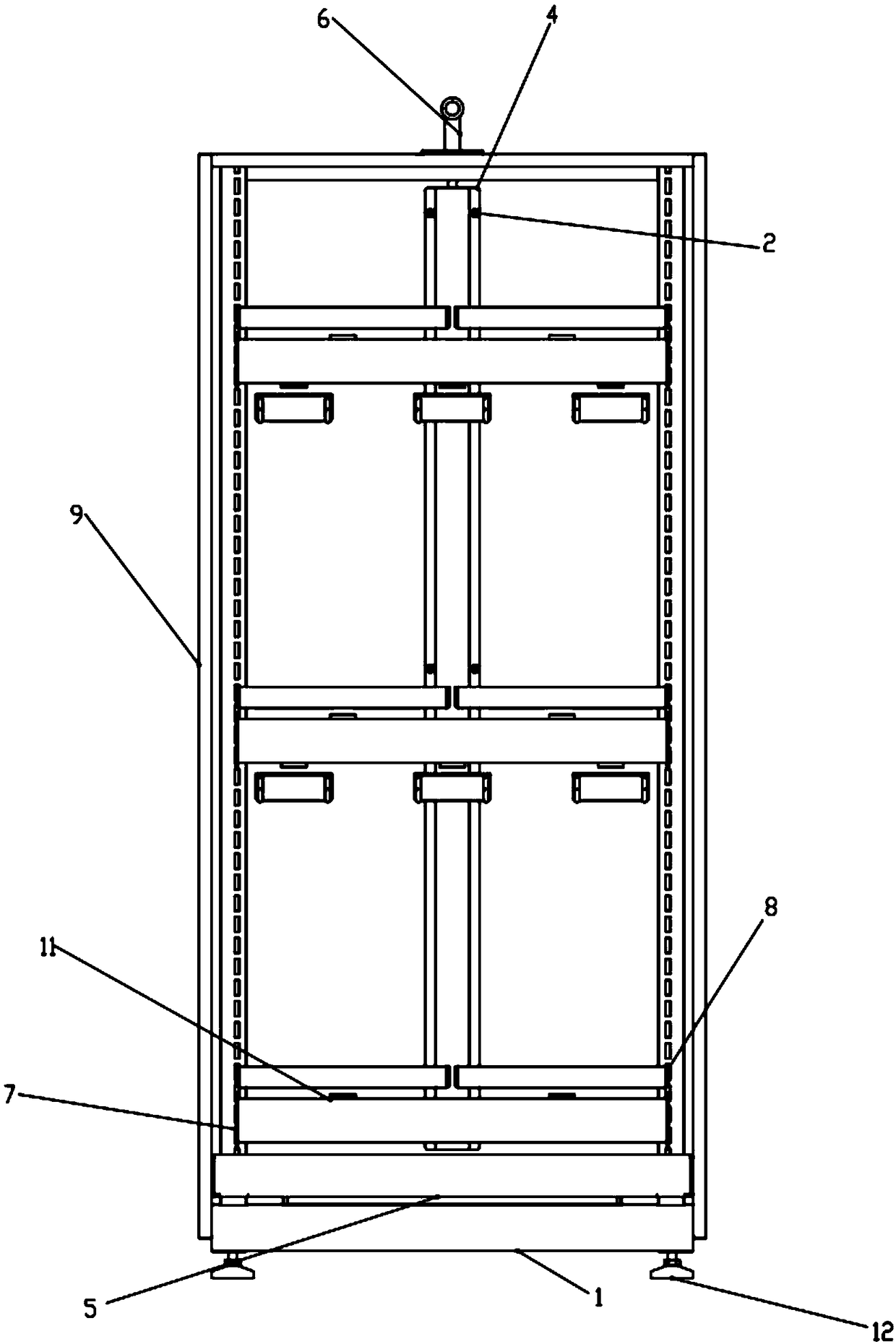

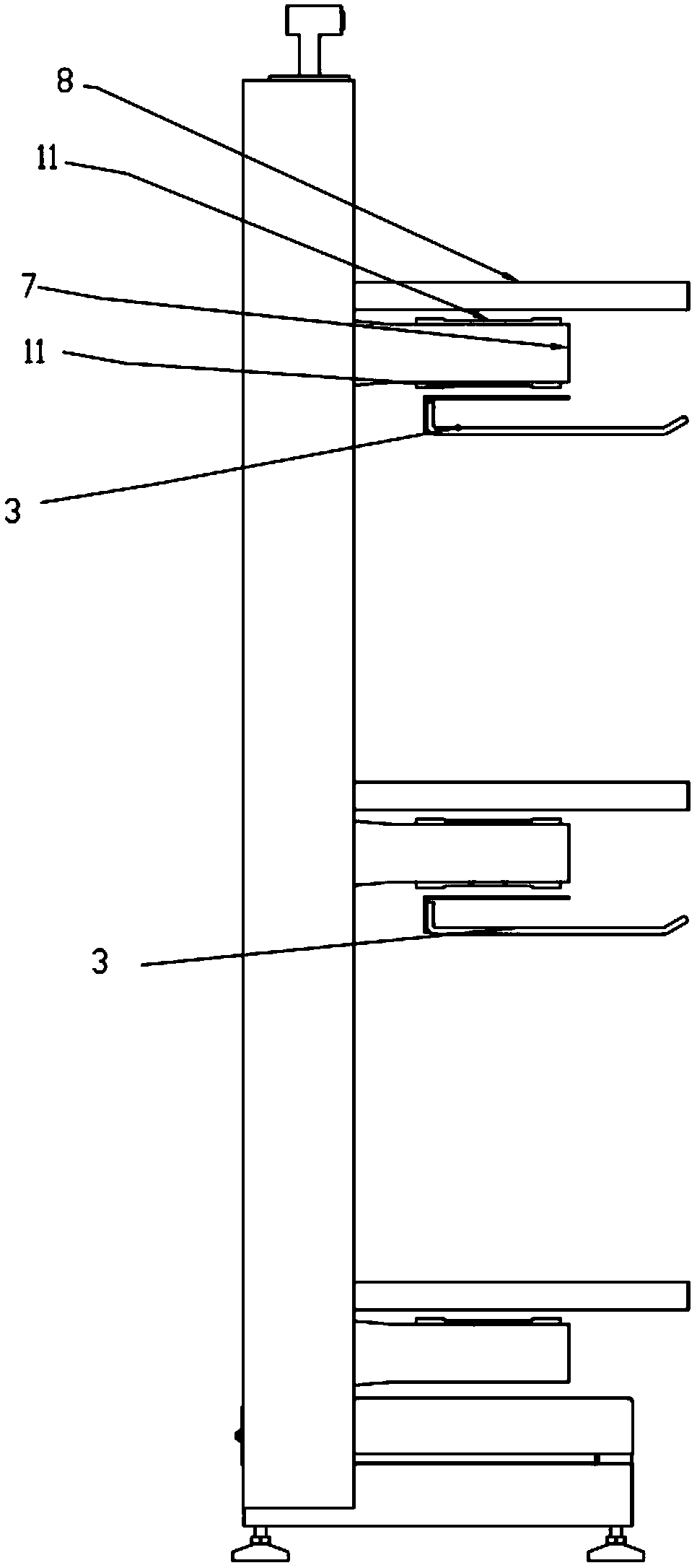

[0036] Specific implementation mode one, the following combination figure 1 , 2 , 3, 4, and 5 illustrate this implementation mode. In order to solve the problems of the traditional storage system storing and picking up the goods, the difficulty of taking inventory and the low safety factor of the warehouse,

[0037] In order to achieve the above object, the present invention provides a smart warehouse based on gravity sensing and a method for accessing goods. The smart warehouse based on gravity sensing includes a warehouse 13, and also includes a user terminal 14 and a server 15. The warehouse 13 and the user Terminal 14 two-way communication, warehouse 13 and server 15 two-way communication, user terminal 14 and server 15 two-way communication, described warehouse 13 is provided with shelf and main control box 10, and described shelf is provided with bottom frame 1, screw spring pad Flat pad assembly 2, hook 3, rear cover 4, bottom plate 5, camera 6, bracket 7, tray 8, weld...

specific Embodiment approach 2

[0039] Specific implementation mode two, the following combination figure 1 , 2 , 3, 4, and 5 illustrate this embodiment. In order to optimize system performance, as a further optimization of the present invention, the present invention is based on a gravity-sensing smart warehouse, and the bottom of the welding frame 9 is welded with feet 12 .

specific Embodiment approach 3

[0040] Specific implementation mode three, the following combination figure 1 , 2 , 3, 4, and 5 illustrate this embodiment, the present invention is based on the gravity-sensing smart warehouse and the goods access method, and the specific steps of the gravity-sensing-based smart warehouse goods access method are,

[0041] Step 1. Perform identity verification. If the verification fails, go to step 2; if the verification is successful, go to step 3;

[0042] Step 2, send out an alarm prompt;

[0043] Step 3, open the door and enter the warehouse 13;

[0044] Step 4. Find the location of the goods on the official account;

[0045] Step 5: After receiving the query instruction, the server 15 sends the instruction to the corresponding shelf, and the official account also displays the specific coordinates of the goods;

[0046] Step 6. After the shelf receives the query instruction, it emits sound and light to remind the staff of the specific location of the goods;

[0047]St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com